Method for buffering the reaction force of reciprocating impact excavation and the buffer roadheader implementing the method

A technology of reaction force and roadheader, which is applied in the direction of cutting machinery, earth drilling and cutting machinery, etc., and can solve the problems of cutting power unit and machine body damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

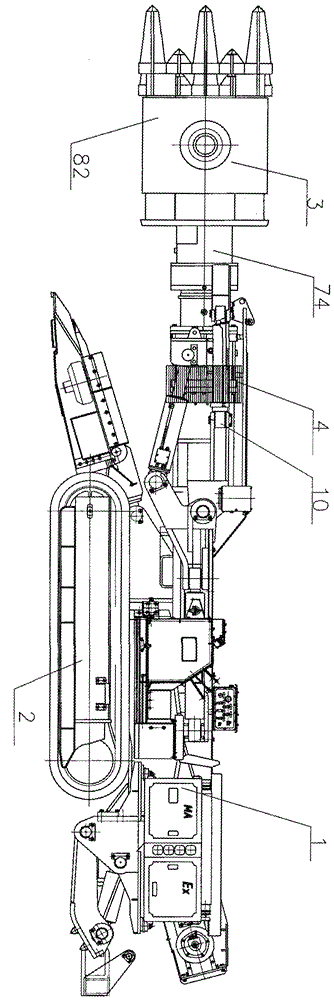

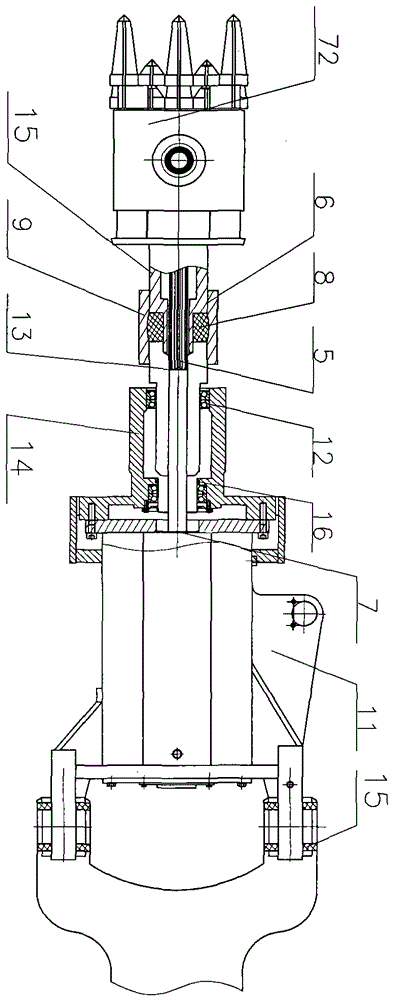

[0097] Figure 1 to Figure 3 It is a buffer roadheader for buffering the reaction force of reciprocating impact excavation described in Example 1, including a fuselage 1 , a running part 2 , a reciprocating impact part 3 , and a buffer device 4 . The buffer device 4 includes a power buffer device 5 and a structural buffer guide device 6. The power buffer device 5 includes a rotating power buffer device 7. The structural buffer guide device 6 includes a structural buffer device 8 and a buffer guide device 9. The reciprocating impact part includes an impact drive device 10. , the impact driving device 10 includes a rotary power source part 11, a rotary impact transmission part 12, a rotary power buffer device 7 is arranged between the rotary power source part 11 and the rotary impact transmission part 12, and the rotary power buffer device 7 includes a sliding travel spline shaft Cover the buffer device 13, the reciprocating impact part 3 also includes a fixed support 14 and a b...

Embodiment 2

[0102] Figure 4 It is the buffer boring machine described in embodiment 2. Different from Embodiment 1, the rotating power buffer device 7 includes a belt buffer device 17, and the belt buffer device 17 includes a driving pulley 18, a belt 19, and a driven pulley 20, and the driving pulley 18 is fixed on the fixed support 14, and the rotating power source The part is a motor 21, the driving pulley 18 is connected with the drive shaft 22 of the motor 21 or the drive sleeve, the driven pulley 20 is arranged on the buffer support member 15, the belt 19 is arranged on the driving pulley 18 and the driven pulley 20, and the driven pulley 20 As the buffer support member 15 is subjected to impact movement, the belt 19 absorbs the impact reaction force to form a belt buffer device 17, and the belt buffer device 17 prevents the motor 21 from being damaged.

[0103] The rotary power source 11 may also be a hydraulic motor or an air motor.

[0104] Others are with embodiment 1.

Embodiment 3

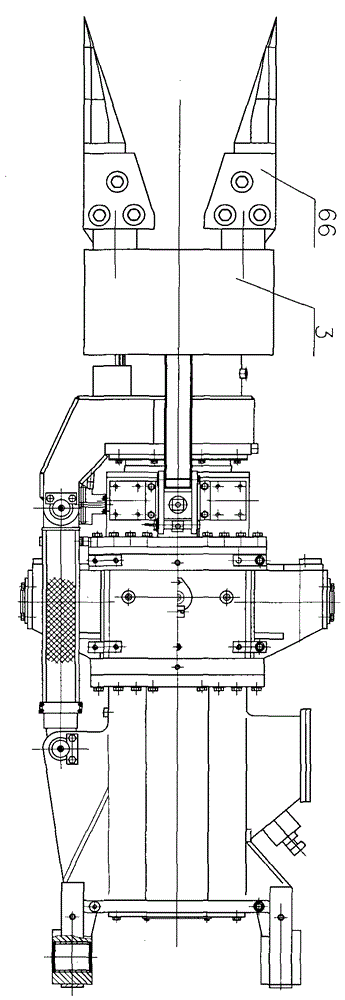

[0106] Figure 5 , 6 It is the buffer boring machine described in embodiment 3. What is different from Embodiment 1 is: the belt buffer device 17 comprises a driving pulley 18, a belt 19, a driven pulley 20, the driving pulley 18 is fixed on the fixed support 14, the rotating power source part 11 is a motor 21, and the driving pulley 18 and the motor 21 of the drive shaft 22 or the drive sleeve connection, the driven pulley 20 is arranged on the buffer support 15, the belt 19 is arranged on the driving pulley 18 and the driven pulley 20, and the driven pulley 20 is impacted with the buffer support 15. , The belt 19 absorbs the impact reaction force to form a belt buffer device 17, and the belt buffer device 17 prevents the motor 21 from being damaged. Belt buffer device 17 also comprises tensioner 23, and tensioner 23 comprises connecting arm 24, bearing 25, return spring 26, positioning pin 27 etc., connecting arm 24, return spring 26 and bearing 25 are hinged by hinge , C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com