Francis turbine or francis pump or francis pump turbine

A water turbine and impeller technology, applied in the direction of machines/engines, hydroelectric power generation, mechanical equipment, etc., can solve the problem that the spiral shell is not rotationally symmetrical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

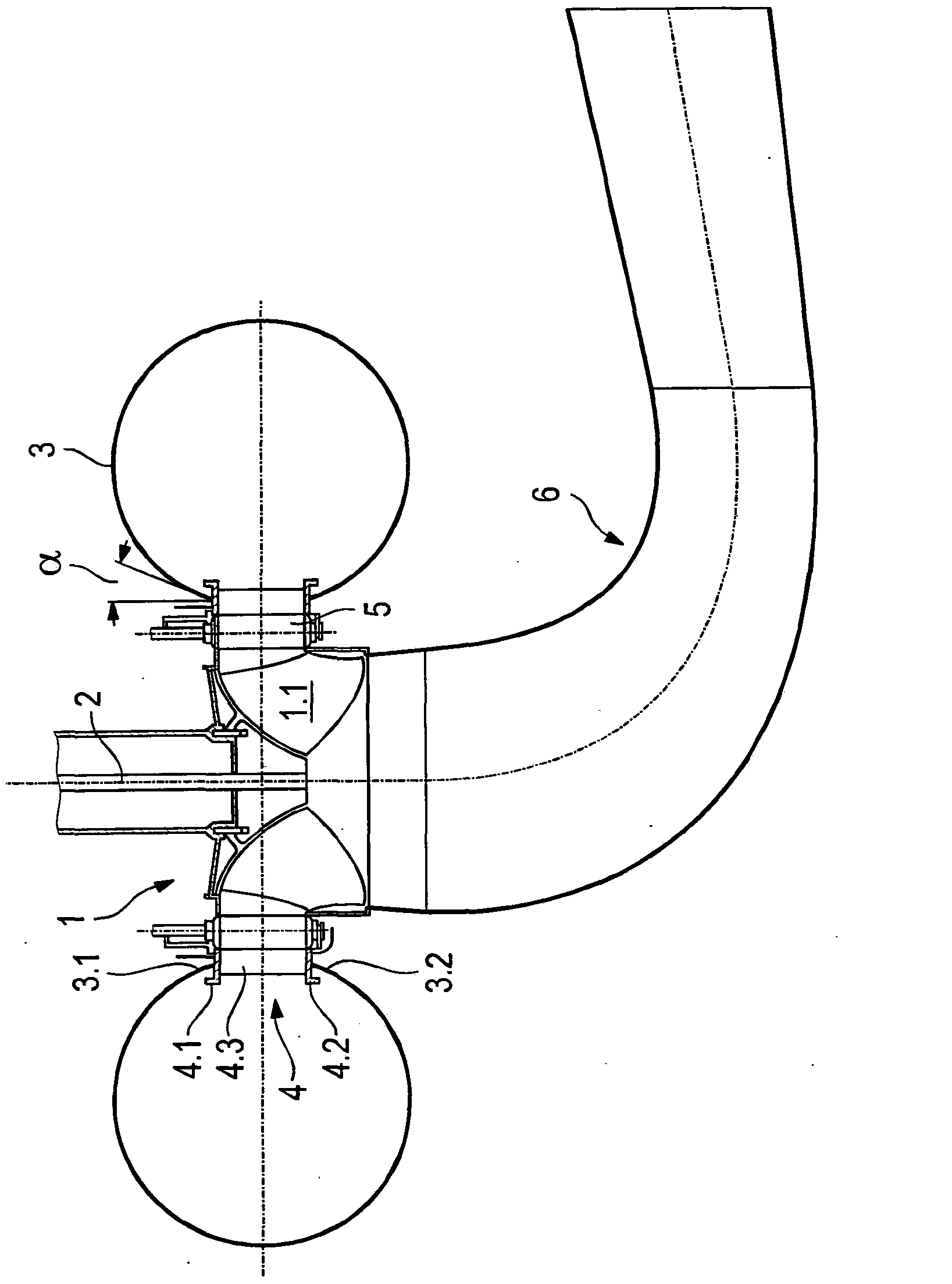

[0018] in figure 1 The Francis turbine shown in has an impeller 1. It includes multiple blades 1.1. The impeller 1 rotates around the rotation axis 2.

[0019] The impeller 1 is surrounded by a spiral casing 3. The spiral housing 3 has a circular cross section, for example. It has a slit-shaped opening along the circumference opposite to the impeller 1. The opening gap is limited by the edges 3.1, 3.2 along the circumference.

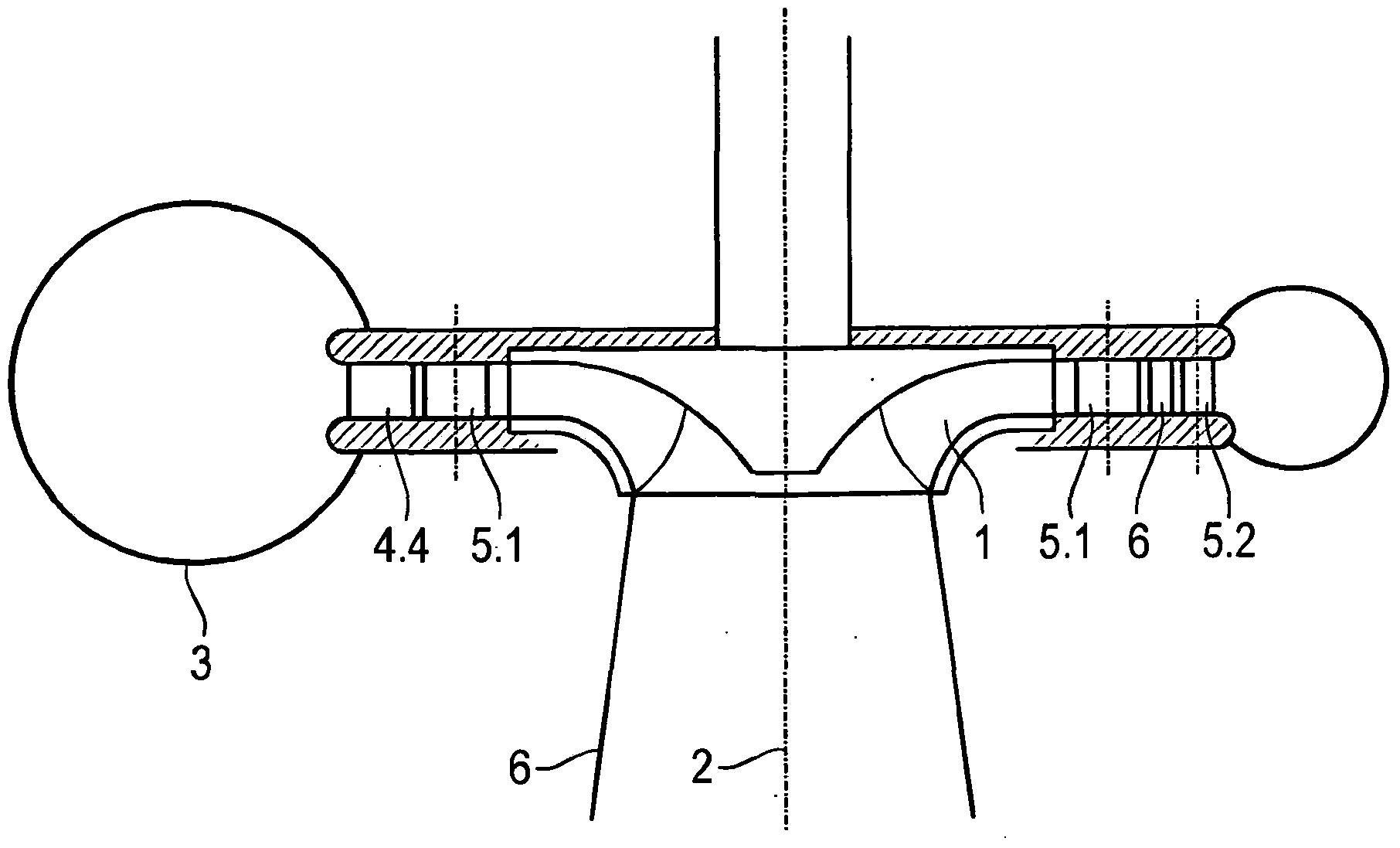

[0020] The beam ring 4 is connected to the gap formed by the edges 3.1, 3.2 along the circumference. The beam ring has two beam ring covers 4.1 and 4.2. The beam 4.3 is used as a tie rod.

[0021] The circumferential edges 3.1 and 3.2 of the spiral shell are welded to the beam ring covers 4.1 and 4.2.

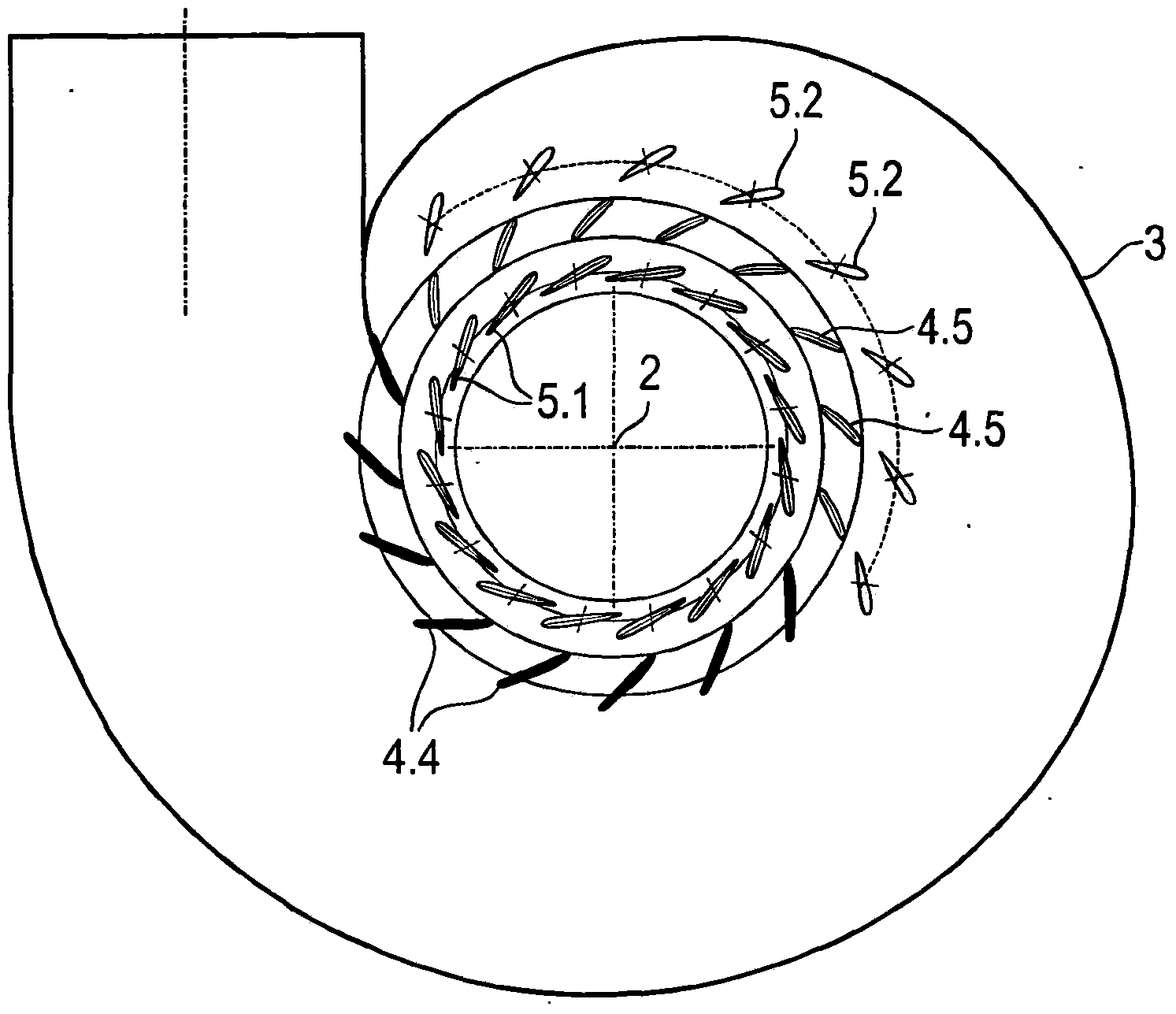

[0022] A guide device with guide blades 5 is arranged between the beam ring and the impeller.

[0023] Viewed from the direction of the water flow, the suction pipe 6 is connected to the impeller 1, and the suction pipe has a plurality of sections.

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com