Fuel supporting plate for improving non-premixed combustion of RBCC (rocket-based combined cycle) bimodal combustion chamber

A combustion chamber and dual-mode technology, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of incoming flow conditions and single fuel injection position, and achieve easy processing, strong turbulence, and compact structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] This embodiment is a fuel support plate for improving mixed combustion in an RBCC dual-mode combustor.

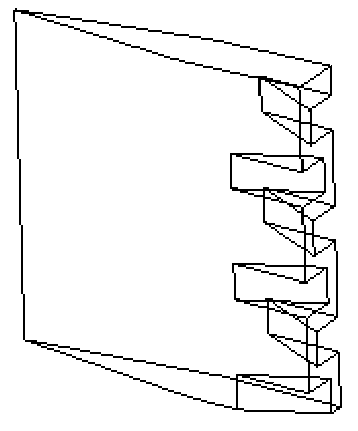

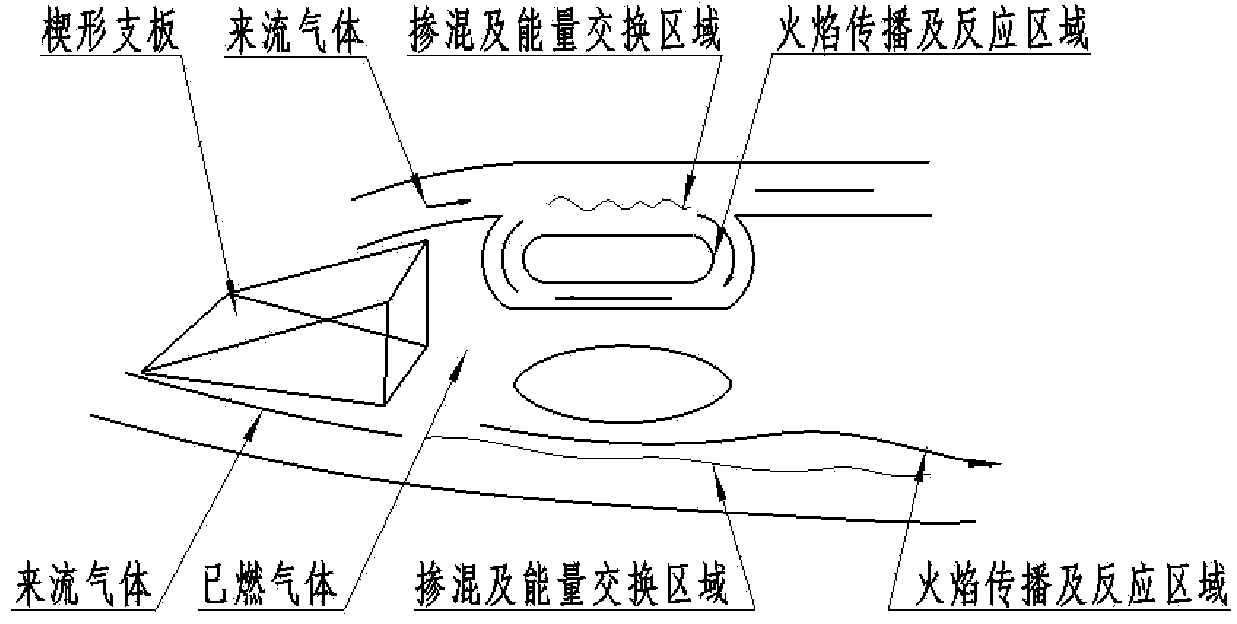

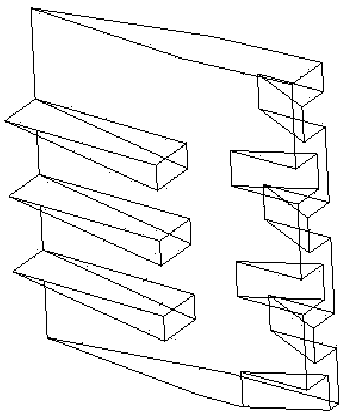

[0033] refer to Figure 1 to Figure 13 , the present invention is used to improve the fuel support plate of RBCC dual-mode combustor mixed combustion, is a kind of fuel support plate suitable for RBCC combustion organization under wide flow conditions, and is a flow direction vortex fuel support plate with a wedge-shaped protrusion on one side The structure of the fuel support plate includes the fuel support plate main body 1 and the fuel support plate injection block 2 .

[0034] The specific structure and assembly are as follows:

[0035] (1) The front body of the fuel support plate is a wedge-shaped structure with a wedge angle of 15°, and the rear body of the support plate is a straight section with a length of 25 mm and a thickness of 10 mm; three equally spaced wedge-shaped protrusions are evenly distributed on the outside of the fuel support plate in the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com