Plasma flow control method for suppressing flow separation of suction surface of wind turbine blade

A wind turbine blade and plasma technology, which is applied in the control of wind turbines, wind turbines, machines/engines, etc., can solve the problems of flow separation on the suction surface of the blades, reducing the output power of the wind turbine, and increasing the resistance of the wind turbine blades. Achieve the effect of fast response, low power consumption, wide bandwidth and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

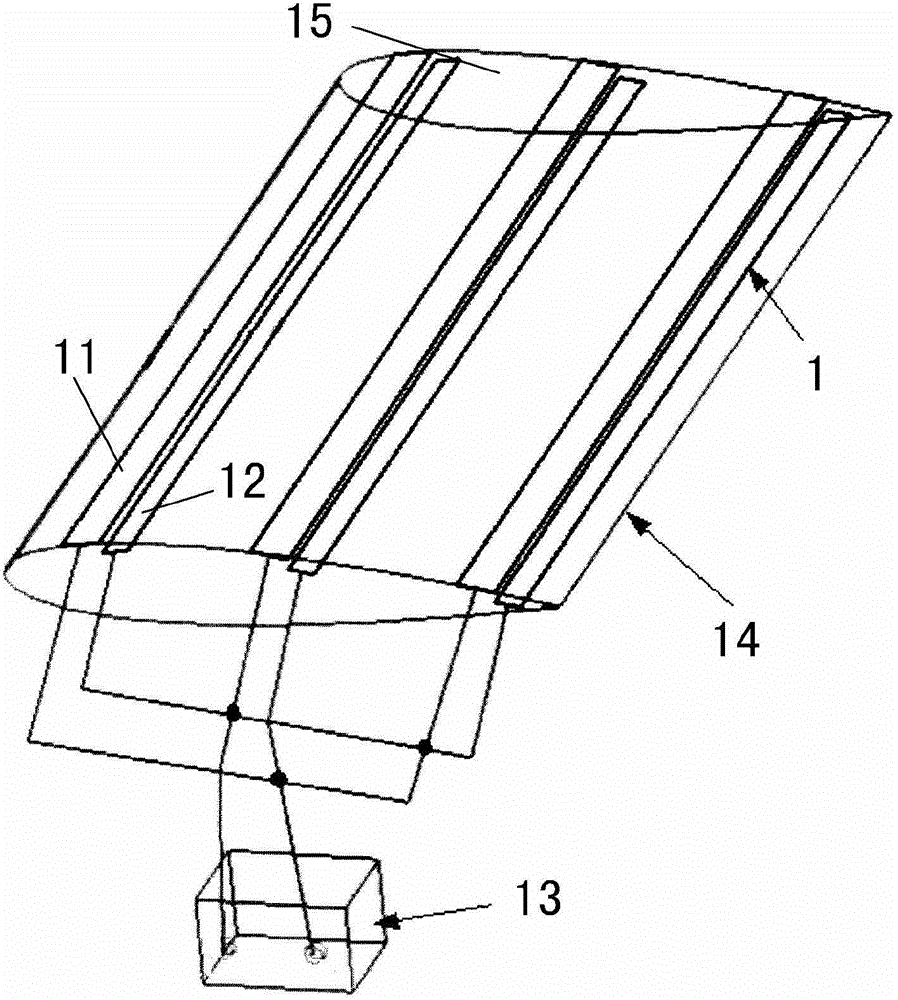

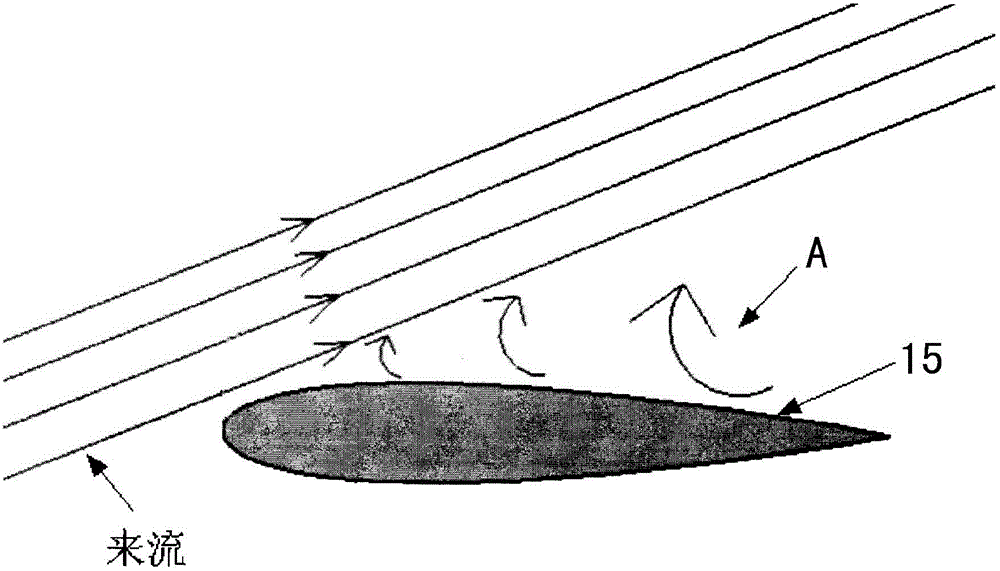

[0025] The plasma flow control method for suppressing the flow separation of the suction surface of the wind turbine blade can suppress the flow separation of the suction surface of the wind turbine blade and improve the output power of the wind turbine.

[0026] The plasma flow control method for suppressing flow separation on the suction surface of wind turbine blades provided by the present invention includes the following parts:

[0027] The blades of the wind turbine play the role of driving the generator to generate electricity, and are also the carrier of the plasma exciter;

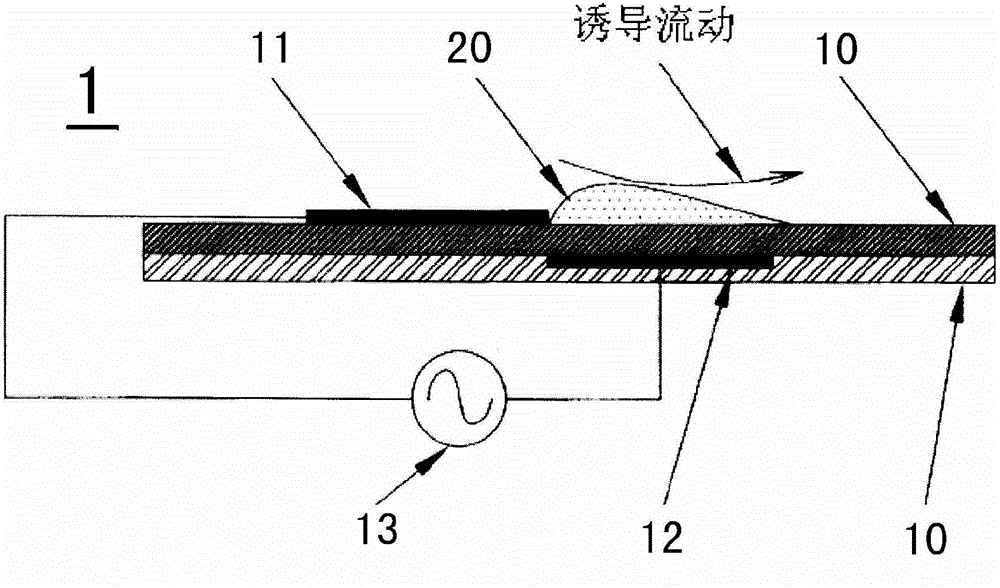

[0028] Plasma exciter, which generates plasma after being connected to high-voltage electricity, and accelerates the nearby air;

[0029] The plasma excitation voltage is to provide power for the plasma exciter through a high-voltage AC power supply;

[0030] From the perspectives of fluid mechanical aerodynamic thermodynamics and plasma physics, the invention adopts a plasma excitation method su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com