A compressor cascade experimental device

An experimental device, compressor technology, applied in mechanical equipment, machine/engine, pump control, etc., can solve the problem that the blade surface and the end wall of the blade cascade, and suction experiments cannot be carried out at the same time, so as to reduce the loss and weaken the secondary Flow, the effect of improving flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

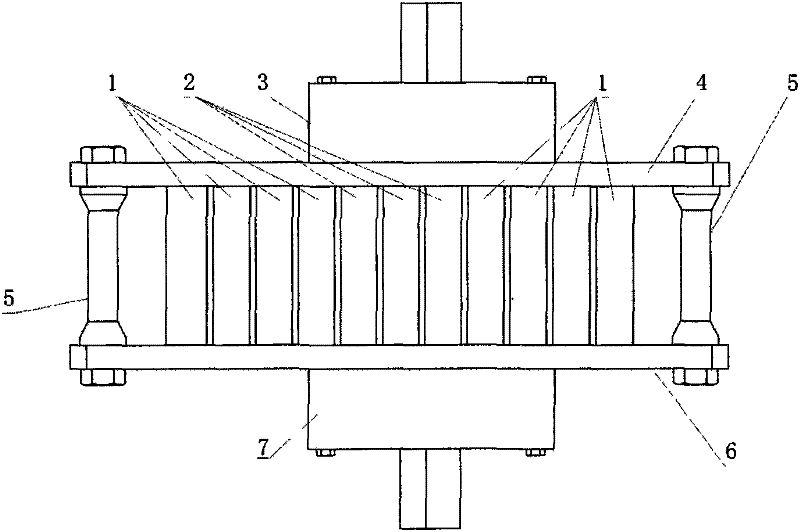

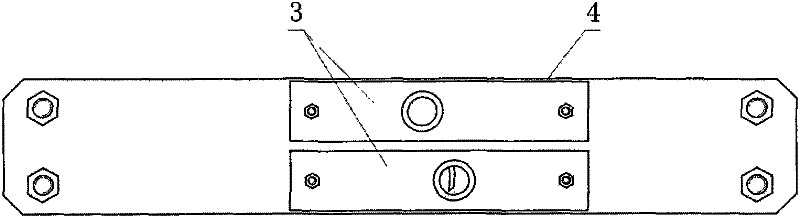

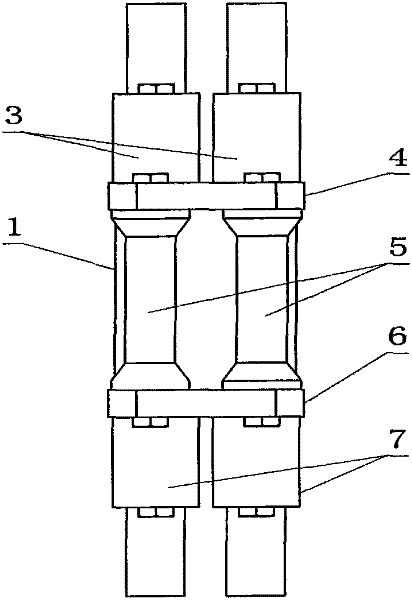

[0032] This embodiment is an experimental device for a combined suction type compressor cascade on the surface of the blade and the end wall of the cascade, which mainly consists of the blade 1, the suction blade 2, the first suction cover 3, the mounting frame and the second Suction cover 7 forms. In the present invention, according to the grid pitch of the compressor cascade, the number of blades 1 is determined to be 4 to 8, the number of suction blades 2 is 1 to 5, and the number of blades 1 is an even number, and the number of suction blades 2 is an odd number. In the present invention, a rectangular blade suction slot is opened on the suction surface of the suction blade 2, and the center of the blade suction slot is distributed in the chord direction position of the suction blade 2 on the suction blade 2. 25-60% of the chord length. In this embodiment, taking 8 blades 1 and 3 suction blades 2 as an example, taking the center of the blade suction slot on the suction bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com