Marine flowing type evaporator and application method thereof

A flow-type, evaporator technology, applied in the direction of evaporator/condenser, heat exchanger shell, indirect heat exchanger, etc., can solve the problem of low replacement efficiency of evaporator, high refrigerant injection volume, and poor oil return effect To achieve the effect of compact structure, low refrigerant charge and high degree of freedom in structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

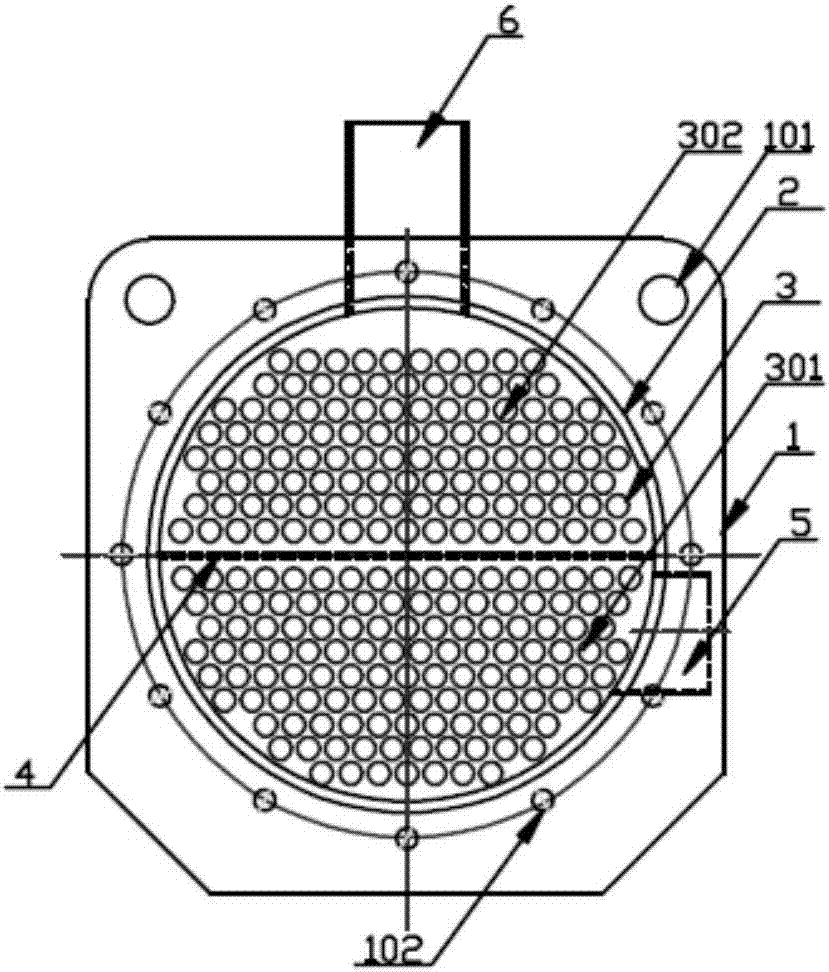

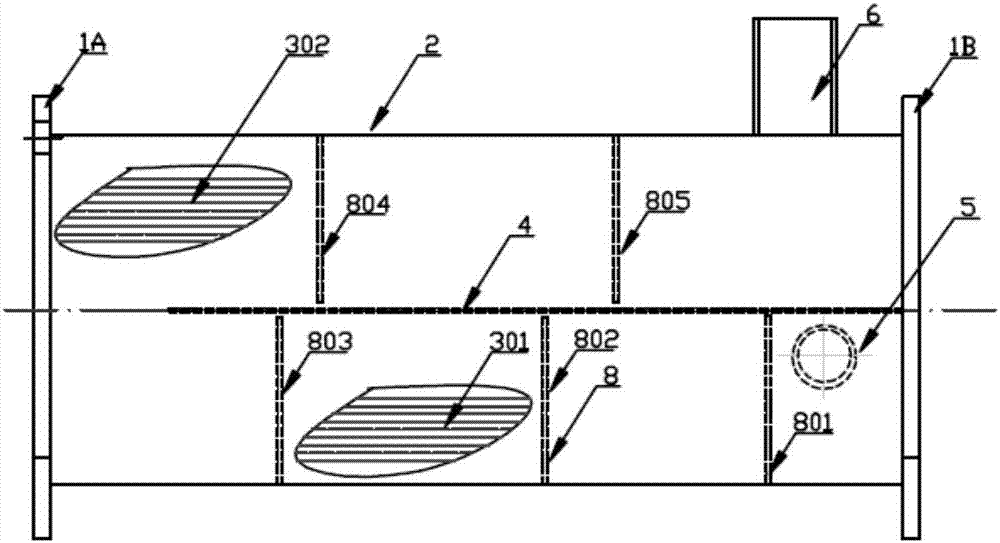

[0040] This example is a flow-type evaporator used in a refrigeration and air-conditioning system with a cooling capacity of 500kW, a chilled water return temperature of 12°C, an outlet water temperature of 7°C, and an evaporation temperature of 6.5°C. The model is FJE150. figure 1 and figure 2 It is installed by the structure, which is composed of end plate 1, cylinder body 2, evaporation tube bundle 3, partition plate 4, liquid inlet 5, air outlet pipe 6, baffle plate 8; end plate 1 and the outer diameter φ500, length 3000mm The steel cylinder 2 forms a closed space, and the air outlet pipe 6 with an outer diameter of φ100mm is arranged vertically near the water outlet, on the upper part of the cylinder 2; the evaporation tube bundle 3 and the end plate 1 are fixed by expansion joints or welding, and the partition plate 4 will evaporate The tube bundle is divided into upper and lower areas, the first evaporation area 301 and the second evaporation area 302, and the flow num...

Embodiment 2

[0045] Figure 7 and Figure 8 It is a combination of flow evaporators. The relative position is stacked up and down. The outlet of the lower flow evaporator is the inlet of the upper flow evaporator, which is realized through the pipeline 9. The combination includes a refrigerant liquid inlet 5 and a gas outlet 6 , the spacing of the baffles 8B becomes larger along the refrigerant flow direction, and the flow evaporator has no partition 4 .

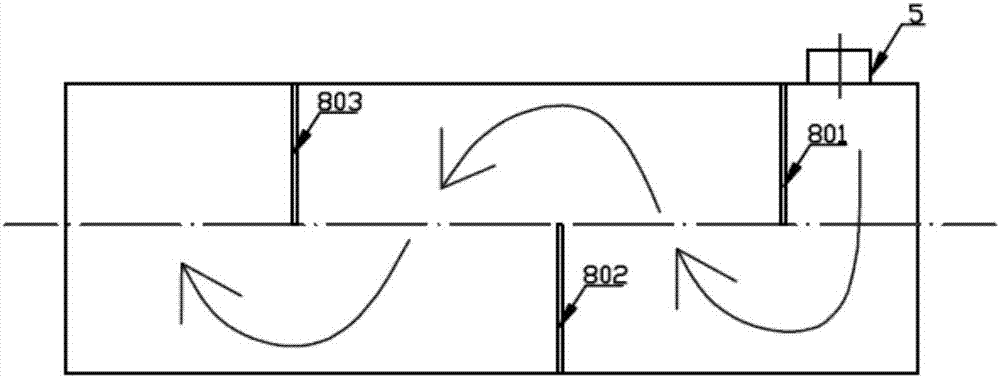

[0046] like Figure 9 As shown, the refrigerant flows in the flow evaporator combination under the action of the baffle plate 8 .

[0047] Both the inside and the outside of the heat exchange tube are subjected to heat exchange enhancement treatment, coupled with the flushing of the refrigerant, the heat transfer coefficient of the present invention is better than that of flooded evaporators and falling film evaporators, due to the simple design and simple manufacture , the cost of this heat exchanger is better than that of the fallin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com