Modular handguard device for a firearm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

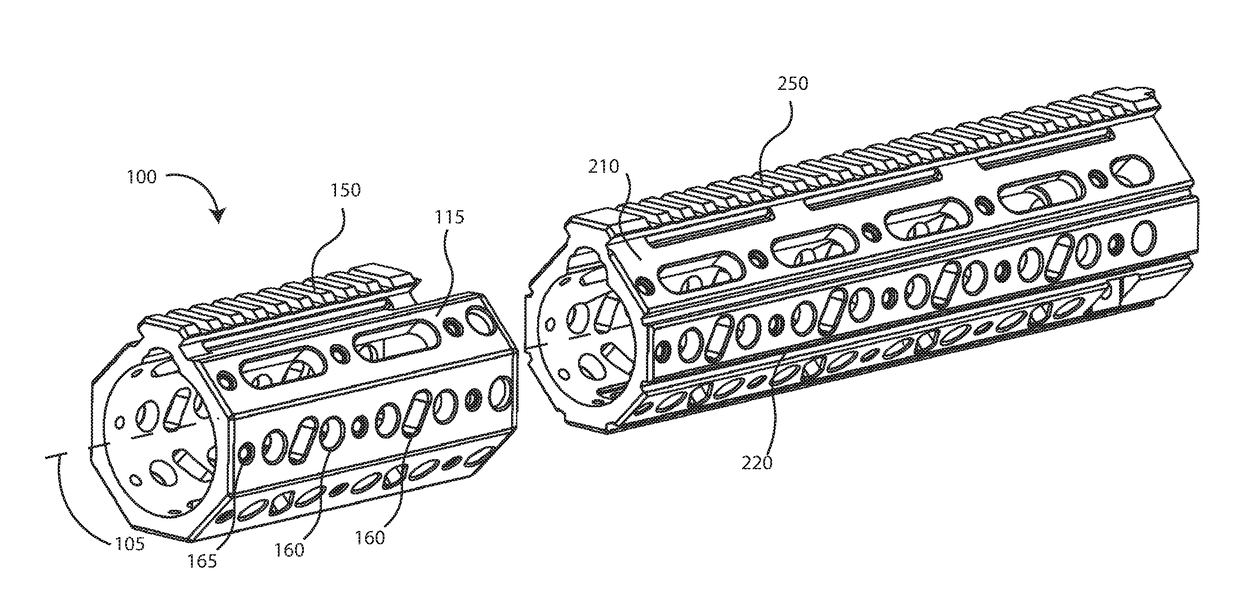

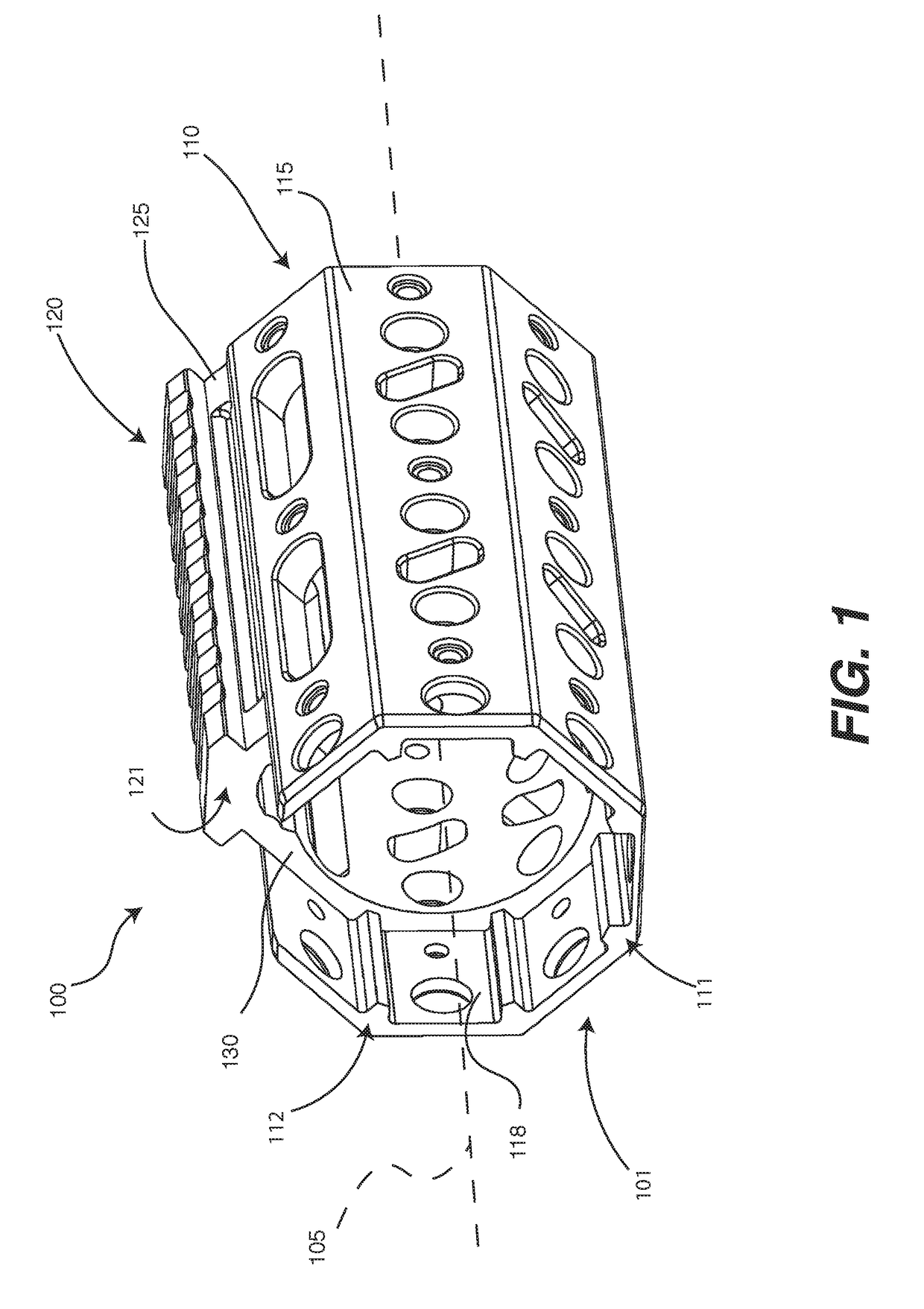

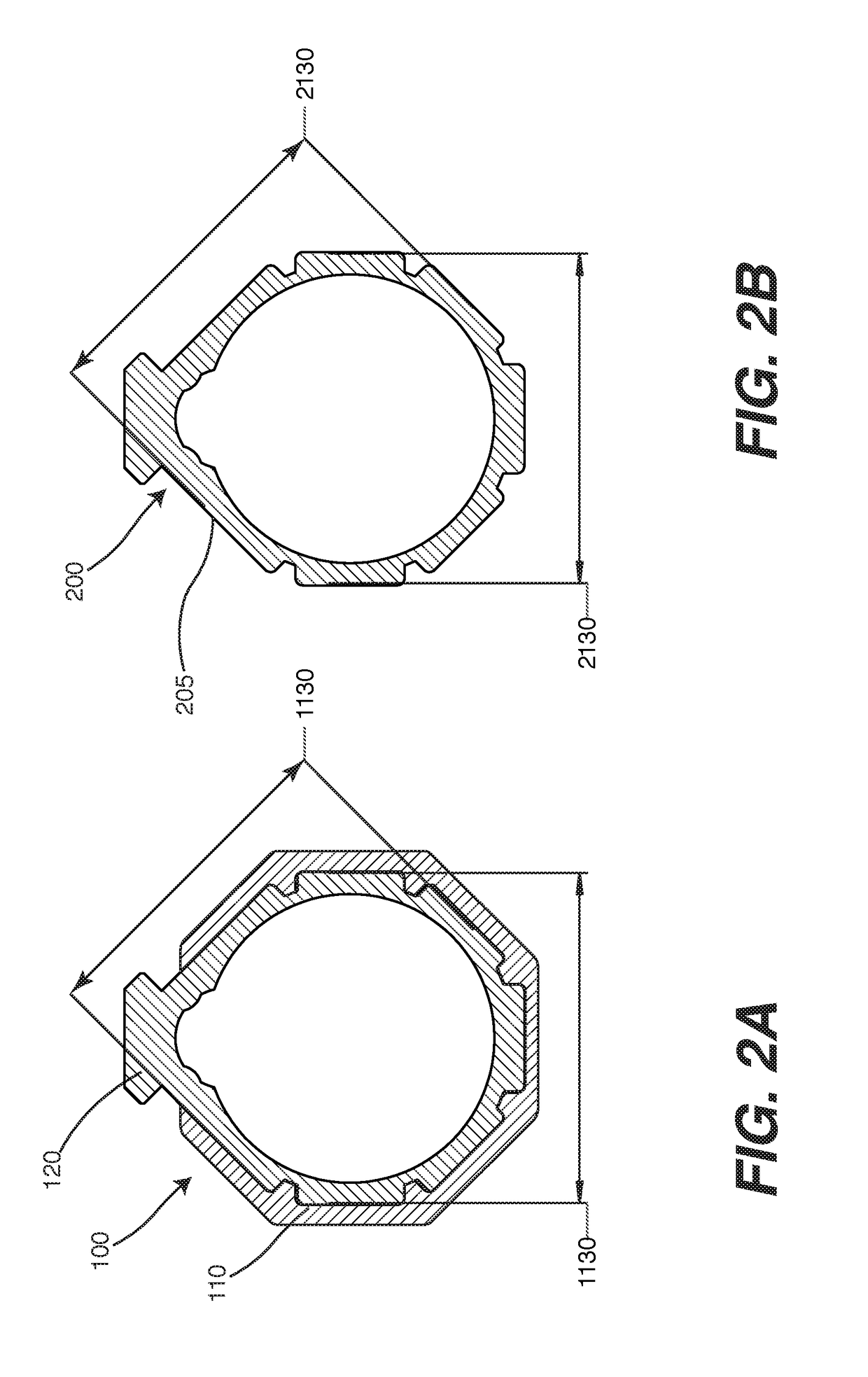

[0026]Certain embodiments of the invention comprise a modular handguard configured to be disposed over a barrel or suppressor component at a distal end of a barrel. Such embodiments of the modular handguard are configured to mate with an affixed handguard. The modular handguard mitigates accidental contact with distal surfaces of a firearm having elevated temperature such as a barrel or suppressor affixed to the firearm.

[0027]It will be appreciated that an affixed handguard may comprise an existing handguard comprising aluminum or steel, or a heat mitigating handguard as disclosed in U.S. application Ser. No. 14 / 932,924, Heat Mitigating Handguards for Rifles and Method of Manufacture Thereof, to Garst (“the '924 Application”), incorporated by reference in its entirety.

[0028]Certain embodiments comprise a modular handguard comprising a heat mitigating material composition with a low heat transfer coefficient. Certain embodiments of the present invention are manufactured from material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com