Heat pump drying system

A heat pump drying and water pump technology, applied in drying, heat pump, dryer and other directions, can solve the problems of high condensing temperature, small flow rate, low refrigeration cycle efficiency, etc., and achieve the effect of improving heat transfer coefficient and easy heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

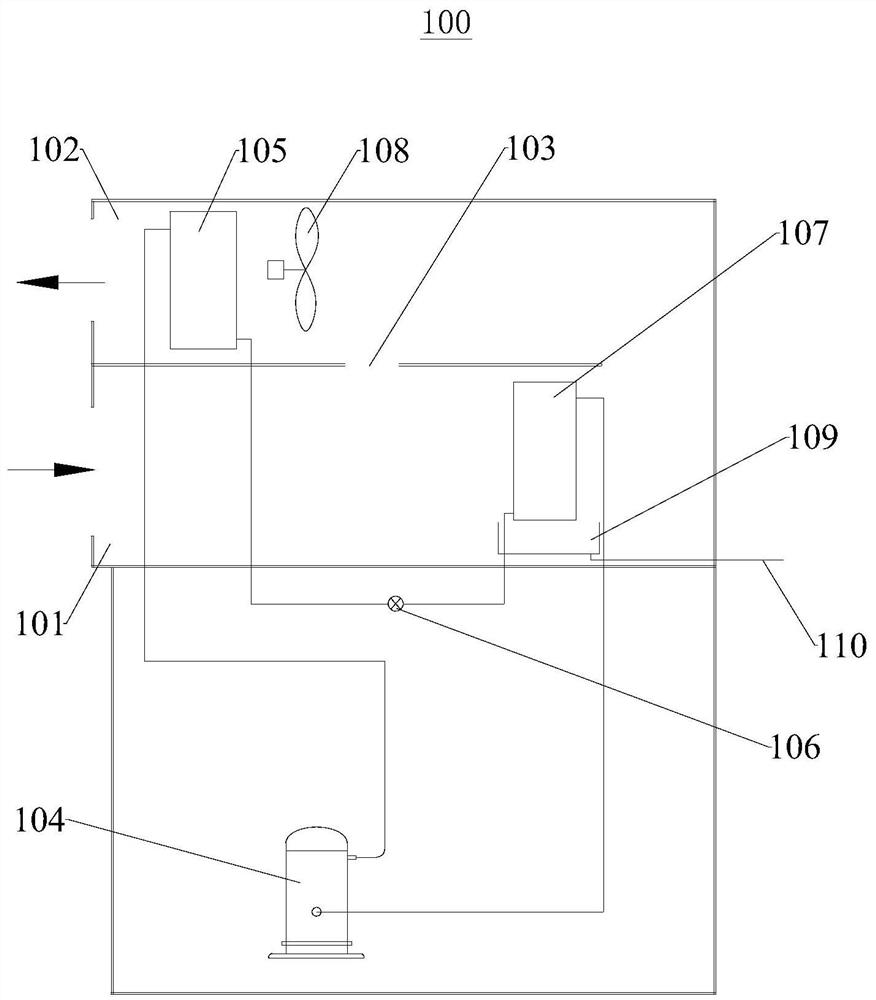

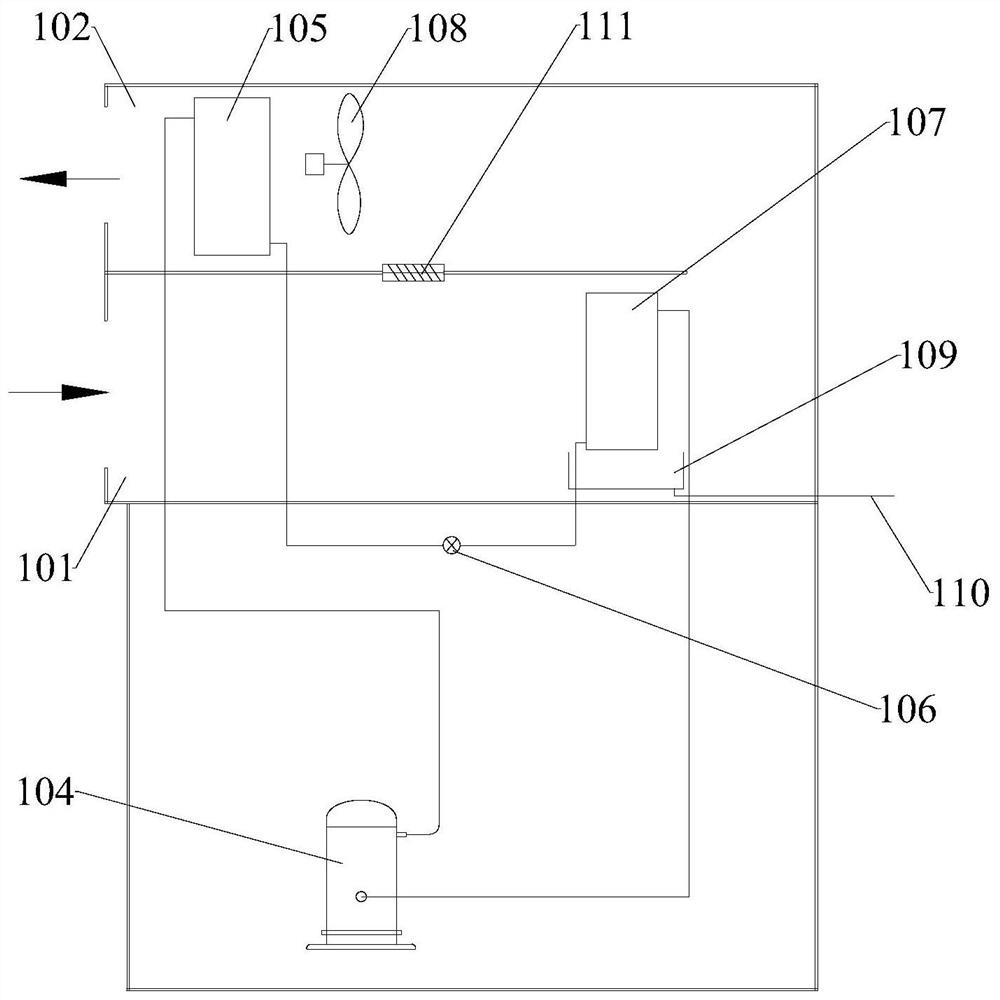

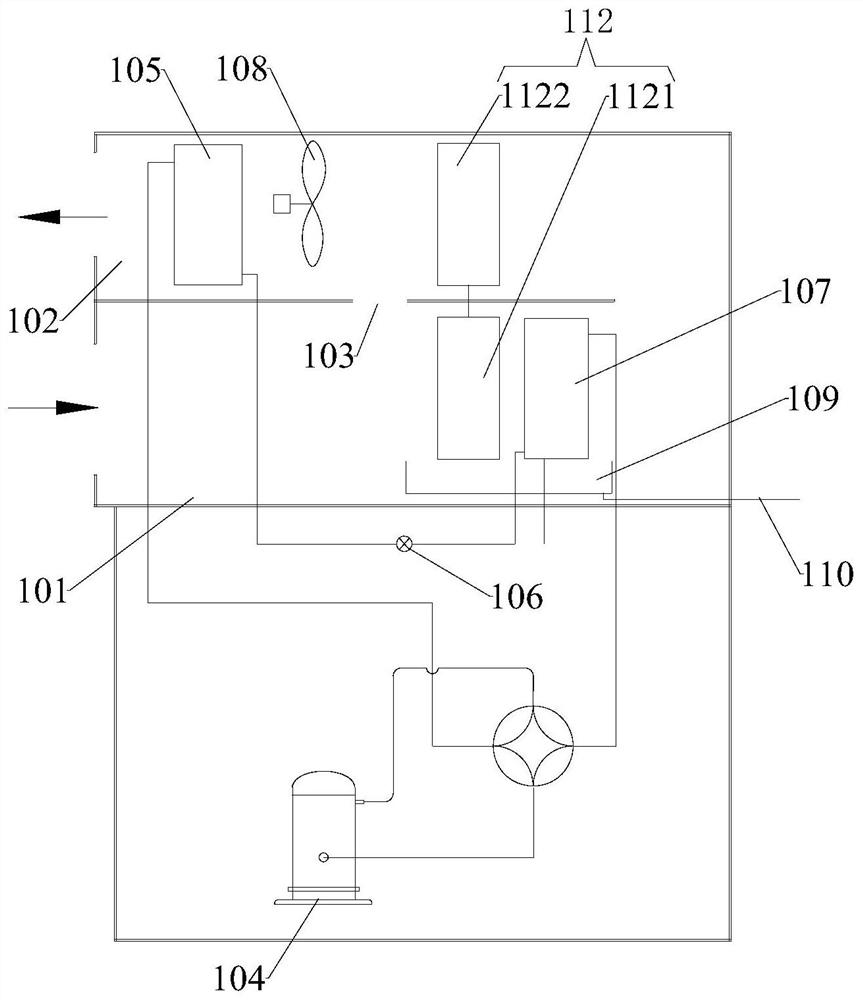

[0036] see figure 1 , the embodiment of the present invention provides a heat pump drying system 100 . The heat pump drying system 100 can be applied to a heat pump drying system to dry crops, medicinal materials, sludge and the like. The embodiment of the present invention can achieve a higher outlet air temperature at a lower condensation temperature, thereby improving the efficiency of the refrigeration cycle and improving the drying treatment efficiency of crops, medicinal materials, sludge, etc.

[0037] In the embodiment of the present invention, the heat pump drying system 100 includes a return air duct 101 , an air supply duct 102 , a bypass air duct ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com