Blade cascade and turbomachine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

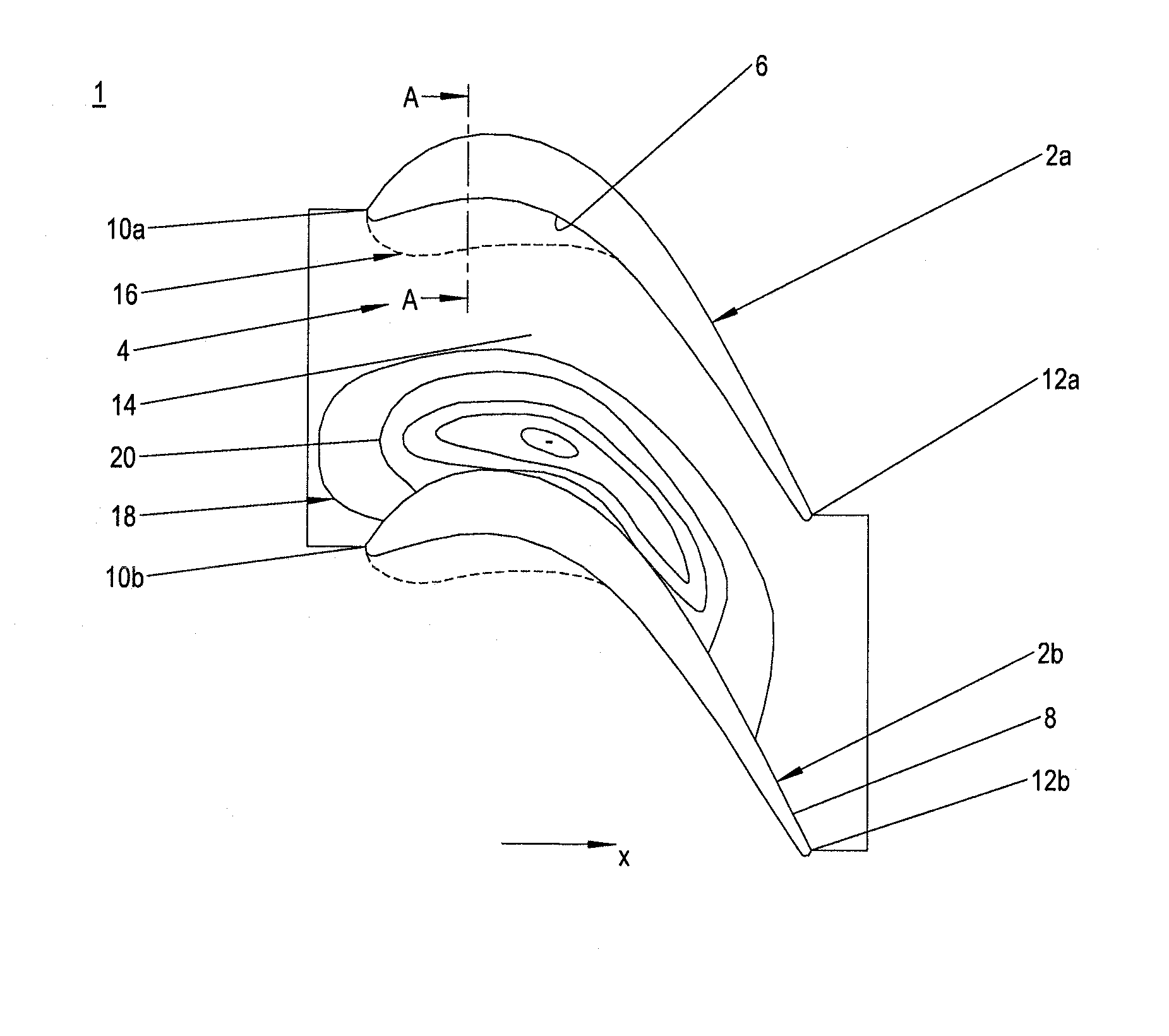

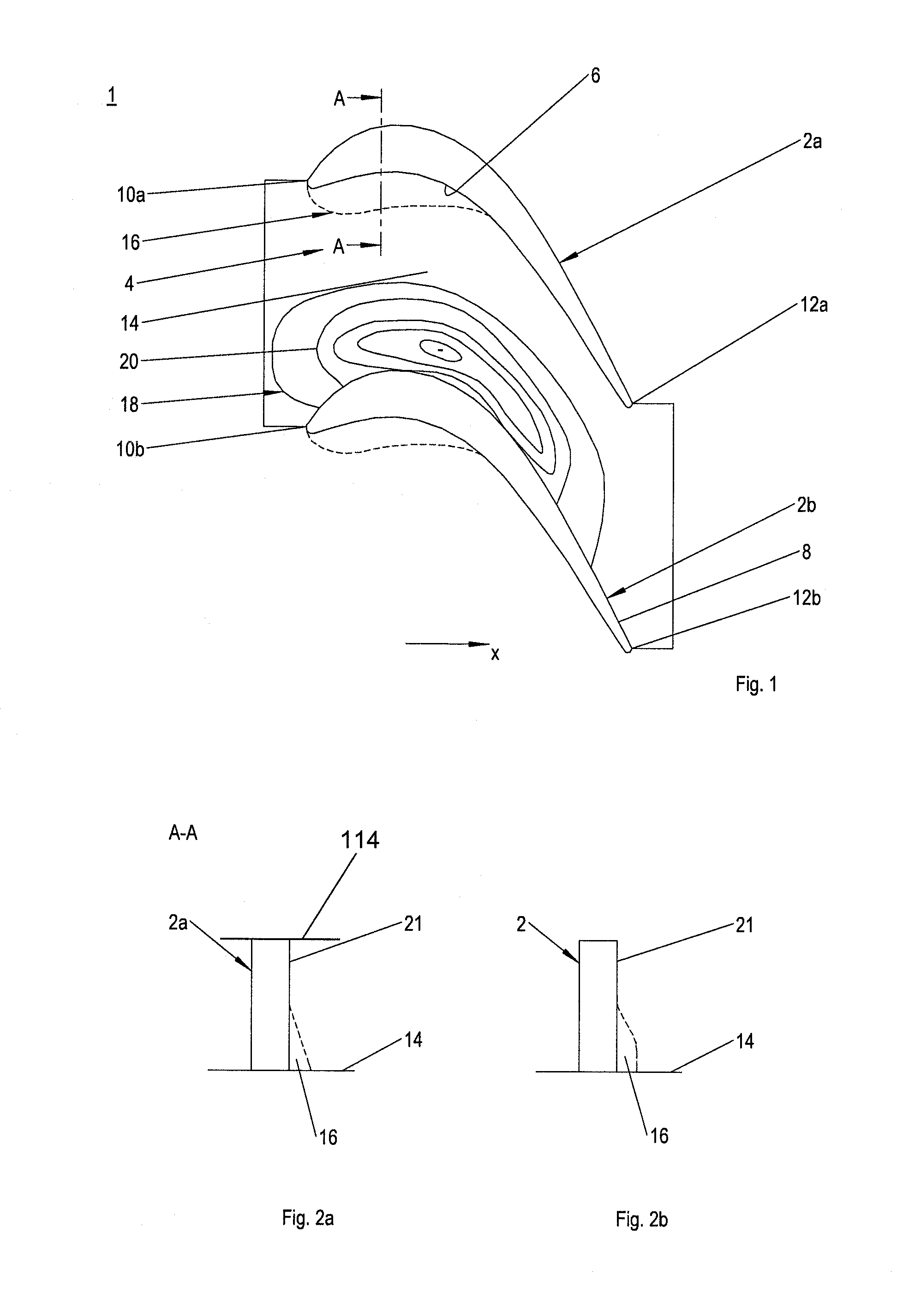

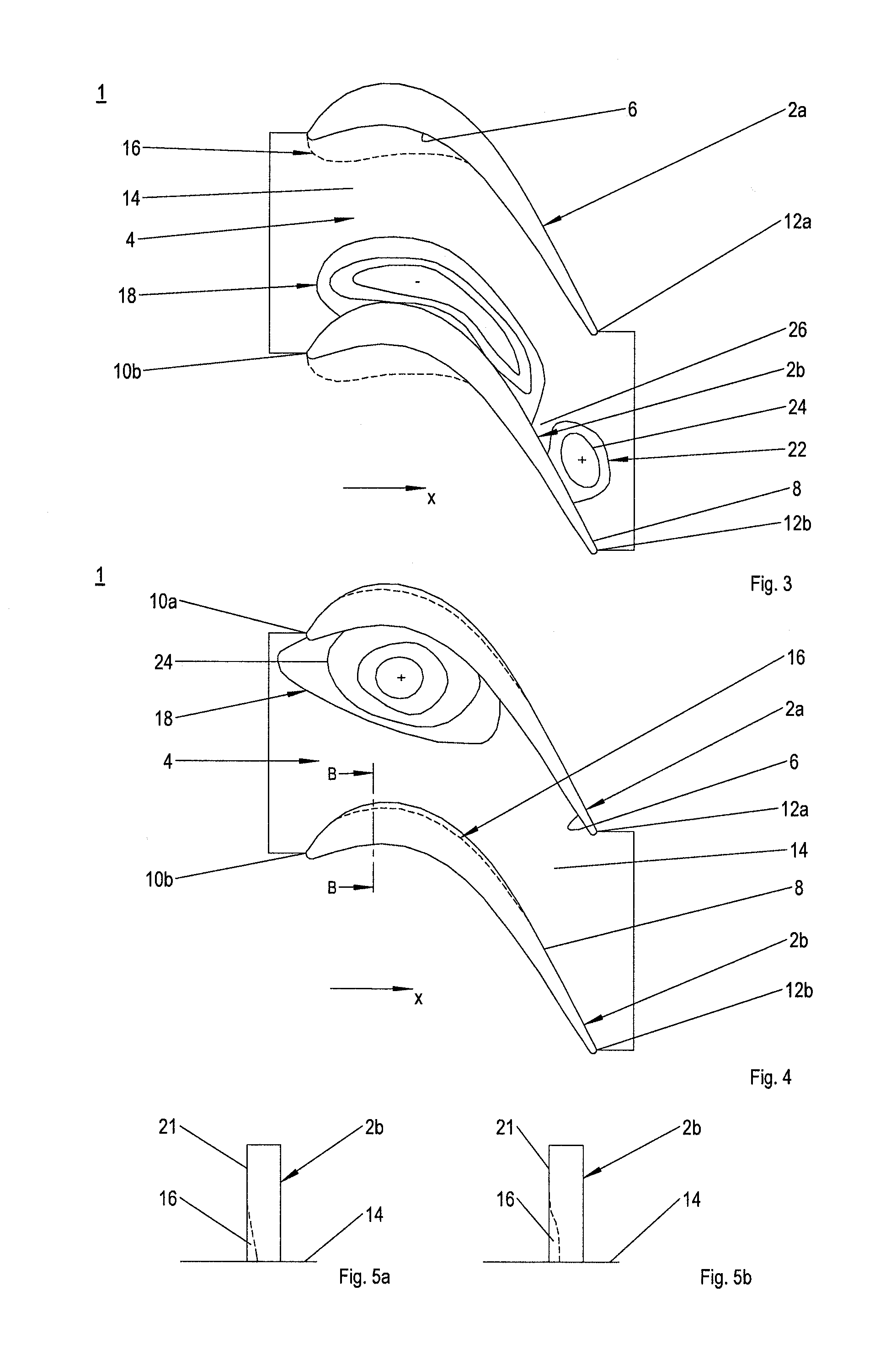

[0025]As shown in the first exemplary embodiment according to FIG. 1, a blade cascade 1 according to the present invention has a plurality of blades 2a, 2b which are situated next to one another in the peripheral direction of blade cascade 1 and which in each case delimit a blade channel 4. Blade cascade 1 is preferably a blade cascade of an axial turbomachine such as an aircraft engine or a stationary gas turbine. For example, blade cascade 1 is situated in the low-pressure turbine of the turbomachine.

[0026]Blade cascade 1 is situated concentrically with respect to a machine axis or rotor axis, not shown, which extends in axial direction x. According to the illustration in FIG. 1, a main flow, not shown, flows through the blade cascade from left to right, the main flow in blade channels 4 being correspondingly deflected in the peripheral direction.

[0027]In the peripheral direction, each blade channel 4 is delimited by a pressure side 6 of first blade 2a and by an oppositely situate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com