Patents

Literature

43results about How to "Uniform reaction force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

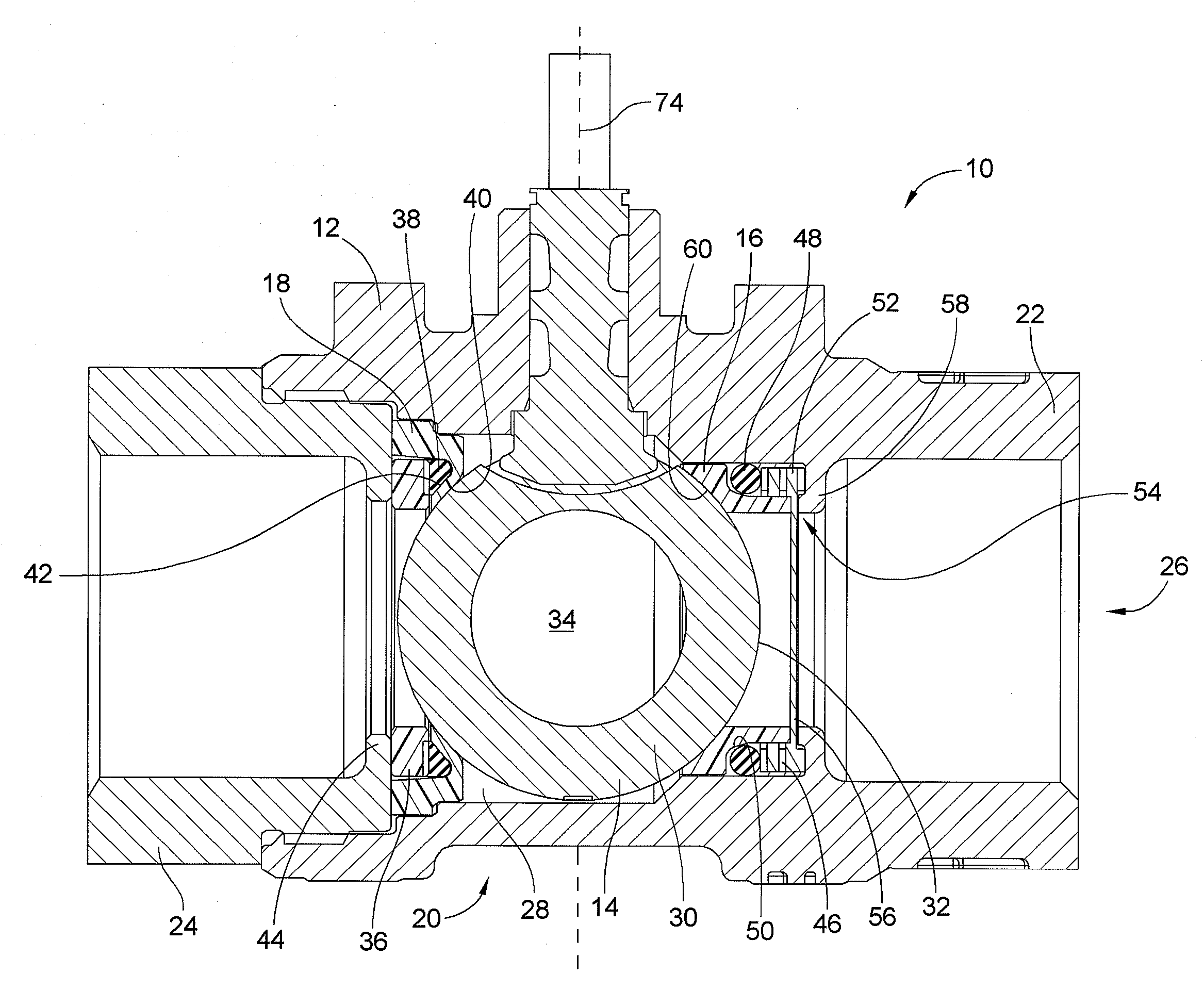

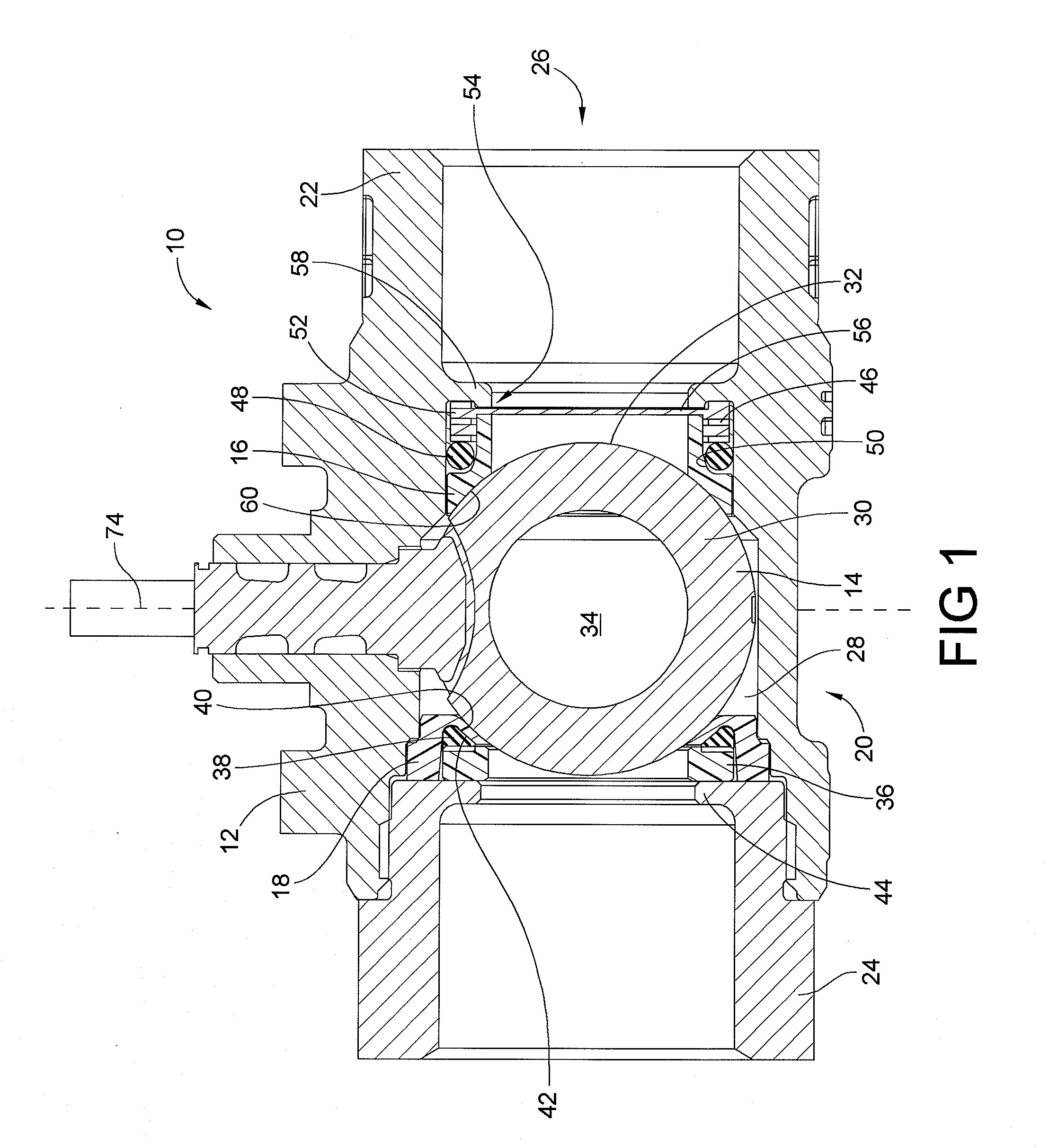

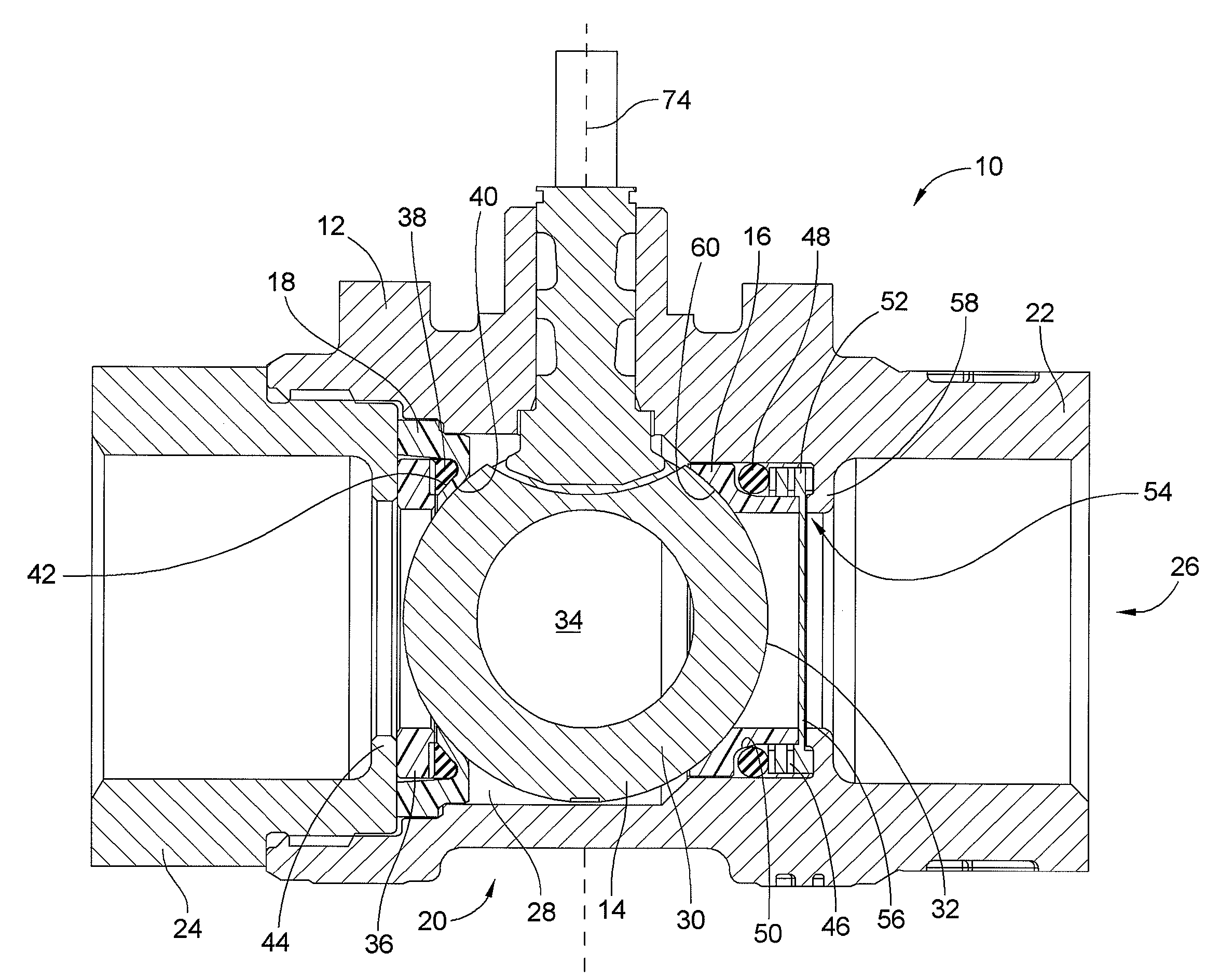

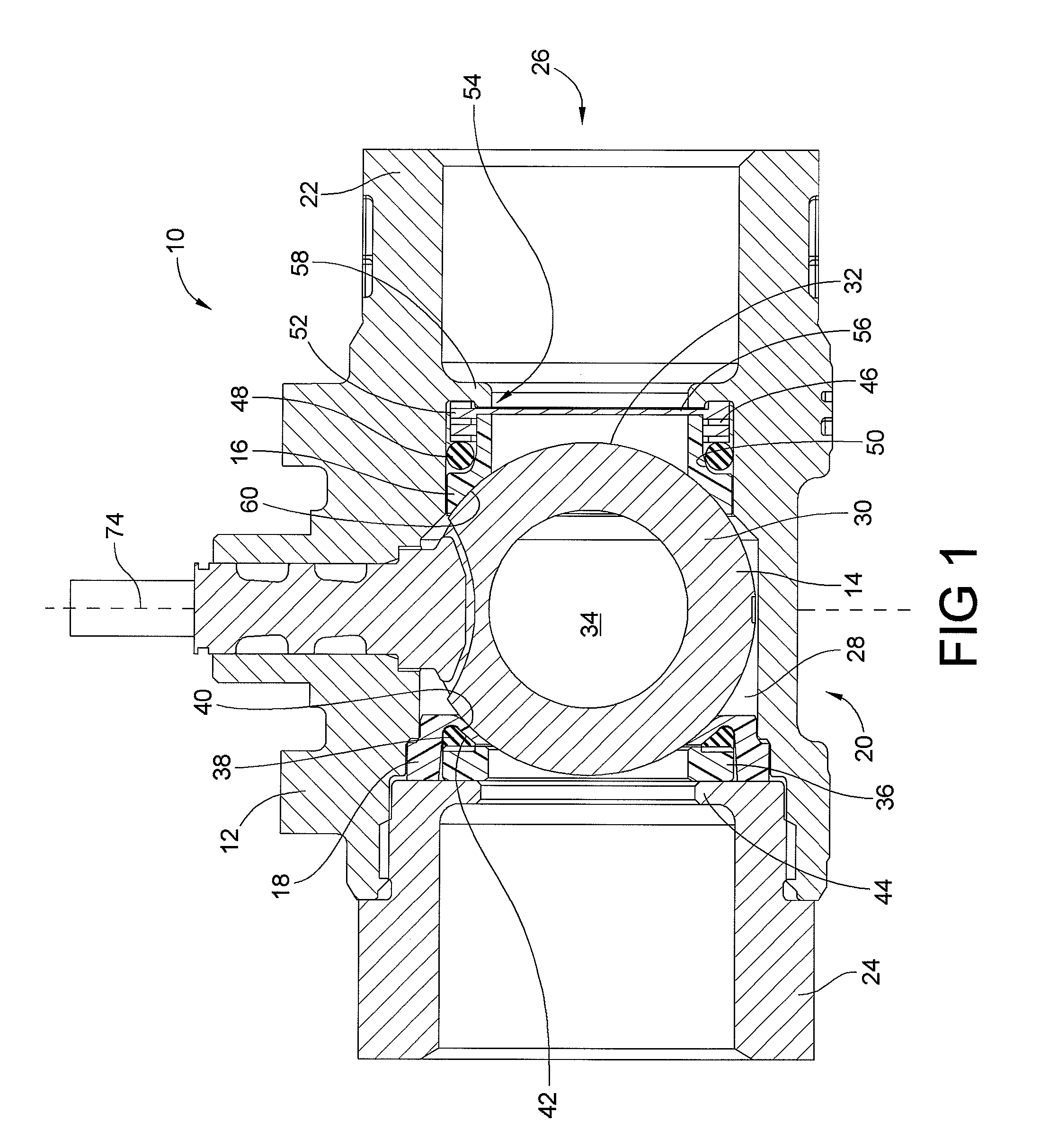

Low Torque Ball Valve With Dynamic Sealing

ActiveUS20080128648A1Reduce torqueIncrease torquePlug valvesValve member-seat contactsEngineeringInlet pressure

A ball valve having reduced torque requirements for rotation is presented. Torque reduction is realized by providing a shaped sealing back member to provide a back force behind essentially the entire sealing surface of the downstream seal. Torque reduction is also realized by providing a dynamic sealing configuration that varies the sealing force over the valve's operating pressure conditions. An initial bias sealing force is applied by a spring member which also provides a low uniform as-assembled valve torque. As fluid pressure increases, the sealing pressure also increases as an o-ring is forced along a ramped surface of the seal. As inlet pressure decreases, the o-ring is allowed to back down the ramped surface to reduce the sealing force against the valve member. This sealing configuration allows for reverse flow or improper installation of the ball valve, and bottoms out to maintain a sealing force at higher back pressure conditions.

Owner:TAC LLC A LIMITED LIABILITY COMPANY ORGANIZED & EXISTING UNDER THE LAWS OF DELAWARE

Low torque ball valve with dynamic sealing

ActiveUS7559531B2Reduce torqueIncrease torquePlug valvesValve member-seat contactsInlet pressureEngineering

Owner:SCHNEIDER ELECTRIC BUILDINGS AMERICAS INC

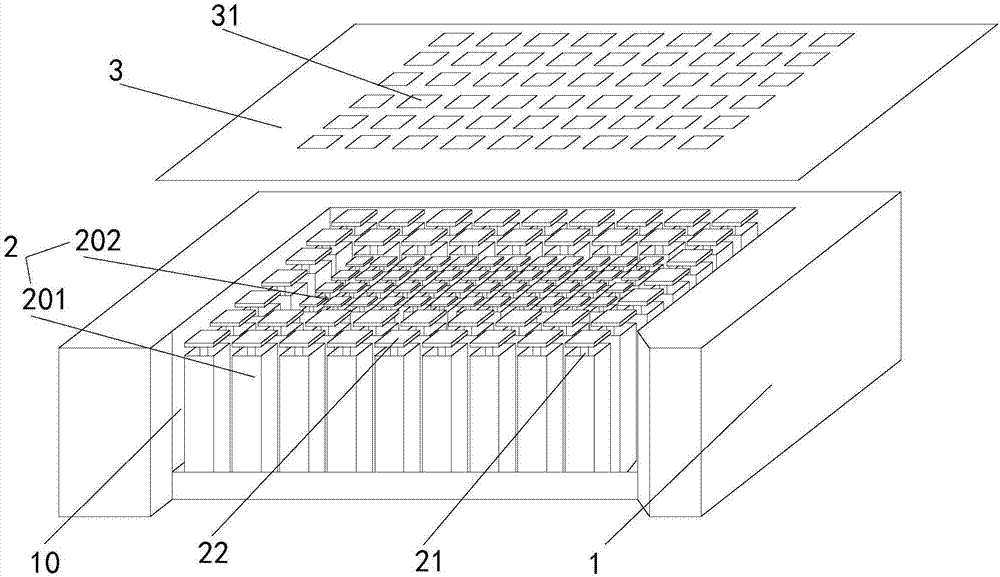

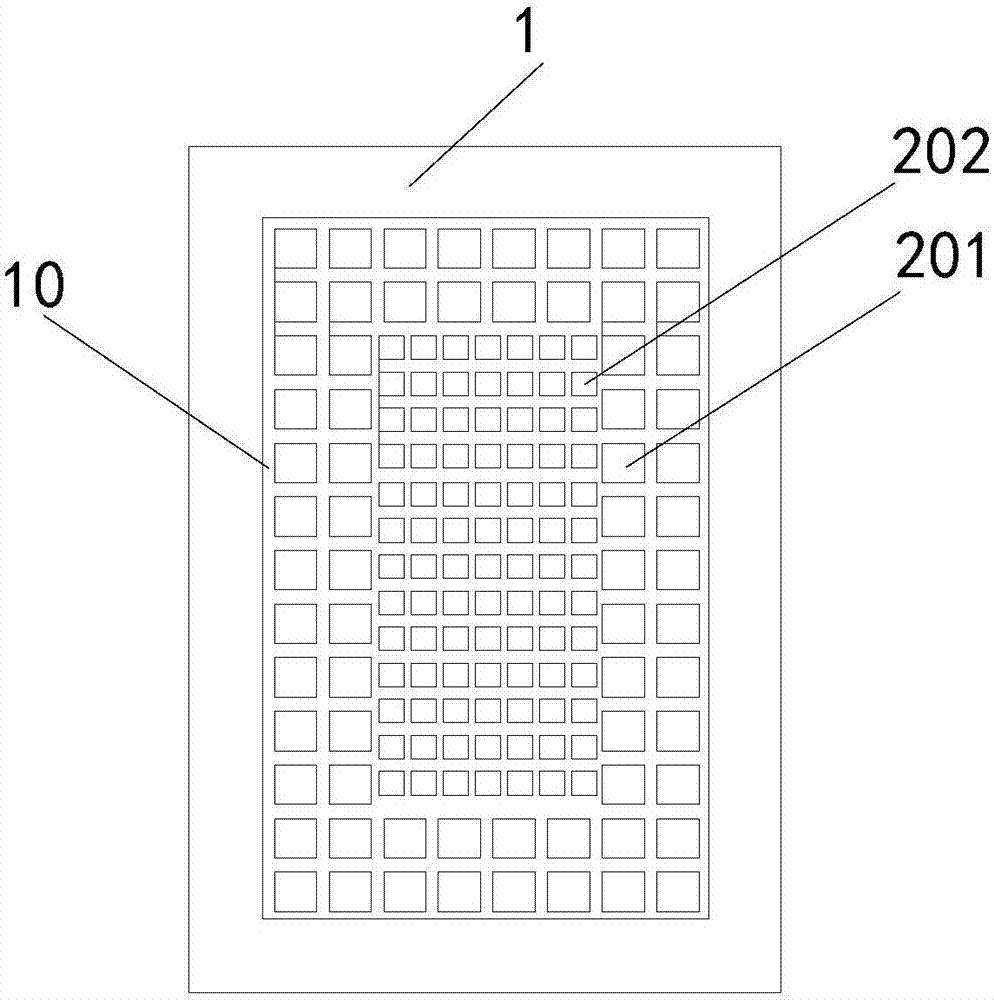

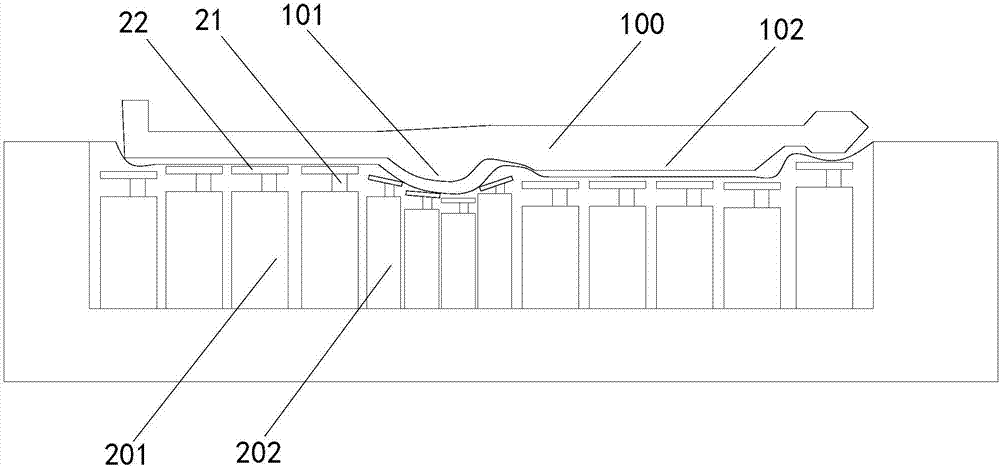

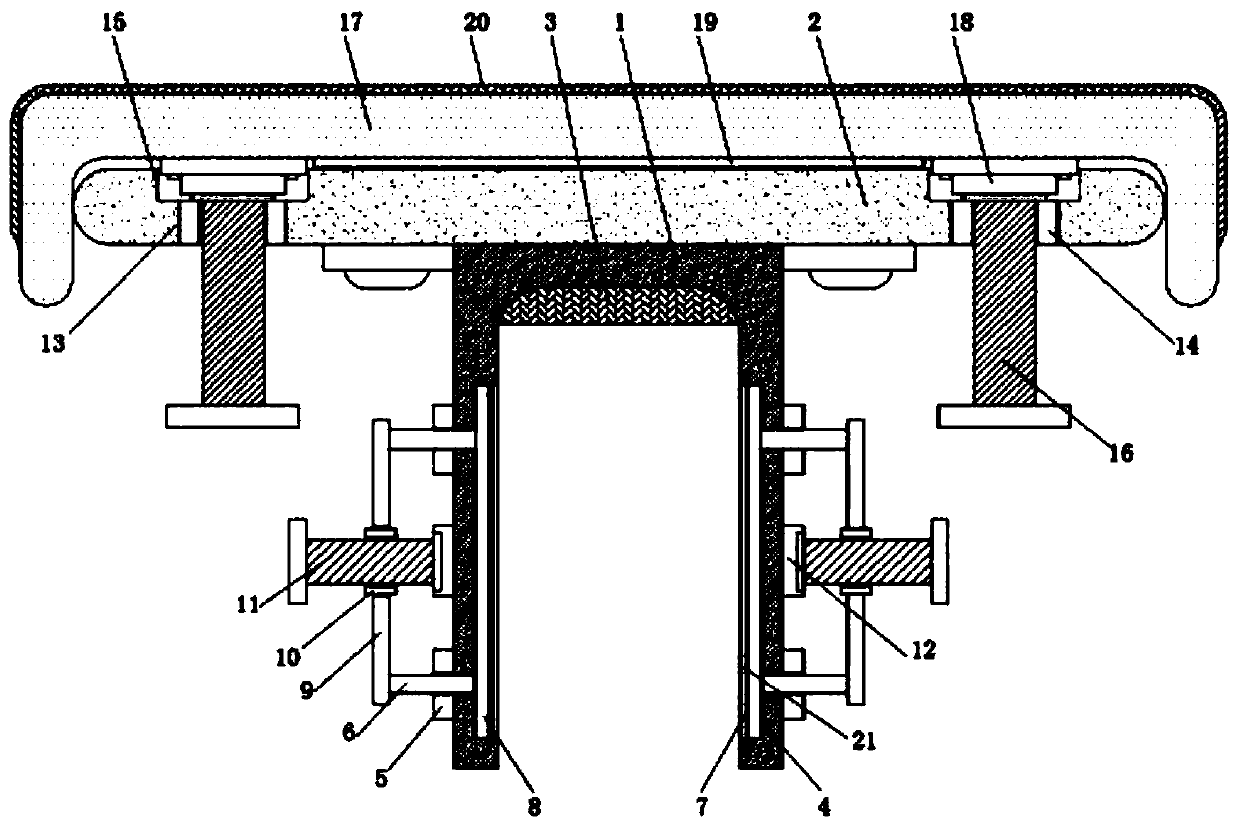

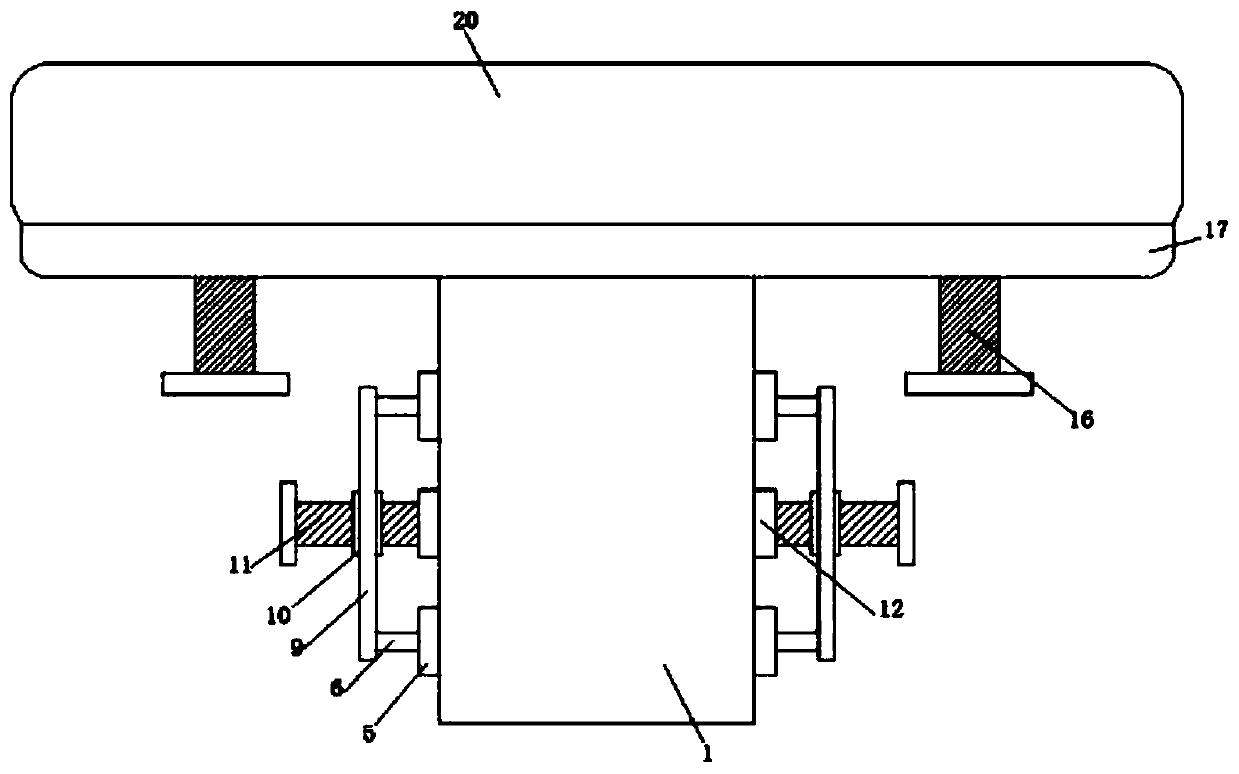

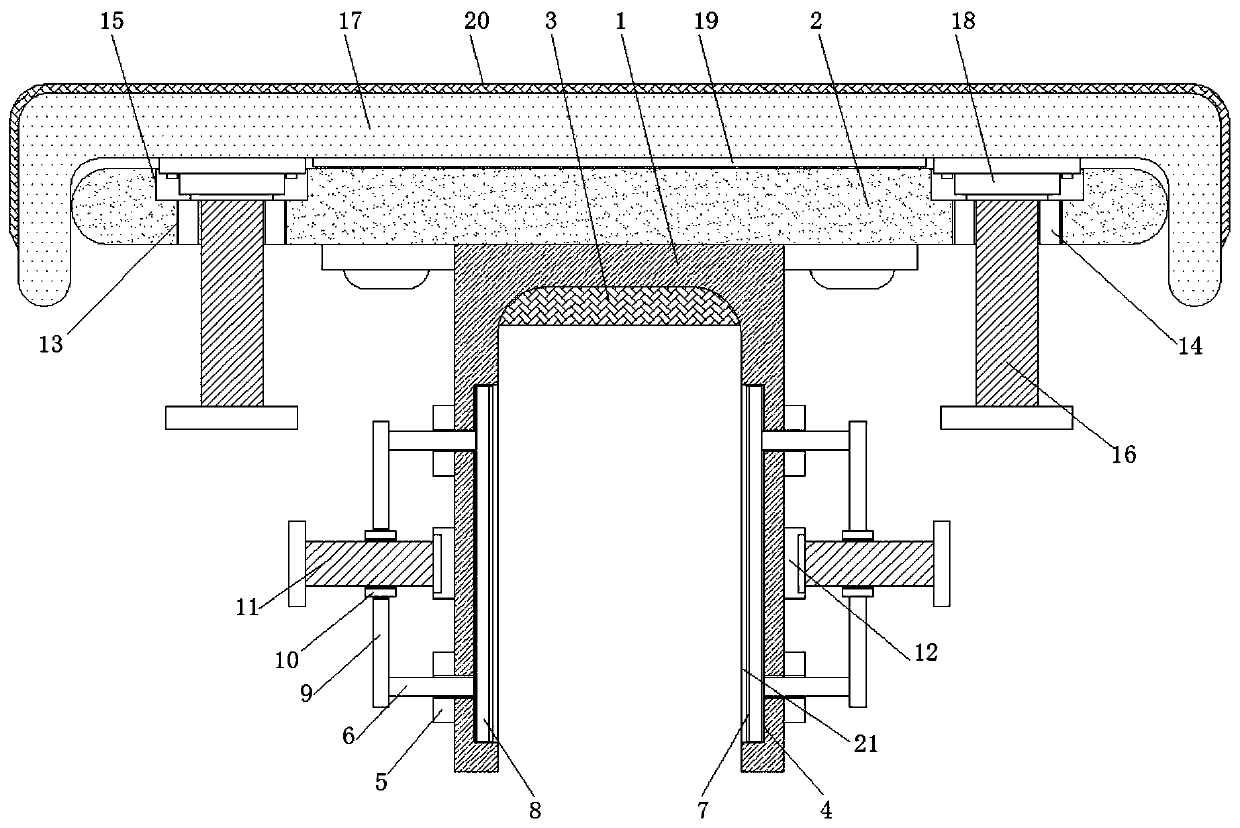

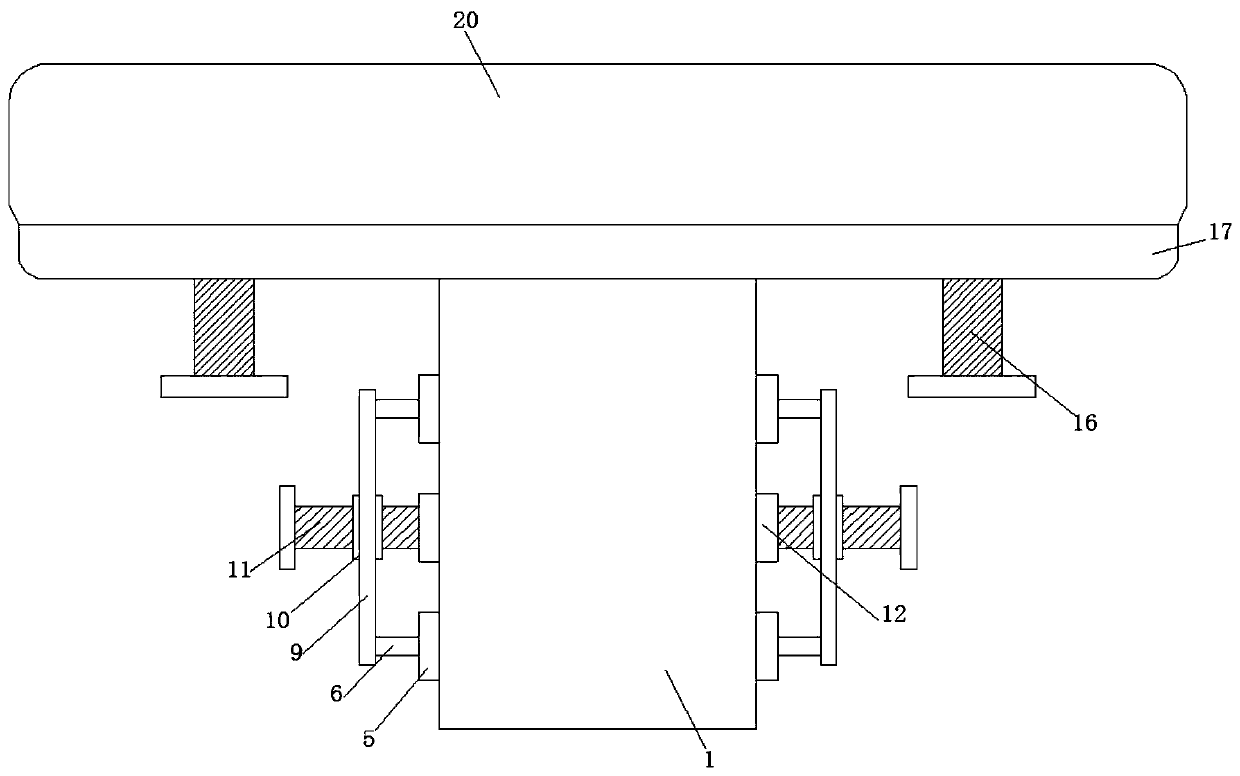

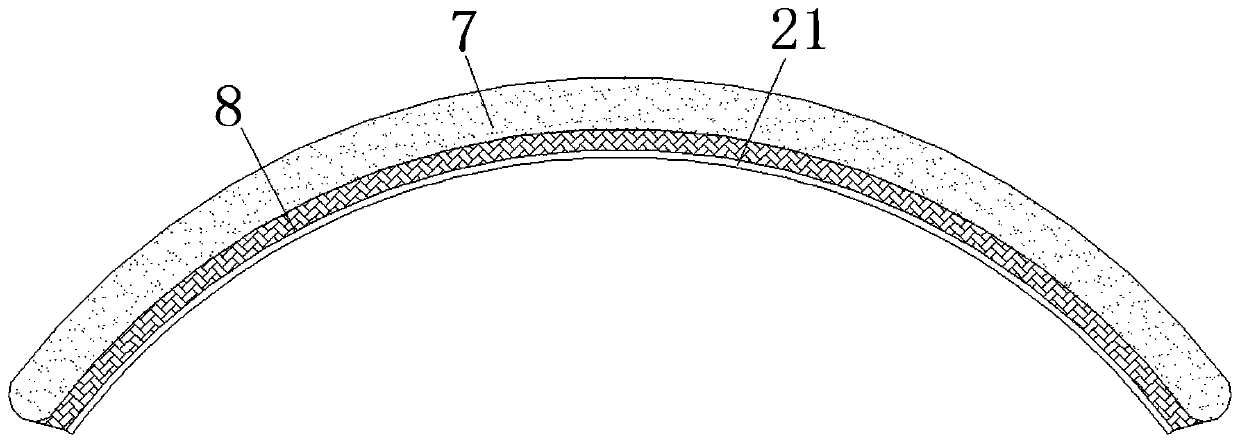

Intelligent mattress capable of being adjusted according to sleeping postures

InactiveCN107041650AUniform reaction forceImprove comfortStuffed mattressesSpring mattressesInductorEngineering

The invention relates to an intelligent mattress capable of being adjusted according to sleeping postures. The intelligent mattress comprises a mattress body and a latex layer, wherein a movable slot is formed in the upper surface of the mattress body, a plurality of fixed boxes are arranged in the movable slot, drivers and push rods connected with the drivers are arranged in the fixed boxes, fixed plates are connected to the top ends of the push rods, and first inductors are arranged on the fixed plates; the drivers can drive the push rods to stretch out or shrink along the vertical direction; the latex layer covers the fixed plates; a plurality of second inductors are fixed on the latex layer; and a first pressure inductor is used for acquiring pressure borne by the fixed plates, a processor is used for matching the pressure with a sleeping posture model so as to determine the sleeping postures of a user and determining pressure parameters of each fixed plate mapped by the sleeping postures of the user according to a preset mapping relation, and the drivers are used for driving the extension or shrink according to the pressure parameters until the pressure of the fixed plates reaches a pressure limited by the pressure parameters. According to the intelligent mattress, the surface shapes of the mattress are matched with the sleeping postures of a human body, so that the comfort level is greatly increased.

Owner:DONGGUAN DERUCCI BEDDING CO LTD

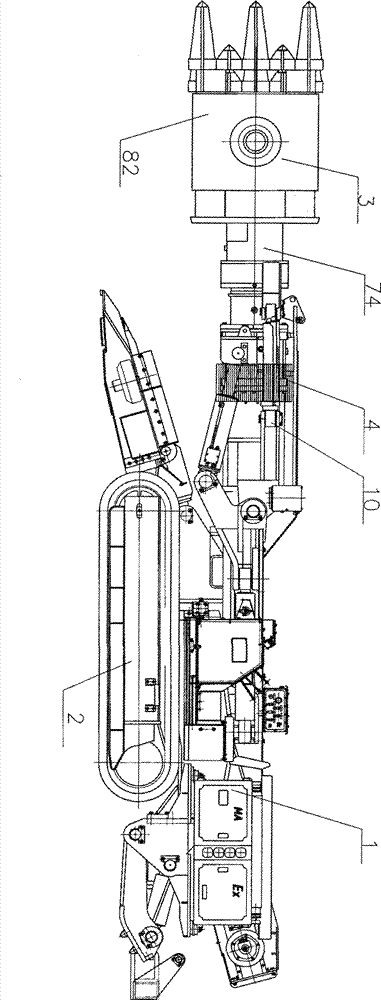

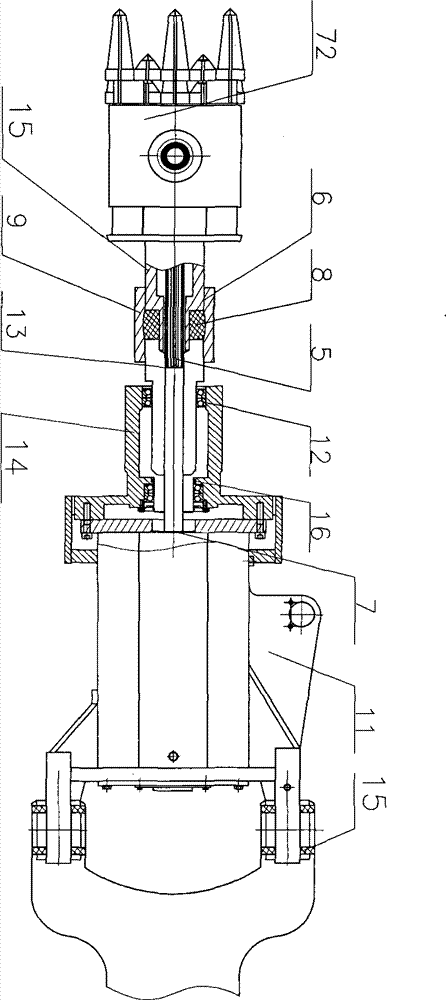

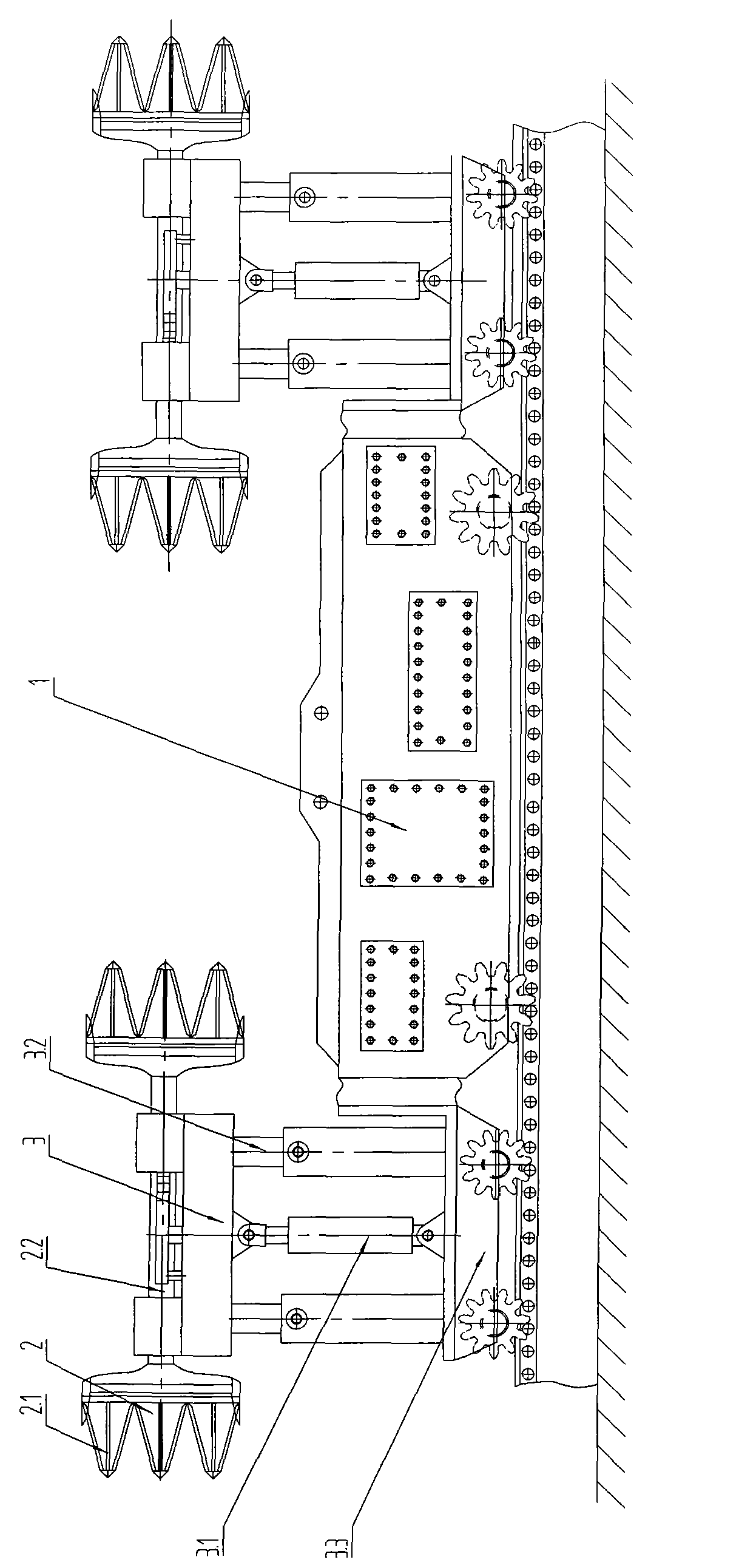

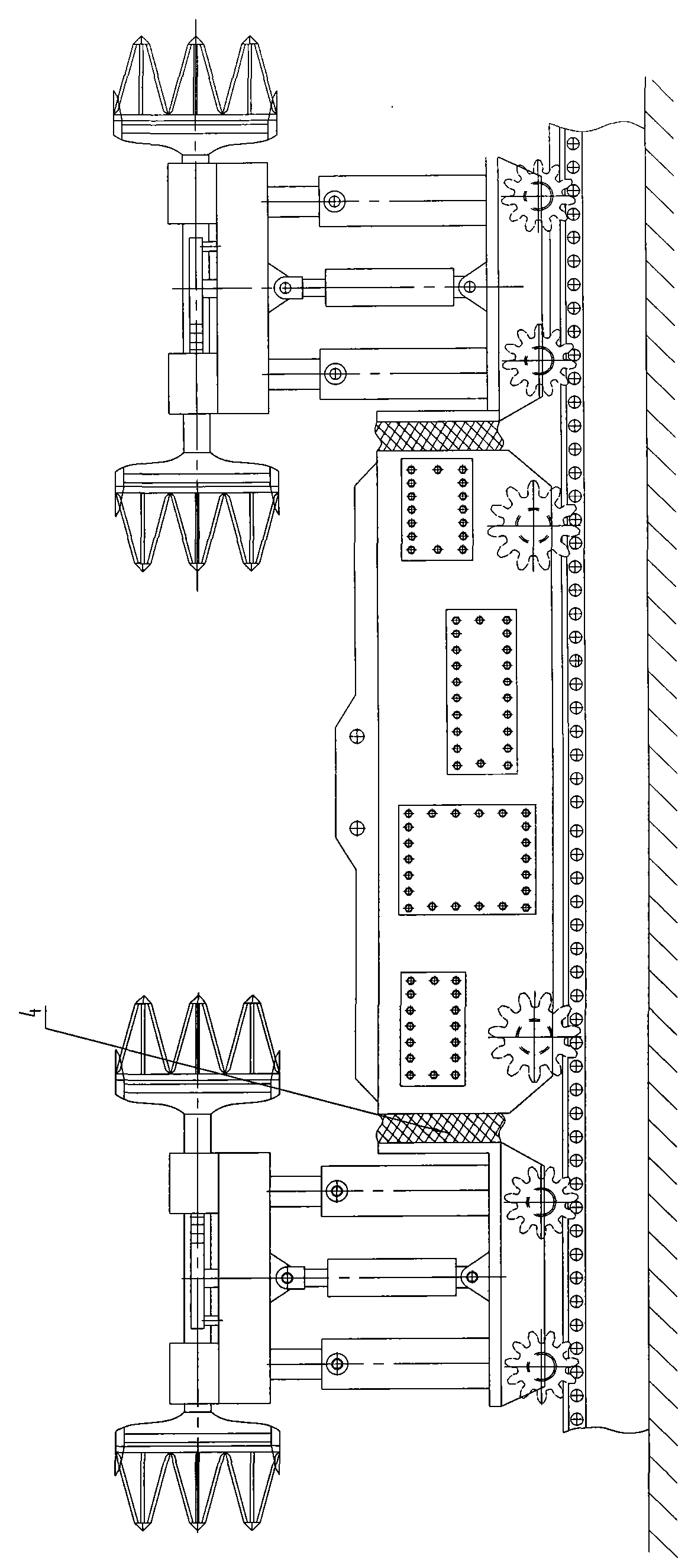

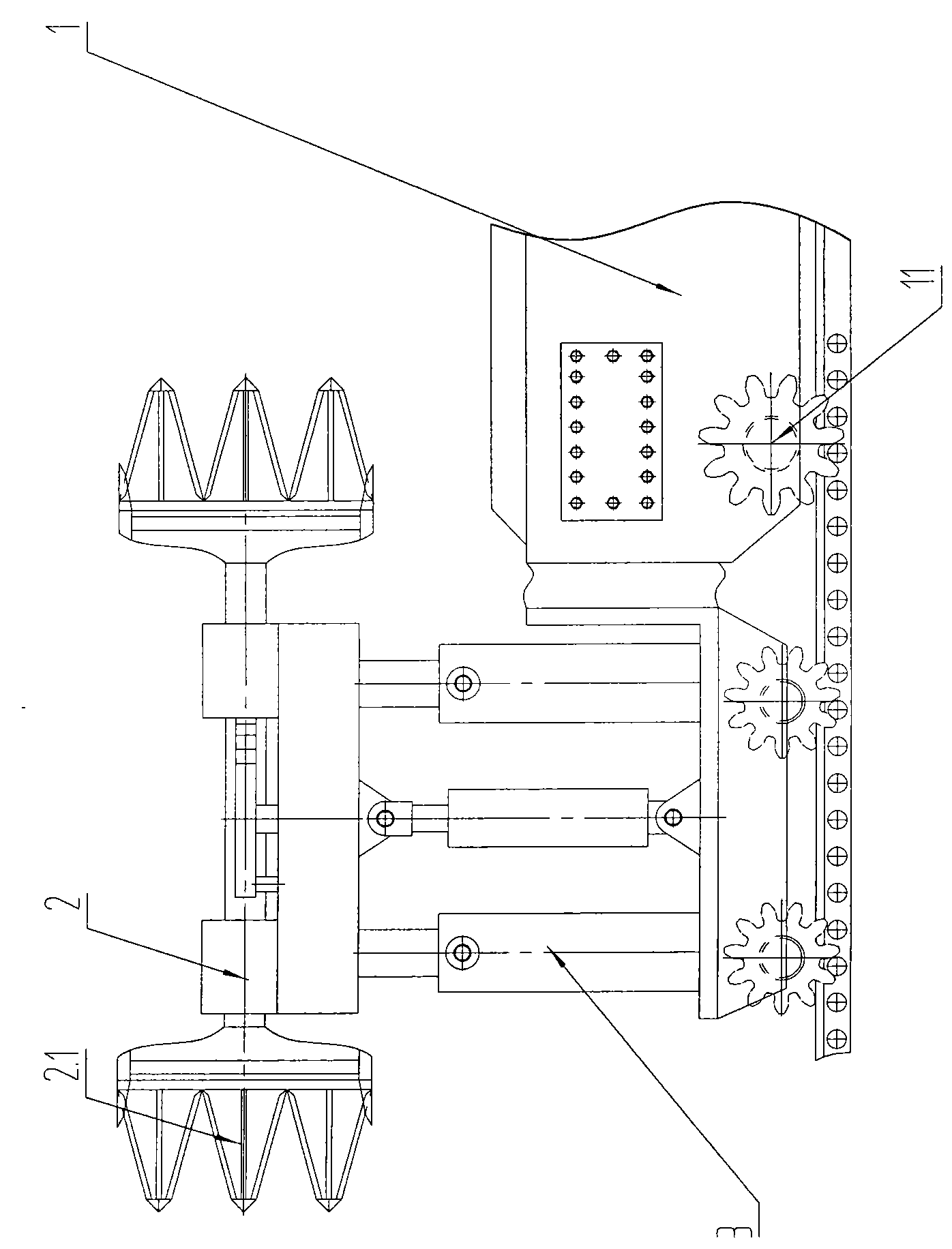

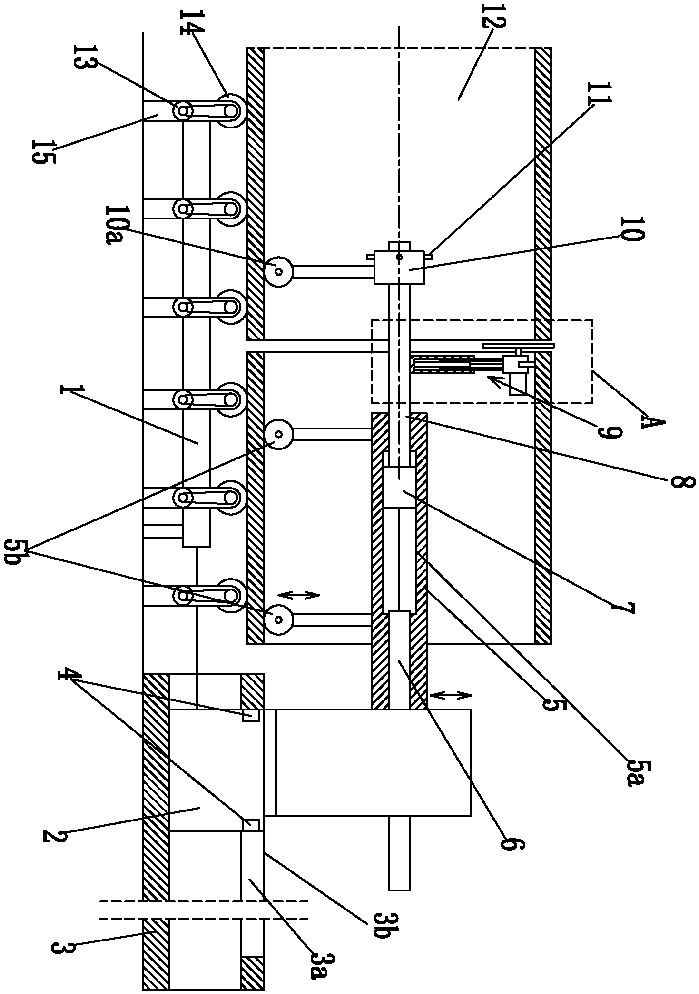

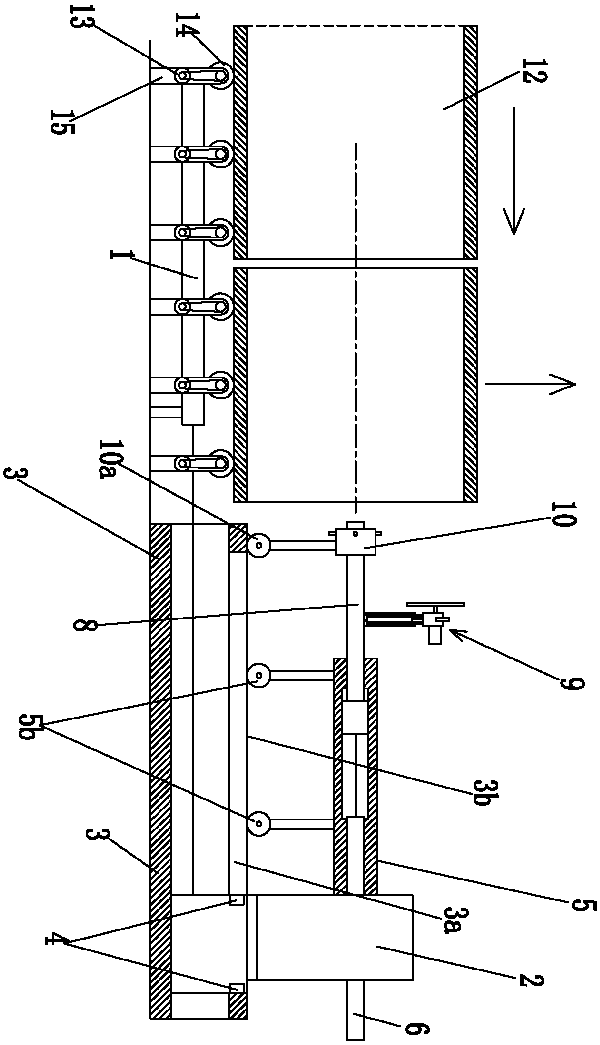

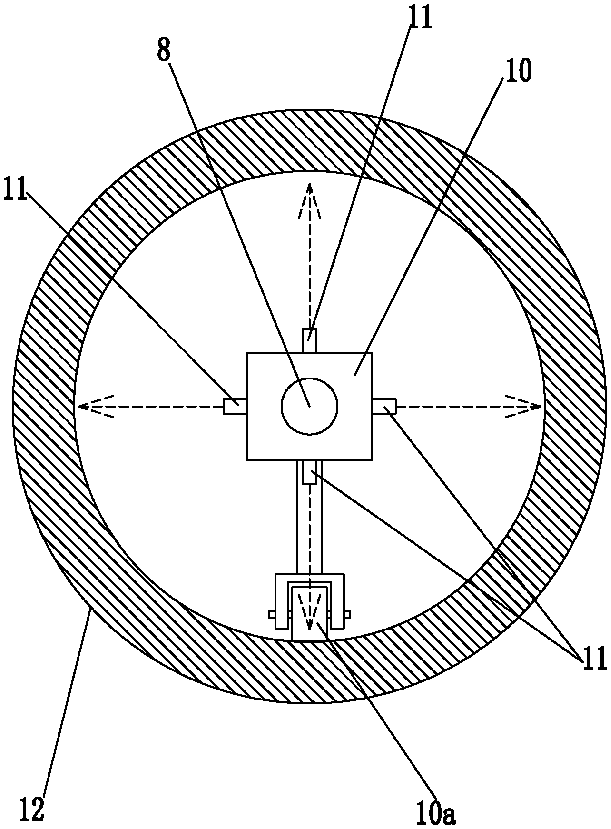

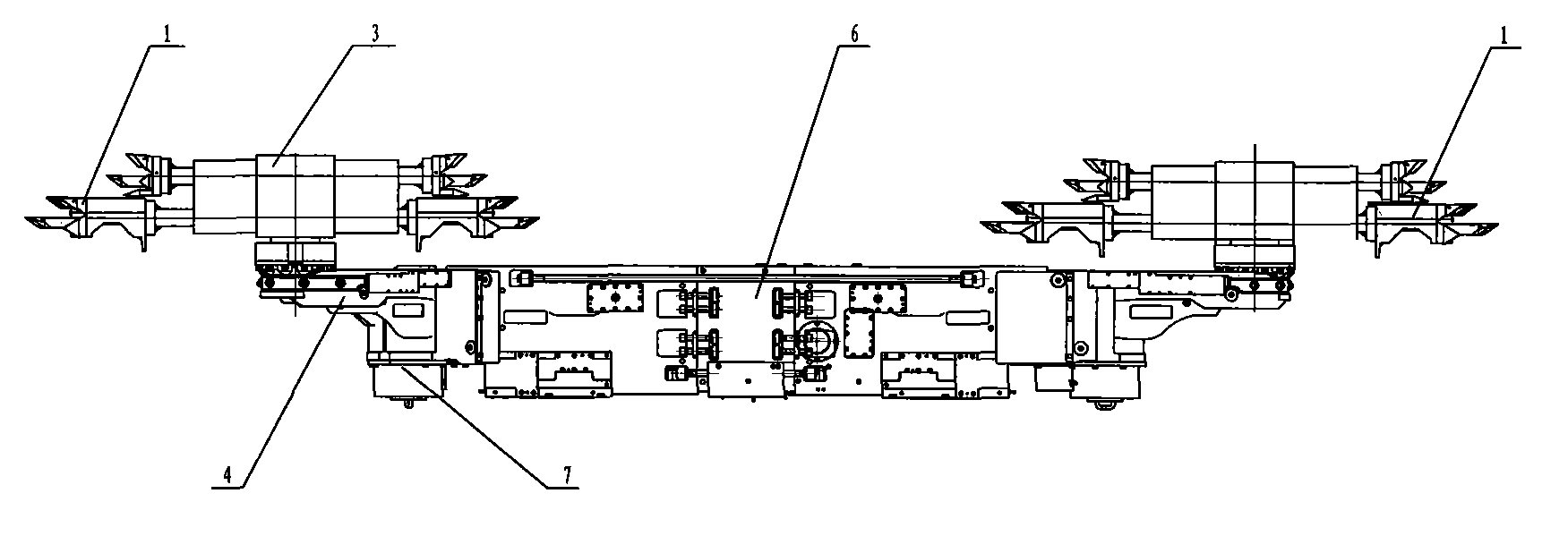

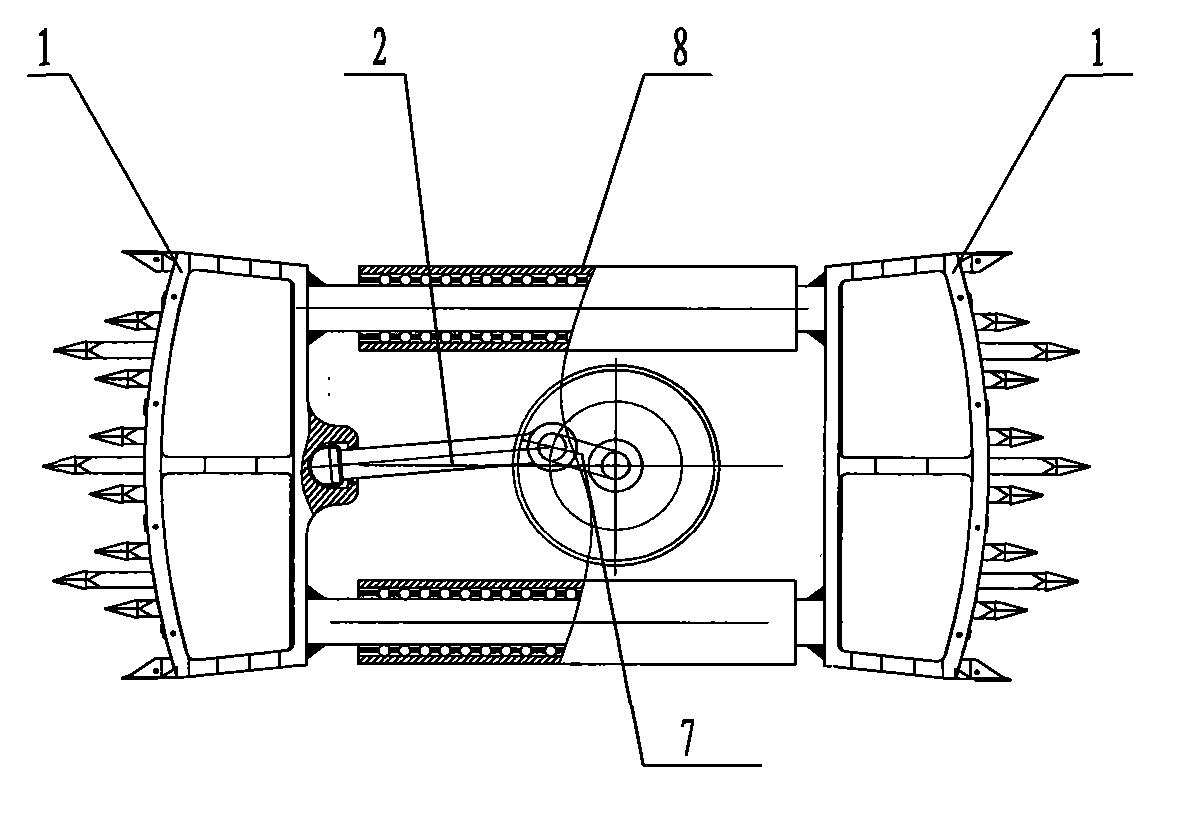

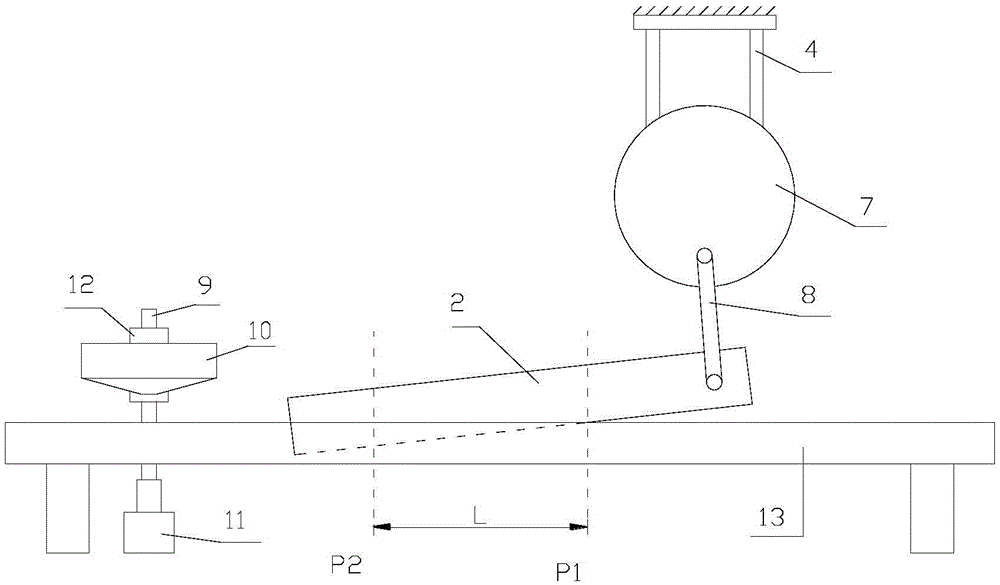

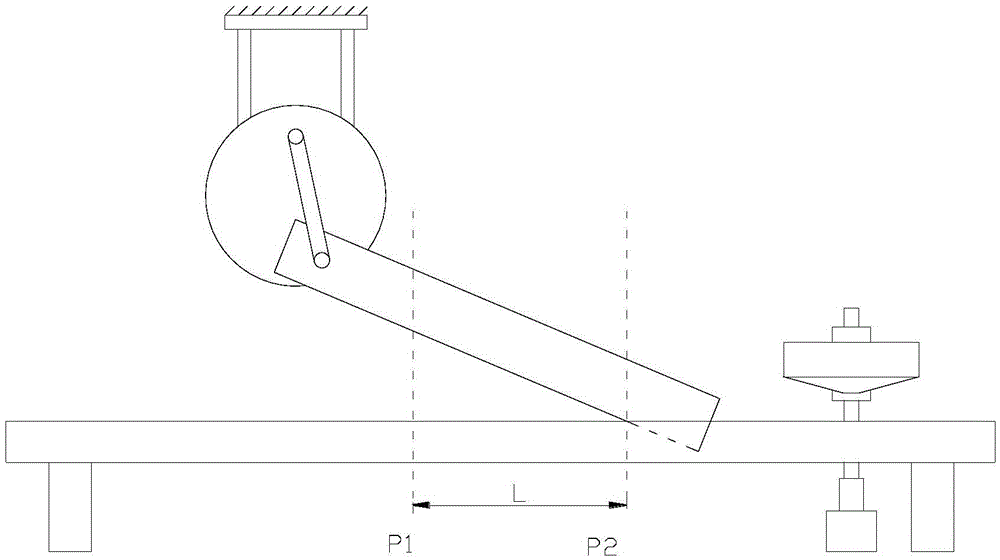

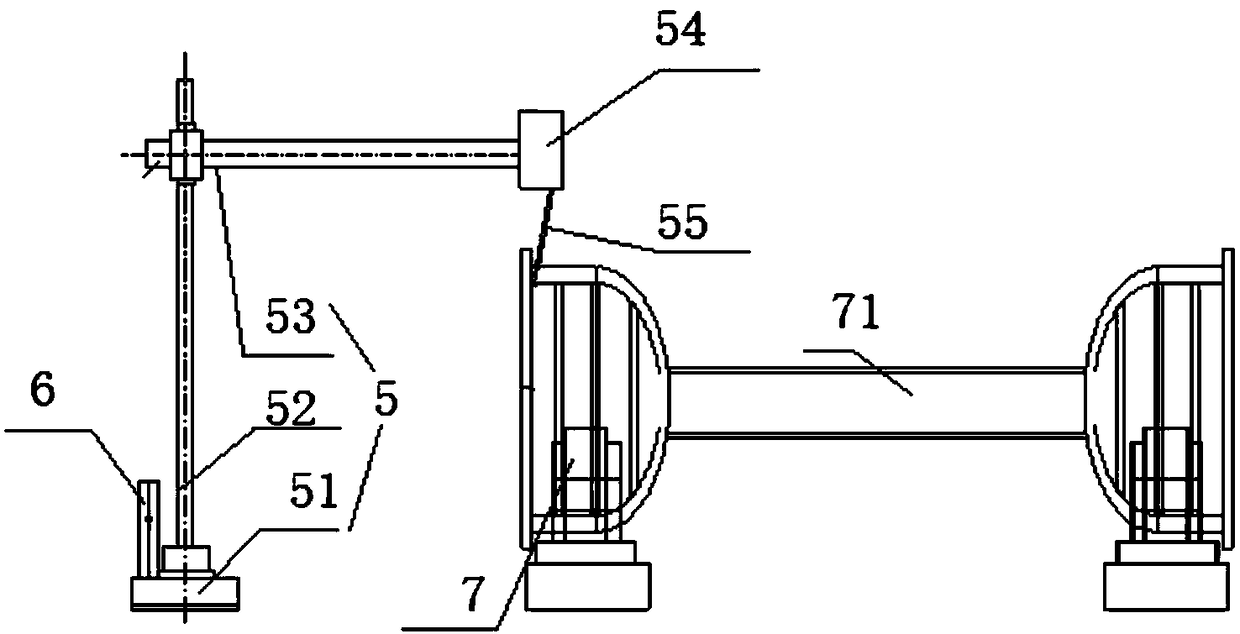

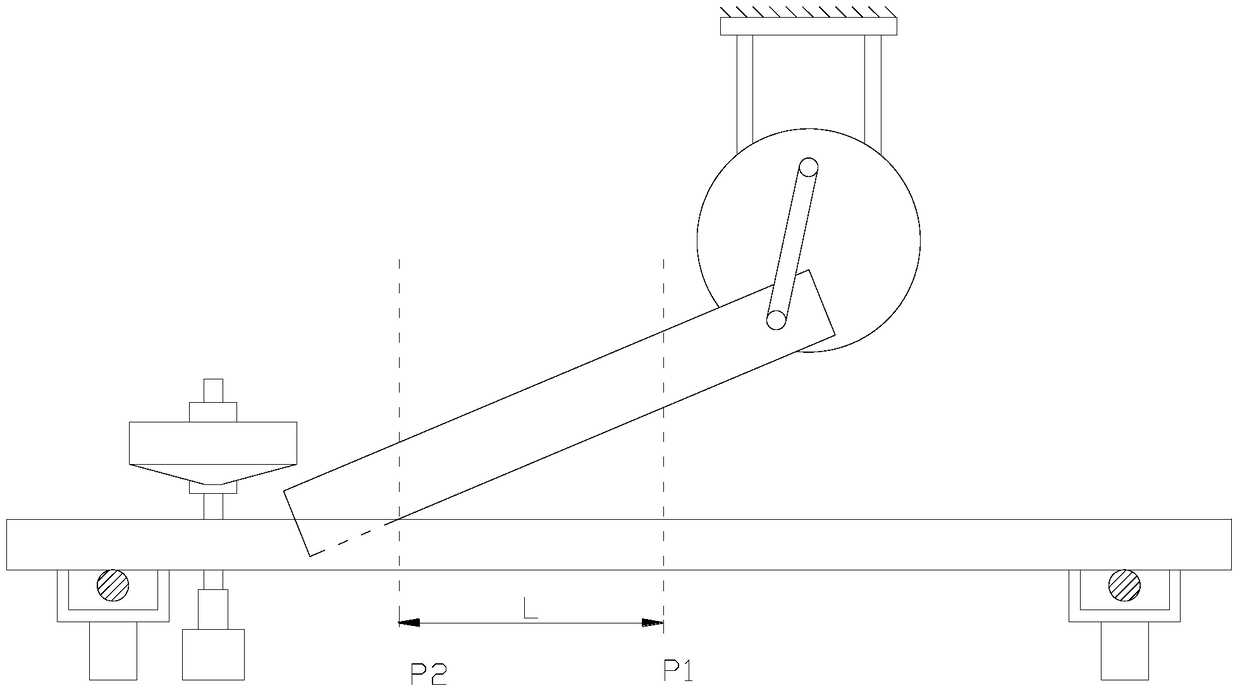

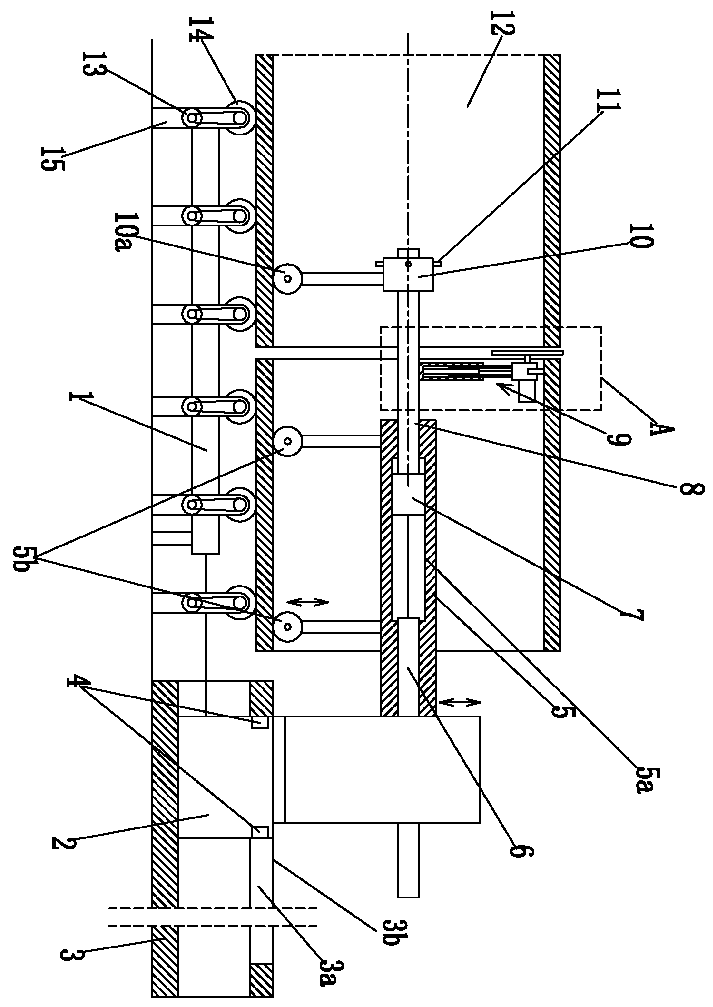

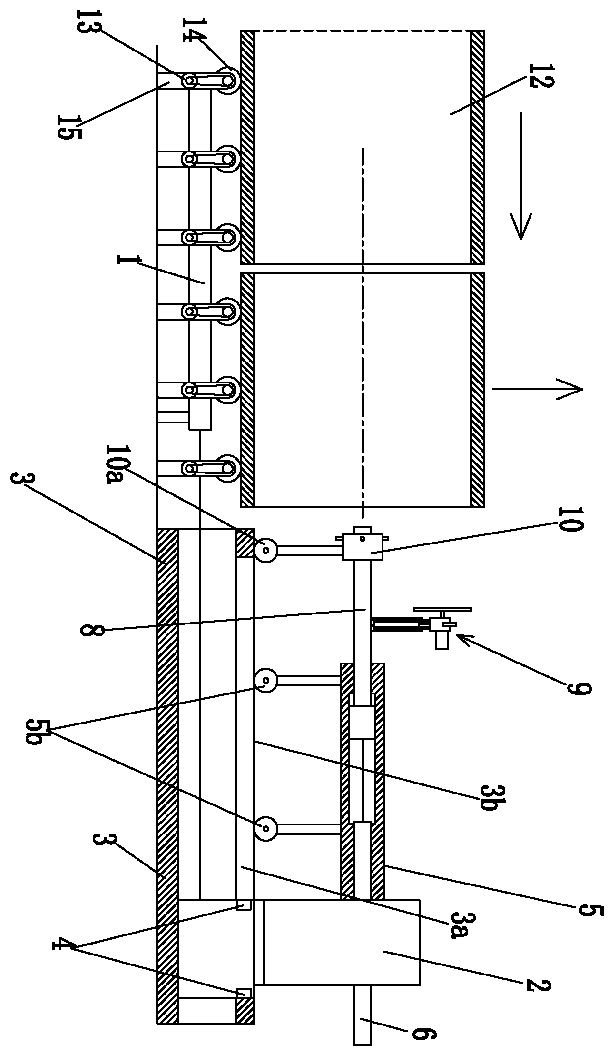

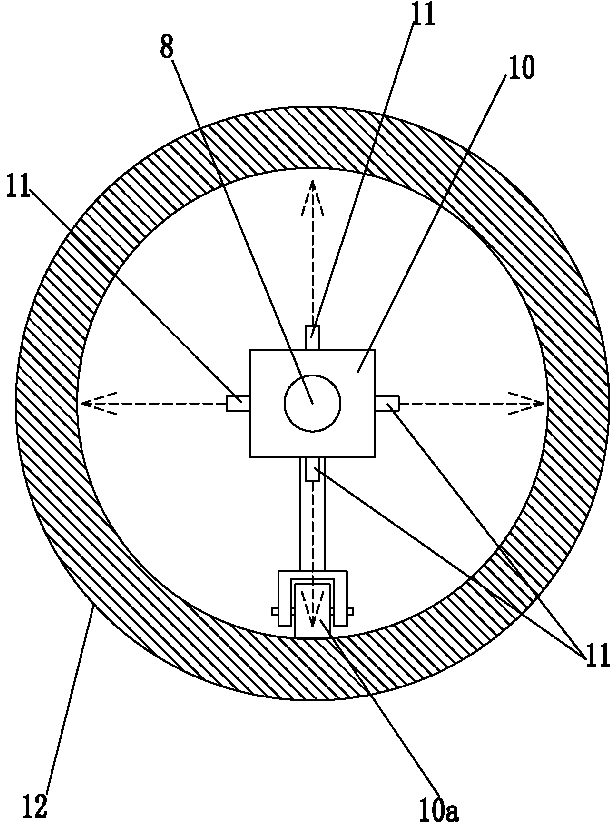

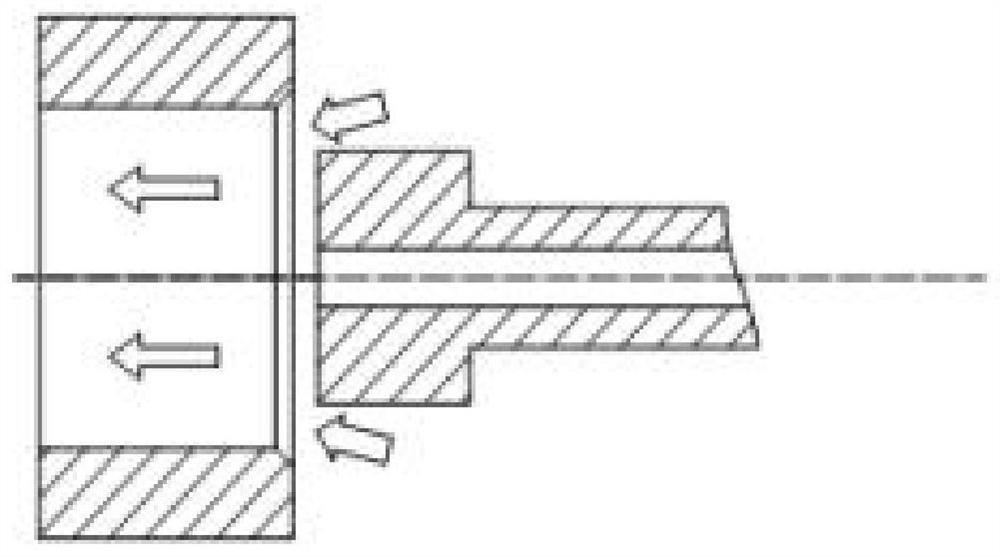

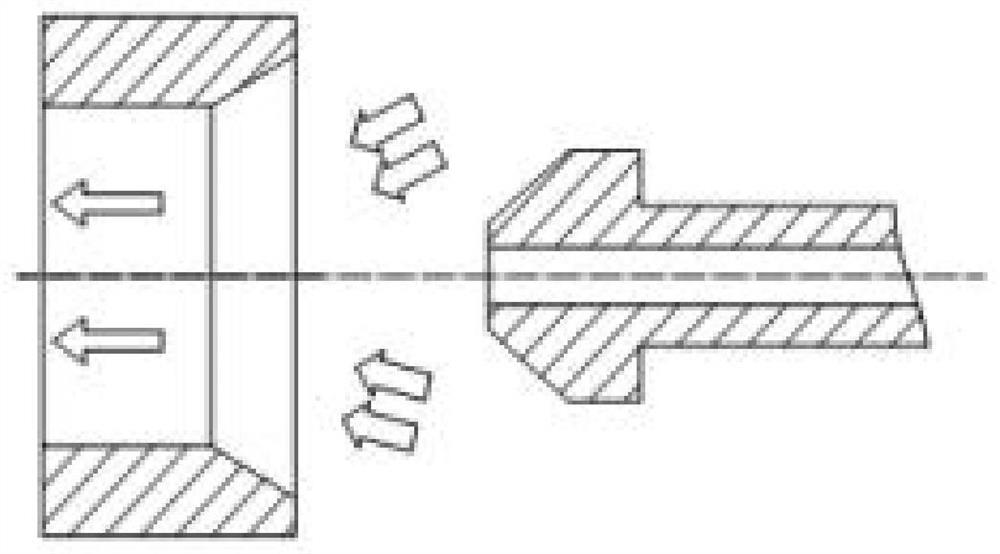

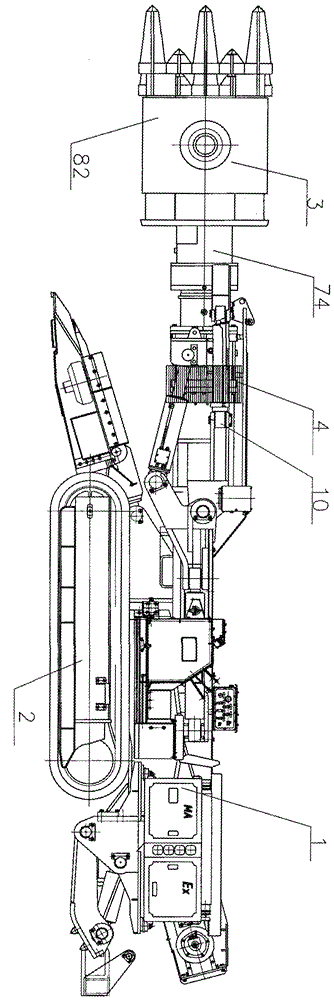

Method for buffering reciprocating impact tunneling counter-acting force and buffering heading machine adopting the method

ActiveCN103195420AEffective protectionExtended service lifeDriving meansCutting machinesEngineeringMechanical engineering

The invention belongs to the field of digging and relates to a method for buffering a reciprocating impact tunneling counter-acting force and a buffering heading machine adopting the method. The buffering heading machine comprises a machine body, a travel unit, a reciprocating impact unit, and a buffering unit. The buffering unit comprises a dynamic buffering device or a structure buffering guiding device. The reciprocating impact unit comprises an impact driving device, a fixing support and a buffering support. The dynamic buffering device comprises a rotary dynamic buffering device. The rotary dynamic buffering device comprises a slide stroke splined hub buffering device or a belt buffering device. The structure buffering guiding device is arranged between the reciprocating impact unit and the machine body or between the fixing support and the buffering support. The structure buffering guiding device can guide a buffering direction of the dynamic buffering device and / or a structure buffering device. The buffering unit can buffer and resolve a counter-acting force on the reciprocating impact unit. The reciprocating impact unit is arranged at the machine body. The travel unit drives the machine body to travel.

Owner:刘素华

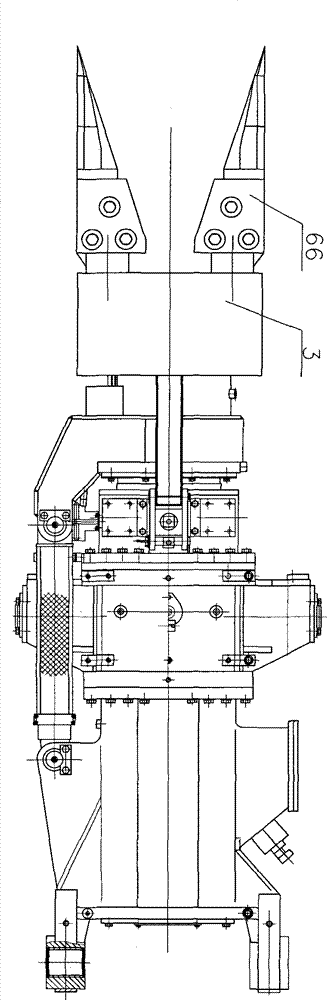

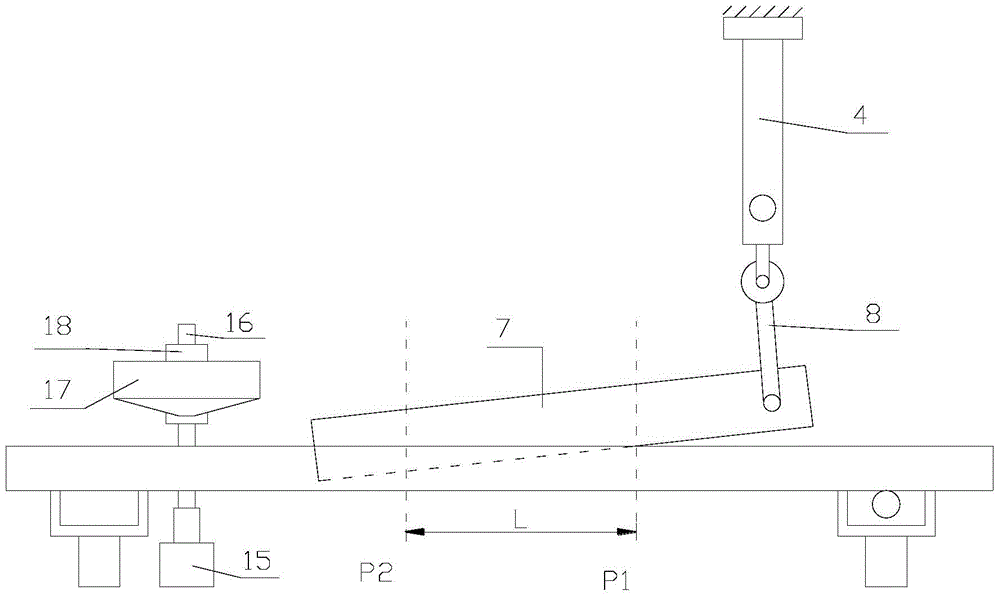

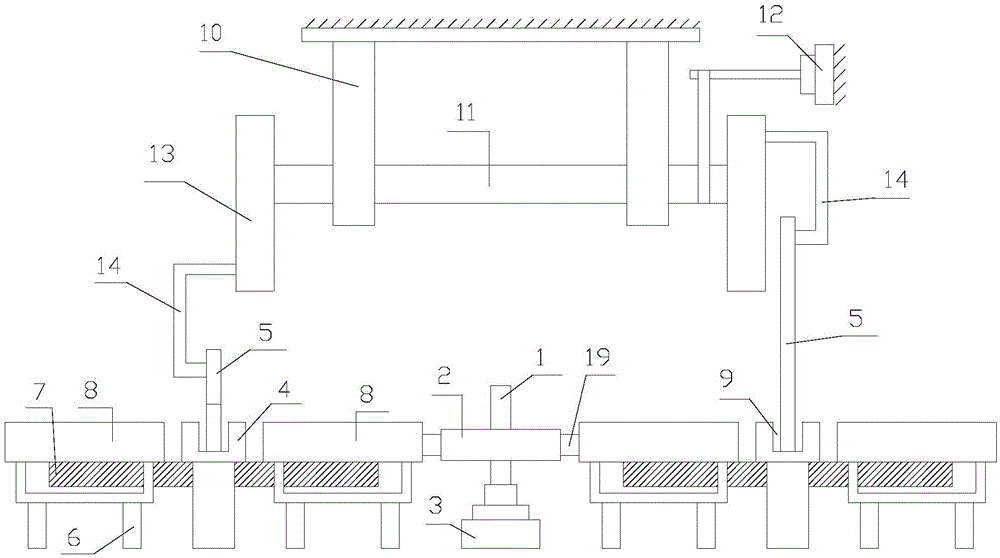

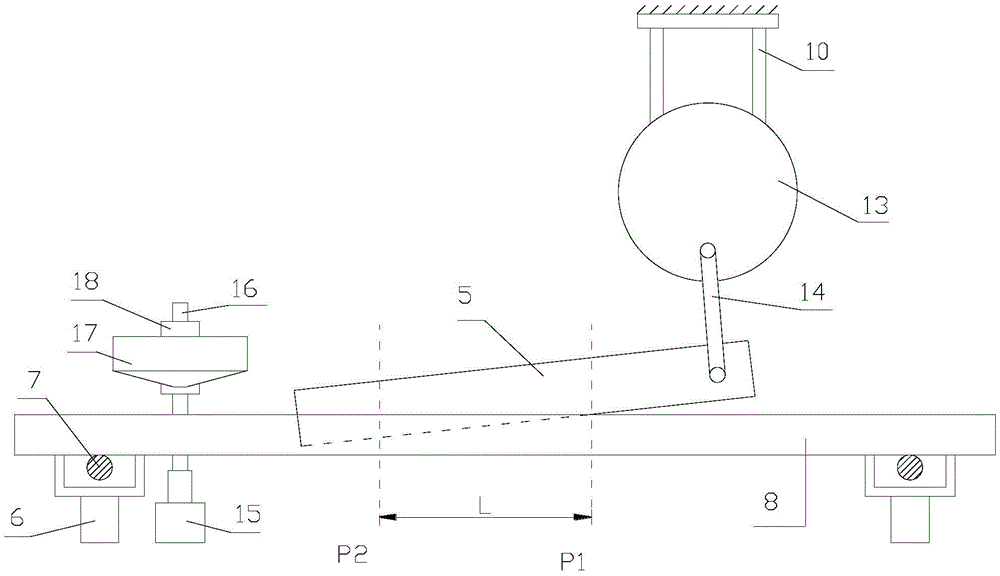

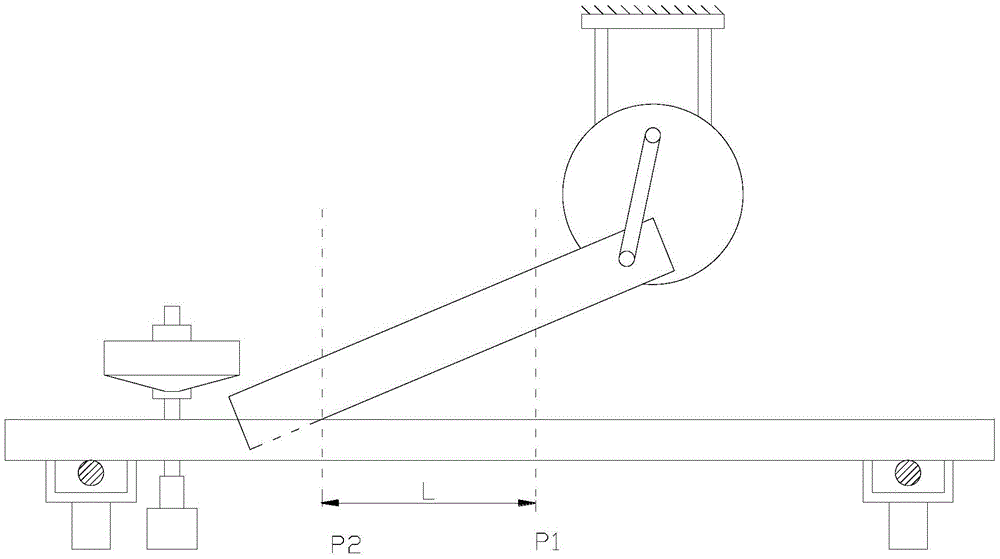

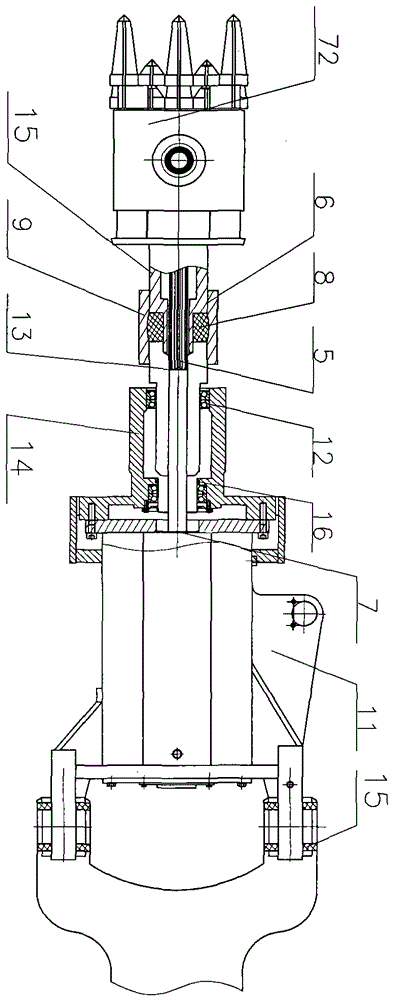

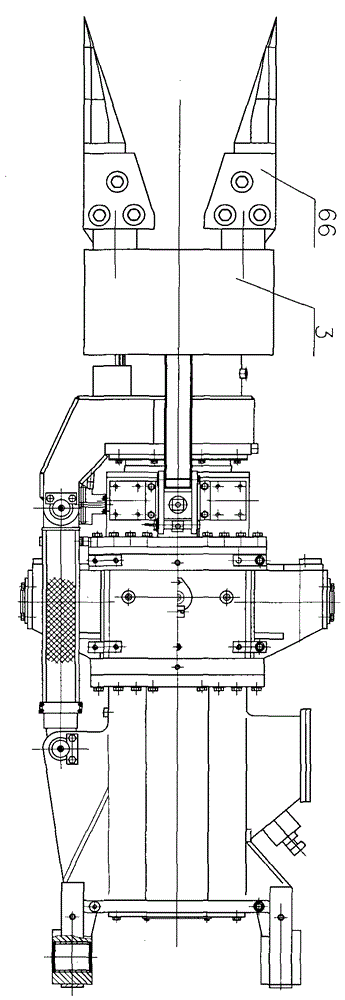

Method for retaining vertical impact of impacting mechanism and vertical-lift impact-cutting digger implementing same

InactiveCN103206213AIncrease arm lengthReduce farewellDriving meansCutting machinesEngineeringFuselage

The invention specifically relates to a method for retaining vertical impact of an impacting mechanism and a vertical-lift impact-cutting digger implementing the method, belonging to the field of machinery, especially to the field of mining. The digger comprises a body, the impacting mechanism and a vertical lift mechanism, wherein the impacting mechanism comprises a guiding member and an impacting head, the vertical lift mechanism comprises a vertical lift driving unit, a lifting and moving part, a supporting seat and the like, the lifting and moving part is movably connected with the supporting seat, the supporting seat is connected with the body, the impacting mechanism is arranged on the lifting and moving part, the vertical lift driving unit drives the lifting and moving part to vertically move up and down, and the lifting and moving part drives the impacting mechanism to vertically rise and fall. The digger provided by the invention has the advantages of a long service life, a small amount of maintenance, high work efficiency, shortened body length and applicability to a complex usage occasion.

Owner:刘素华

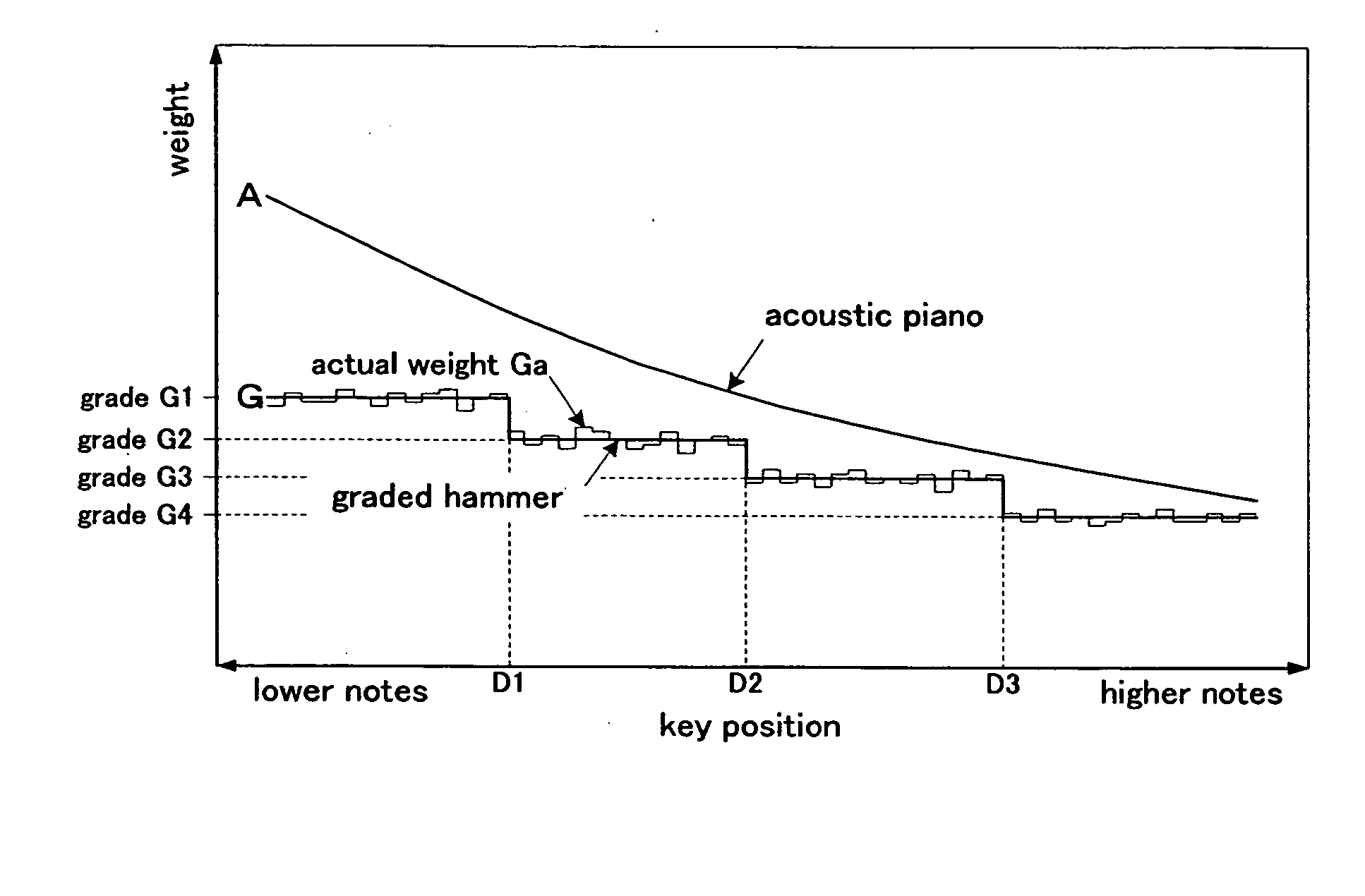

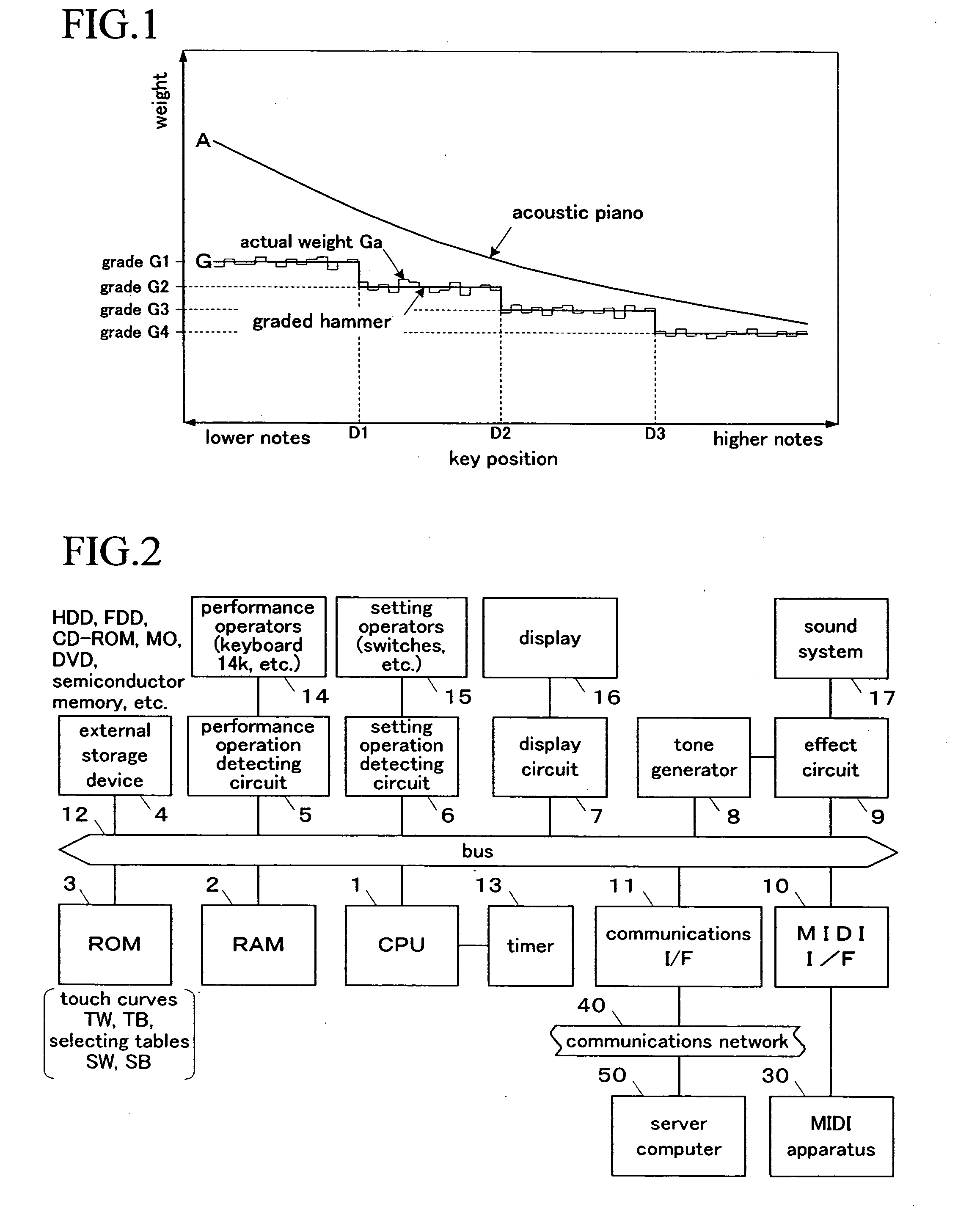

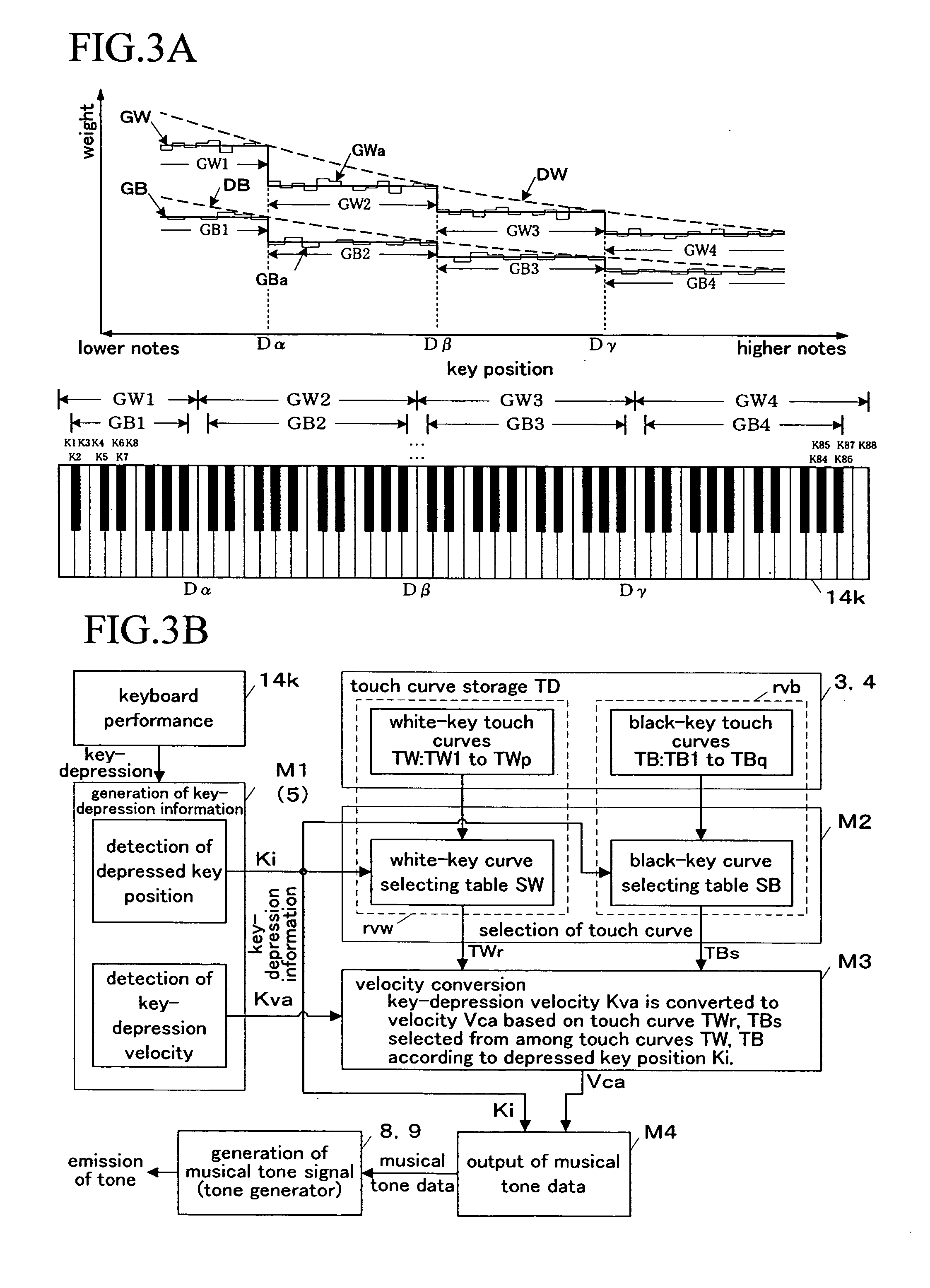

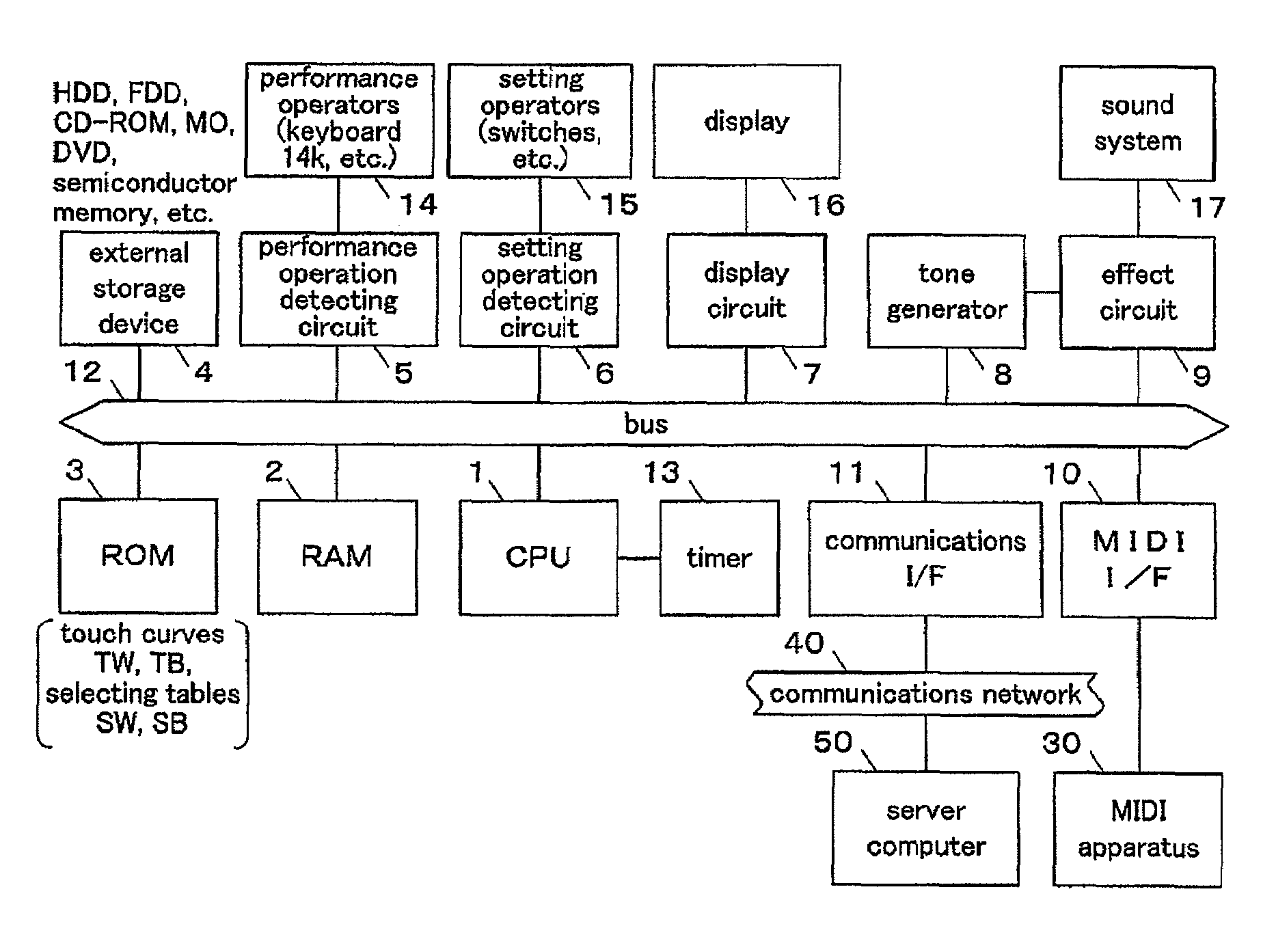

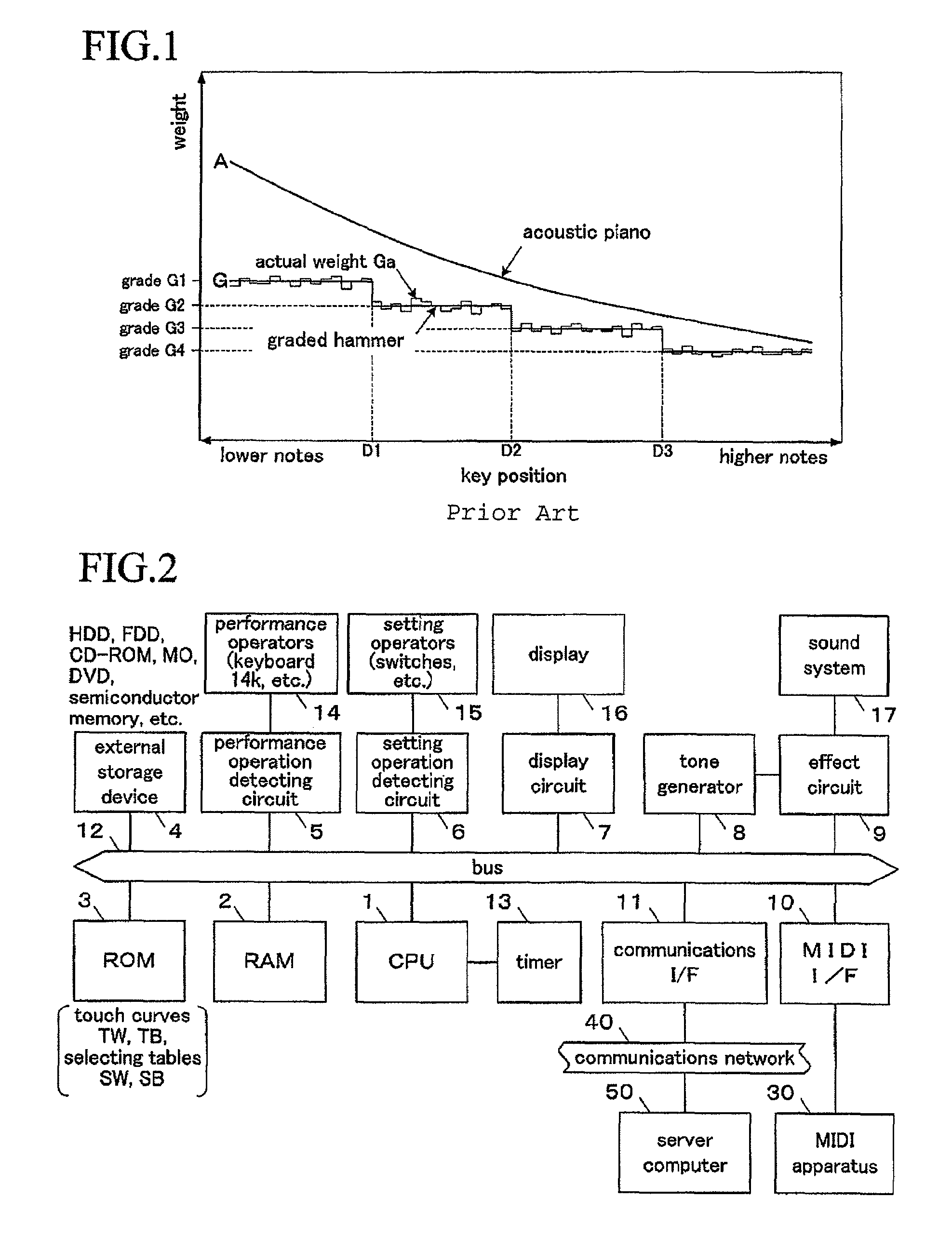

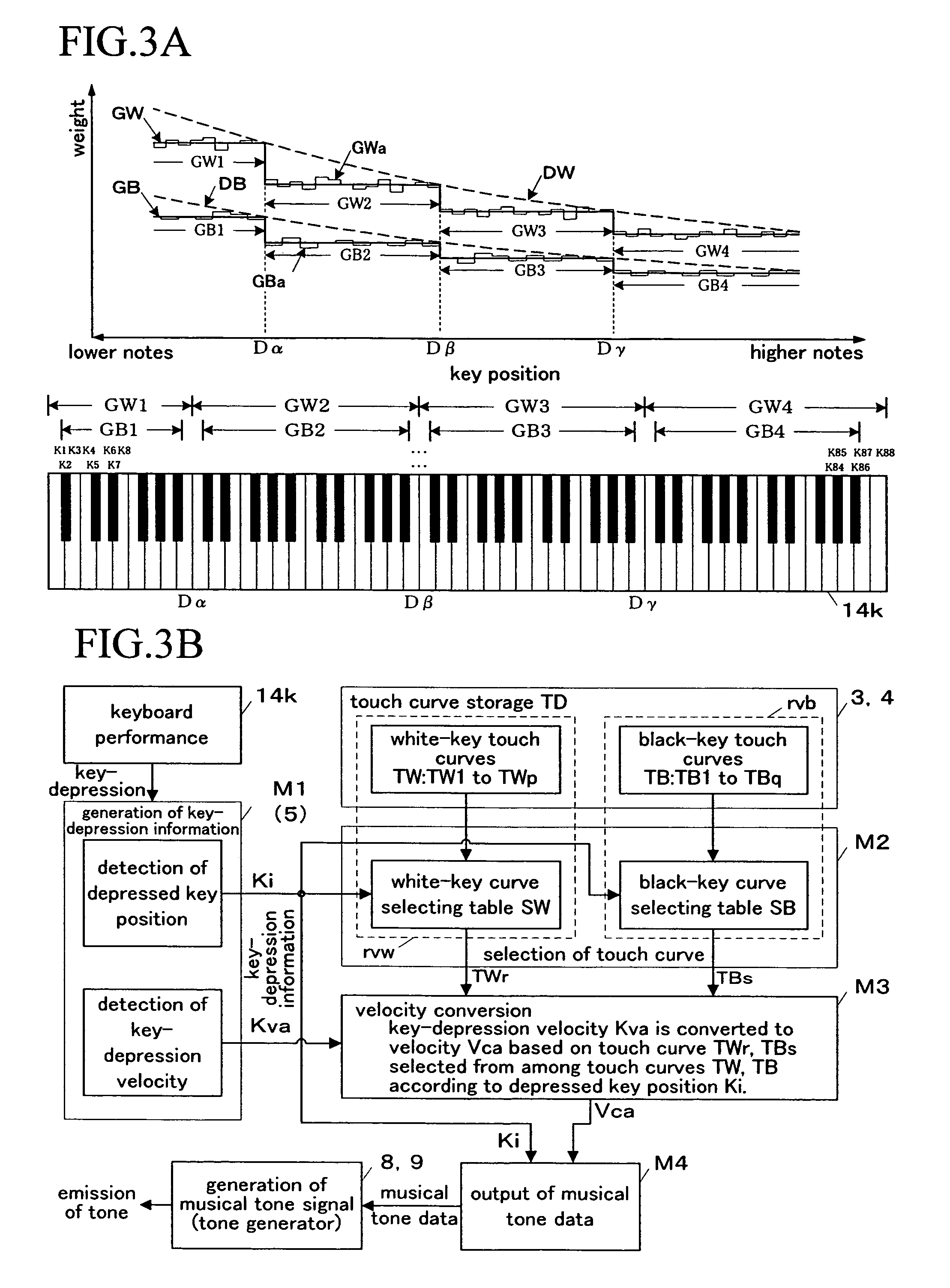

Keyboard apparatus of electronic musical instrument

ActiveUS20070131099A1Uniform reaction forceSmall velocityElectrophonic musical instrumentsLinear/angular speed measurementElectronic instrumentEqualization

A keyboard apparatus of this electronic musical instrument is provided with touch curves TW1 through TWp, TB1 through TBq each defining a velocity value Vc varying with a key-depression velocity Kv (TD). Each of keys K1 through Kn of a keyboard 14k is associated with one of the touch curves TW1 through Twp, TB1 through TBq by touch selecting tables SW, SB in accordance with an equalization rule and a weighting rule. Upon a key-depression, in accordance with the velocity curve TWr, TBs selected on the basis of an actual depressed key position Ki (M2), an actual key-depression velocity Kva is converted into a velocity Vca for controlling emission of a tone (M3).

Owner:YAMAHA CORP

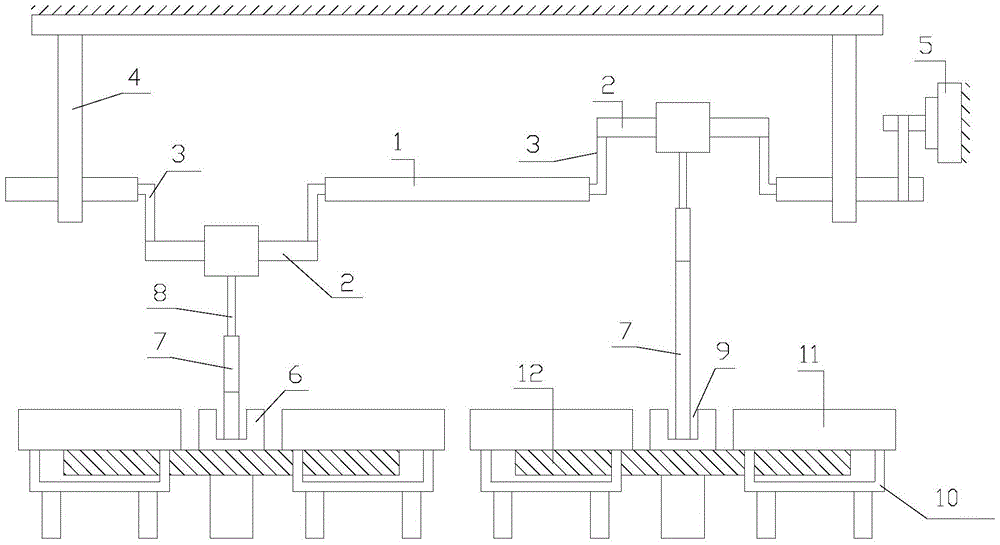

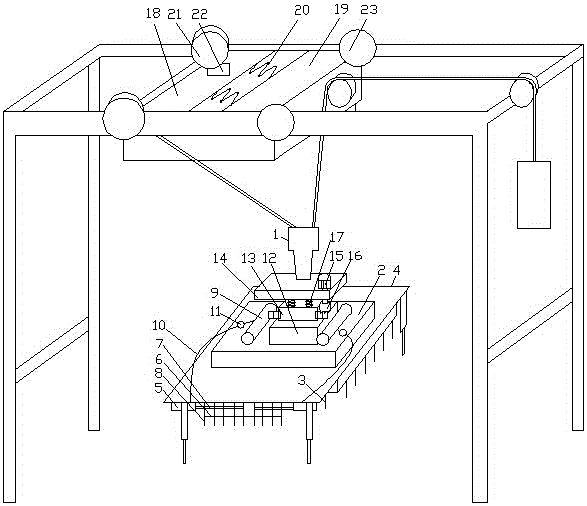

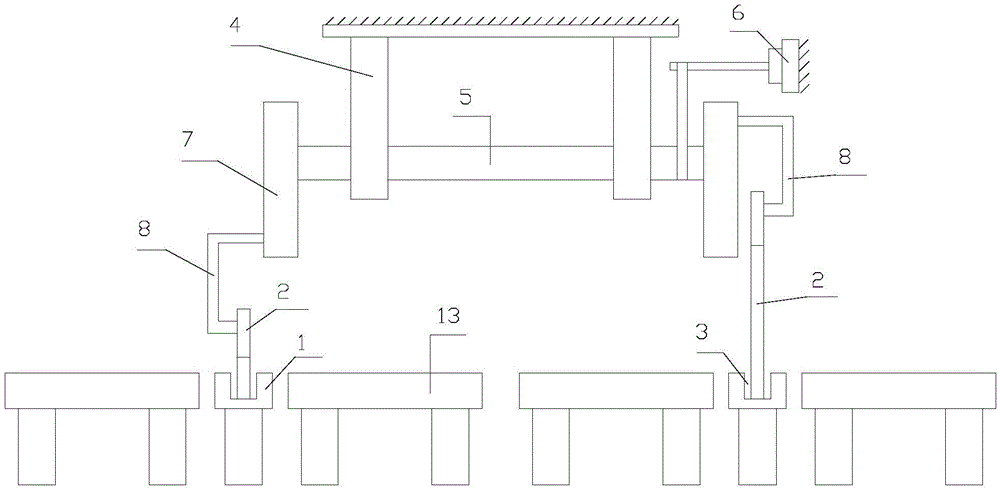

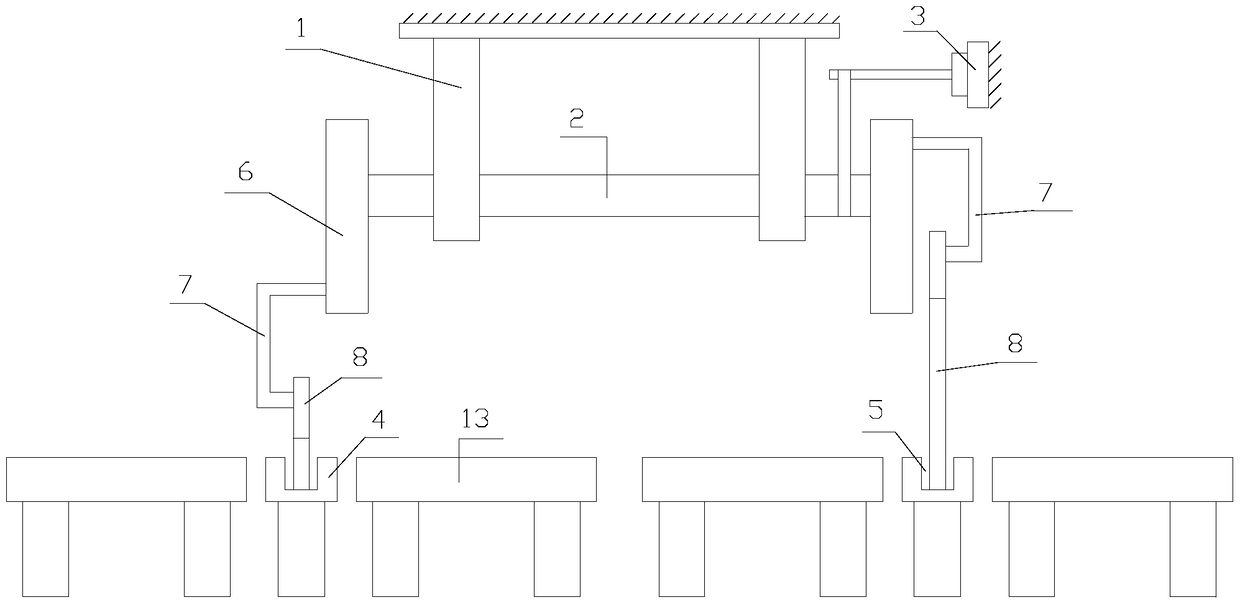

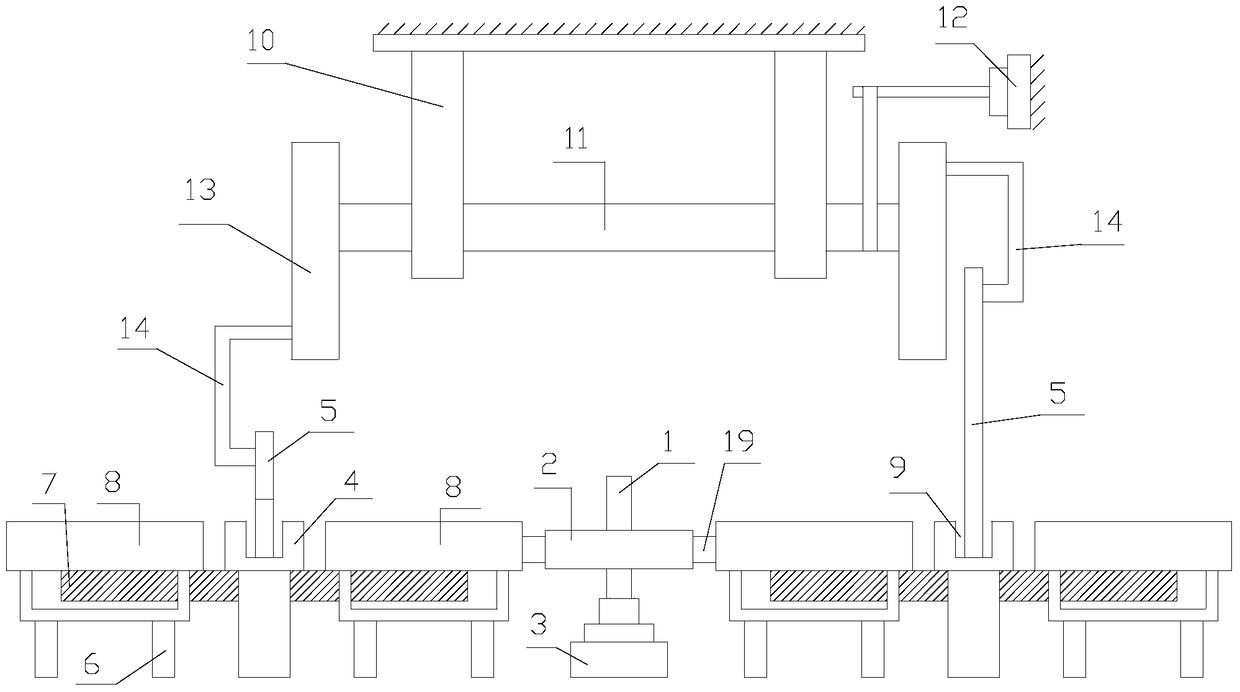

Metal workpiece machining device

ActiveCN108213553ASmall sizeUniform reaction forceTube shearing machinesShearing machine accessoriesPipe fittingEngineering

The invention discloses a metal workpiece machining device in the technical field of metal workpiece machining. The metal workpiece machining device comprises a translation conveying mechanism for urging pipe fittings to perform translation in the axis direction. The metal workpiece machining device further comprises a foundation base. The metal workpiece machining device further comprises a mainslide base horizontally mounted on the foundation base in a sliding manner, wherein the sliding direction is adapted to the translation direction of the pipe fittings. The metal workpiece machining device further comprises a first-grade driving oil cylinder for urging the main slide base to slide. The metal workpiece machining device further comprises a PLC; a reference plane is arranged on the foundation base; the height position of the reference plane is adapted to the heights of the bottoms of the inner peripheral walls of the pipe fittings; an annular cutting actuation mechanism for cutting off the pipe fittings and extending in the radial directions of the pipe fittings is mounted at the outer periphery of an annular cutting driving shaft, and is positioned between a front support frame and a main-grade extension base; and the front support frame is provided with multiple distance measurers which are uniformly distributed in the peripheral direction with the axis of the annular cutting driving shaft as reference. The metal workpiece machining device can guarantee the cutting size precision of the pipe fittings, and is convenient to operate.

Owner:扬州正德机械制造有限公司

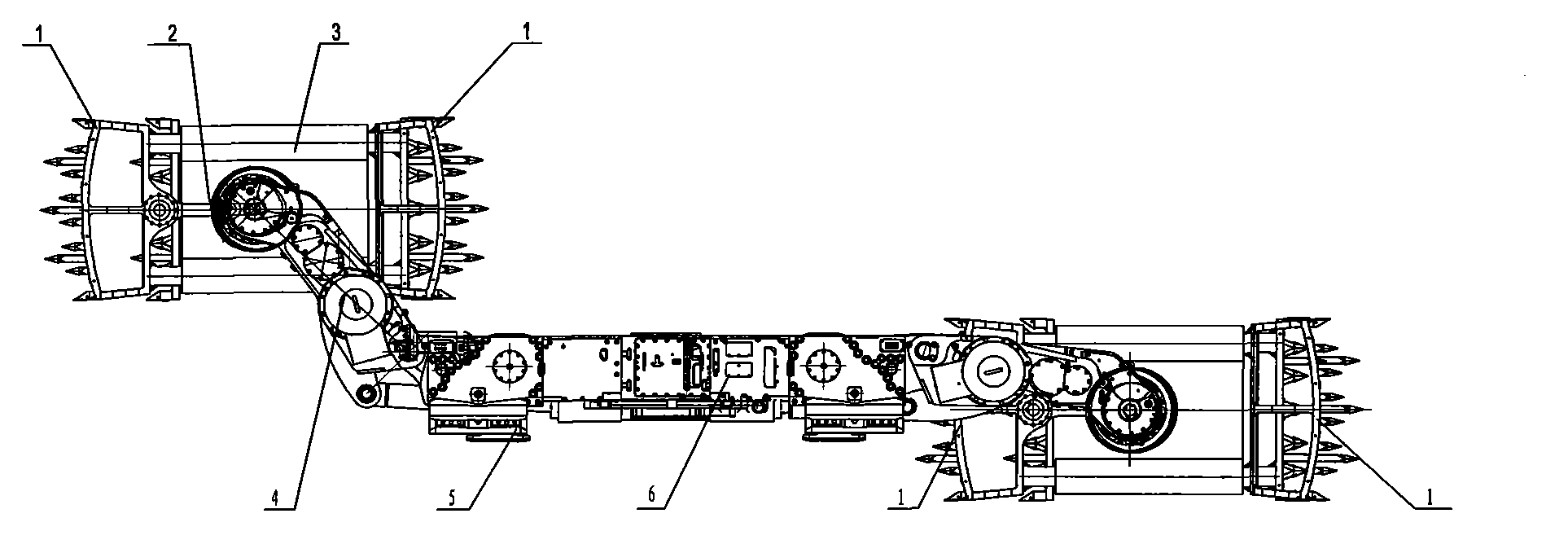

Punch-cutting mining method and punch-cutting mining machine implementing method

The invention belongs to the machinery field and especially relates to a punch-cutting mining method suitable for the mining field and a punch-cutting mining machine implementing the method. According to the method, a machine body, a walking part, a reciprocating impact part and the like are arranged; a lifting device is arranged or not arranged on the machine body; a dynamic impacting member is disposed on an impact driving device; a guiding device is provided with an impact guiding element; two ends of the impact guiding element are both equipped with an impactor or one end is provided with an impactor and the other end is provided with a counterweight; and the machine body supports the impactor to shock dropping materials back and forth. The equipment comprises the machine body, the walking part, the reciprocating impact part and the like. The reciprocating impact part comprises the dynamic impacting member, the impact driving device, the impactor and the like. The impact driving device comprises the dynamic impacting member. The guiding device comprises the impact guiding element; the dynamic impacting member drives the impactor to shock the coal wall or rock faces for blanking materials; the lifting device is arranged or not arranged on the machine body; the walking part is disposed on the lower part of the machine body and drives the machine body to walk so as to blank materials during walking and walk back to blank materials without turning the machine body.

Owner:刘素华

Machining device for retractable door production

ActiveCN105729119AStable power outputReduce vibrationEdge grinding machinesShearing machinesEngineeringMechanical engineering

The invention discloses a machining device for retractable door production. The machining device comprises N first rotating shafts, (N+1) second rotating shafts, connecting parts, supports, a driving unit and (N-1) conveying mechanisms, wherein N is a positive integer greater than 1; the N first rotating shafts are sequentially arranged, and distributed with the (N+1) second rotating shafts at intervals; two first rotating shafts distributed at the two ends are rotationally connected with the supports; the two ends of the second rotating shafts are connected with the adjacent first rotating shafts through the connecting parts; the axes of the second rotating shafts are parallel to those of the first rotating shafts; the axes of any two adjacent second rotating shafts are parallel to each other; and the (N-1) conveying mechanisms are all arranged below the second rotating shafts, and arranged with the (N+1) second rotating shafts in a one-to-one correspondence manner. The machining device provided by the invention is simple in structure and good in machining effect.

Owner:天津智投技术成果转化有限公司

Automatic green brick stacking machine of brick kiln

ActiveCN105923404AClamp evenlyAvoid extrusion damageTrolley cranesStacking articlesDrive wheelStack machine

The invention discloses an automatic green brick stacking machine of a brick kiln. The machine is characterized in that a telescoping frame is connected to the bottom part of a chuck, wherein a clamp is fixed to the inner wall of the telescoping frame; a cylinder is fixed to the telescoping frame; a clamping plate passes through a telescoping rod; the cylinder communicates with an air storing tank through an air distributing tube; the air distributing tube is connected with an air pressure regulator; a base on which a gyring support is arranged is connected to the top part of the chuck; a pressing plate on which a speed reducer is arranged is rotatably connected to the gyring support; a connecting gear is connected to an output shaft of the speed reducer; a spring column is arranged between the pressing plate and the gyring support; the pressing plate is connected with a lifting device; a moving device comprises a first frame plate, a second frame plate and a tension spring column; a driving wheel which is driven through a servo motor is arranged on the first frame plate; a driven wheel is arranged on the second frame plate. With the adoption of the machine, each green brick can be successfully clamped; the chuck can self-adaptively adjust the inertia force during rotating; when pausing, the moving device can self-adaptively buffer the inertia impacting force, so that the stability of the green brick in moving can be improved, and as a result, the green brick stacking efficiency can be improved.

Owner:天长市天釜新型建材有限公司

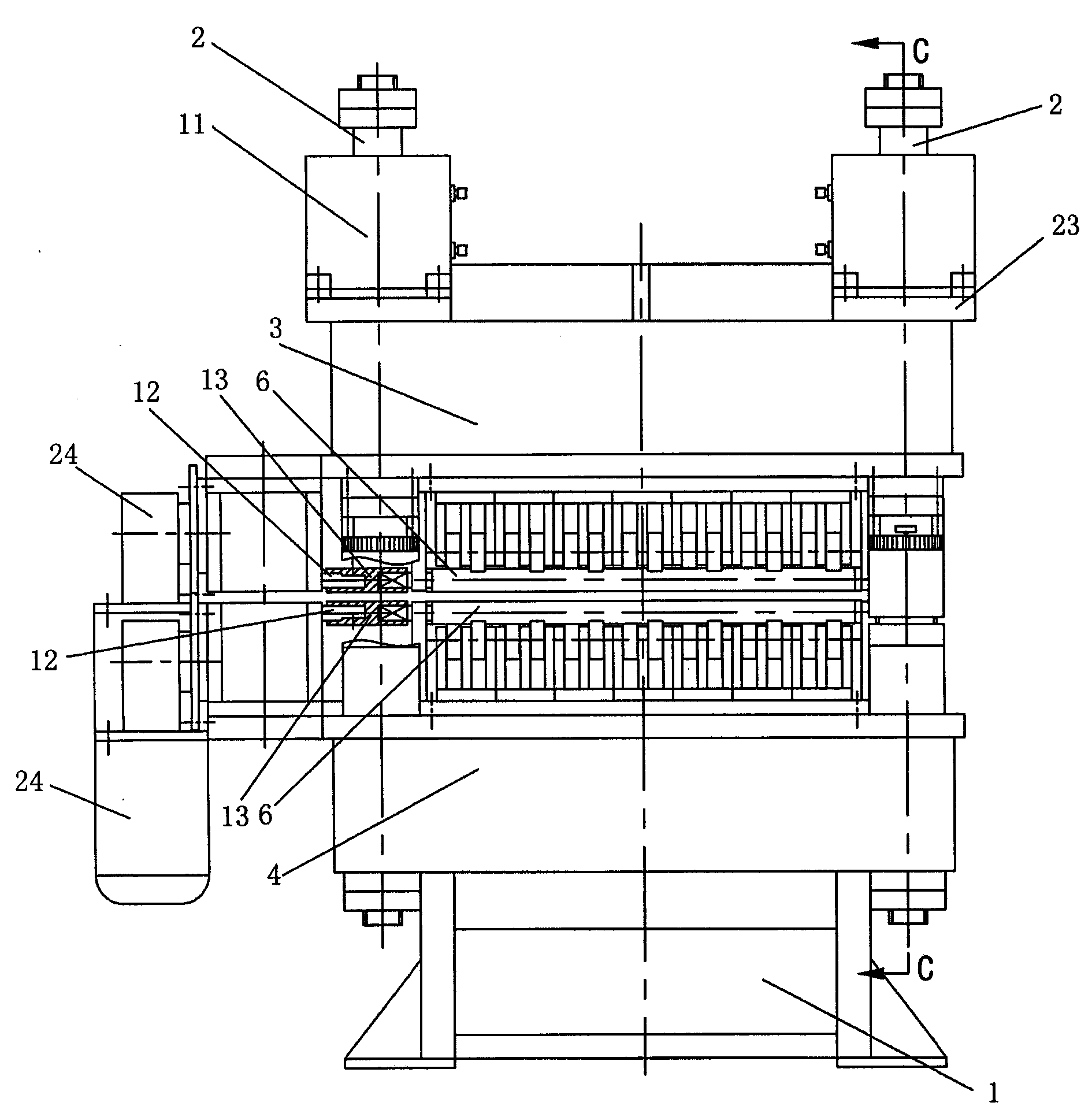

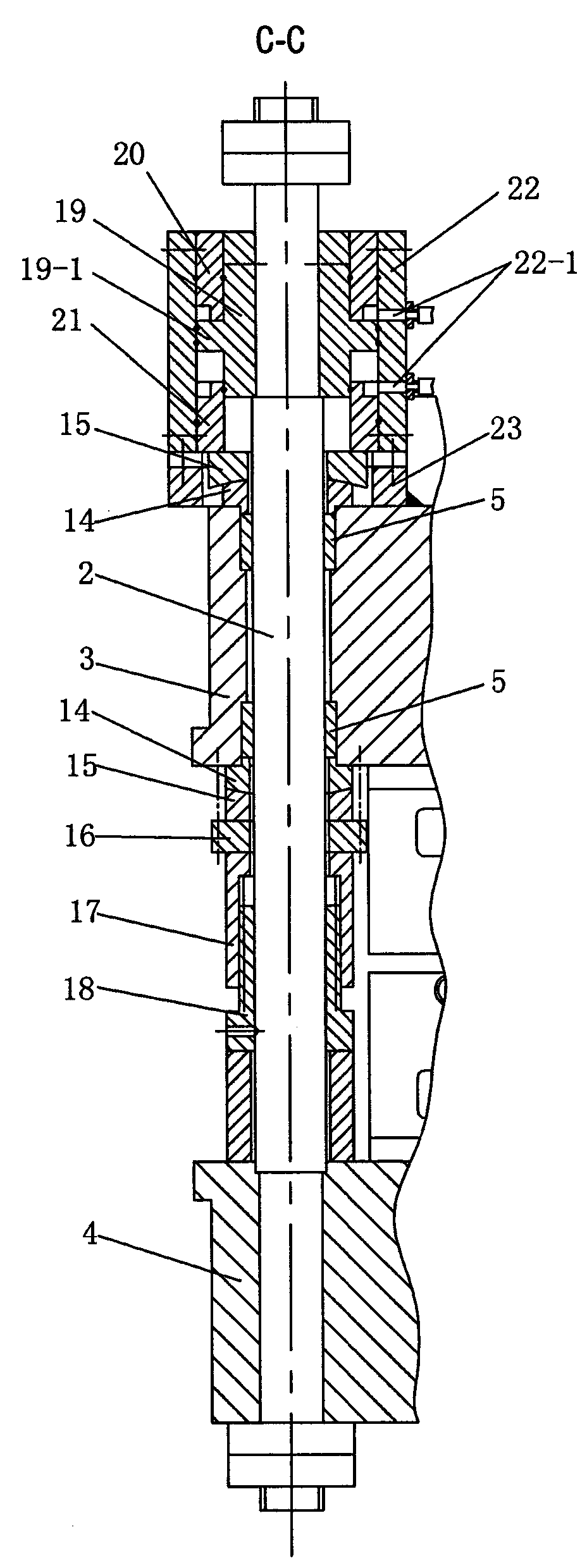

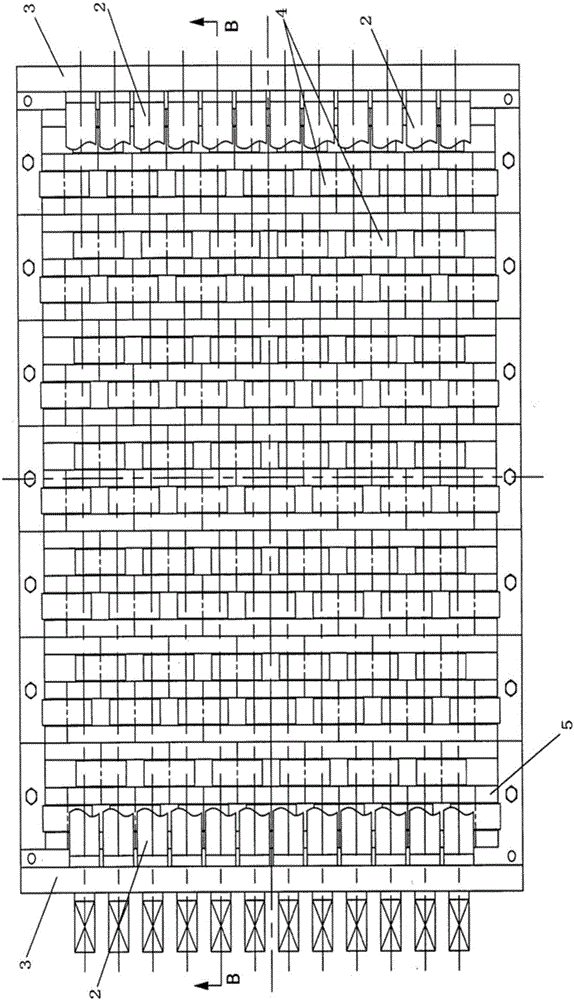

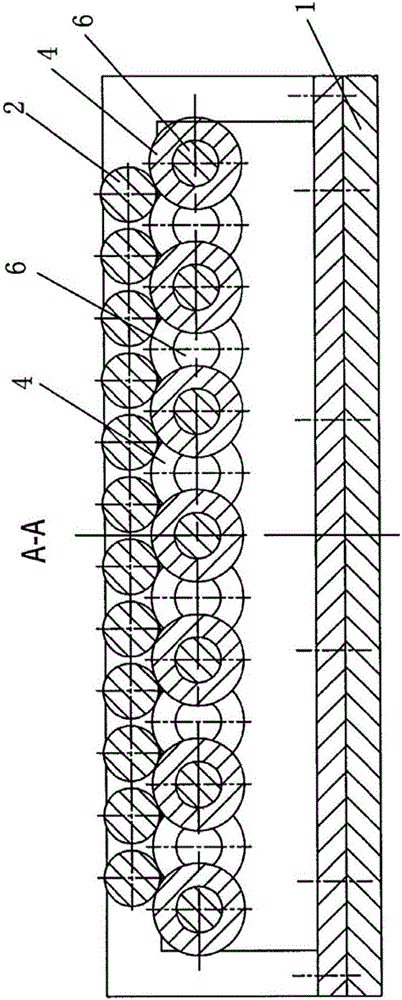

Hydraulic precision leveling machine

The invention discloses a hydraulic precision leveling machine which comprises an upper roller group, a lower roller group, a load bearing beam, a machine base and four upright posts, wherein the upper roller group and the lower roller group are respectively and fixedly provided with power decelerating devices, the load bearing beam is composed of an upper beam and a lower beam which is fixedly arranged on the machine base, the upper roller group is fixedly connected with the upper beam, the lower roller group is fixedly connected with the lower beam, the four upright posts are respectively and fixedly sheathed on four corners of the lower beam, and the upper beam can be movably sheathed on the four upright posts. Both the upper roller group and the lower roller group comprise a plurality of leveling rollers, wall plates, a plurality of support brackets, a plurality of fixing shafts and a plurality of support jockey pulleys, wherein the leveling rollers are arranged side by side and can be rotatablely supported on the wall plates on both sides, the fixing shafts are supported on the support brackets, and the support jockey pulleys can be rotatablely sheathed on the corresponding fixing shaft. The hydraulic precision leveling machine has the advantages of high leveling precision, simple structure and low manufacturing cost, and leveling requirements for plates with different thicknesses can be satisfied.

Owner:常州市中安机械制造有限公司

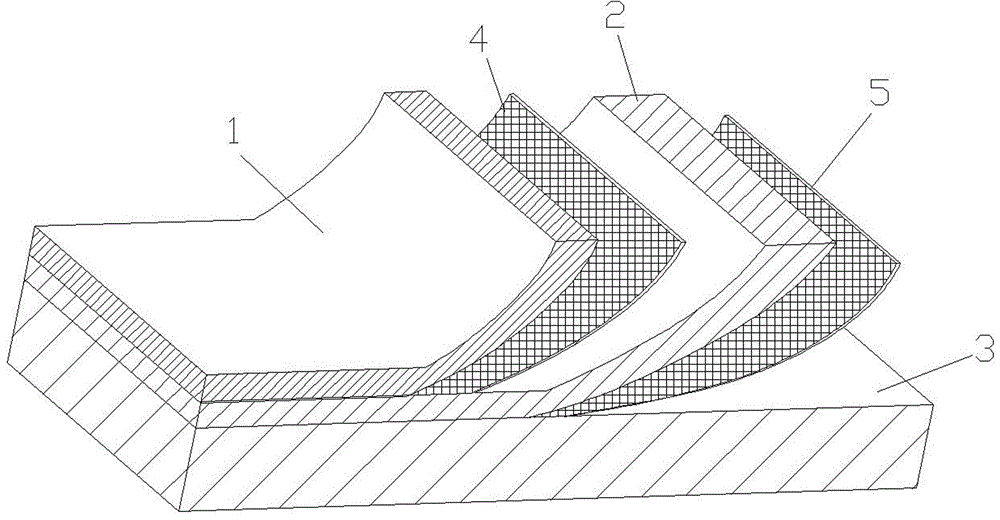

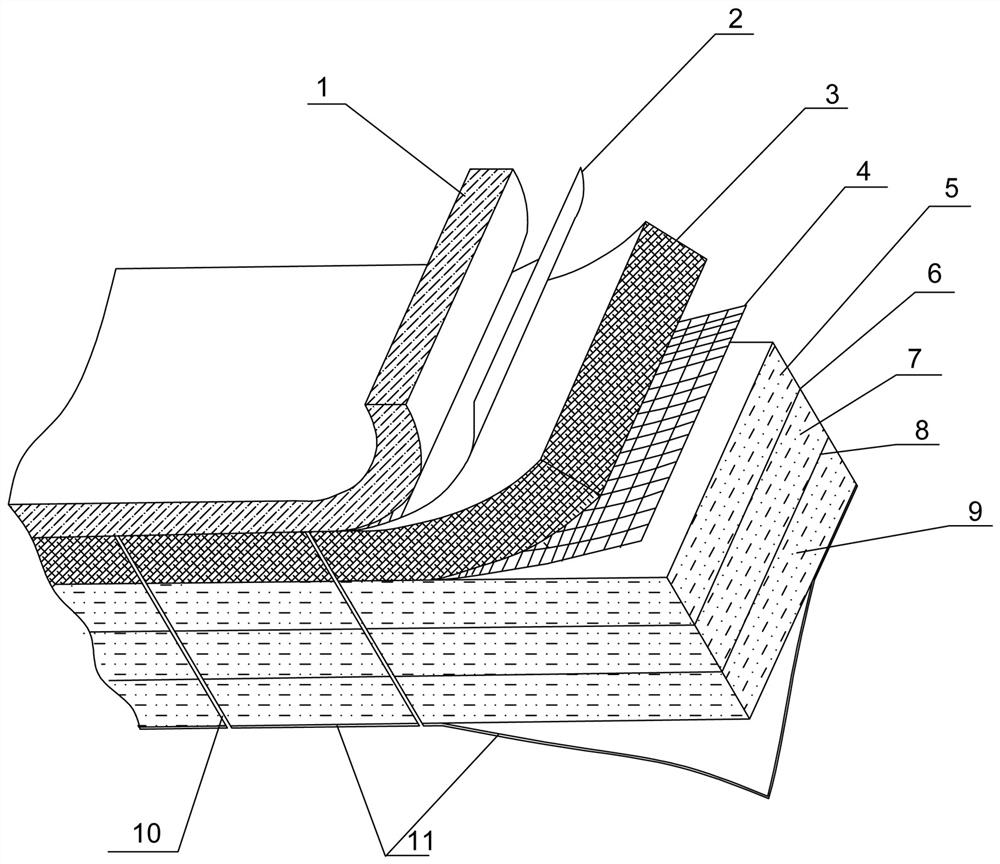

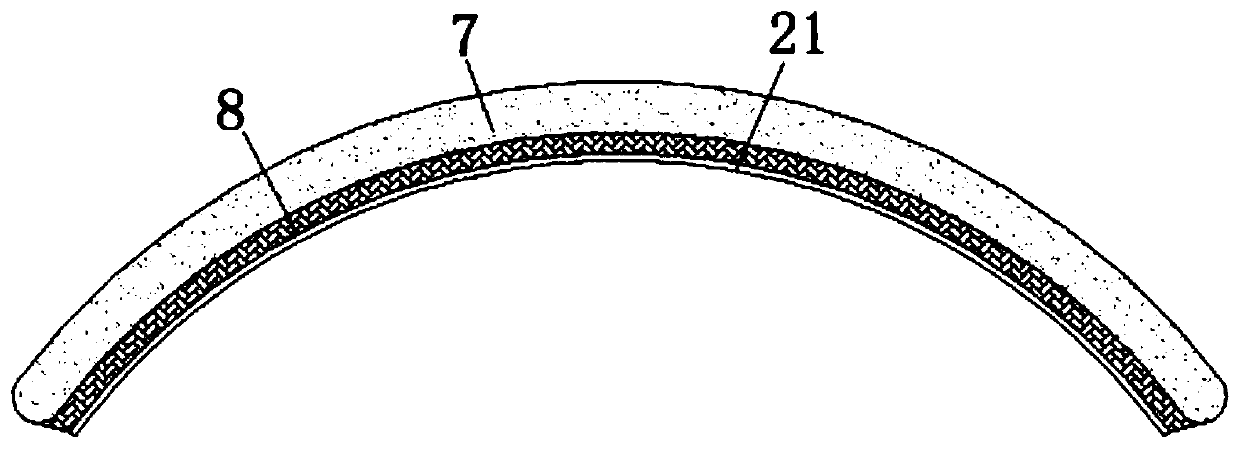

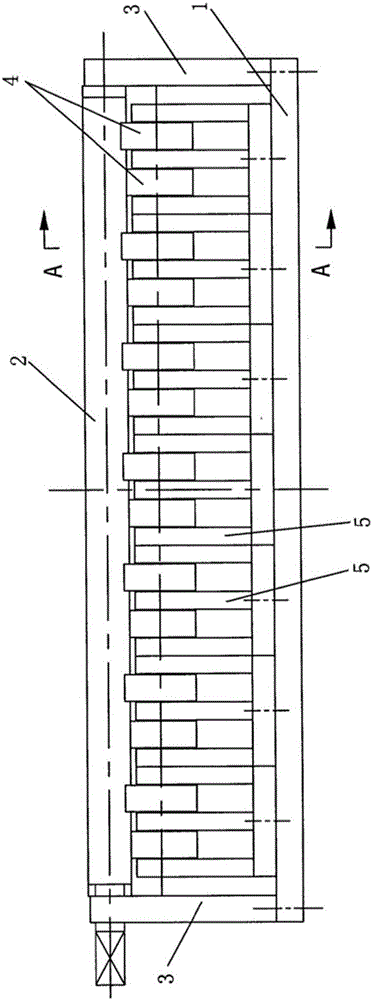

Novel ground mat for training and competition of cheerleading

InactiveCN107433007AImprove technical playQuality improvementSynthetic resin layered productsGlass/slag layered productsFiberFiberglass mesh

The invention provides a novel ground mat for training and competition of cheerleading. The novel ground mat for training and competition of cheerleading is characterized in that the novel ground mat comprises a first ground mat (1), a second ground mat (2) and a third ground mat (3), which are arranged in a vertically overlapped manner; a first glass fiber net (4) is arranged between the first ground mat (1) and the second ground mat (2); and a second glass fiber net (5) is further arranged between the second ground mat (2) and the third ground mat (3). The novel ground mat is simple in structure, convenient in application and environmentally friendly without any pollution. Therefore, the mat can support collective jumping, rotation, extension of cheerleading members. Technical performance and movement quality of members are effectively improved. Therefore, possible motion damage is avoidedto the maximal extent by overcoming thedesign defect of material of the ground mat.

Owner:南京新恒鼎体育科技发展有限公司

Keyboard apparatus of electronic musical instrument

ActiveUS7750231B2Uniform reaction forceSmall velocityElectrophonic musical instrumentsLinear/angular speed measurementEqualizationComputer science

A keyboard apparatus of this electronic musical instrument is provided with touch curves TW1 through TWp, TB1 through TBq each defining a velocity value Vc varying with a key-depression velocity Kv (TD). Each of keys K1 through Kn of a keyboard 14k is associated with one of the touch curves TW1 through Twp, TB1 through TBq by touch selecting tables SW, SB in accordance with an equalization rule and a weighting rule. Upon a key-depression, in accordance with the velocity curve TWr, TBs selected on the basis of an actual depressed key position Ki (M2), an actual key-depression velocity Kva is converted into a velocity Vca for controlling emission of a tone (M3).

Owner:YAMAHA CORP

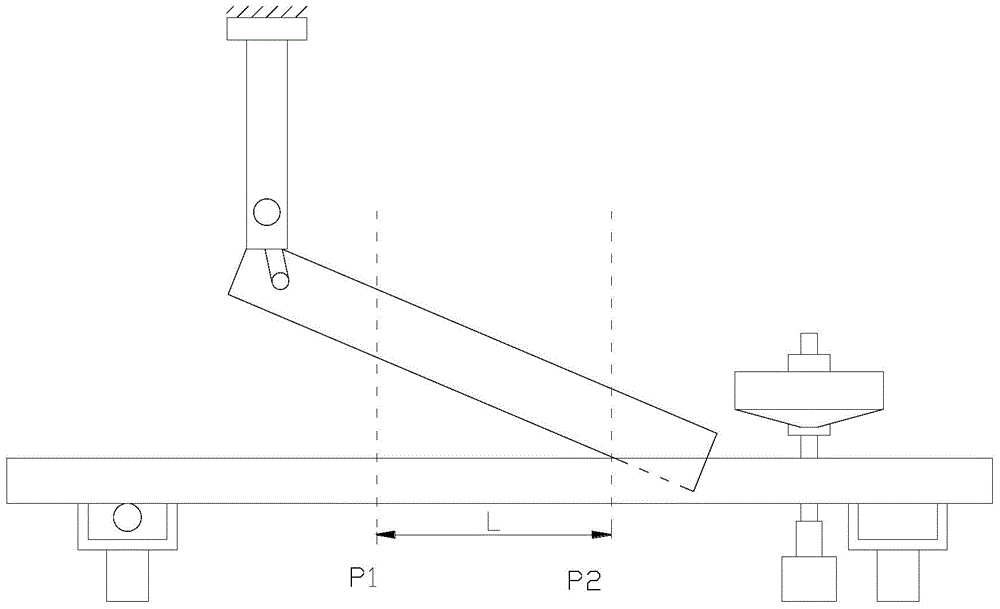

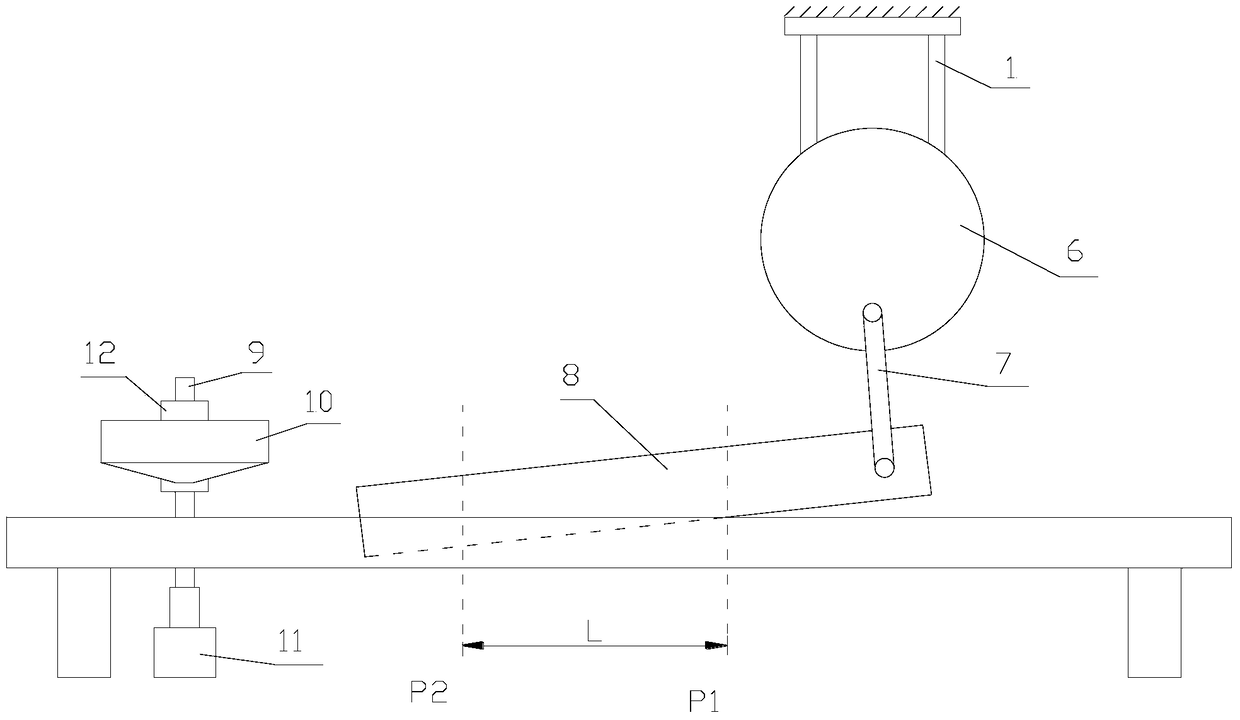

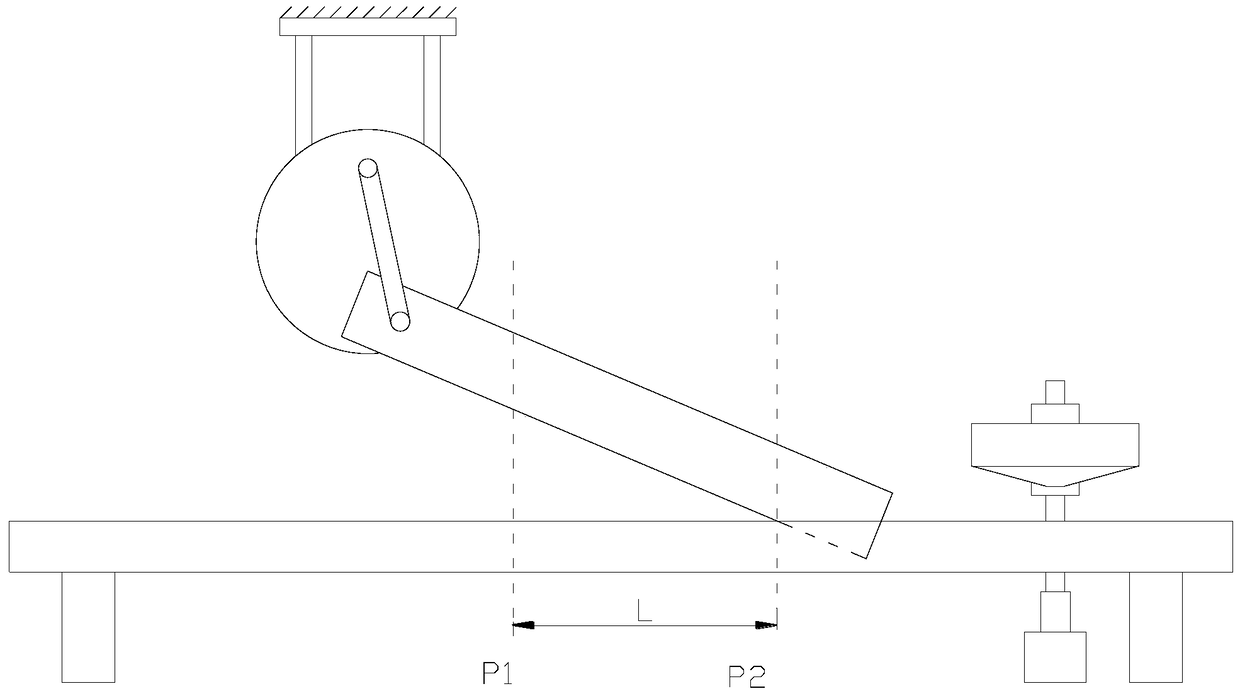

Metal plate shearing system for electric retractable door production

ActiveCN105598523AUniform reaction forceThere will be no excessive concentration of forceAutomatic control devicesShearing machinesEngineeringPosition sensor

The invention discloses a metal plate shearing system for electric retractable door production. The metal plate shearing system comprises a transporting part, a driving mechanism, a first position sensor, a second position sensor and a controller, wherein the transporting part comprises a supporting table, a cutting knife and a transporting mechanism, an accommodating groove for accommodating the cutting knife is formed in the supporting table, the first end of the cutting knife is hinged with the accommodating groove, the projection of the cutting knife on the supporting table is positioned in the accommodating groove, and the driving mechanism is used for driving the cutting knife to get into or break away from the accommodating groove; the transporting mechanism is used for transporting metal plates, the transporting mechanism comprises two transporting units, the two transporting units are respectively arranged at two sides of the supporting table, and the transporting directions of the two transporting units are parallel to the length direction of the accommodating groove; along the transporting directions of the transporting units, a first detection station and a second detection station are arranged on the transporting units in sequence, and the first detection station and the second detection station are positioned at the upstream side of the cutting knife. The metal plate shearing system is simple in structure and good in effect.

Owner:ANHUI PIONEER DOOR IND TECH

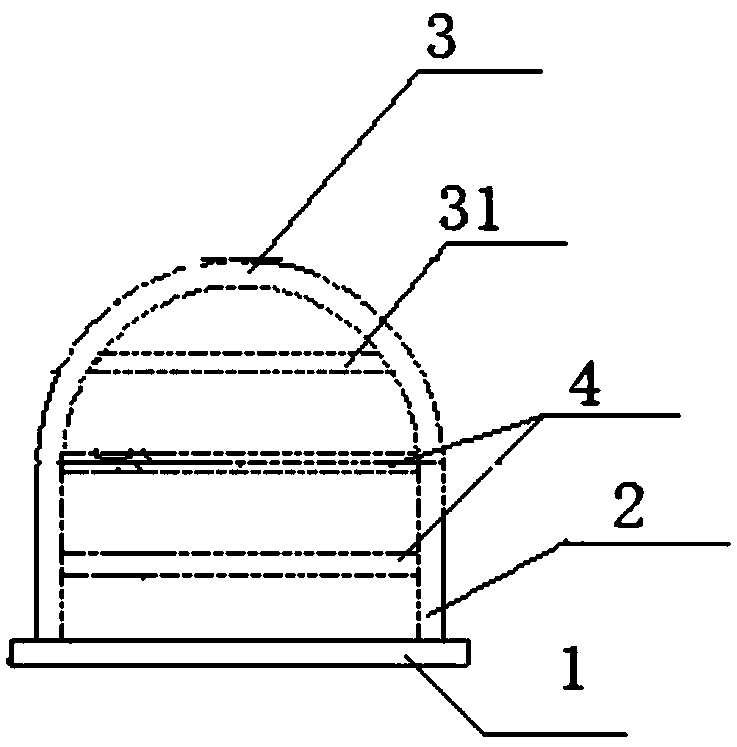

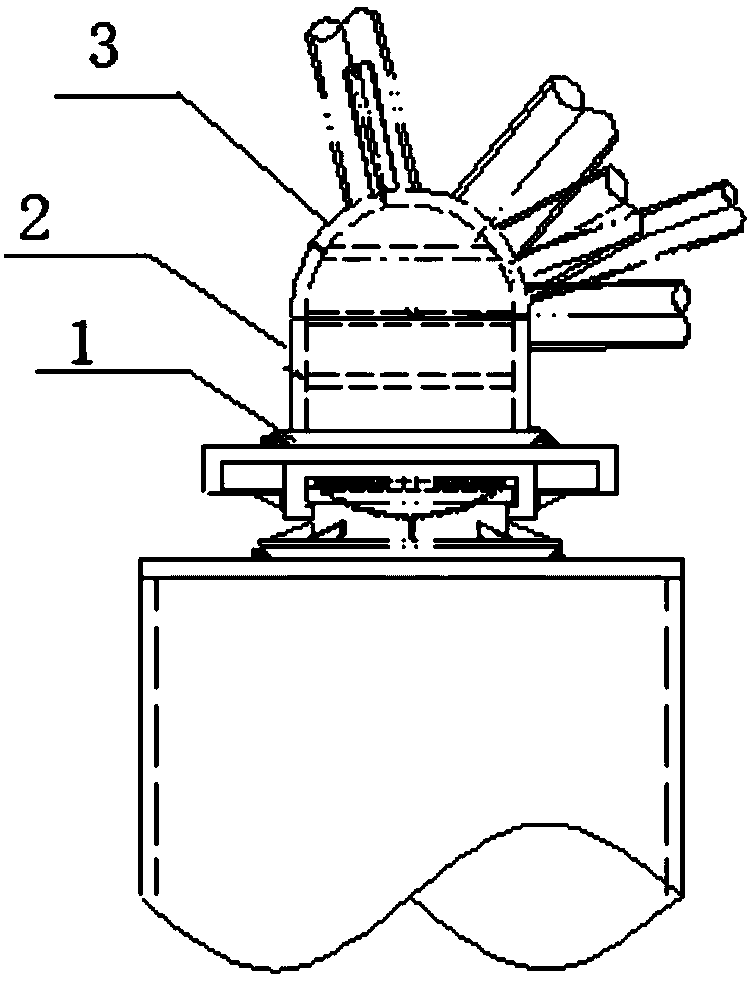

Hemispherical support node and manufacturing process thereof

The invention discloses a hemispherical support node. The hemispherical support node comprises a support baseplate, a circular pipe and a hemisphere body, the circular pipe is arranged above the support baseplate, the hemisphere body is arranged above the circular pipe, a stiffening assisting plate is arranged in the hemisphere body, and a group of stiffening plates are arranged in the circular pipe. According to the hemispherical support node, the structure of the support node is optimized, and the hemisphere body is arranged; a force is transmitted through a spherical surface, so that a reaction force acting on supporting concrete is relatively uniform, and the use stability and safety of the support node are greatly improved. The invention also relates to a manufacturing process of thehemispherical support node, and the problems are solved that the operation during manufacturing of large-diameter thick-walled hemispherical support nodes is difficult, the welding quality is unlikelyto be guaranteed, and deformation is easily caused after welding.

Owner:JIANGSU HUNING STEEL MECHANISM

Metal plate cutting device for retractable door production

ActiveCN105665810AGuaranteed uptimeReduce noiseShearing machinesShearing machine accessoriesGear wheelEngineering

The invention discloses a metal plate cutting device for retractable door production. The device comprises a support rod, a driving gear, a first power unit, two conveying mechanisms and a driving mechanism; the support rod is arranged in the vertical direction; the driving gear is mounted on the support rod, and the axis of the driving gear is overlapped with the axis of the support rod; the first power unit drives the driving gear to rotate; the two conveying mechanisms are distributed on two sides of the driving gear; the conveying mechanisms include support tables, cutters, support frames, lead screws and two moving plates; accommodating tanks are formed in the support tables; first ends of the cutters are hinged to the accommodating tanks; projections of the cutters on the support tables are positioned in the accommodating tanks; the driving mechanism drives the cutters to enter or deviate from the accommodating tanks; and the cutting directions of the cutters in the two conveying mechanisms are opposite. The device is simple in structure and convenient for use.

Owner:天津智投技术成果转化有限公司

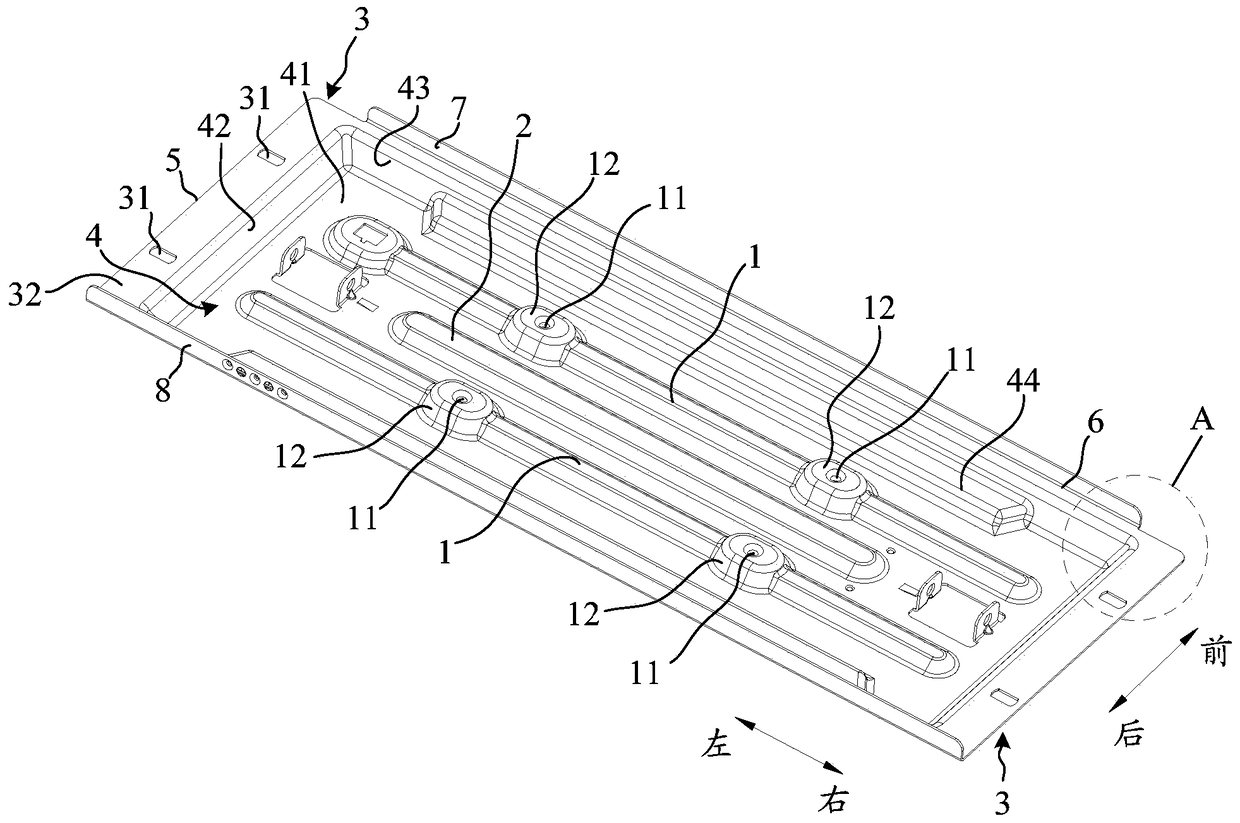

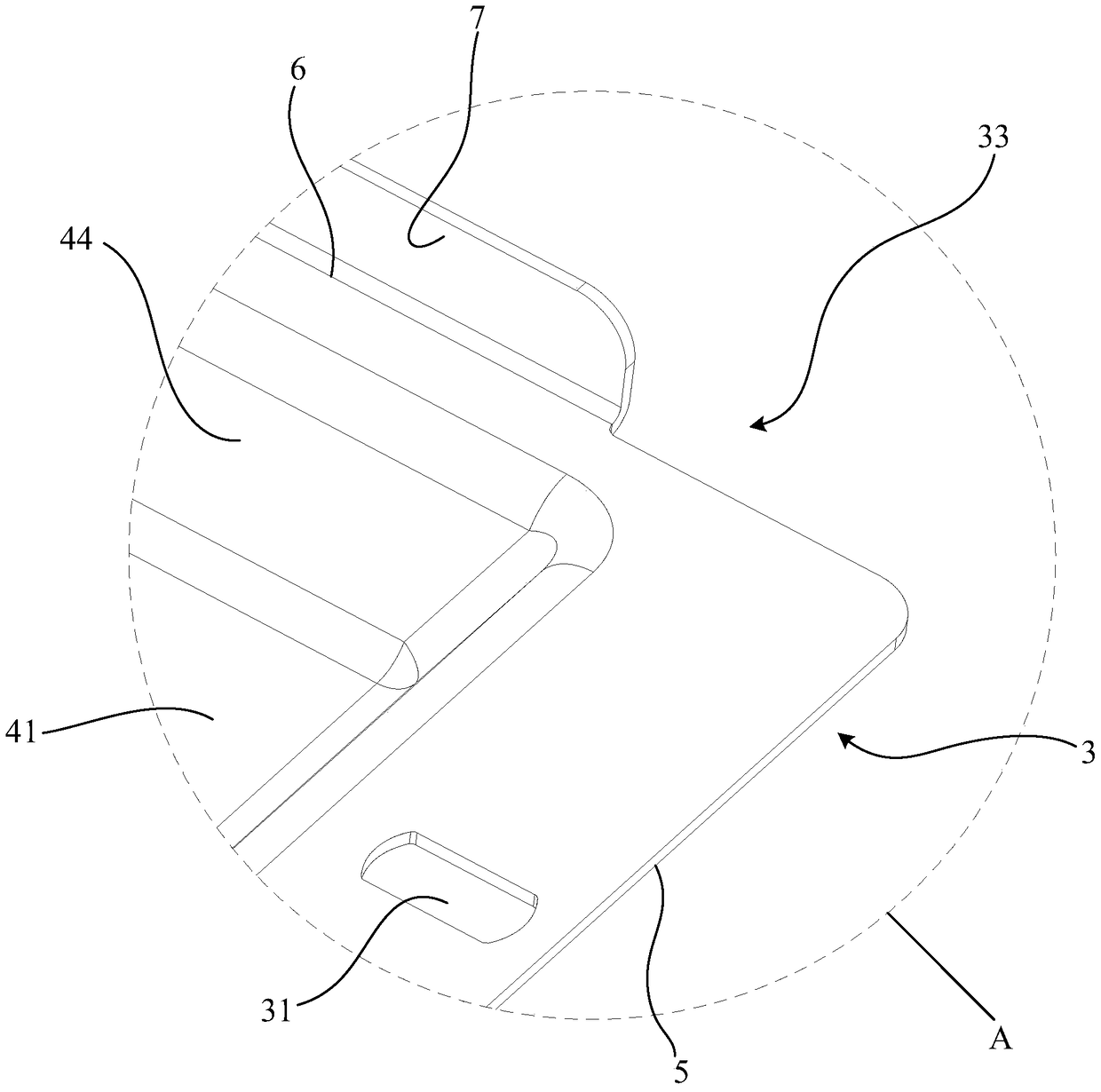

Refrigerator compressor mounting plate and refrigerator

ActiveCN105222472BGuaranteed StrengthIncrease contact areaLighting and heating apparatusRefrigeration devicesDrop impactEngineering

The invention discloses a refrigerator compressor mounting plate and a refrigerator, wherein, the refrigerator compressor mounting plate includes two opposite first sides, and two spaced and parallel bars are arranged between the two first sides. The first rib, the first rib is provided with a fixing hole for fixing the refrigerator compressor, and the two first sides are located in the extending direction of the first rib; the ends of the first rib are A supporting portion is provided between the adjacent first side, and a through hole for fixing the side plate of the refrigerator is provided on the supporting portion, and the supporting portion has a supporting surface for abutting against the side plate of the refrigerator , The supporting surface is a continuous plane. The mounting plate of the refrigerator compressor of the present invention can reduce the probability of deformation of the portion of the side plate of the refrigerator that is in contact with the mounting plate of the refrigerator compressor during vibration or drop impact.

Owner:HEFEI HUALING CO LTD +1

A foldable staggered elastic plate hemostatic structure with a cable, and a hemostatic device and method

ActiveCN109091188BIncrease reaction forceUniform reactionNon-adhesive dressingsSurgeryHemostatic functionEngineering

The invention discloses a foldable staggered elastic plate hemostatic structure with a cable and a hemostatic device. The structure is composed of an external coating film of hemostatic material and an adaptive elastic plate expansion structure. The adaptive elastic plate expansion structure consists of elastic plates, support rods and cables. The elastic plate is fixed on the support rod. There are two elastic plates in each layer. The elastic plates in each layer are arranged according to a certain angle difference θ. The geometric linearity of the elastic plate is an involute line. The base circle radius of the involute line is R. The hemostatic material The external film is pasted and fixed on the outside of the elastic plate. The support rod consists of a scissor hinge unit and an elastic element. When in use, inject the hemostatic structure into the wound, release the cable, and the elastic element releases elastic potential energy to drive the support rod to expand in the axial direction; the elastic plate releases the elastic potential energy to expand in the radial direction, driving the external coating of the hemostatic material to fit the wound surface. Thereby achieving rapid hemostasis function.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

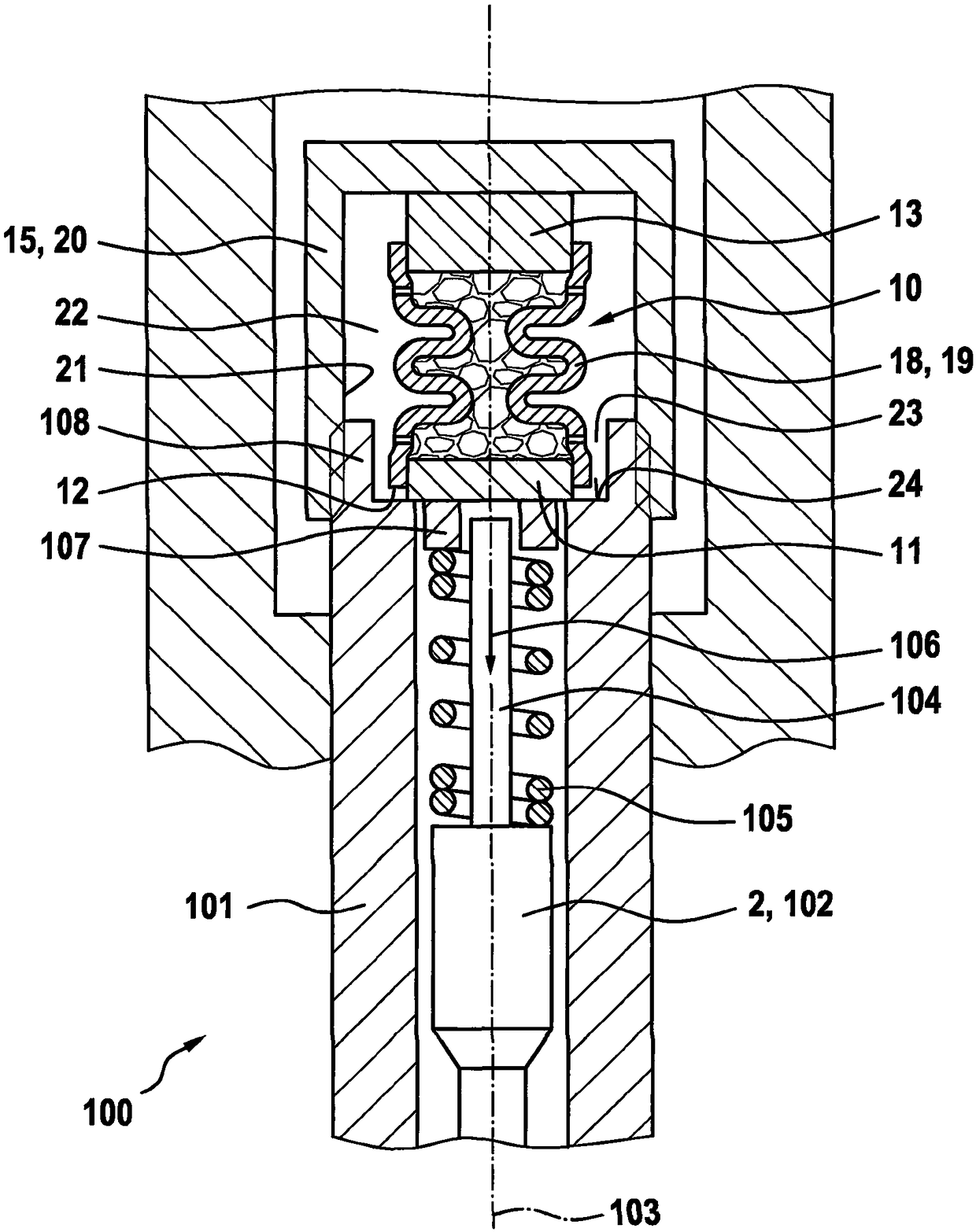

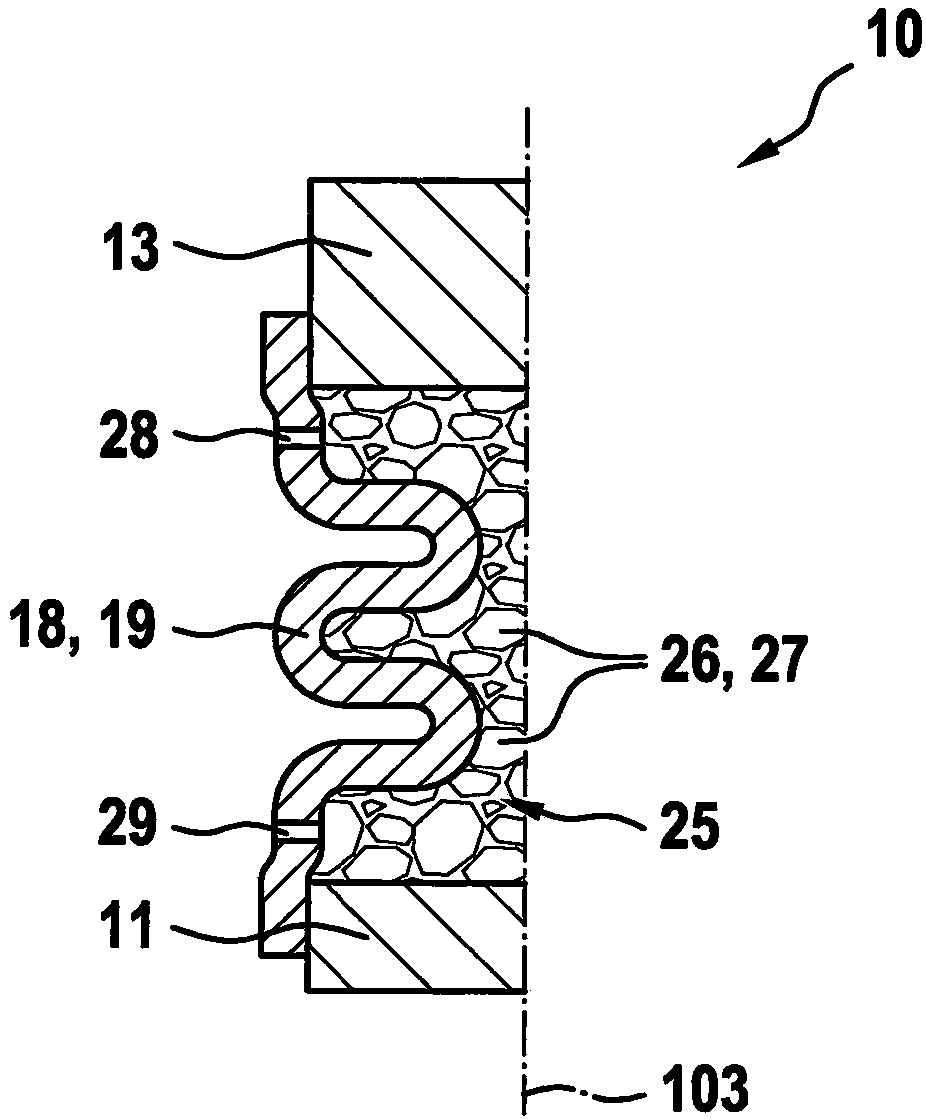

Damping device and gas injector with a damping device

ActiveCN108223669AWith damping effectSimple and Robust ConstructionInternal combustion piston enginesSpringsEngineeringInjector

Owner:ROBERT BOSCH GMBH

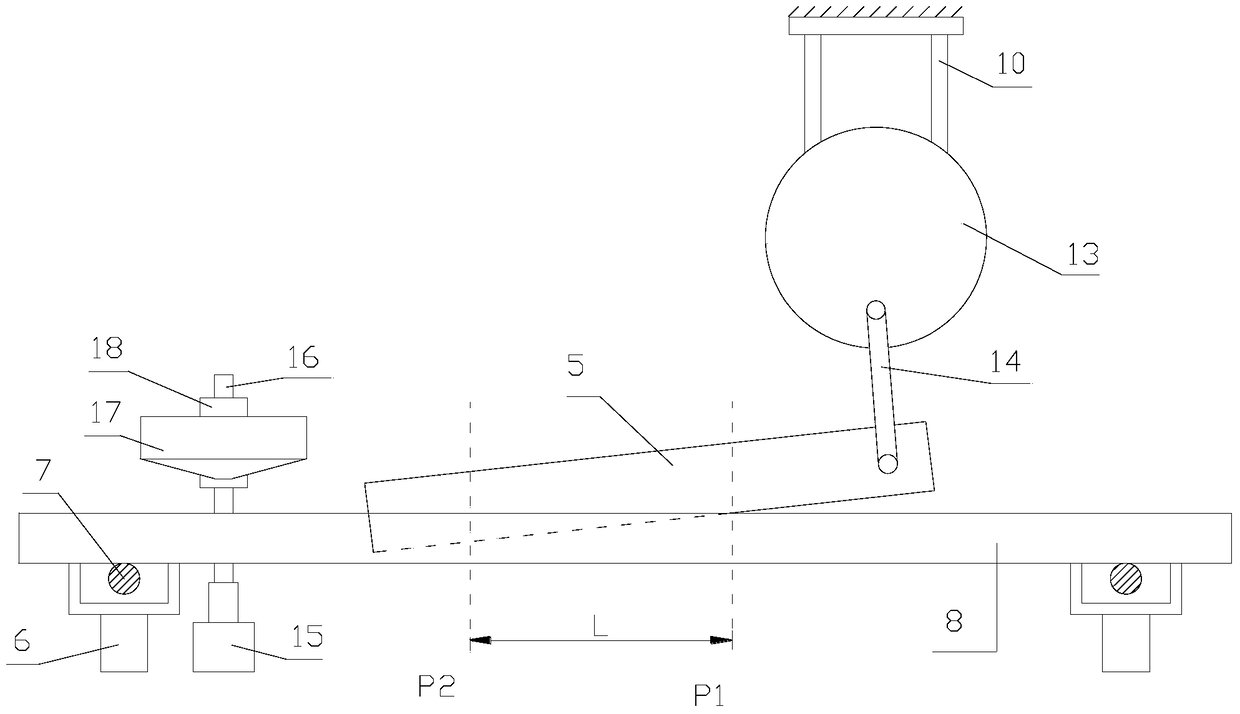

A swing type metal plate shearing machine for the production of electric telescopic doors

ActiveCN105598521BGuaranteed uptimeReduce noiseShearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention discloses a swing type metal plate shearing machine for electric retractable door production. The swing type metal plate shearing machine comprises two transporting parts, a support, a rotating shaft, a driving mechanism and two shearing units, wherein the two transporting parts are arranged side by side, each transporting part comprises two transporting mechanisms and a supporting table, the two transporting mechanisms are arranged symmetrically about the supporting table, an accommodating groove is formed in the supporting table, and the length direction of the accommodating groove is parallel to the transporting directions of the transporting mechanisms; the rotating shaft is mounted on the support in a rotating manner, the rotating shaft is arranged above the transporting parts, and the axis of the rotating shaft is vertical to the transporting directions of the transporting mechanisms; the driving mechanism is used for driving the rotating shaft to rotate. The swing type metal plate shearing machine is simple in structure and convenient to use.

Owner:ANHUI PIONEER DOOR IND TECH

A metal plate cutting device for the production of retractable doors

ActiveCN105665810BGuaranteed uptimeReduce noiseShearing machinesShearing machine accessoriesGear wheelEngineering

The invention discloses a metal plate cutting device for retractable door production. The device comprises a support rod, a driving gear, a first power unit, two conveying mechanisms and a driving mechanism; the support rod is arranged in the vertical direction; the driving gear is mounted on the support rod, and the axis of the driving gear is overlapped with the axis of the support rod; the first power unit drives the driving gear to rotate; the two conveying mechanisms are distributed on two sides of the driving gear; the conveying mechanisms include support tables, cutters, support frames, lead screws and two moving plates; accommodating tanks are formed in the support tables; first ends of the cutters are hinged to the accommodating tanks; projections of the cutters on the support tables are positioned in the accommodating tanks; the driving mechanism drives the cutters to enter or deviate from the accommodating tanks; and the cutting directions of the cutters in the two conveying mechanisms are opposite. The device is simple in structure and convenient for use.

Owner:天津智投技术成果转化有限公司

A processing device for metal workpieces

ActiveCN108213553BGuaranteed cutting dimensional accuracyEasy to operateTube shearing machinesShearing machine accessoriesPipe fittingEngineering

The invention discloses a metal workpiece machining device in the technical field of metal workpiece machining. The metal workpiece machining device comprises a translation conveying mechanism for urging pipe fittings to perform translation in the axis direction. The metal workpiece machining device further comprises a foundation base. The metal workpiece machining device further comprises a mainslide base horizontally mounted on the foundation base in a sliding manner, wherein the sliding direction is adapted to the translation direction of the pipe fittings. The metal workpiece machining device further comprises a first-grade driving oil cylinder for urging the main slide base to slide. The metal workpiece machining device further comprises a PLC; a reference plane is arranged on the foundation base; the height position of the reference plane is adapted to the heights of the bottoms of the inner peripheral walls of the pipe fittings; an annular cutting actuation mechanism for cutting off the pipe fittings and extending in the radial directions of the pipe fittings is mounted at the outer periphery of an annular cutting driving shaft, and is positioned between a front support frame and a main-grade extension base; and the front support frame is provided with multiple distance measurers which are uniformly distributed in the peripheral direction with the axis of the annular cutting driving shaft as reference. The metal workpiece machining device can guarantee the cutting size precision of the pipe fittings, and is convenient to operate.

Owner:扬州正德机械制造有限公司

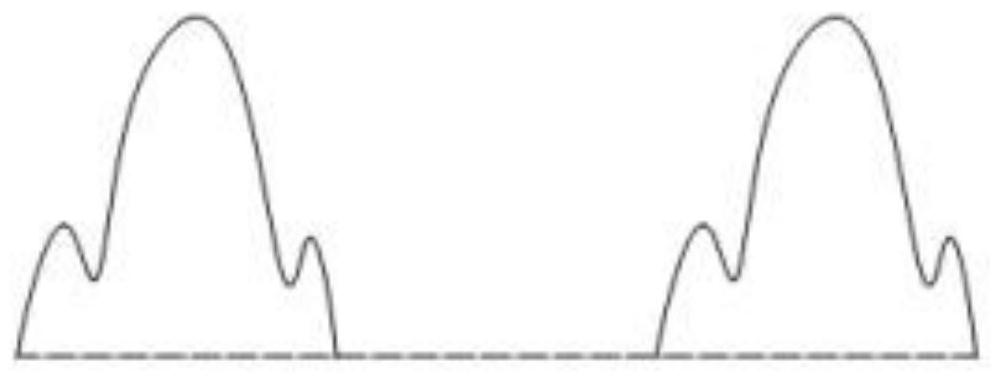

Anti-interference pulse generator driving head

PendingCN112576242AUniform reaction forceConducive to drilling operationsSurveyInterference resistanceEngineering

The invention relates to the technical field of wireless inclinometers while drilling, and particularly discloses an anti-interference pulse generator driving head. The anti-interference pulse generator driving head comprises a mushroom head and a flow limiting ring, the mushroom head is connected with the flow limiting ring in a sliding fit mode, one end of the mushroom head is of a first conicalstructure, a second conical structure is arranged on the flow limiting ring, the first conical structure is matched with the second conical structure, and the first conical structure and the second conical structure are both conical. According to the anti-interference pulse generator driving head, by arranging the mushroom head and the flow limiting ring structure, the waveform intensity is adjustable, the anti-attenuation and anti-interference capabilities of the transmitted signal are stronger, the pressure change is more uniform, the signal is more anti-interference, and later decoding ismore facilitated.

Owner:北京拓尔丰科技有限公司

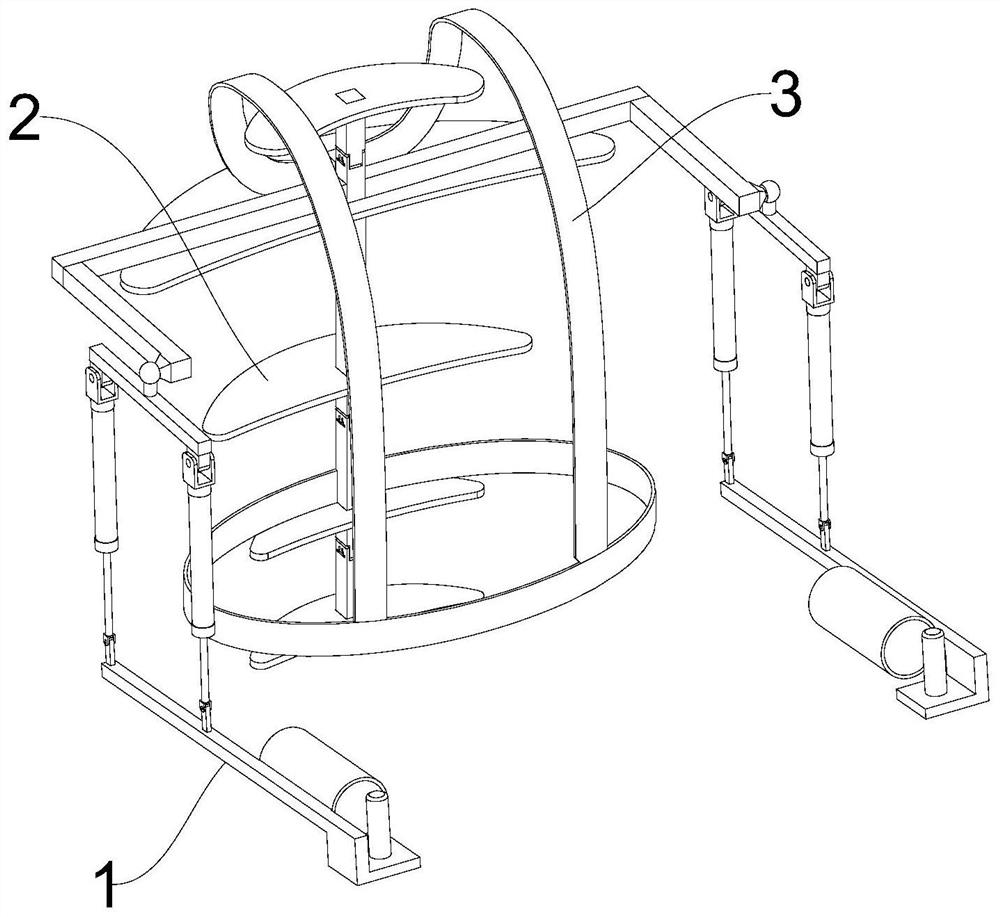

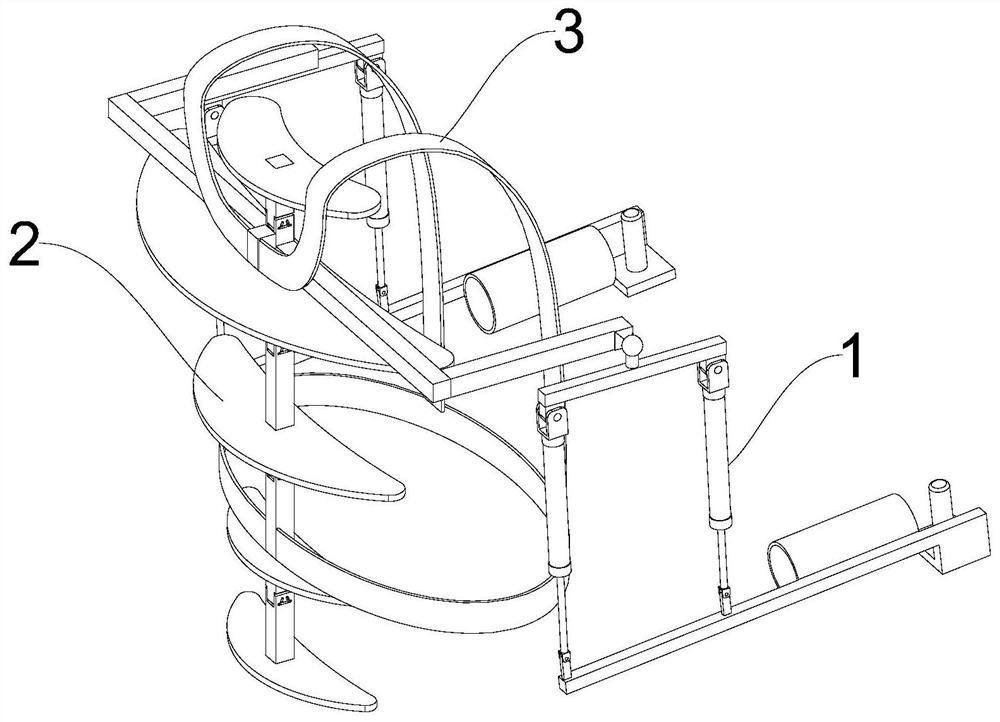

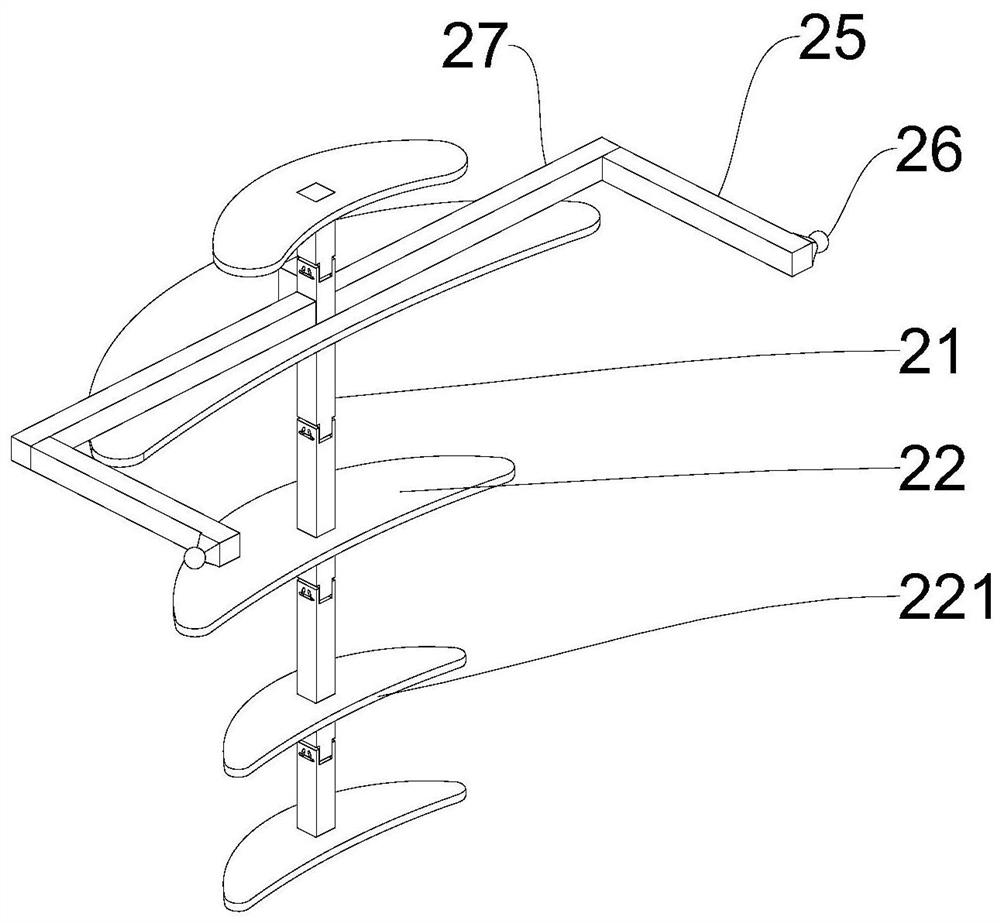

Fishbone-type exoskeleton device

ActiveCN111618823AGuaranteed comfortImprove experienceProgramme-controlled manipulatorChiropractic devicesHuman bodyEntire human body

The invention provides a fishbone-type exoskeleton device, and belongs to the technical field of exoskeleton devices. The fishbone-type exoskeleton device comprises an attachment base and a power assisting mechanism. The attachment base is provided with a fishbone-type coating frame, and the fishbone-type coating frame is fixed to the back of a human body through straps and used for being tightlyattached and relatively fixed to the whole back of the human body. The power assisting mechanism is connected to the attachment base and used for providing additional power for the motion of the upperlimbs of the human body. The fishbone-type exoskeleton device can solve the problem that an existing exoskeleton device is poor in use effect.

Owner:HANDAN POLYTECHNIC COLLEGE

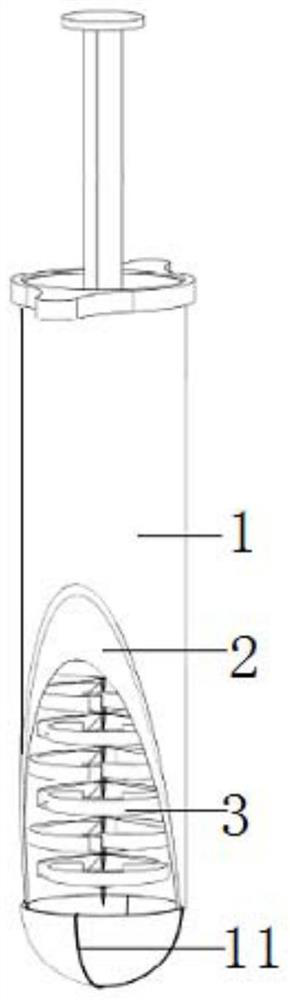

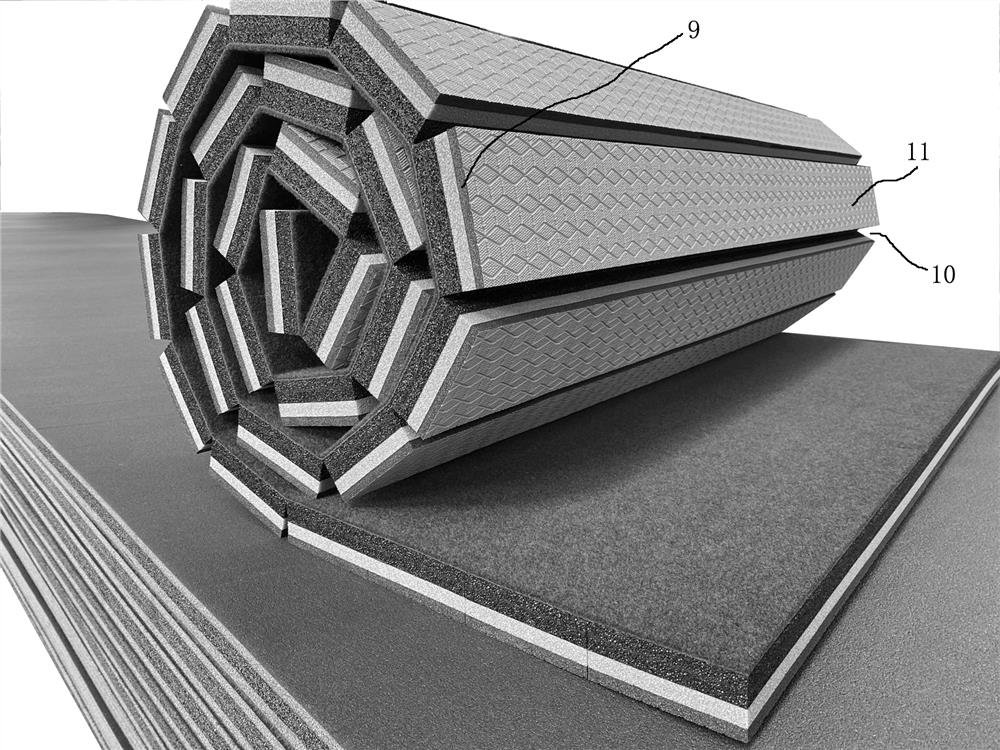

Improved ground mat special for cheerleading training competition

The invention relates to an improved ground mat special for cheerleading training competition. A first mat layer (3), a second mat layer (5), a third mat layer (7) and a fourth mat layer (9) which are made of XPE foaming materials and have gradually decreased density are connected below an environment-friendly soft blanket (1); a transition hard board layer (2) made of the XPE material is arranged between the environment-friendly soft blanket and the first mat layer (3); a first fiber net (4), a second fiber net (6) and a third fiber net (8) which are made of rigid nanofibers are arranged among the first mat layer (3), the second mat layer (5), the third mat layer (7) and the fourth mat layer (9) for separation, and the product is characterized in that the lower surface of the fourth mat layer (9) is connected with a PE embossed film (11). The ground mat has the advantages that the ground mat inherits the overall excellent movement performance of an original ground mat, the PE embossed film is arranged on the bottom face of the ground mat, tiny instant movement of the ground mat is completely eliminated, the movement stability of an athlete is greatly improved, and the protection effect on ankles of the athlete is very obvious.

Owner:南京新恒鼎体育推广有限公司

Method for buffering the reaction force of reciprocating impact excavation and the buffer roadheader implementing the method

ActiveCN103195420BEffective protectionExtended service lifeDriving meansCutting machinesControl engineeringMachine

The invention belongs to the field of digging and relates to a method for buffering a reciprocating impact tunneling counter-acting force and a buffering heading machine adopting the method. The buffering heading machine comprises a machine body, a travel unit, a reciprocating impact unit, and a buffering unit. The buffering unit comprises a dynamic buffering device or a structure buffering guiding device. The reciprocating impact unit comprises an impact driving device, a fixing support and a buffering support. The dynamic buffering device comprises a rotary dynamic buffering device. The rotary dynamic buffering device comprises a slide stroke splined hub buffering device or a belt buffering device. The structure buffering guiding device is arranged between the reciprocating impact unit and the machine body or between the fixing support and the buffering support. The structure buffering guiding device can guide a buffering direction of the dynamic buffering device and / or a structure buffering device. The buffering unit can buffer and resolve a counter-acting force on the reciprocating impact unit. The reciprocating impact unit is arranged at the machine body. The travel unit drives the machine body to travel.

Owner:刘素华

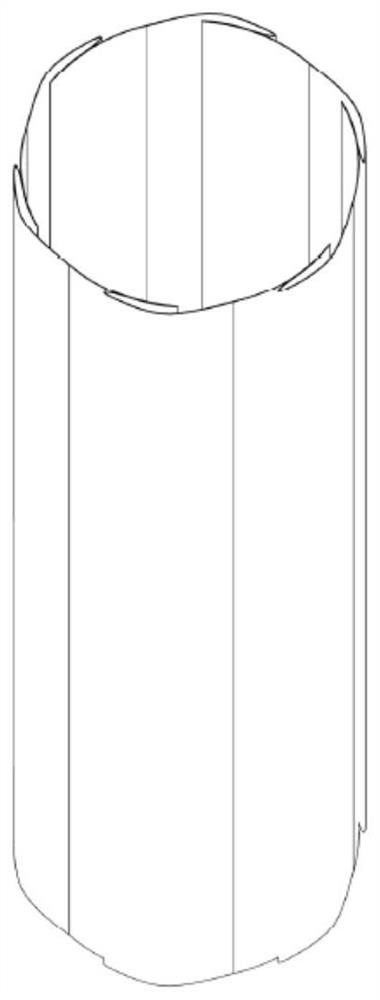

Vertical jack top extension supporting equipment and supporting method

The invention relates to the technical field of jack related equipment, and discloses vertical jack top extension supporting equipment and a supporting method. The vertical jack top extension supporting equipment comprises a barrel, the outer side wall of the cross section of the barrel is square, the cross section of the inner side wall of the barrel is circular, the barrel is free of a base, thetop of the barrel is fixedly connected with a circular supporting disc through a locking screw, a round soft rubber block is bonded to the top of the inner side of the barrel, arc-shaped containing grooves are formed in the inner walls of the left side and the right side of the barrel, two movable through holes are formed in each of the left side face and the right side face of the barrel, movable reinforcing rings are welded to the movable through holes in the left side face and the right side face of the barrel, polish rods penetrate through the inner sides of the four reinforcing rings, and the four polish rods correspondingly penetrate through the inner sides of the corresponding movable through holes and extend to the inner sides of the corresponding arc-shaped containing grooves. According to the vertical jack top extension supporting equipment, it is guaranteed that the top of a jack is evenly clamped and stressed, and therefore the top of the jack is well fixed.

Owner:杨何应

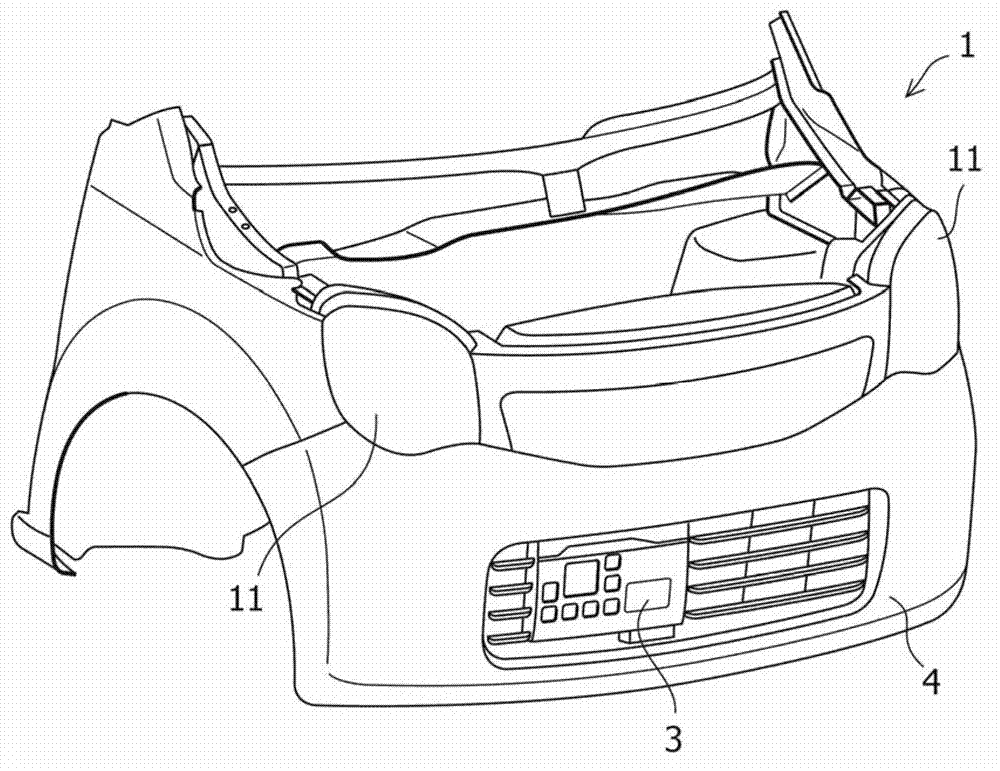

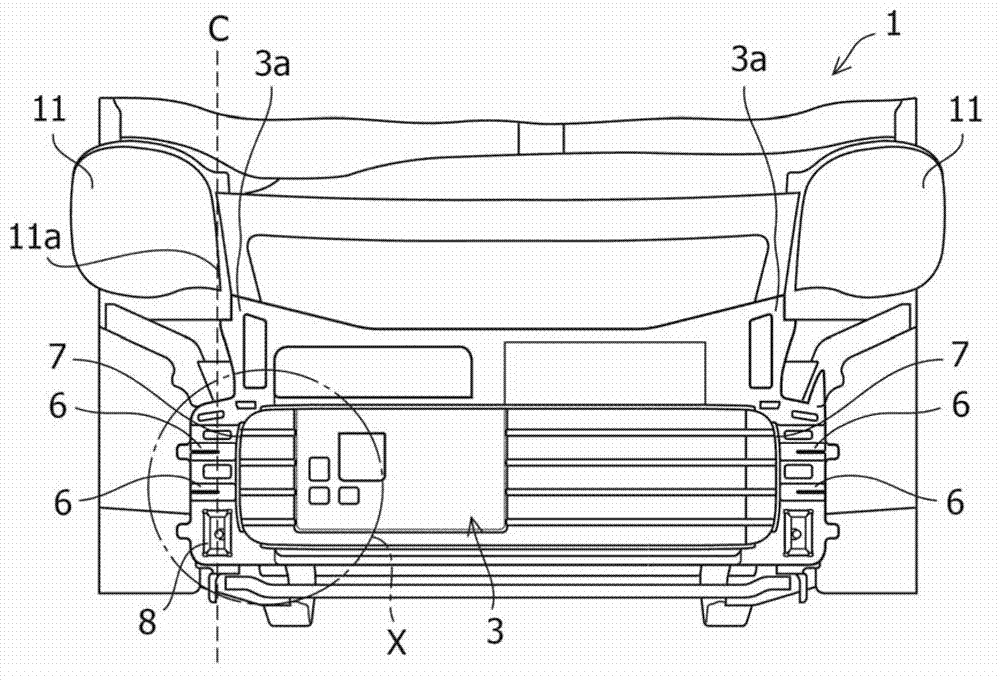

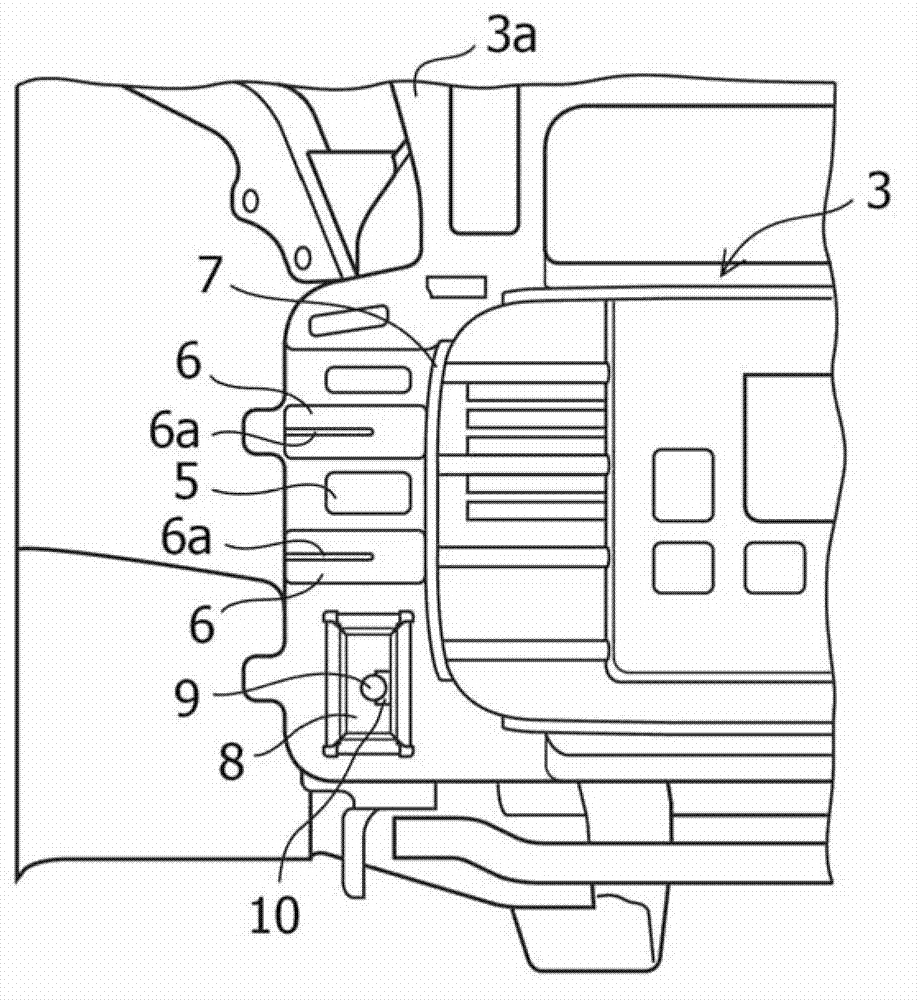

Structure for vehicle body front

InactiveCN103201160AIncrease reaction forceEffectively folds and crushesSuperstructure subunitsRadiatorsEngineeringMechanical engineering

Owner:SUZUKI MOTOR CORP

A vertical jack top extension support device

Owner:贵州翼峰建筑加固技术有限责任公司

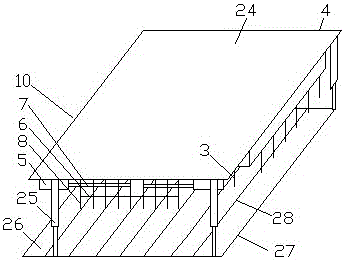

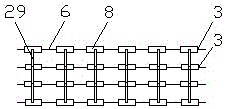

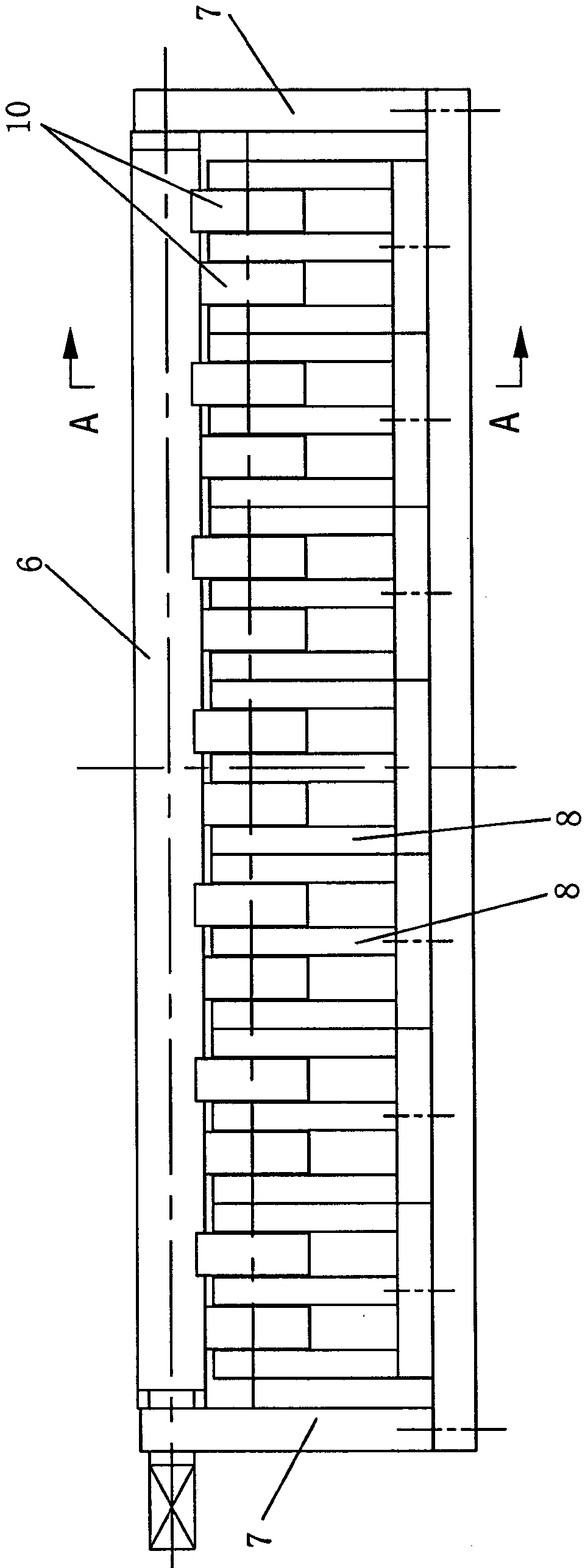

Levelling roller structure for levelling machine

InactiveCN106238509ANot easy to bend and deformUniform reaction forceEngineeringPulp and paper industry

The invention discloses a levelling roller structure for a levelling machine. The levelling roller structure for the levelling machine comprises a bottom plate, a plurality of supporting wheels and a plurality of levelling rollers which are arranged side by side; a wall plate is fixed to each of the two sides of the bottom plate; the levelling rollers are rotatably supported on the two wall plates; each levelling roller is also supported on two rows of the supporting wheels; the two rows of the supporting wheels are of a staggered arrangement structure in the axial direction of the levelling rollers; a supporting frame is arranged between every two adjacent supporting wheels in the axial direction of the levelling rollers; a fixed shaft is supported on each supporting frame; and each supporting wheel is rotatably arranged on the corresponding fixed shaft in a sleeving manner. According to the levelling roller structure for the levelling machine, the levelling rollers are not easily bent and deformed after the levelling machine works for a long time, so that the levelling effect of the levelling machine is good.

Owner:NANTONG HENGDING HEAVY DUTY MACHINE TOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com