Macromolecule material cold keeping agent making method

A technology of polymer material and cooling agent, which is applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of high cost, slow water absorption, and small water absorption, and achieve the effect of low cost of raw materials and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

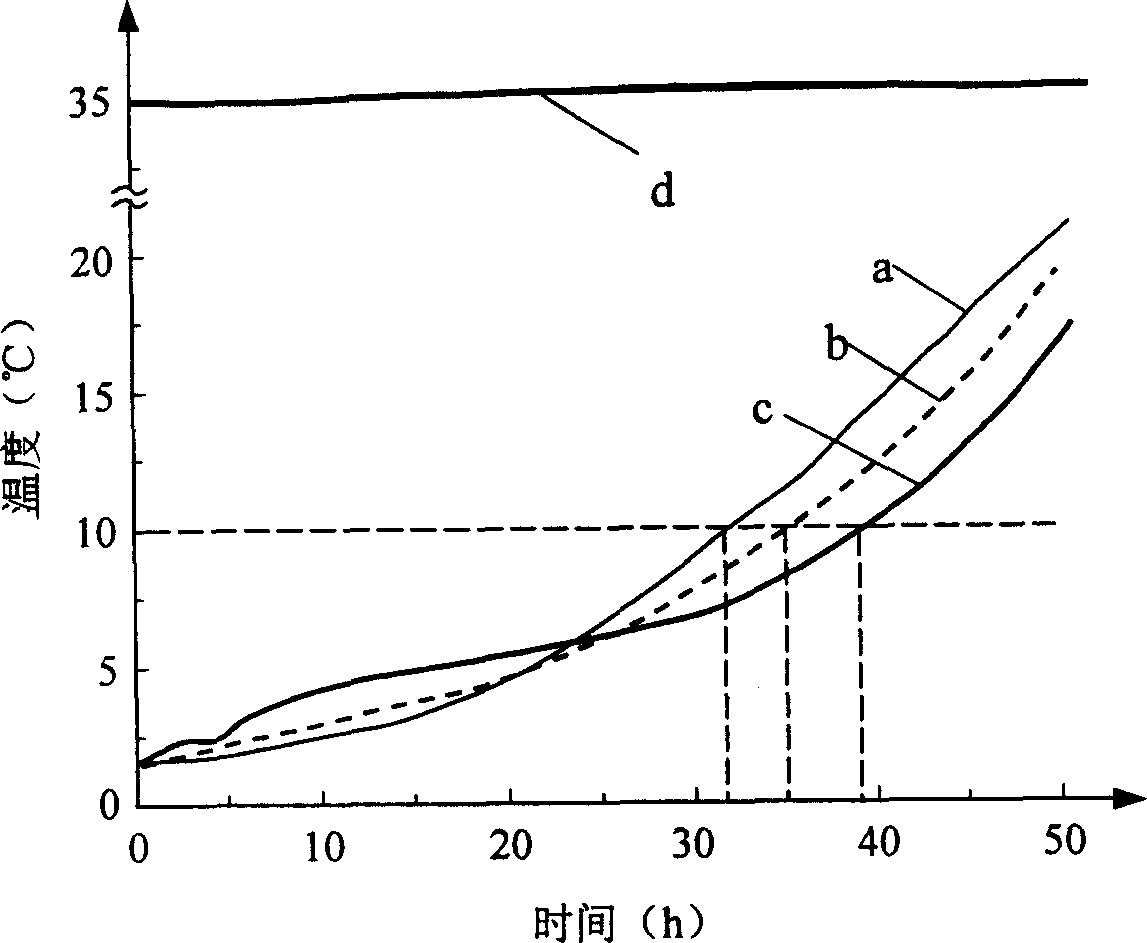

[0027] Using water as a solvent, stirring and preparing an aqueous solution of carboxymethyl cellulose with a mass concentration of 0.2%; adding a neutralization degree of 70% and a mass composition of 0.87 parts of acrylic acid, 0.1 part of hydroxyethyl methacrylate and 0.03 parts of carboxymethyl cellulose to the solution Part of maleic anhydride monomer, mix uniformly; then add 0.03% ethylene glycol diacrylate crosslinking agent of total monomer mass, stir evenly; finally add potassium persulfate initiator of 0.1% total monomer mass, mix uniformly, React for 1 hour at 55°C and normal pressure. Dry at 100°C for 2.5 hours, crush to 200 meshes, and obtain a white powdery polymer material, which is mixed with water to form a mixture with a concentration of 0.7%, and it can be fully dissolved in 40 seconds, forming a translucent colloid in actual use coolant. The solid-liquid phase transition temperature of the cold storage agent is -3°C, the specific heat of colloid is 4.9kJ / k...

Embodiment 2

[0029] Using water as a solvent, stir to form an aqueous solution of sodium polyacrylate with a mass concentration of 0.6%; add 0.8 parts of acrylic acid with a neutralization degree of 60% and a mass composition of 0.13 parts of hydroxyethyl methacrylate and 0.07 parts of Maleic anhydride monomer, mix well; then add ethylene glycol diacrylate crosslinking agent with 0.1% of total monomer mass, stir well; finally add potassium persulfate initiator with 0.02% total monomer mass, mix well, 70°C , Reverse 0.5 hours under normal pressure conditions. Dry at 110°C for 2 hours, crush to 150 meshes, and obtain a white powdery polymer material, which is mixed with water to form a mixture with a concentration of 0.85%, and it can be fully dissolved in 60 seconds, forming a translucent colloid in actual use coolant. The solid-liquid phase transition temperature of the cold storage agent is -2°C, the specific heat of colloid is 4.7kJ / kg.K, and the latent heat of phase transition is 324kJ...

Embodiment 3

[0031] Using water as a solvent, stir to form an aqueous solution of carboxymethyl starch with a mass concentration of 1%; add a neutralization degree of 75% and a mass composition of 0.9 parts of acrylic acid and 0.1 part of hydroxyethyl methacrylate monomer to the solution, Mix evenly; then add 0.3% of the total monomer mass of ethylene glycol diacrylate crosslinking agent, and stir evenly; finally add 0.5% of the total monomer mass of potassium persulfate initiator, mix evenly, and react at 45°C under normal pressure conditions 1.5 hours. Dry at 105°C for 4 hours, crush to 200 meshes, and obtain a white powdery polymer material, which is mixed with water to form a mixture with a concentration of 1.1%, and it can be fully dissolved in 80 seconds, forming a translucent colloid in actual use coolant. The solid-liquid phase transition temperature of the cold storage agent is -5°C, the specific heat of colloid is 5.2kJ / kg.K, and the latent heat of phase transition is 343kJ / kg. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com