Francis turbine runner with ultra-low specific rotating speed specially used for driving cooling tower fan

A specific speed, turbine technology, used in machines/engines, hydroelectric power generation, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

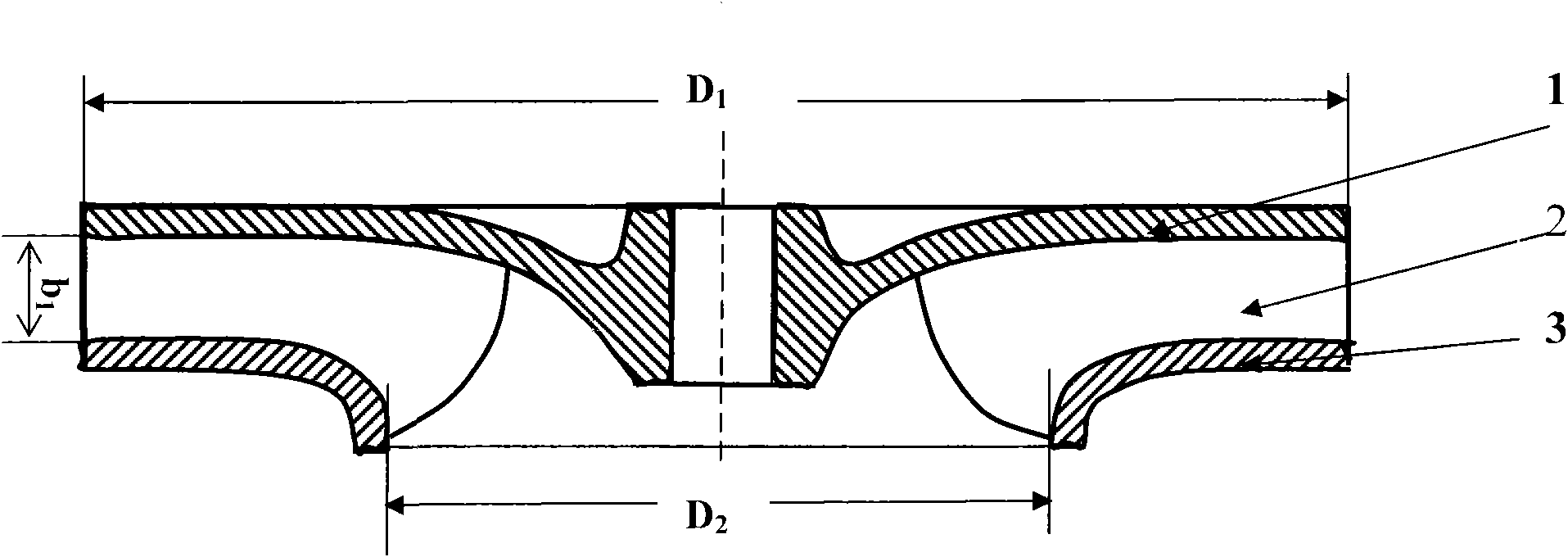

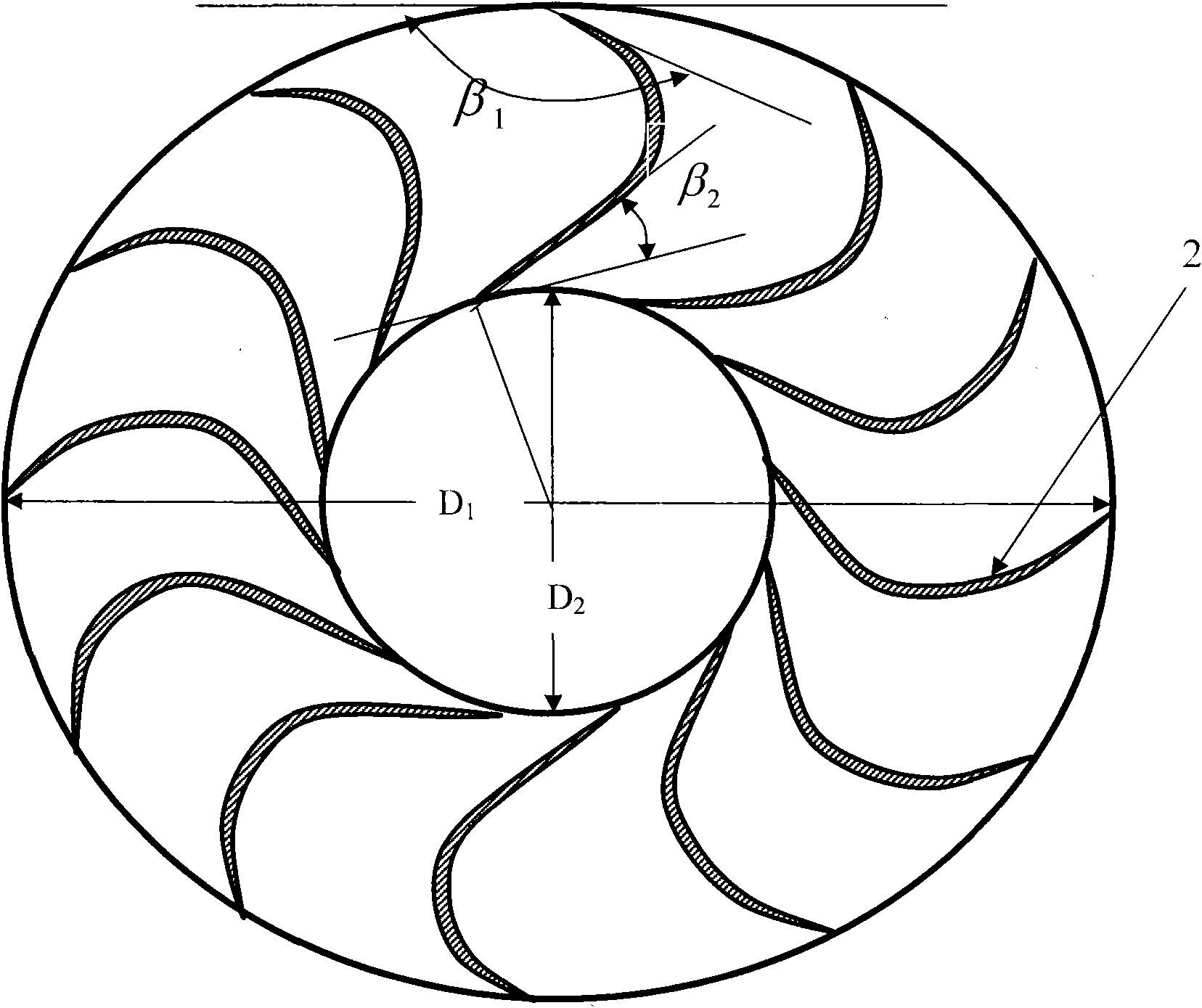

[0011] Depend on figure 1 , 2 As shown, the present invention includes a water turbine runner flow path formed by an upper crown 1, blades 2 and lower ring 3, and the blades are evenly distributed between the upper crown 1 and the lower ring 3 in the shape of an airfoil section, and the runner has a larger progress , Outlet diameter ratio, inlet diameter D 1 with outlet diameter D 2 than (D 1 / D 2 ) is 1.5 to 2.5, that is, the inlet diameter D 1 1.5 to 2.5 times the diameter of the outlet, the height of the inlet side of the runner b 1 With runner inlet diameter D 1 ratio (b 1 / D 1 ) between 0.07 and 0.1, the ratio is equal to the relative height of the guide vane of the turbine, and the specific speed n s It is 60-70m.kW (the specific speed refers to the speed of the turbine itself when the water head is 1m and the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com