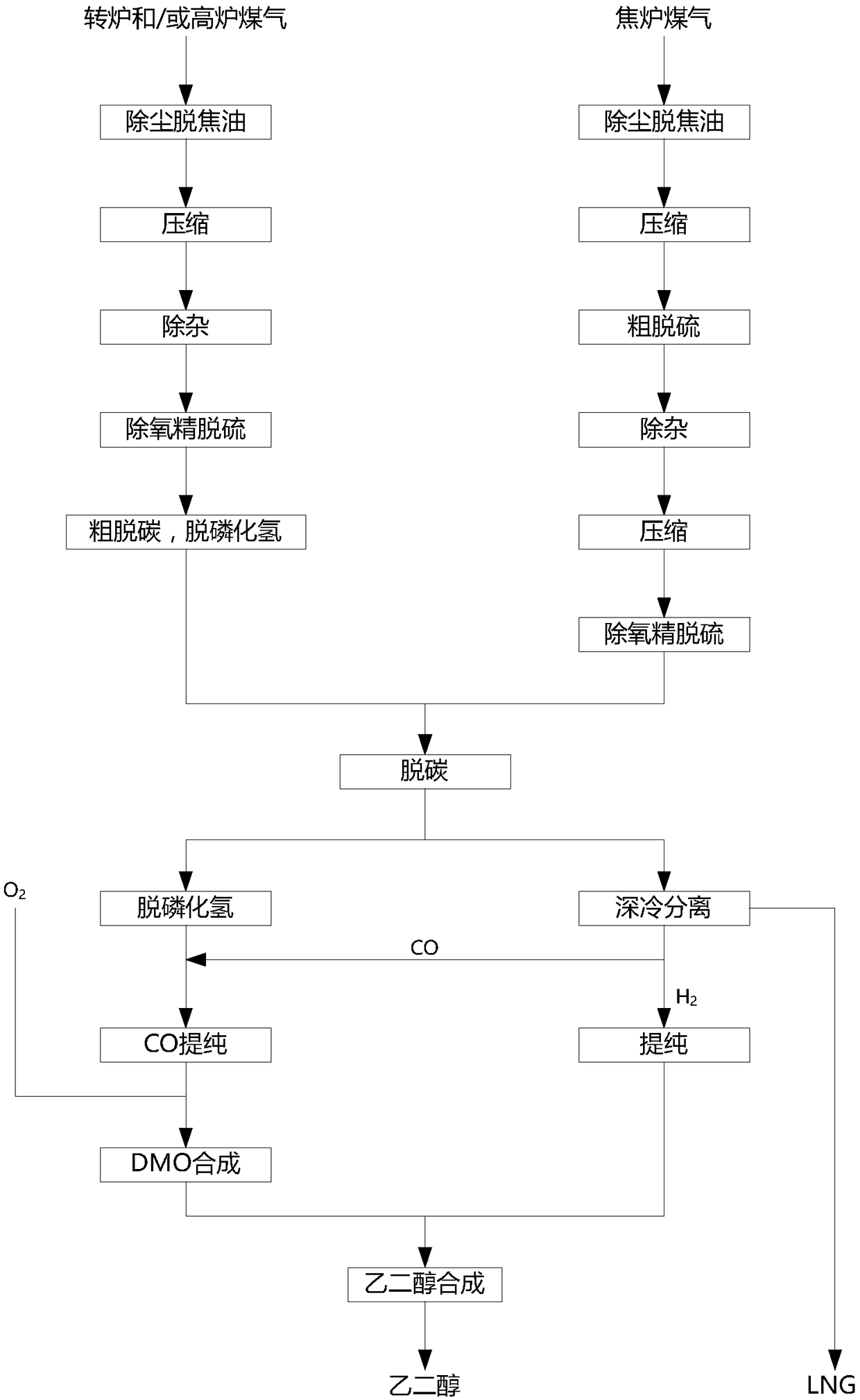

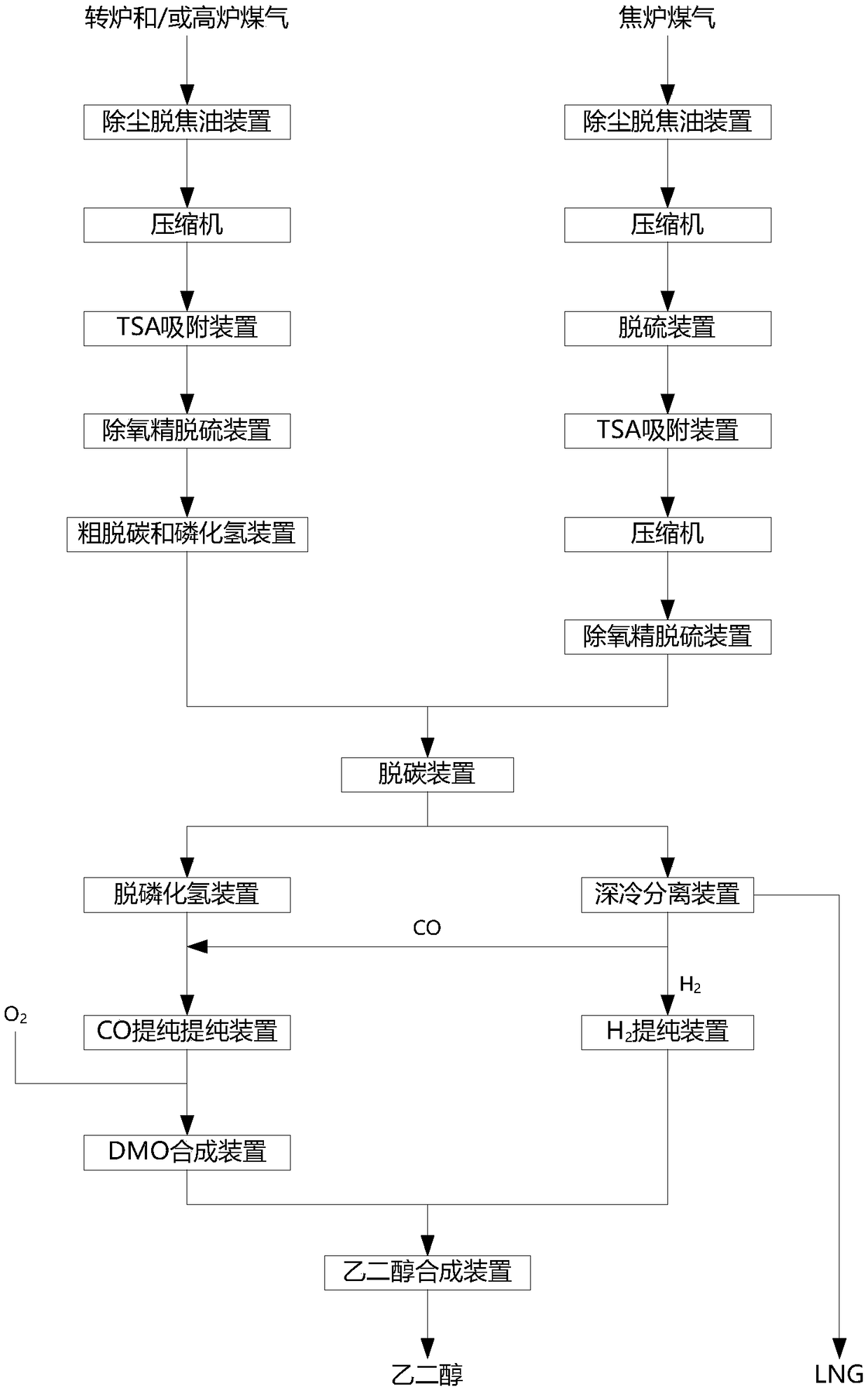

Method for synthesis of glycol and co-production of LNG by using coke oven gas and converter and/or blast-furnace gas

A technology of coke oven gas and blast furnace gas, which is applied in the field of synthesizing ethylene glycol and co-producing LNG, which can solve the problems of only being used as fuel, ineffective components being fully utilized, and poor regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

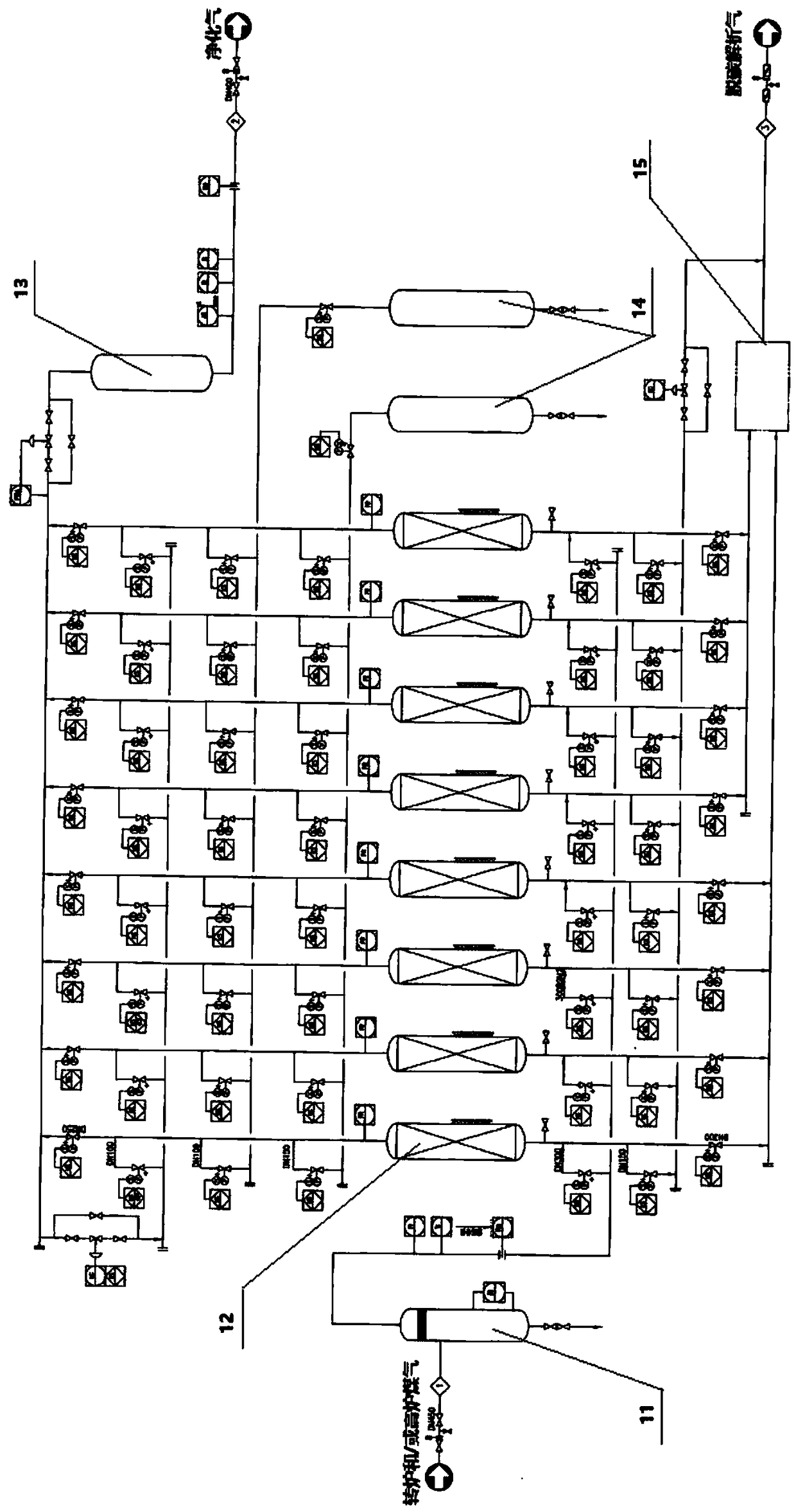

[0196] A method for co-producing LNG with coke oven gas and converter and / or blast furnace gas to synthesize ethylene glycol,

[0197] Including the following steps:

[0198] S0), initial purification of coke oven gas and converter and / or blast furnace gas

[0199] The flow of coke oven gas before initial purification is 83052Nm 3 / h, the pressure is 0.005Mpa, the temperature is 20℃; among the active ingredients, the volume fraction of methane is 20.8%, the volume fraction of hydrogen is 60.31%, the volume fraction of carbon monoxide is 8.9%, and the volume fraction of oxygen is 0.82 %, the volume fraction of carbon dioxide is 2.58%, and the content of tar and dust is 0.015g / Nm 3 , The content of hydrogen sulfide is 50mg / Nm 3 , The content of other sulfides is 155.2mg / Nm 3 ; The flow rate of the converter and / or blast furnace gas before the initial purification is 29000Nm 3 / h, the pressure is 0.005Mpa, and the temperature is 20°C; among the active ingredients, the volume fraction of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com