Ecological power unit

A power unit and ecological technology, applied in the field of ecological propulsion devices, can solve problems such as radiation waste gas, impact on sustainable development, and accompanying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

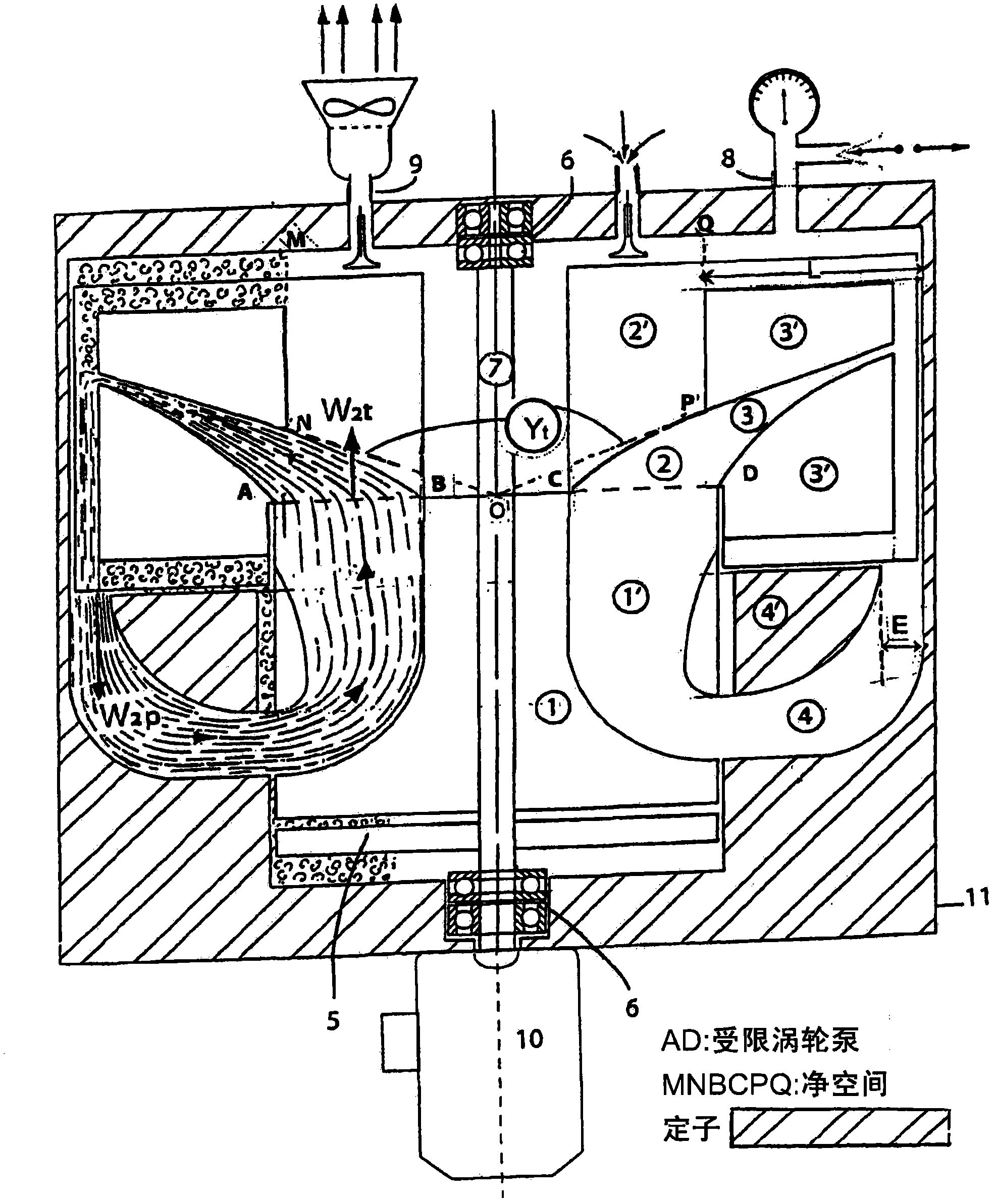

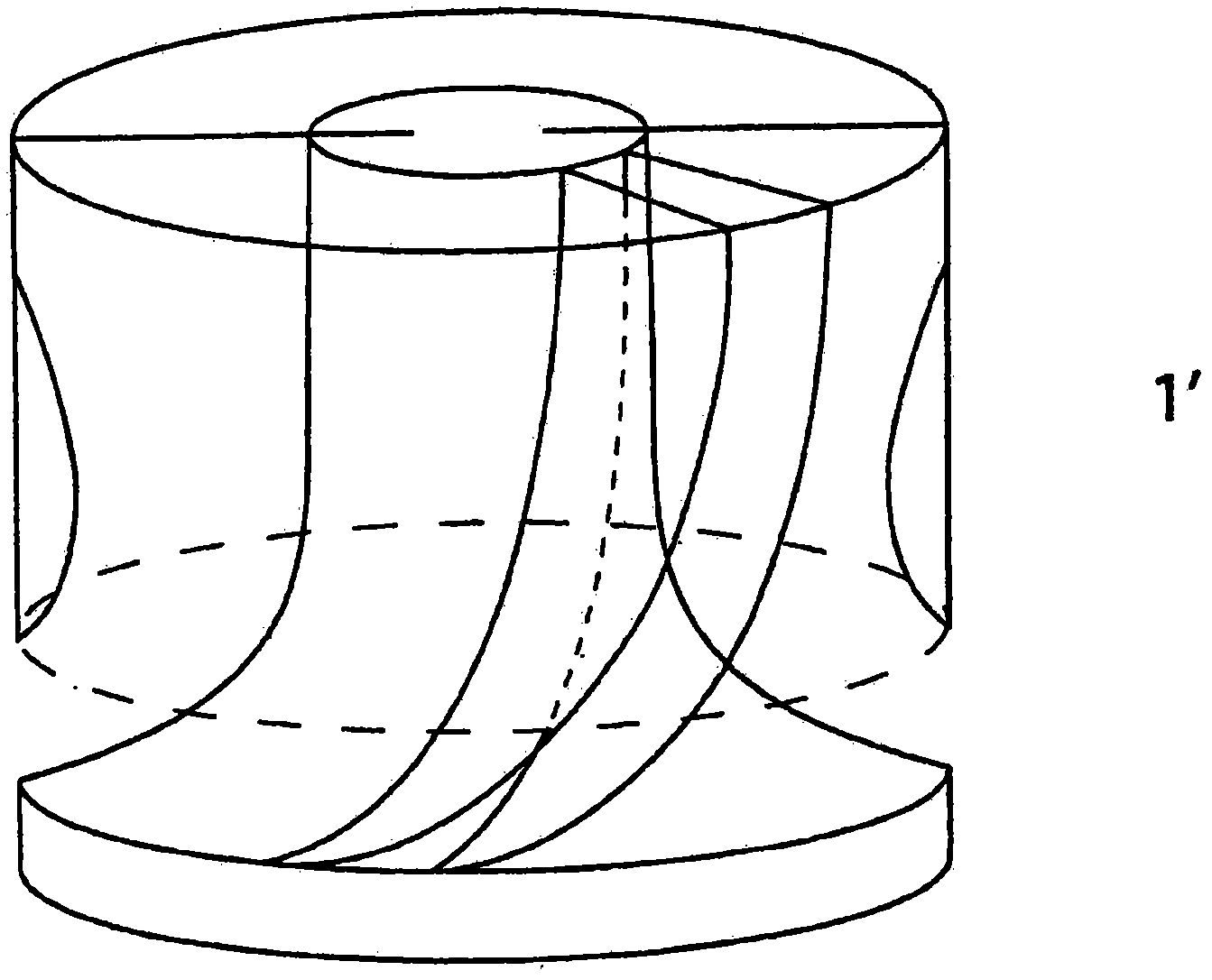

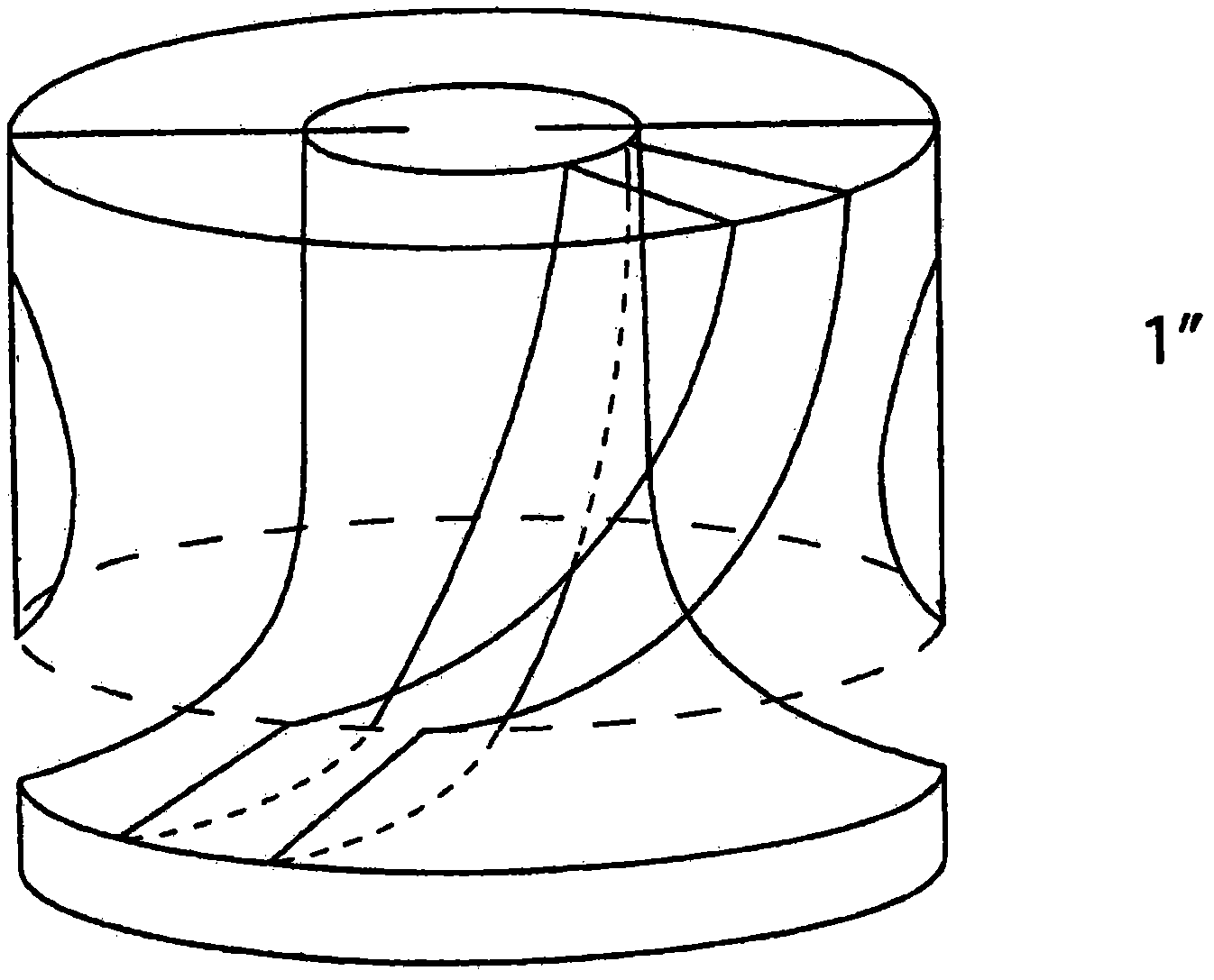

[0039] Referring to these figures, the device consists of a special type of Francis turbine (1) whose impeller blades (1') adjust the velocity vector at the inlet, C 1t ( Figure 5 ) is perpendicular to the rotation axis at 90°, and extends radially to the outlet at the minimum relative speed in the axial direction, which is equal to the circumferential speed r×ω (r is the radius of the turbine, and ω is the angular velocity). At the outlet, the fluid is collected in the free area MADQ (MNBCPQ is the net free area) defined by the linear radial pump (2) whose fins (2') are formed with the turbine blades (1') in order to maintain flow continuity joint.

[0040] The fins (2') are held and reinforced by two spatially streamlined crown structures (3'), forming a unit (3) for directing fluid flow. For better fluid transport, these units (3) conform to the boundary of the fixed streamline Yi ( Figure 4 ), regardless of the rotational speed. The relative velocity at the pump outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com