Calibration device and application method of a bod measuring instrument

A technology for calibrating devices and measuring instruments, which is applied in the field of environmental testing instruments, can solve the problems of small application areas of BOD measuring instruments, and achieve the effects of short calibration time, high efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

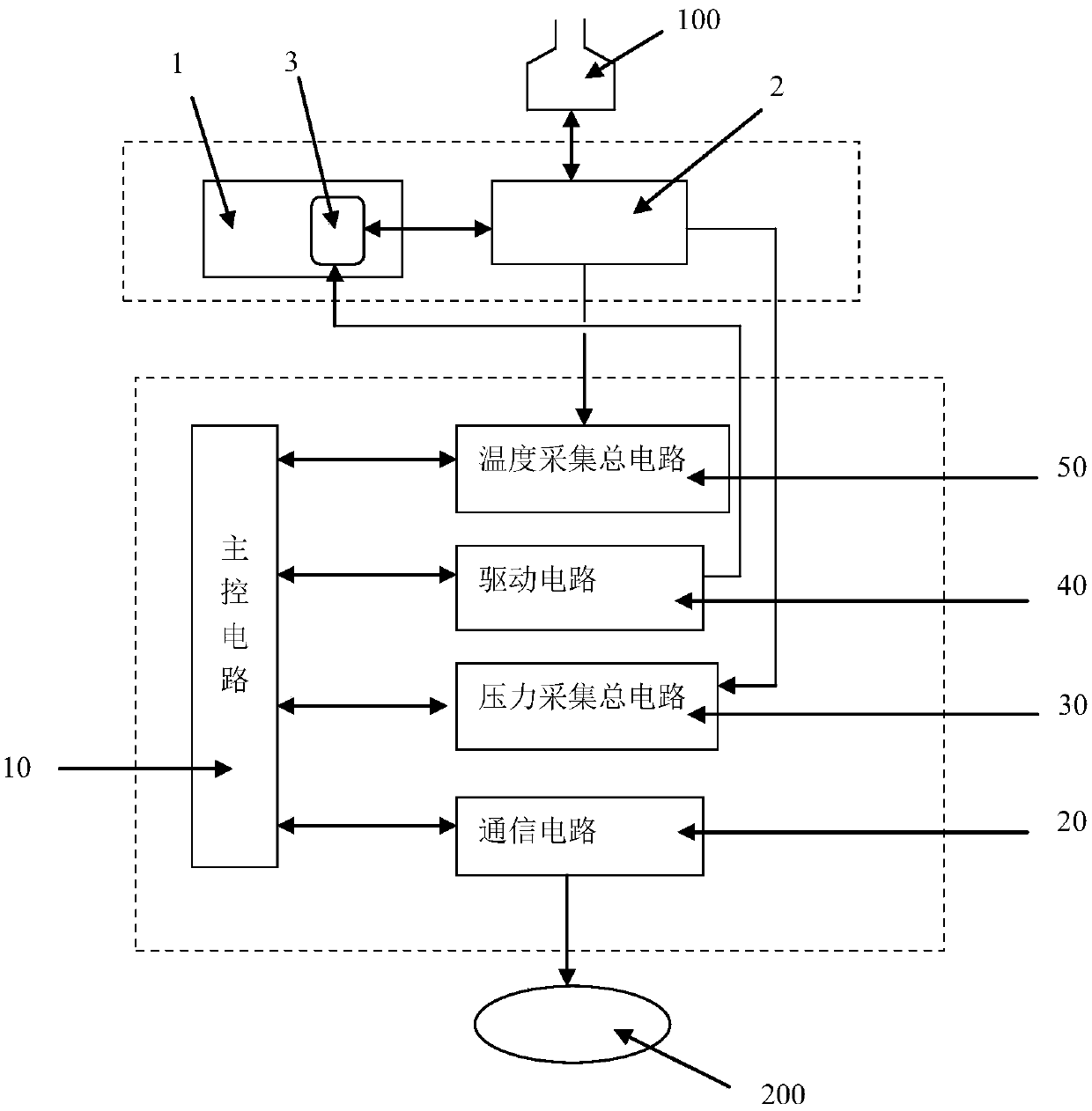

[0043] Such as figure 1 , figure 2 As shown, it includes a gas path part and a circuit part. The gas path part includes a negative pressure generating device 1 and a pressure vessel 2 for calibration. The negative pressure generating device 1 includes a differential pressure control module 3, and the differential pressure control module 3 It is connected with the pressure vessel 2 for calibration, and the circuit part includes a main control circuit 10, a communication circuit 20, a pressure acquisition total circuit 30 and a drive circuit 40, and the communication circuit 20, the pressure acquisition total circuit 30 and the drive circuit 40 are connected with the main control circuit 20 respectively. The control circuit 10 is connected, the pressure acquisition general circuit 30 includes a pressure sensor 301, the pressure sensor 301 is connected to the pressure vessel 2 for calibration, the drive circuit 40 is connected to the differential pressure control module 3, and t...

Embodiment 2

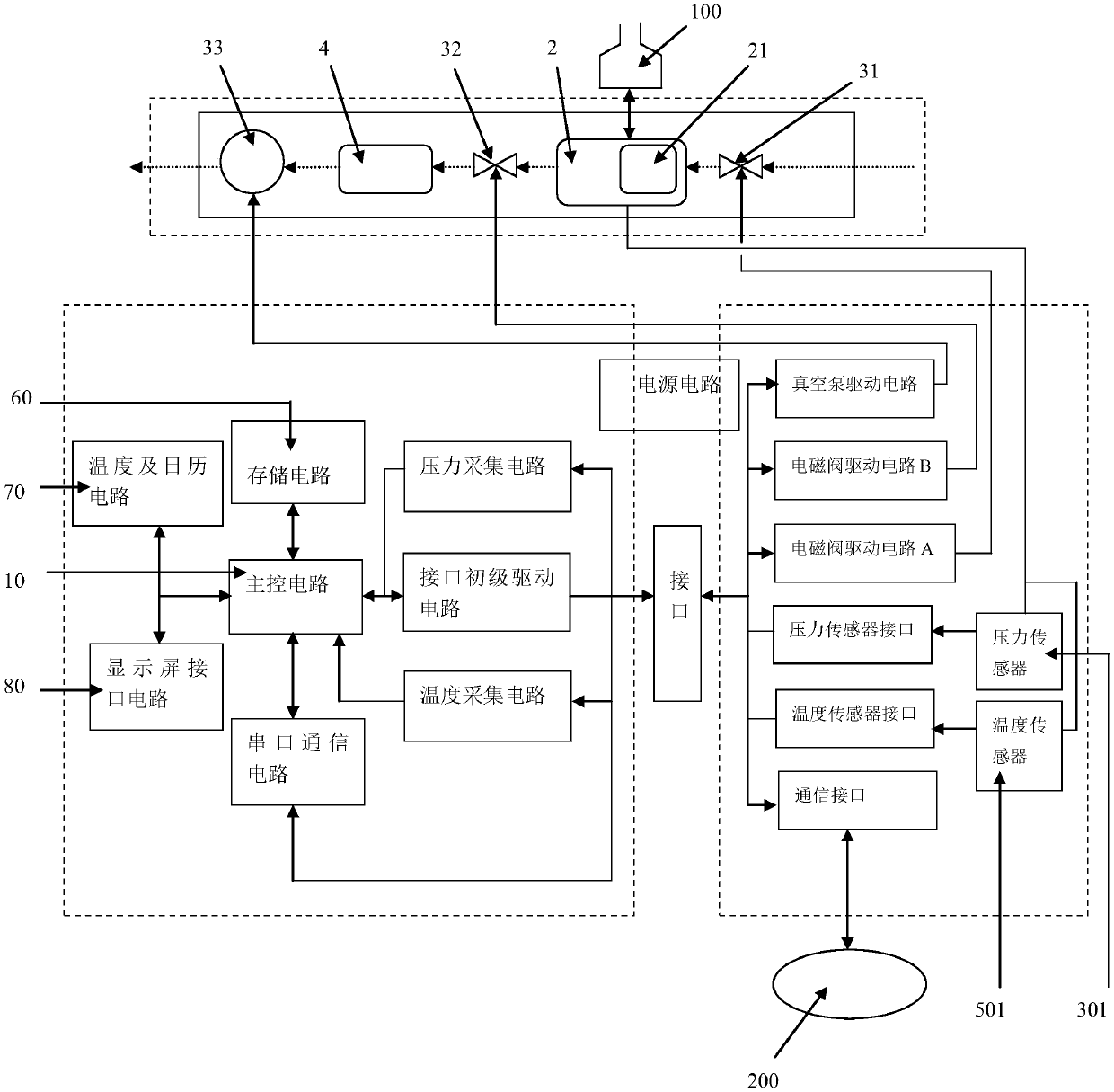

[0053] Such as figure 2 As shown, on the basis of Embodiment 1, the circuit part further includes a storage circuit 60 connected to the main control circuit 10, and the storage circuit 60 is used for storing input instructions or measurement records.

[0054] The storage circuit 60 is provided, which can not only store the input instructions, but also store the previous measurement records, which is convenient for the operator to check. With this technical solution, the function of the BOD measuring instrument calibration device is more complete and easy to use.

[0055] Further, the circuit part also includes a temperature and calendar circuit 70 connected to the main control circuit 10, and the temperature and calendar circuit 70 provides temperature and calendar information for the calibration device of the BOD measuring instrument. By adopting this technical scheme, the function of the calibration device of the BOD measuring instrument is more complete and the use is conv...

Embodiment 3

[0057] On the basis of Example 2, such as figure 2 As shown, a preferred embodiment of the circuit part is that the circuit part further includes a display screen interface circuit 80 connected to the main control circuit 10, and the display screen interface circuit 80 is used for connecting an external display screen.

[0058] The communication circuit 10 includes a serial communication circuit and a communication interface sequentially connected, wherein the serial communication circuit is connected to the main control circuit, the communication interface is connected to an external computer 200, and the communication interface is connected to the serial communication circuit through an interface.

[0059] The driving circuit 40 includes a primary driving circuit, a vacuum pump driving circuit, a solenoid valve driving circuit A, and a solenoid valve driving circuit B, and the vacuum pump driving circuit, the solenoid valve driving circuit A, and the solenoid valve driving c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com