Method for acquiring load distribution curve of blade of double-suction centrifugal pump

A technology of load distribution and centrifugal pumps, which is applied to parts, pumps, and pump elements of pumping devices for elastic fluids. It can solve problems such as weakening the secondary flow in the blade outlet area, and achieve widening of the high-efficiency zone and pressure changes. Uniform, secondary flow weakening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

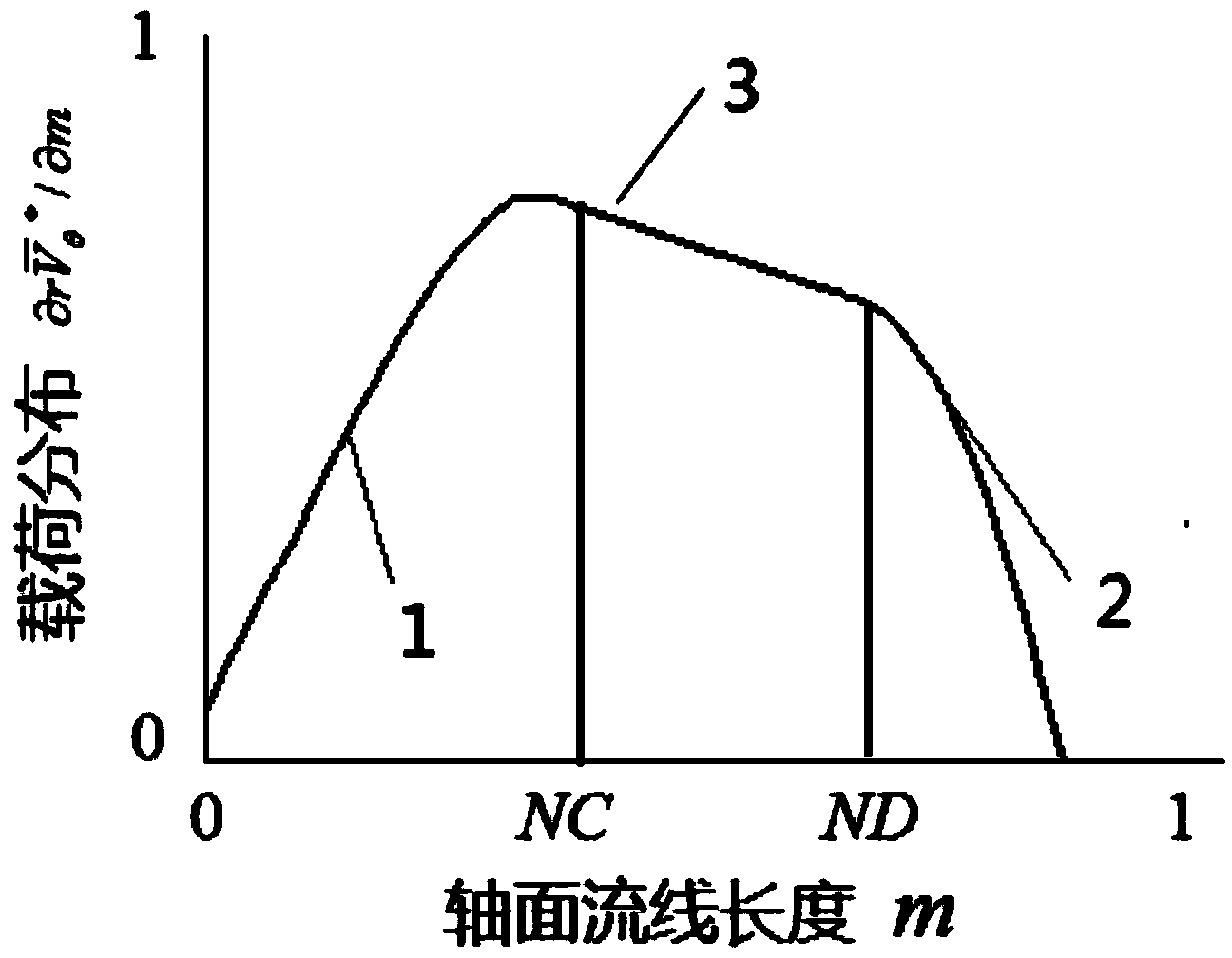

Method used

Image

Examples

Embodiment

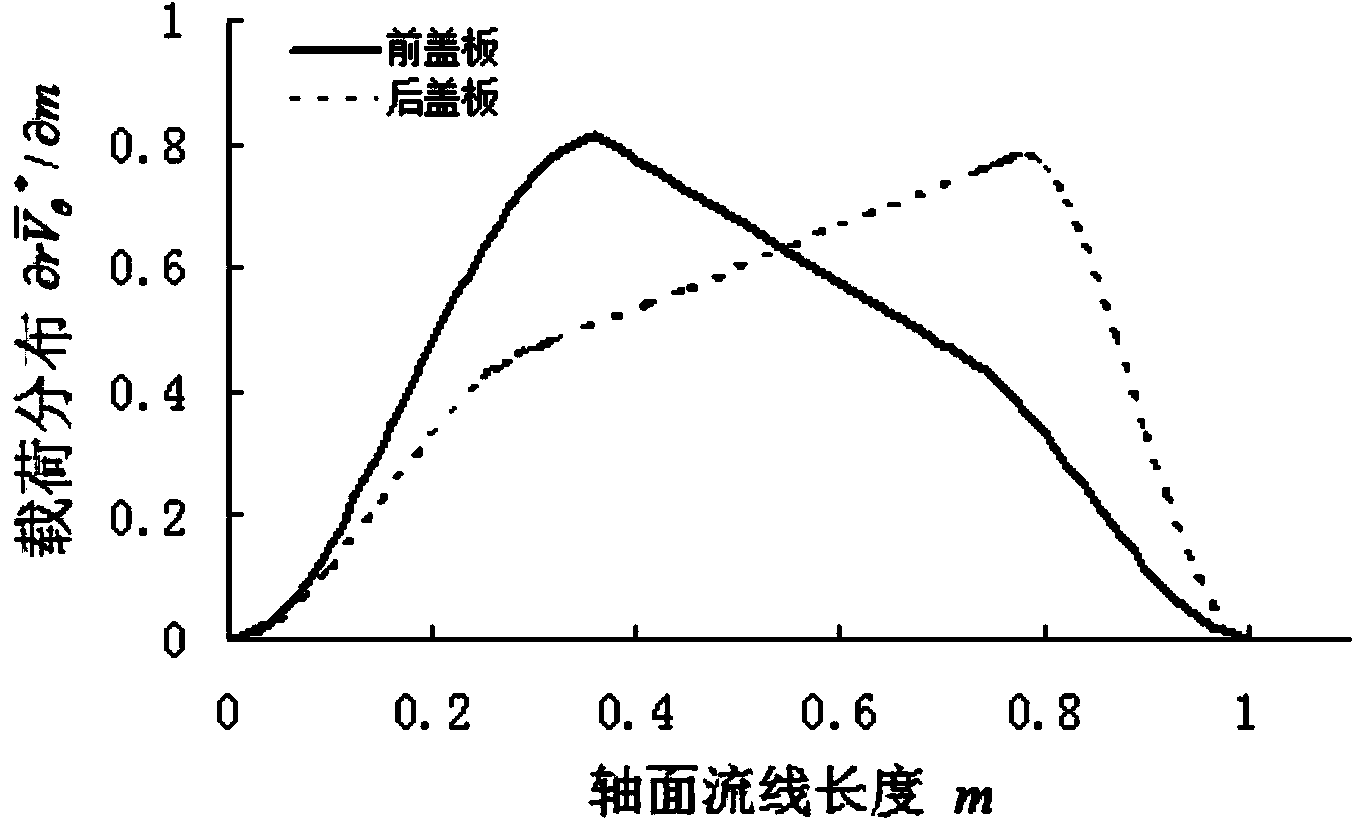

[0043] Example: To satisfy head H=32m, flow Q=10800m 3 / h, speed n=490r / min performance requirements of the double-suction centrifugal pump as an example, apply the method of obtaining the blade load distribution curve of the double-suction centrifugal pump, design the blade of the double-suction centrifugal pump, including the following steps:

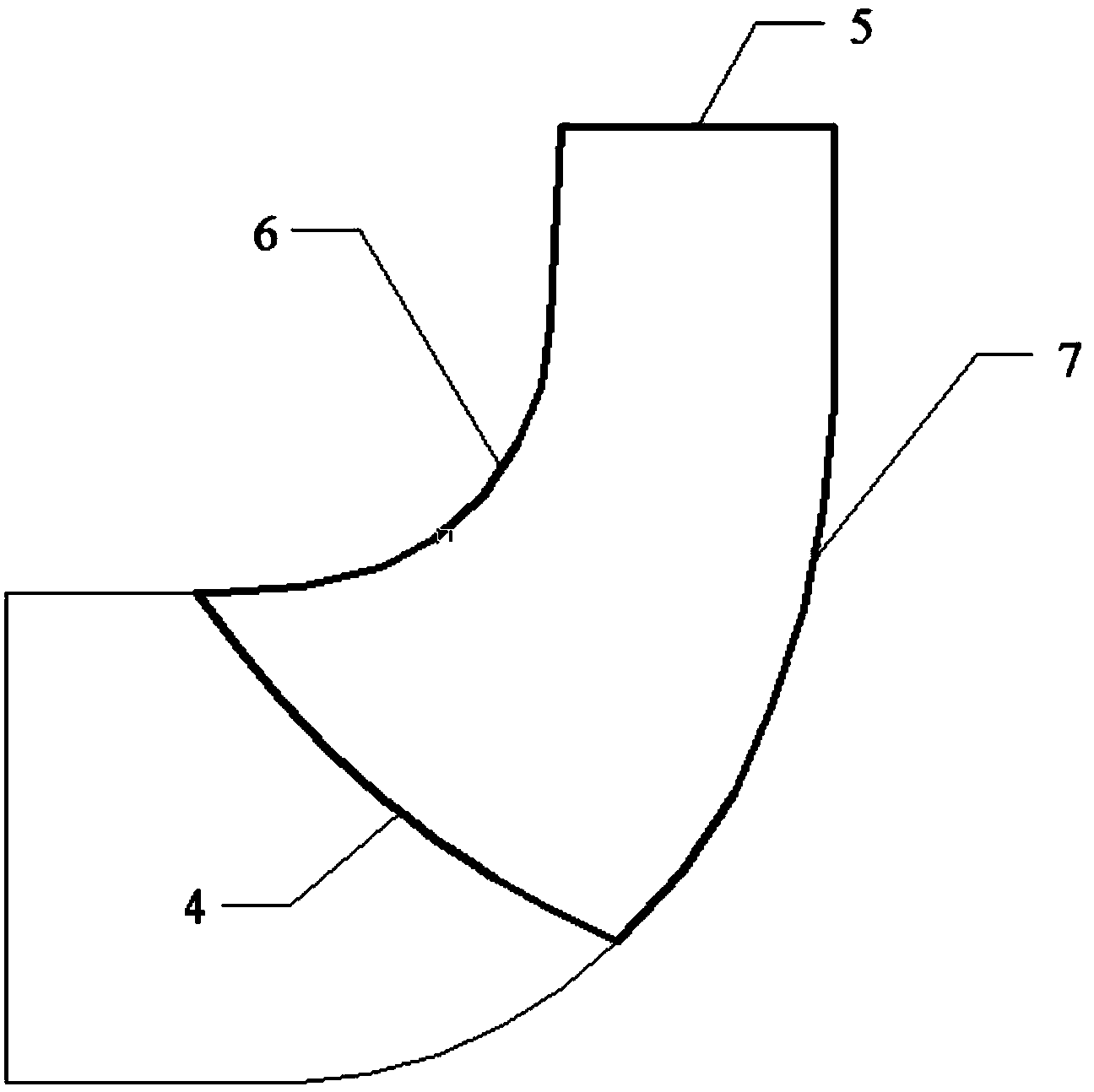

[0044] 1) Calculate the specific speed according to the performance parameters of the double-suction centrifugal pump and draw the blade axial plane projection diagram

[0045] Substituting the performance parameters into the formula (1) to calculate the specific speed n s=163. And determine the inlet diameter, outlet diameter and outlet width of the blade according to the performance parameters, draw the axial plane projection of the blade, determine the streamline of the front cover plate, the streamline of the rear cover plate and the inlet and outlet edges of the blade according to the axial plane projection of the blade, Such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com