Split cable trough of scraper conveyer

A scraper conveyor and cable trough technology, applied in electrical components and other directions, can solve the problems of increased labor, increased safety hazards, unfavorable transportation and underground installation in mines, etc., to facilitate maintenance, reduce work intensity, and improve assembly efficiency. and safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

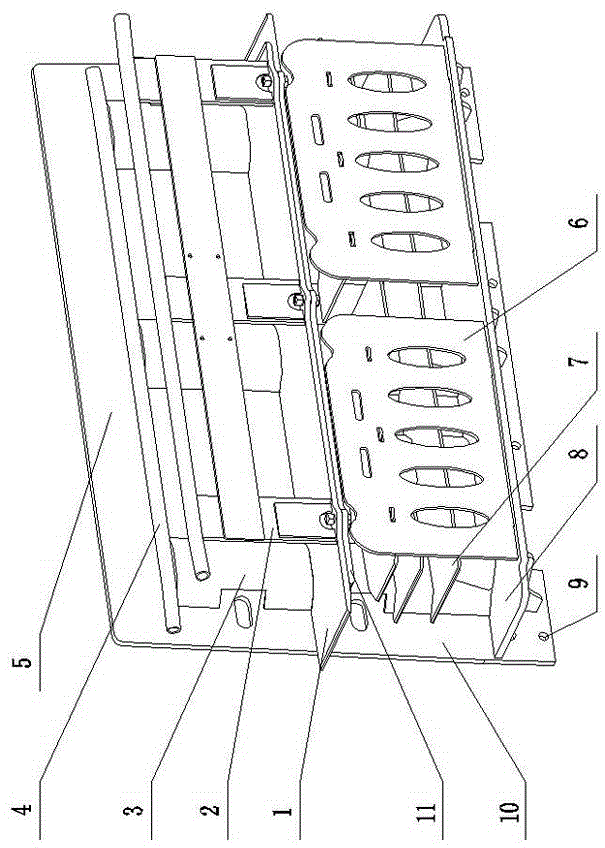

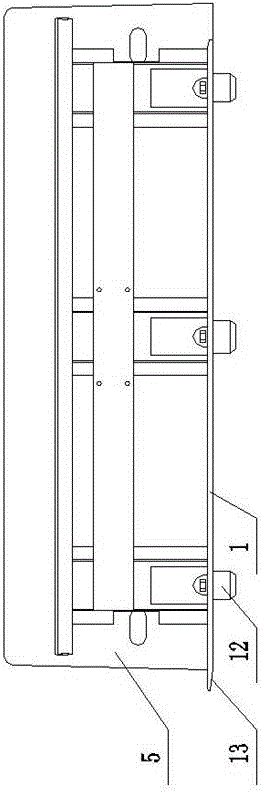

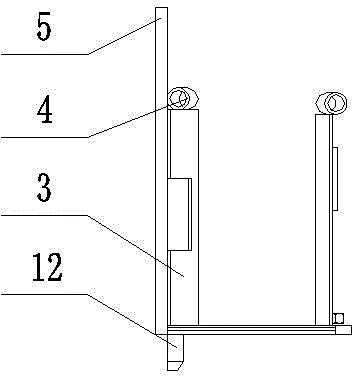

[0017] A split type cable trough for a scraper conveyor, comprising an upper trough body and a lower trough body, the upper trough body of the cable trough is an opening composed of an upper outer vertical plate 5, an upper inner baffle plate 2 and an upper supporting plate 1 Upward U-shaped trough, on the inner side of the upper outer vertical plate and on the top of the upper inner baffle, there are respectively guide pipes 4 for installing cables. The two wire pipes are on the same horizontal plane and parallel to the conveying direction of the scraper conveyor. , both ends of the guide pipe 4 are provided with a bending portion for convenient installation of cables; the lower trough body of the cable trough includes a lower top plate 11 and a lower supporting plate 8, and the lower top plate and the lower supporting plate directly below the upper outer vertical plate There is a lower vertical plate 10 between them, and between the inner lower top plate and the lower support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com