Air quenching method of circular saw web

An air quenching, circular saw blade technology, applied in the field of heat treatment, can solve the problems of large deformation and cracking tendency of materials, difficult cooling speed control, poor temperature uniformity, etc., and achieves low auxiliary costs, large cooling speed adjustment range and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

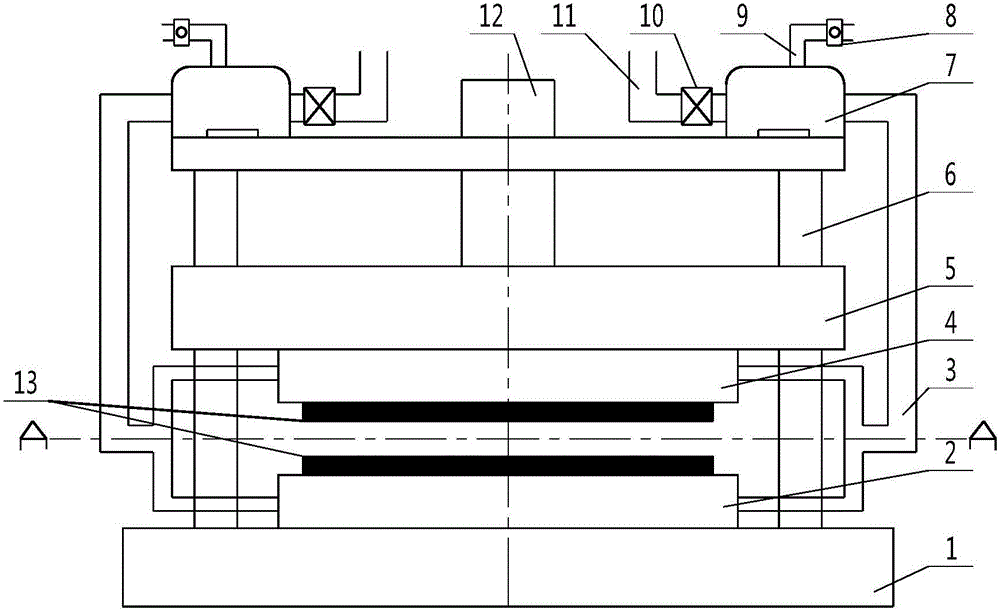

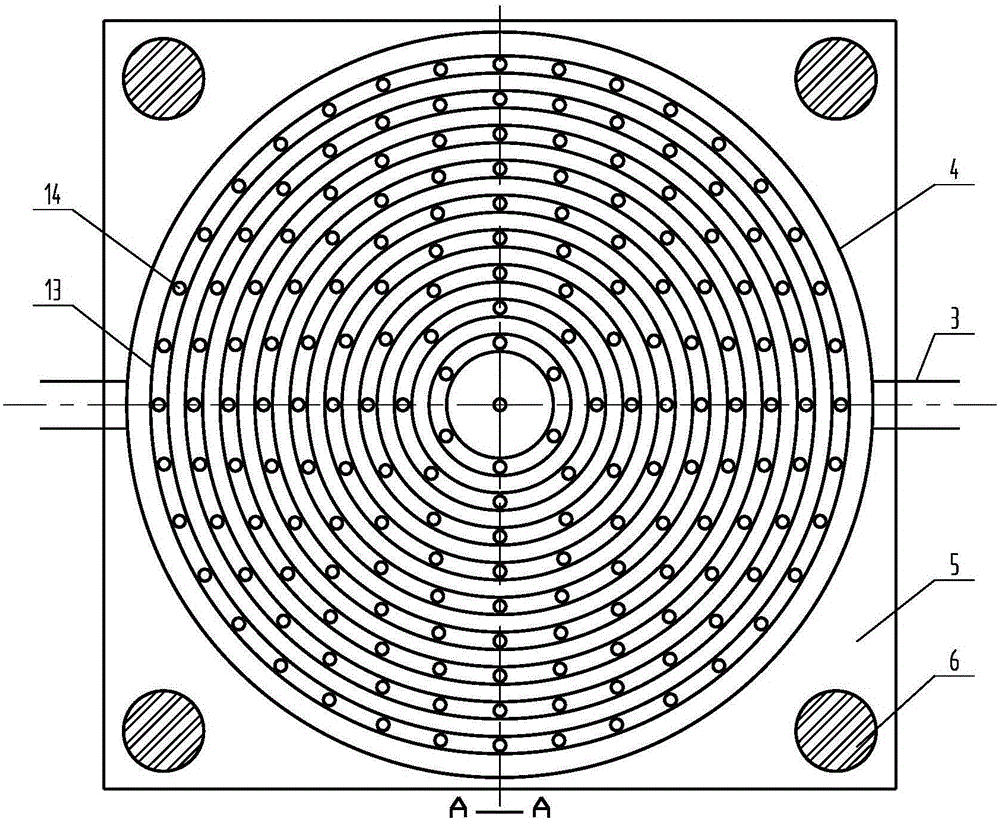

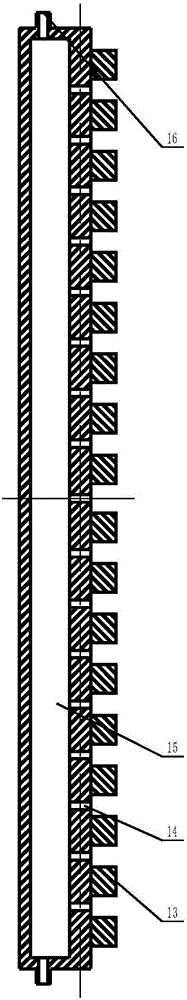

[0057] As shown in the figure, a saw blade air quenching device is characterized in that: the lower pressure plate 2 is installed in the lower support seat 1, the upper pressure plate 4 is installed in the upper support seat 5, and the upper pressure plate 4 and the lower pressure plate 2 There are annular diversion grooves 13 and nozzles 14, air inlets 16 at both ends of the upper and lower pressure plates, air chambers 15 inside the upper and lower pressure plates, hydraulic guide columns 6 around the lower pressure plate 2, and upper support The seat 5 reciprocates up and down along the hydraulic guide column 6 through the hydraulic pump 12, the air enters the gas pipe 11, the gas valve 10 can adjust the gas flow, the water enters from the liquid pipe 9, the water valve 8 can control the water flow, and the air and water enter the atomization Atomized gas is formed after the valve 7, and enters the pressure plate from the air pipe 3.

[0058] Working process of the present ...

Embodiment 2

[0065] An air quenching device for circular saw blades, comprising: a frame, upper and lower pressure plates 2, 4, upper and lower pressure plates 2, 4 that can reciprocate up and down are arranged symmetrically on the frame, and the upper and lower pressure plates 2, 4 are symmetrically arranged on the frame. The pressure plates 2 and 4 are respectively provided with air cavities 15, and nozzles 14 are evenly distributed in the upper and lower pressure plates 2 and 4, and the nozzles 14 communicate with the corresponding air cavities, and the air cavities are respectively connected to the air intake pipes. connected.

Embodiment 3

[0067] An air quenching device for circular saw blades, comprising: a frame, upper and lower pressure plates 2, 4, upper and lower pressure plates 2, 4 that can reciprocate up and down are arranged symmetrically on the frame, and the upper and lower pressure plates 2, 4 are symmetrically arranged on the frame. The pressure plates 2 and 4 are respectively provided with air cavities 15, and nozzles 14 are evenly distributed in the upper and lower pressure plates 2 and 4, and the nozzles 14 communicate with the corresponding air cavities 15, and the air cavities 15 are respectively connected to the inlet Air pipe 11 is connected.

[0068] The upper and lower pressure plates 2 and 4 are also provided with annular guide grooves 13 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com