Francis turbine

A technology of impellers and tires, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as wear and tear enhancement, changes in service conditions, and reduced hydraulic mechanical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

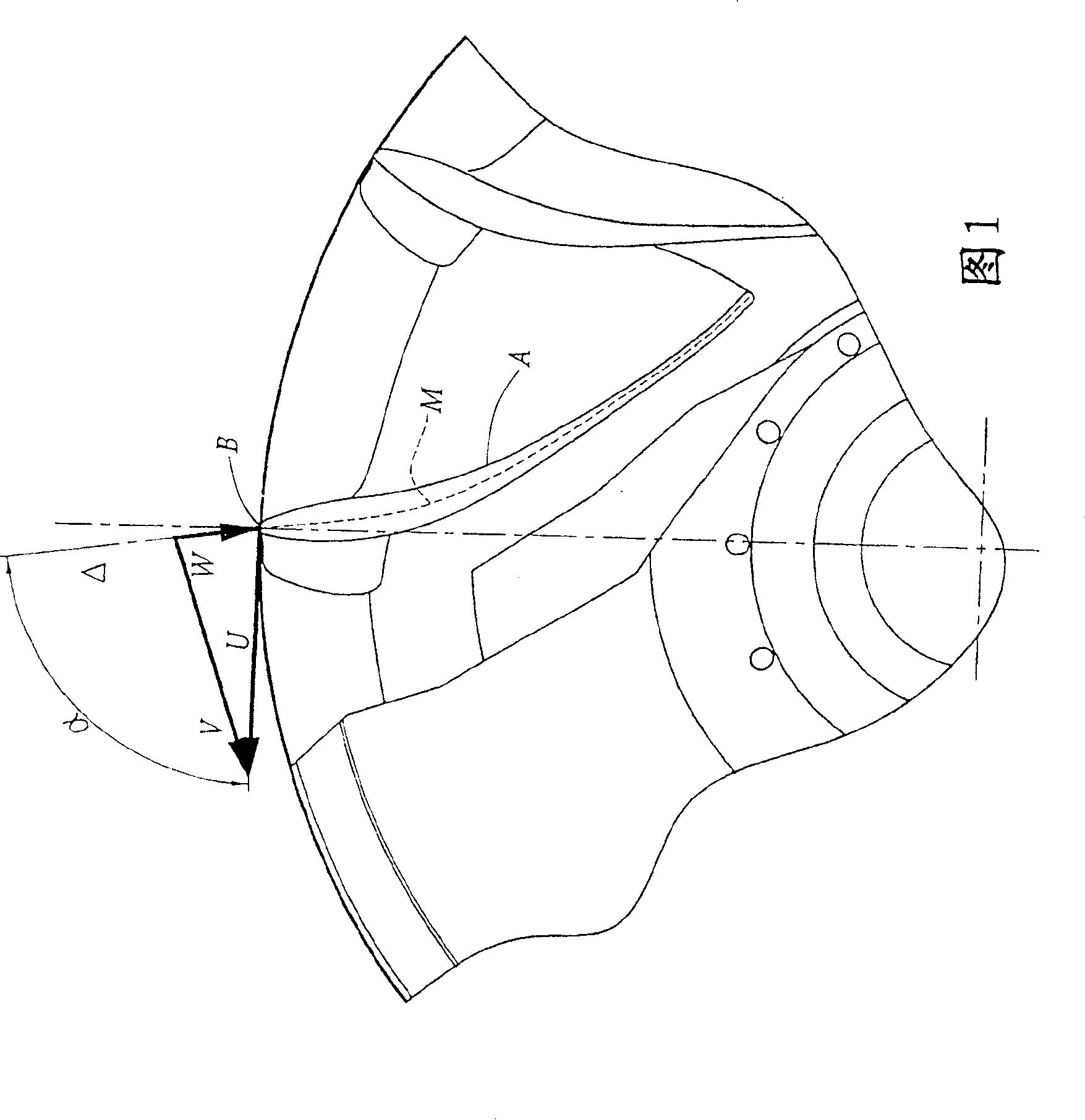

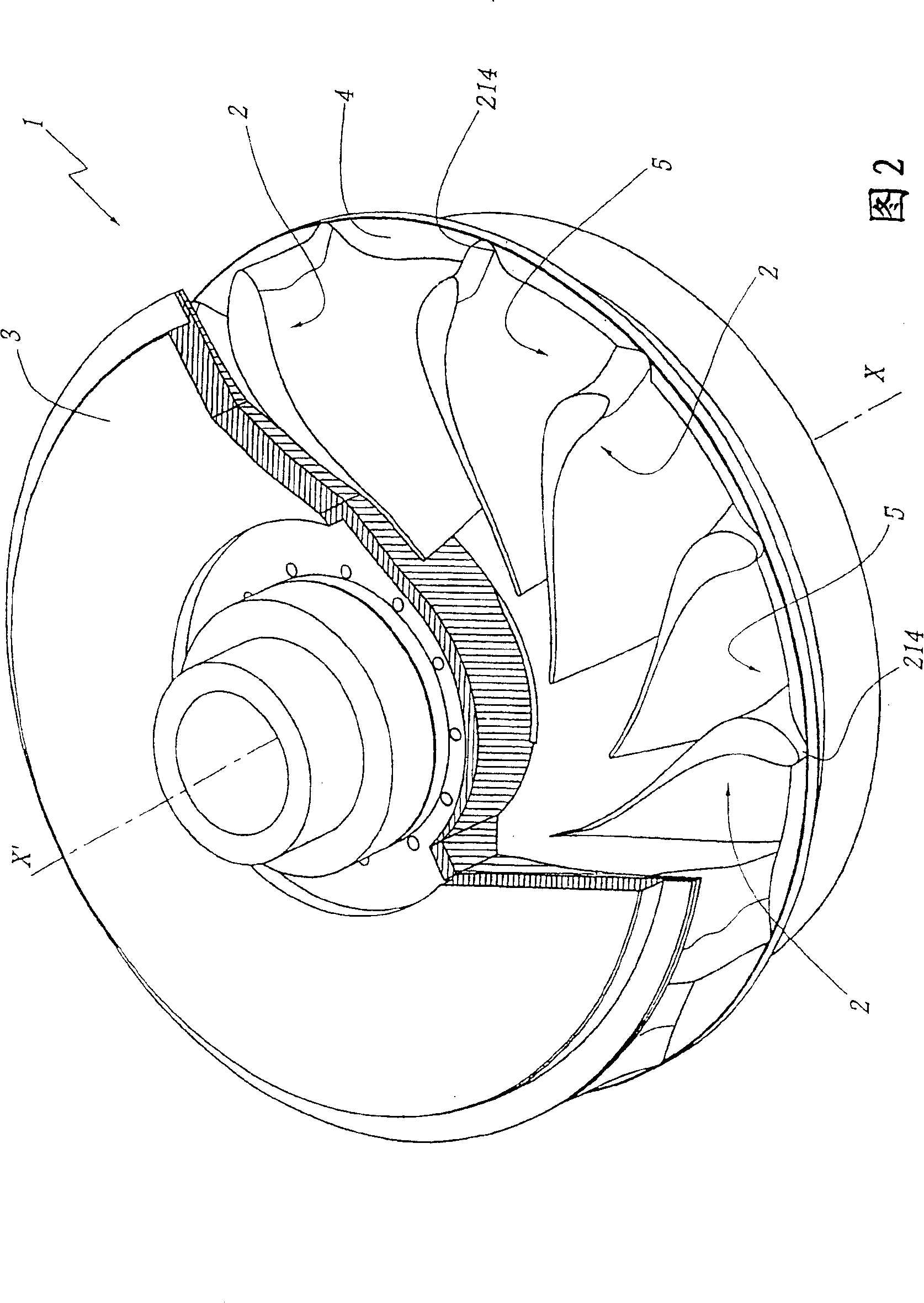

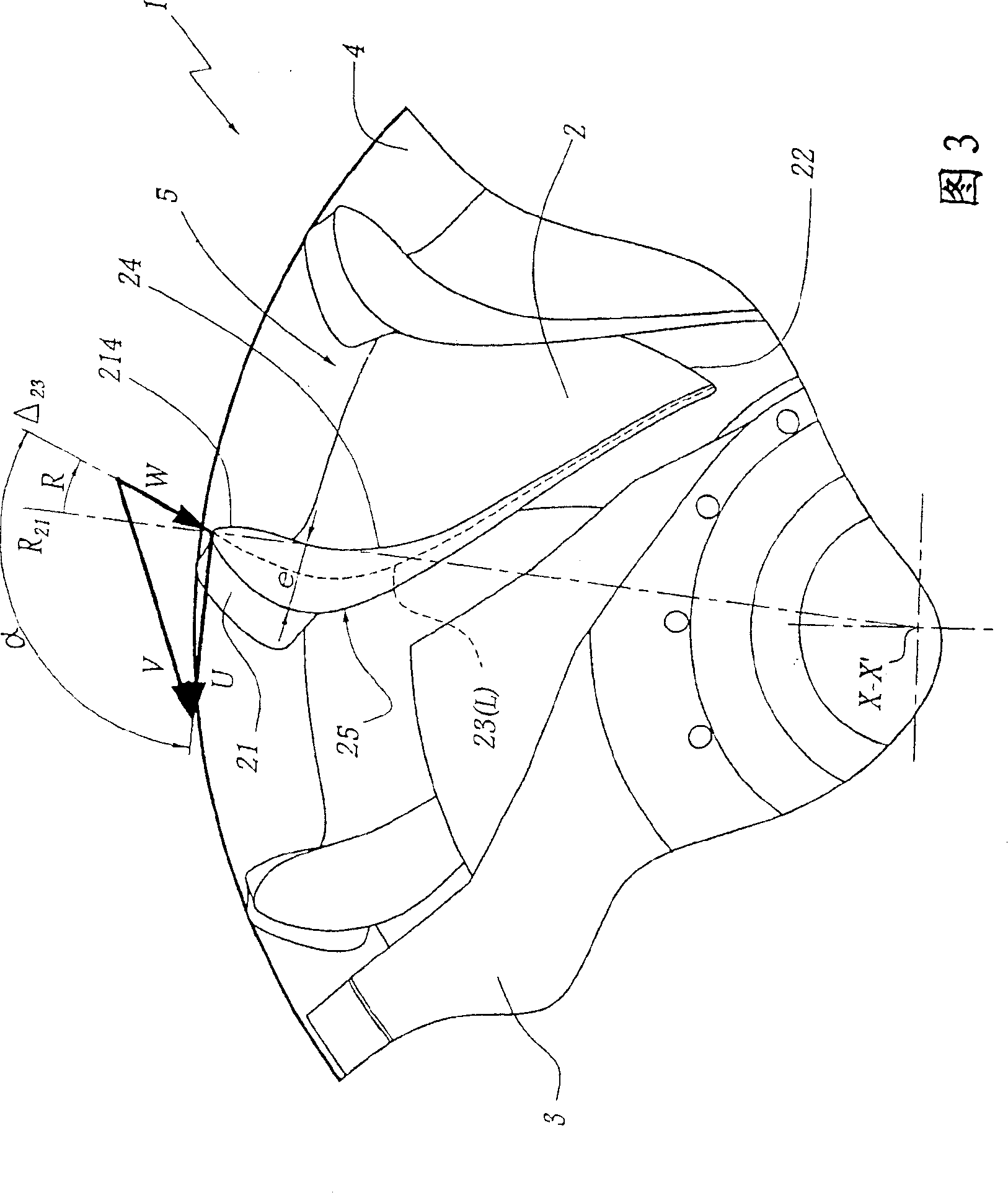

[0020] [20] Fig. 2 to Figure 4 The impeller 1 shown comprises a number of identical blades 2 distributed around the central axis of rotation XX' of the impeller 1 . A top plate 3 is provided on the upper part of the impeller 1 , while a tire 4 serves as the lower boundary of the radially outer portion of the blade 2 . Thus, a flow channel 5 is formed between each pair of adjacent blades 2 , this channel being delimited by the top plate 3 and the rim 4 .

[0021] [21] Reference numeral 21 refers to the flow edge of the blade 2 . 22 designates the overflow edge of the blade. The bisector 23 of the blade 2 is defined as: the curve at the same distance from the lower surface 24 and the upper surface 25 of the blade 2 on each cross-section of the blade.

[0022] [22] L refers to the average length of the bisector 23, which is considered to be equal to half the sum of the two length values of the bisector, one of which is the length of the blade 2 on the plane of the top plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com