Soil sampler for soil remediation

A soil sampler and soil remediation technology, applied in the field of soil area sampling, can solve the problems of unsuitability, low sampling efficiency, soil sample separation, etc., to avoid disturbance and damage, uniform surrounding pressure changes, and uniform force and speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

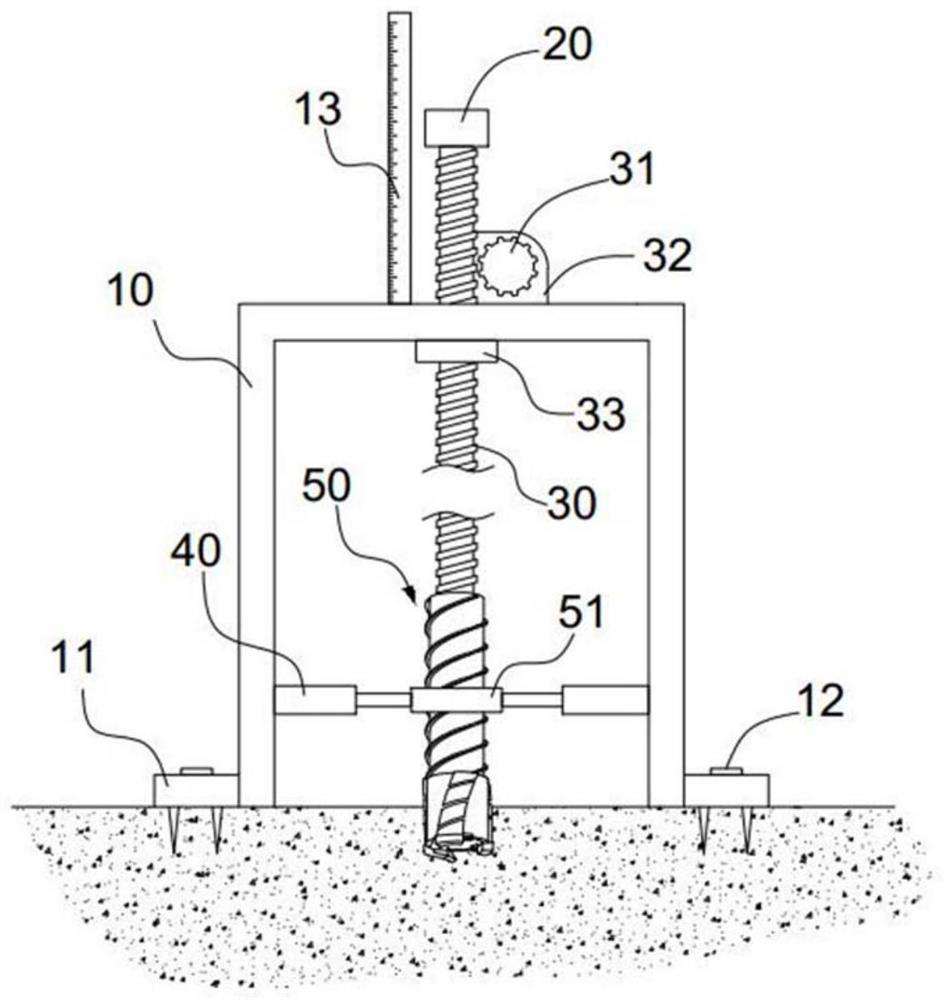

[0036] see Figure 1-11 As shown, a soil sampler for soil remediation, including:

[0037] frame body 10,

[0038] The lifting assembly includes a worm 30 vertically arranged on the frame body 10 with the horizontal plane, a first sleeve 33 cooperating with the worm screw 30 and a turbine 31 for driving the worm screw 30 to move up and down are installed on the frame body 10,

[0039] The sampling assembly 50 is arranged vertically to the horizontal plane, and the sampling assembly 50 is driven by the lifting assembly to rotate and lift up and down to sample the soil.

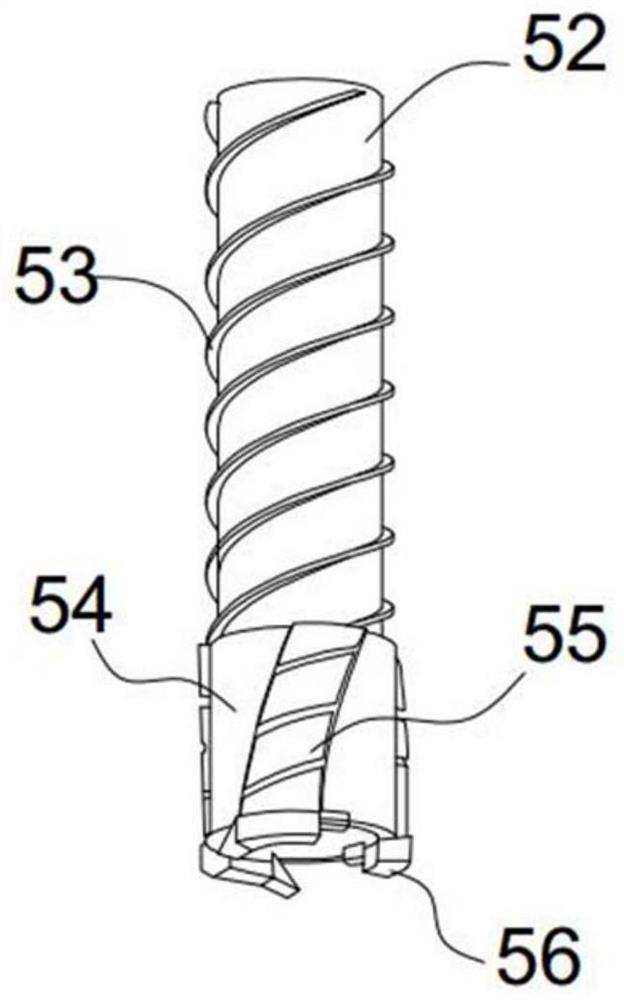

[0040] Wherein, the sampling assembly 50 includes a sampling cylinder 52, a cylindrical hollow sampling chamber 57 is arranged inside the sampling cylinder 52, and memory alloy wires 62 are arranged around the inner wall of the sampling chamber 57, and the memory alloy wires 62 are linear and parallel to the sampling cylinder 52. The central axis of the memory alloy wire 62 can be heated and deformed into a z...

Embodiment 2

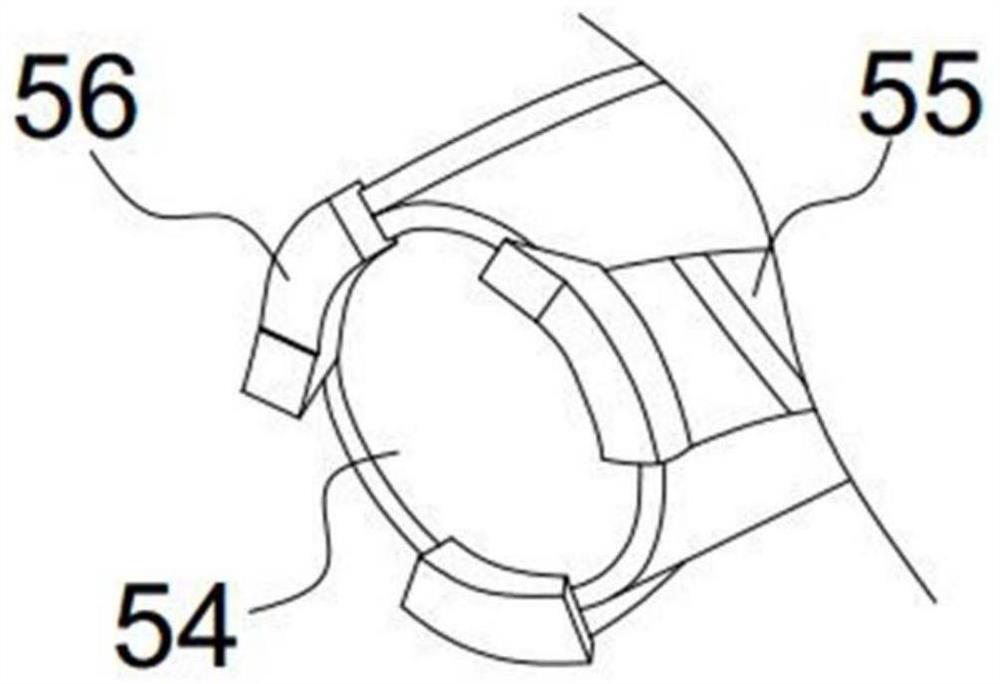

[0052] When the soil sampling device for soil remediation of the present invention is actually used: the frame body 10 is installed on the soil surface of the drilling area, the frame body 10 is adjusted according to the level meter 12, and before the soil sample is drilled, the relative scale 13 of the electric heater 20 is recorded. At the height position, the turbine 31 is driven to rotate by starting the motor 32 to drive the worm 30 to rotate and move downward. The worm 30 drives the assembly 22 to rotate during the rotation, and the assembly 22 transmits the rotational force to the sampling cylinder 52 through the tooth surface And make it rotate, the bottom of the sampling cylinder 52 is provided with a drill sleeve 54, and the soil sample is drilled by rotating. During the drilling process, the shaking of the sampling sleeve 52 is reduced by the second sleeve 51 level support assembly 40 to ensure that the soil sample is obtained. Integrity of the drilled soil sample, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com