Welding positioning device for mixed-flow runner blade and its positioning measurement method

A runner blade, welding positioning technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve problems such as unsatisfactory positioning effect and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

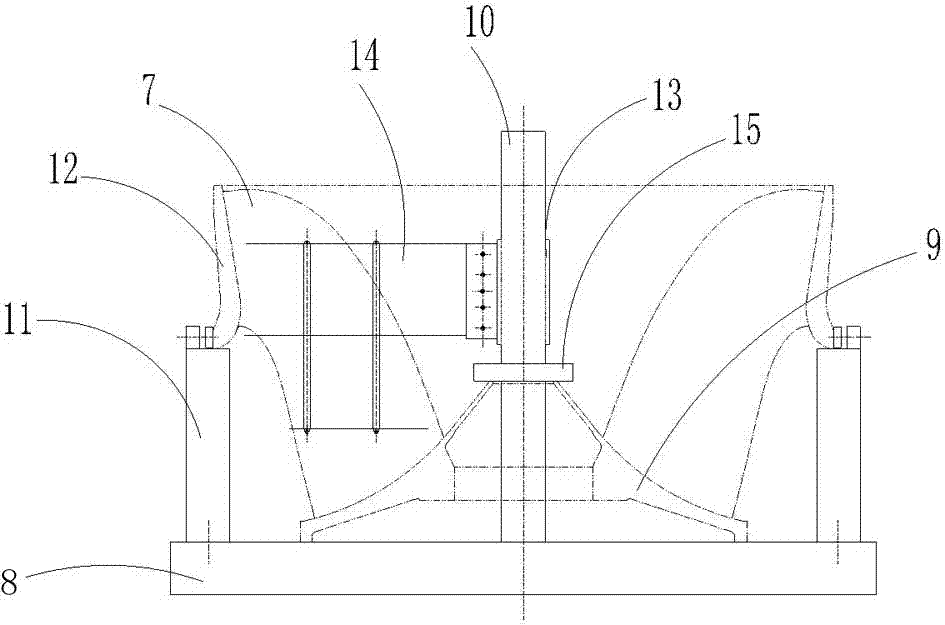

[0047] Embodiment 1: as figure 1 , figure 2 , image 3 with Figure 4 As shown, a welding positioning device for a mixed-flow runner blade includes a runner blade 7 and a bottom plate 8, the bottom plate 8 is provided with a runner upper crown 9, and the runner upper crown 9 passes through the pillar 10 is fixed with the base plate 8, and the two ends of the upper part of the base plate 8 are respectively provided with adjustable lower ring supports 11, and the upper part of the adjustable lower ring support 11 is provided with a runner lower ring 12, and the described rotary The bottom end of the runner blade 7 is fixed to the upper crown 9 of the runner, and the upper end of the runner blade 7 is in movable contact with the runner lower ring 12;

[0048] The support 10 is covered with a rotating shaft 13, and the rotating shaft 13 drives the blade shape line model group 14 to rotate, and the blade shape line model group 14 is positioned with the runner blade 7;

[0049]...

Embodiment 2

[0078] Embodiment 2: the positioning measuring method of the welding positioning device of mixed-flow runner blade, according to the following steps:

[0079] (1) Analysis:

[0080] Use the positioning device to achieve precise positioning of the blade, use a three-dimensional measuring instrument to measure the cross-section of the blade, and match the three-dimensional measured results of the runner blade with the theoretical value in the three-dimensional CAD software, and judge whether the blade installation position is accurate according to the deviation between the two;

[0081] (2), positioning operation:

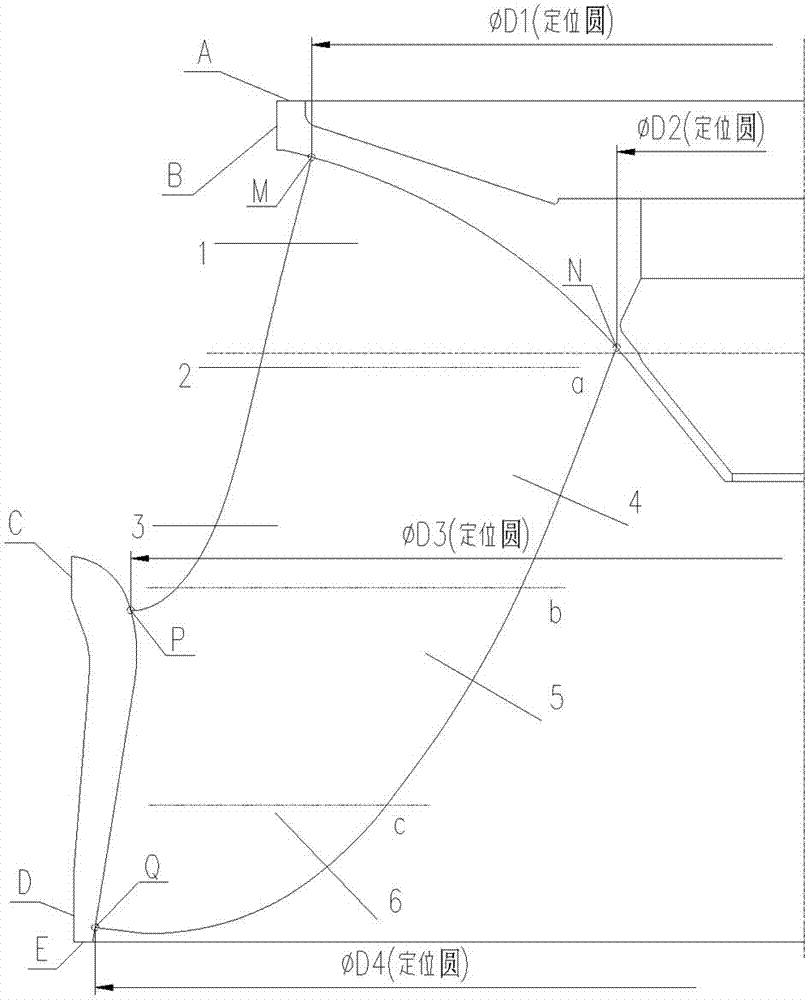

[0082] 1. Design and determine the measurement section and positioning model section, the sections are 1, 2, 3, 4, 5 and 6 sections, the positioning model sections are a, b and c, and the processing runner blades Make points according to the cross-section, that is, locate the reference point, and each cross-section has 3 points;

[0083] According to the diameter o...

Embodiment 3

[0105] Embodiment 3: The positioning measurement method of the welding positioning device of the Francis runner blade, according to the following steps:

[0106] (1) Analysis:

[0107] Use the positioning device to achieve precise positioning of the blade, use a three-dimensional measuring instrument to measure the cross-section of the blade, and match the three-dimensional measured results of the runner blade with the theoretical value in the three-dimensional CAD software, and judge whether the blade installation position is accurate according to the deviation between the two;

[0108] (2), positioning operation:

[0109] 1. Design and determine the measurement section and positioning model section, the sections are 1, 2, 3, 4, 5 and 6 sections, the positioning model sections are a, b and c, and the processing runner blades Make points according to the cross-section, that is, locate the reference point, and each cross-section has 2 points;

[0110] According to the diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com