A rocket-based combined cycle engine with variable suction and removal control inlet port

A technology of engine and air inlet, which is applied in the field of rocket-based combined cycle engine variable absorption control air inlet, can solve the problems of poor realizability, achieve good performance parameters, improve overall performance, and broaden the working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

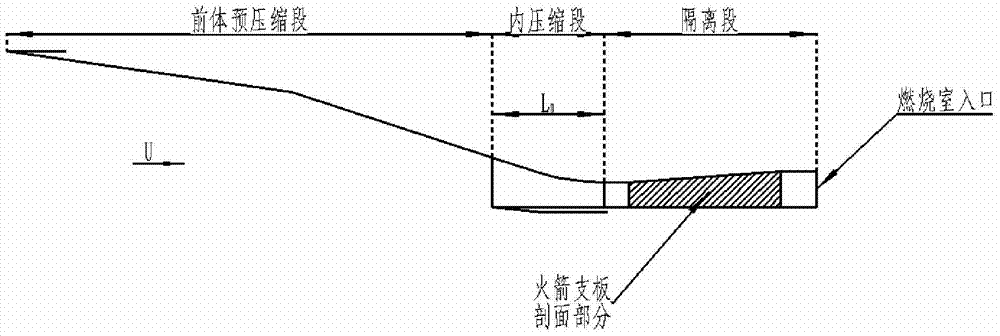

[0019] This embodiment is a rocket-based combined cycle engine variable absorption and removal control inlet.

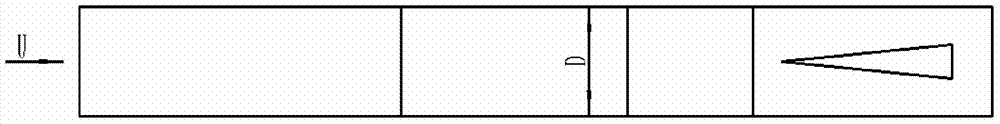

[0020] refer to figure 1 , figure 2 , The variable-structure inlet of the rocket-based combined cycle engine in this embodiment obtains a variable-structure inlet solution that effectively widens the working range of the inlet under the condition that the overall engine is given a constraint on the inlet profile.

[0021] The essence of intake port start-up is that when the incoming flow reaches the start-up Mach number, the captured air volume can completely pass through the throat without causing congestion. If the throat is too narrow or the actual capture area is too large, the intake port will not start. Especially for the intake port of a rocket-based combined cycle engine embedded with a rocket support plate, it is more likely to cause throat blockage and cause the intake port not to start.

[0022] At the same time, the minimum starting Mach numbers corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com