Method for exciting and controlling gas flow of stator blade end wall of axial-flow compressor by aid of plasmas

A technology of axial flow compressor and plasma, applied in the direction of pump control, machine/engine, mechanical equipment, etc., to achieve the effect of suppressing flow separation, improving efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

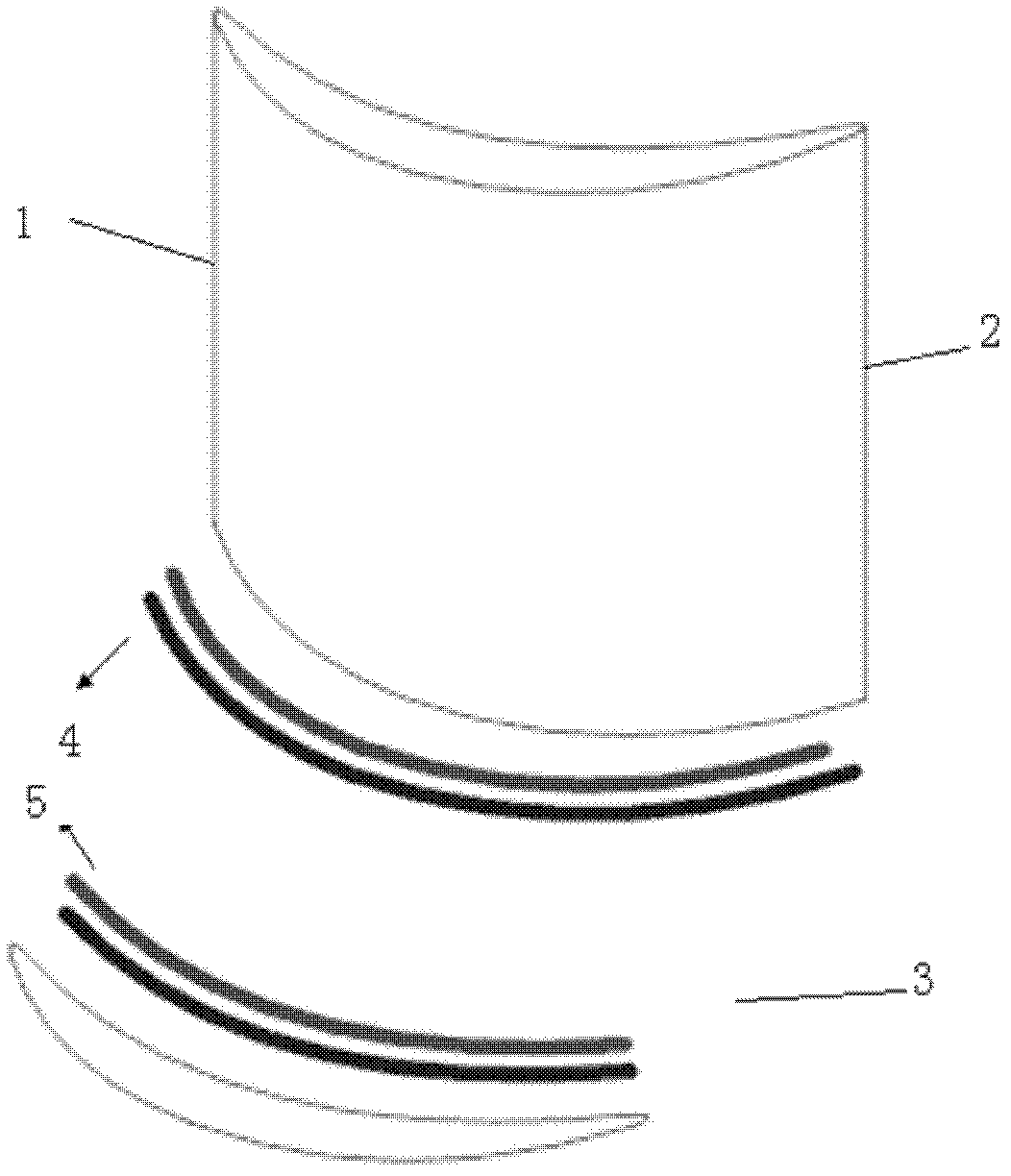

[0027] Step 1: Lay a plasma pneumatic actuator on the end wall of the stator vane channel of the axial flow compressor, such as figure 1 The end wall of the stator blade marked in . The leading edge and the trailing edge of the electrode of the plasma pneumatic exciter are respectively flush with the leading edge and the trailing edge of the stator blade, and the direction of the electrode is parallel to the middle arc of the stator blade;

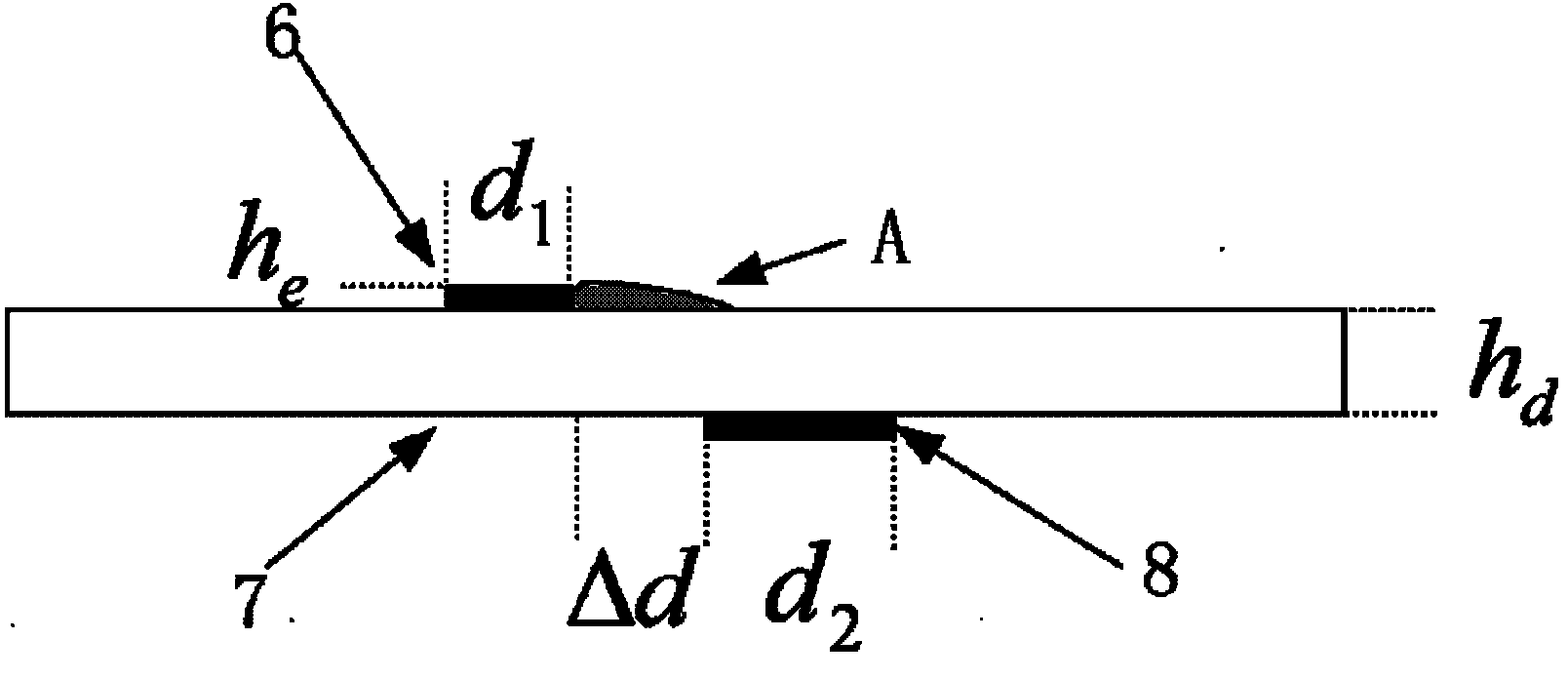

[0028] The electrodes of the plasma pneumatic excitation electrodes are copper electrodes, and the electrodes are separated by insulating materials, and the insulating materials are polyimide. The layout of the plasma pneumatic excitation electrodes is as follows figure 2 As shown, the upper surface electrode width d 1 2mm, the electrode width d on the lower surface 2 is 2mm, the distance between the upper and lower surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com