Exhaust gas turbocharger

A technology of exhaust gas turbine and supercharger, which is applied to gas turbine devices, jet propulsion devices, machines/engines, etc., and can solve problems affecting the function of exhaust gas turbochargers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

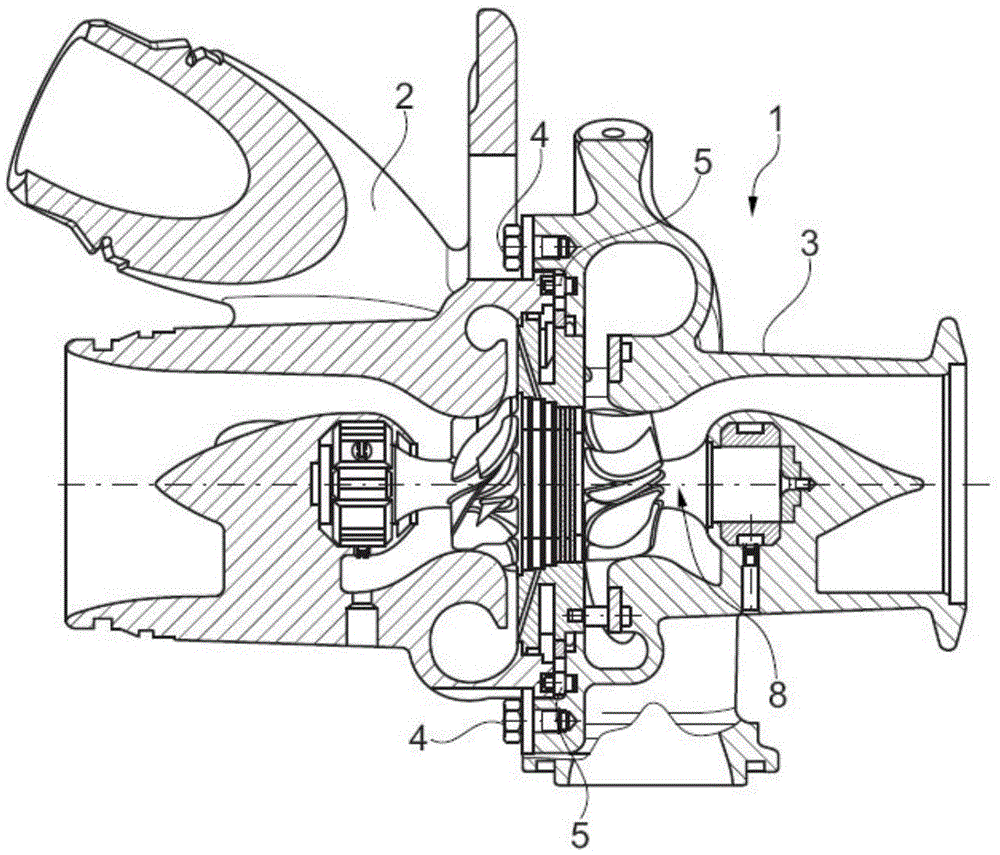

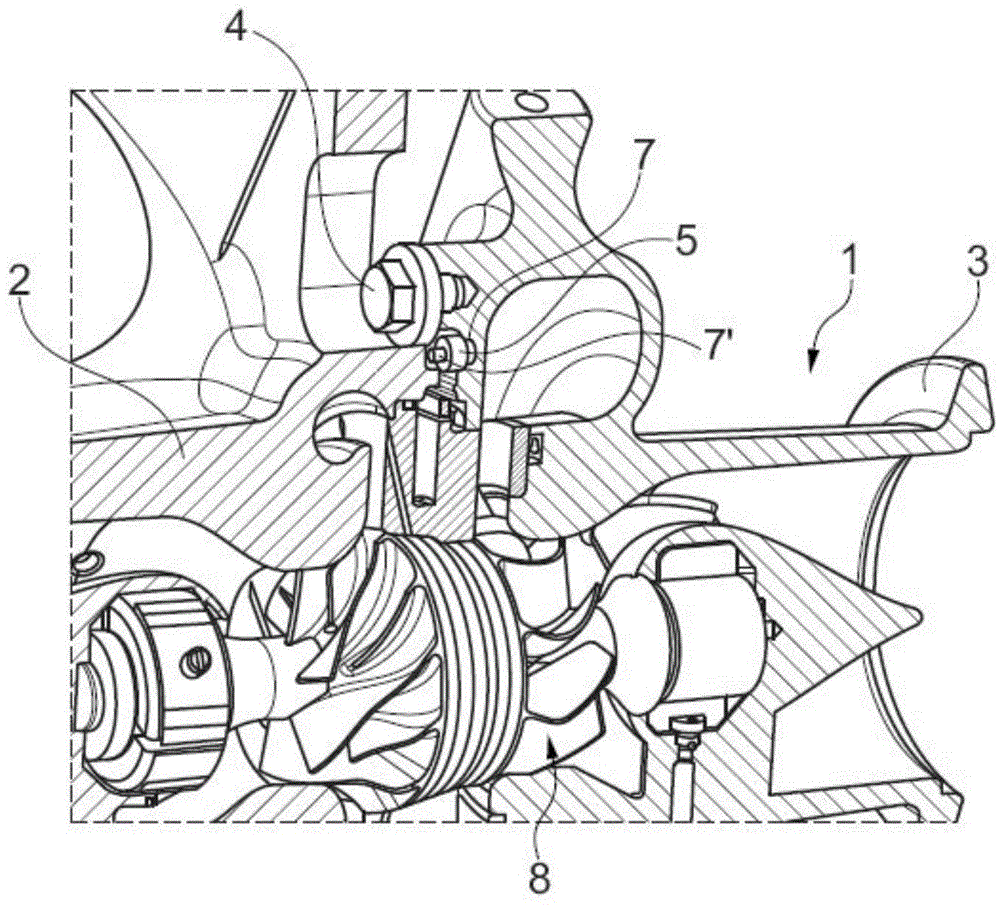

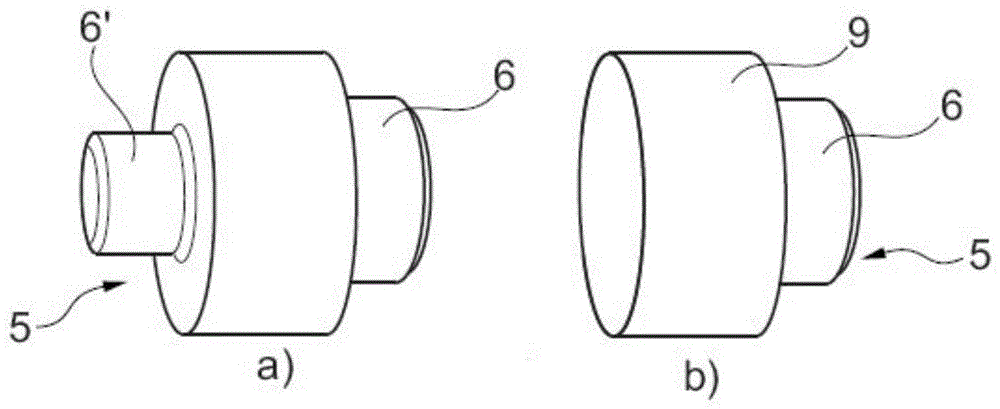

[0022] according to figure 1 , figure 2 and Figure 7 , the exhaust gas turbocharger 1 according to the invention comprises a compressor housing 2 and a turbine housing 3 . The compressor housing 2 is in this case screwed to the turbine housing 3 via bolts 4 . According to the invention, the turbine housing 3 is now connected to the compressor housing 2 via at least three insulating spacer pins 5 . Obviously, four or more spacer pins 5 can also be provided here. According to the invention, these spacer pins 5 are formed of a thermally insulating material, such as ceramic, especially zirconia, with the result that at least the heat transfer between the relatively hot turbine housing 3 and compressor housing 2 is minimized. For the illustrated embodiment of the exhaust gas turbocharger 1 according to the invention, the bearing housing normally arranged between the compressor housing 2 and the turbine housing 3 has been omitted, so that the two housing parts 2 , 3 are mutual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com