Polymerization method for preparing rare earth isoprene rubber

A technology of rare earth isoprene rubber and polymerization method, which is applied in the field of rubber polymerization, which can solve the problems of decreased quality of polymerized products, increased material viscosity, uneven material concentration, and uneven temperature distribution, and achieves the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Under normal temperature and pressure, firstly, the isoprene monomer (23.5kg / h, polymerization grade, commercially available), solvent (152kg / h, used here The solvent is cyclohexane, commercially available) and neodymium catalyst (4.5kg / h, the concentration is 6×10 -6 molNd / ml, the solvent is cyclohexane, and the specific composition of the neodymium catalyst used here is isoprene according to the molar ratio of each component: neodymium neodecanoate: triisobutylaluminum: diethyl chloride Aluminum=50:1:10:3, the catalyst is prepared by the applicant and the prepared neodymium catalyst is diluted to the above concentration with cyclohexane) premixed in a traditional kettle premixer, the premixing time 10min.

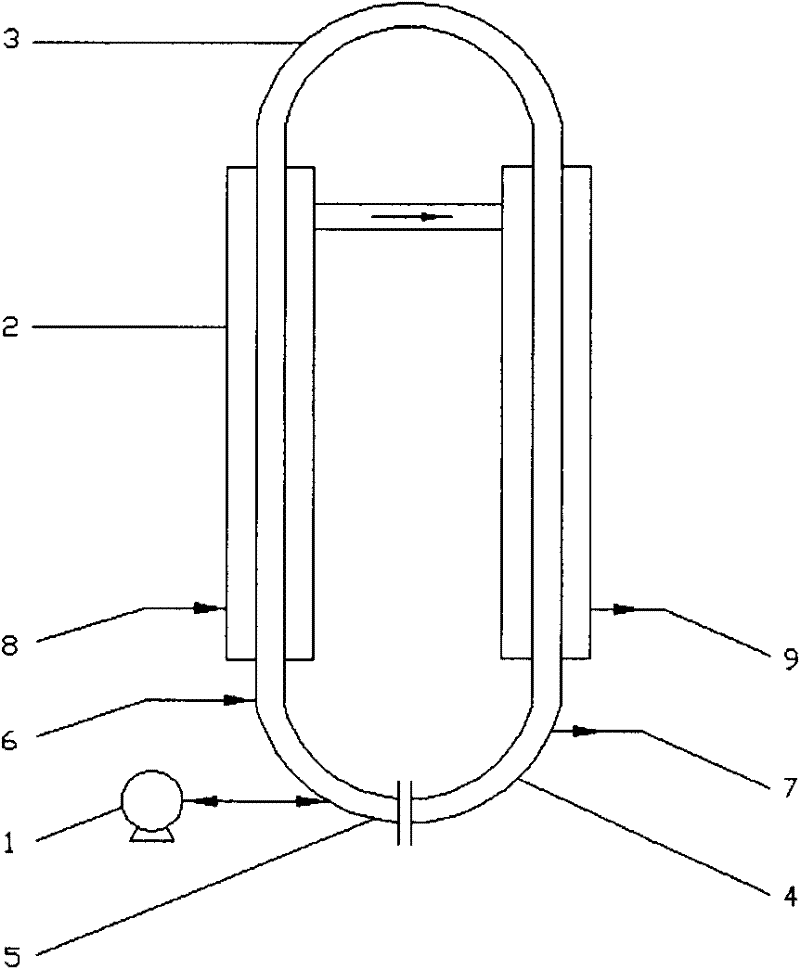

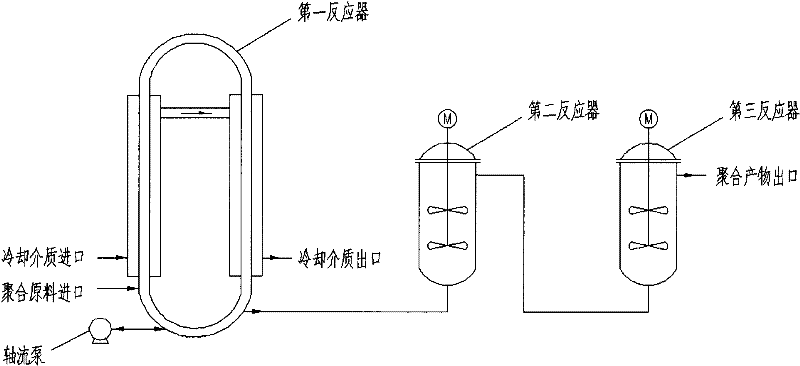

[0047] Then, follow figure 2 The scheme shown operates by feeding the polymerization reaction mass formed after premixing into the loop reactor. Under the action of the axial flow pump, the polymerization reaction material circulates rapidly in the loop reactor...

Embodiment 2

[0052] Example 1 is basically repeated, except that the Q of the loop reactor is made r / Q out for 100.

[0053] According to this embodiment, after the reaction in the loop reactor, the outlet conversion rate of isoprene monomer reaches 54wt%. The final conversion of monomer reached 97 wt%, and the temperature in the third full mixing tank rose to 50°C.

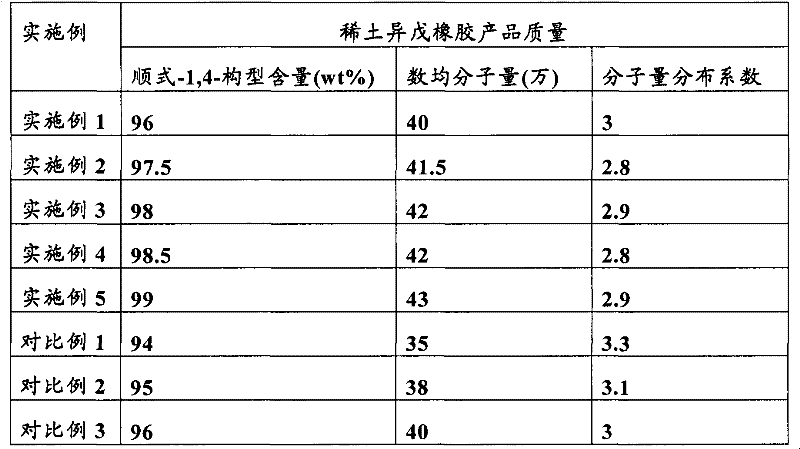

[0054] The quality analysis results of the rare earth isoprene rubber product obtained after the completion of the reaction are listed in Table 1 below.

Embodiment 3

[0056] Example 1 is basically repeated, except that the Q of the loop reactor is made r / Q out for 120.

[0057] According to this embodiment, after the reaction in the loop reactor, the outlet conversion rate of isoprene monomer reaches 56wt%, and after continuing the adiabatic reaction in the second and third fully mixed tanks in series, the isoprene The final conversion of monomer reached 97.5 wt%, and the temperature in the third full mixing tank rose to 51 °C.

[0058] The quality analysis results of the rare earth isoprene rubber product obtained after the completion of the reaction are listed in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com