Compressor for a turbocharger and method for cooling thereof

A technology for compressors and compressor impellers, which is applied to parts of pumping devices for elastic fluids, gas turbine devices, machines/engines, etc., and can solve the problems of reducing the life of turbochargers, centrifugal force of small rotating masses, and deterioration efficiency, etc. problem, achieve the effect of reducing the rotating mass, reducing the size and prolonging the life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

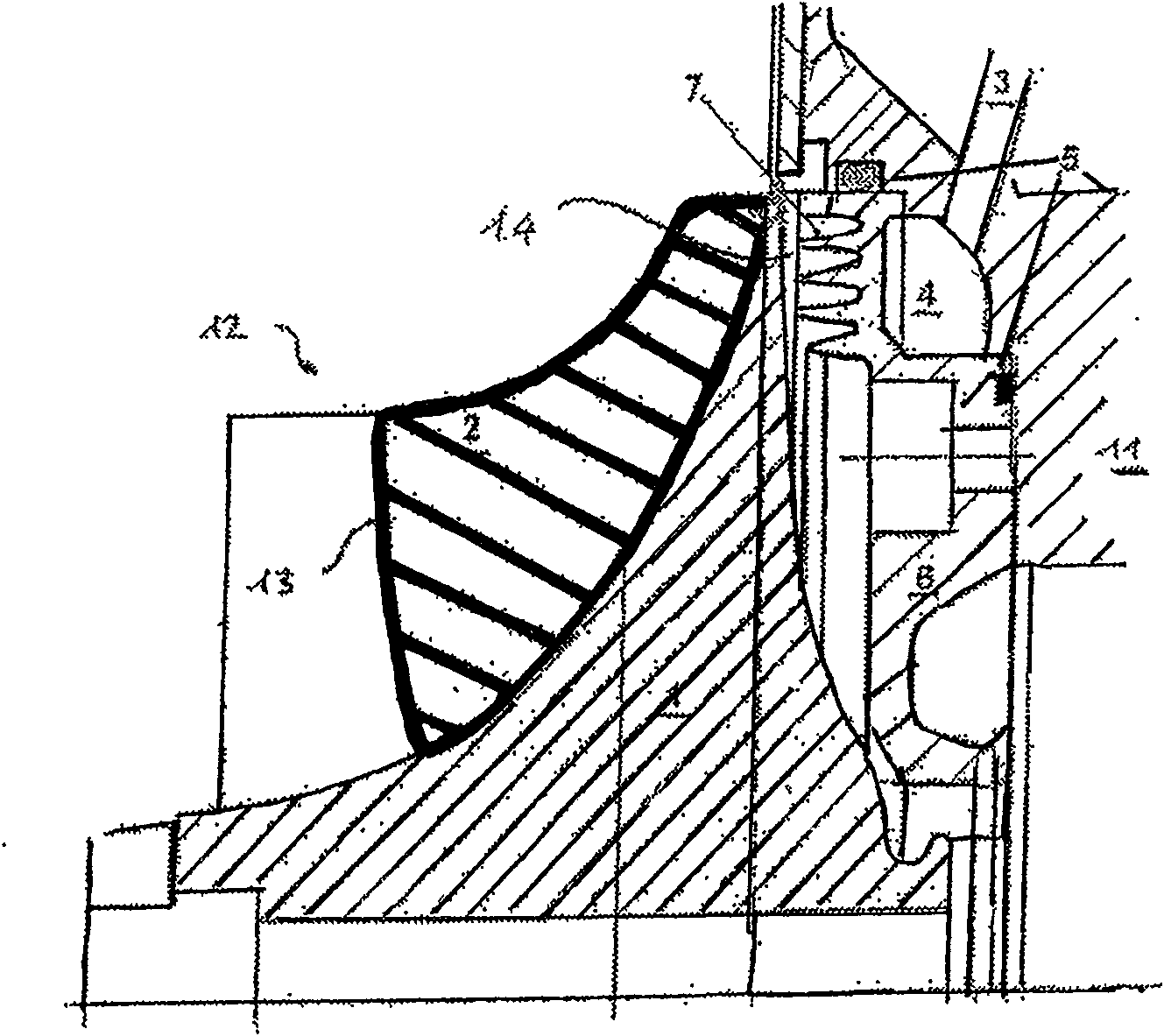

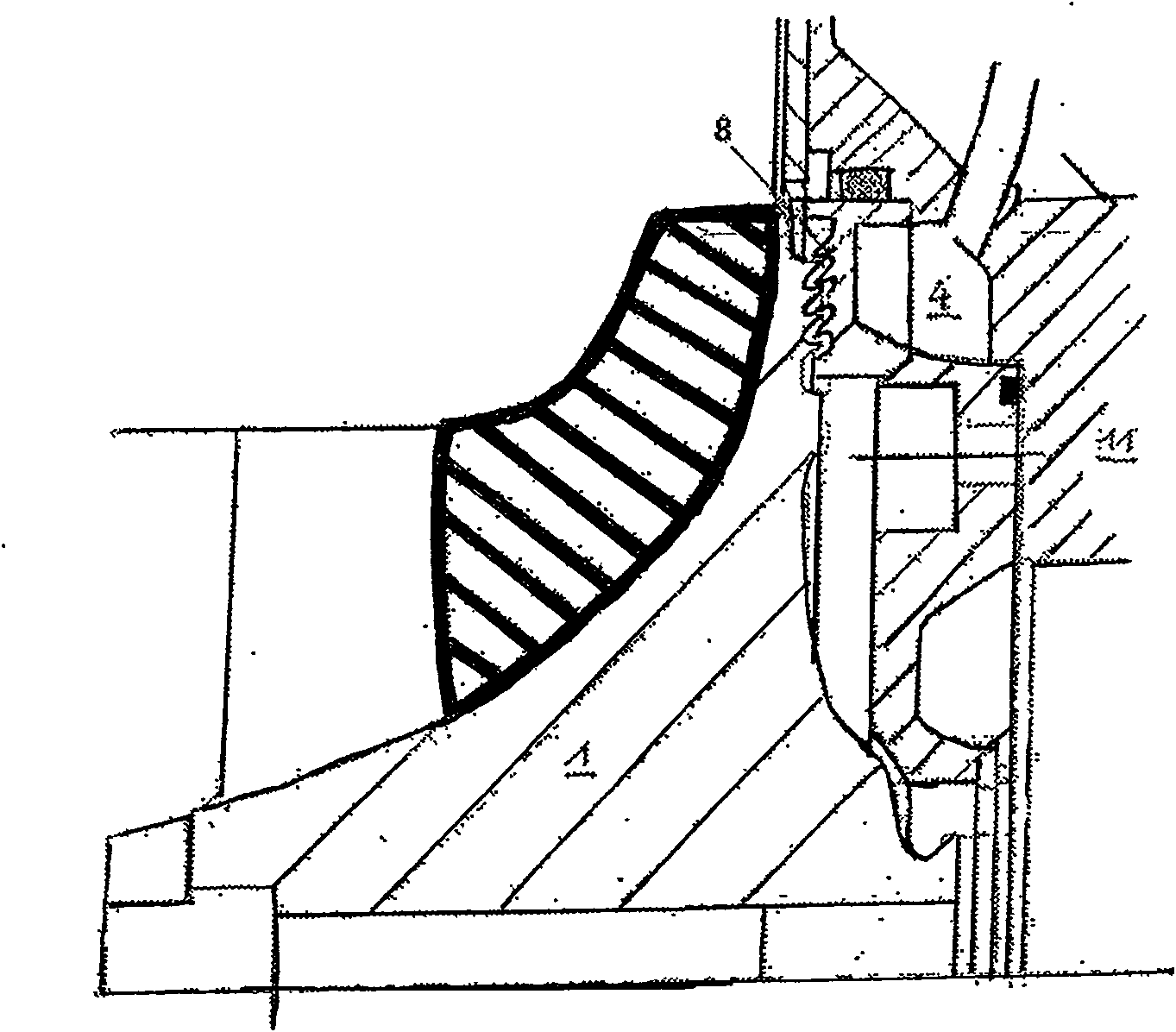

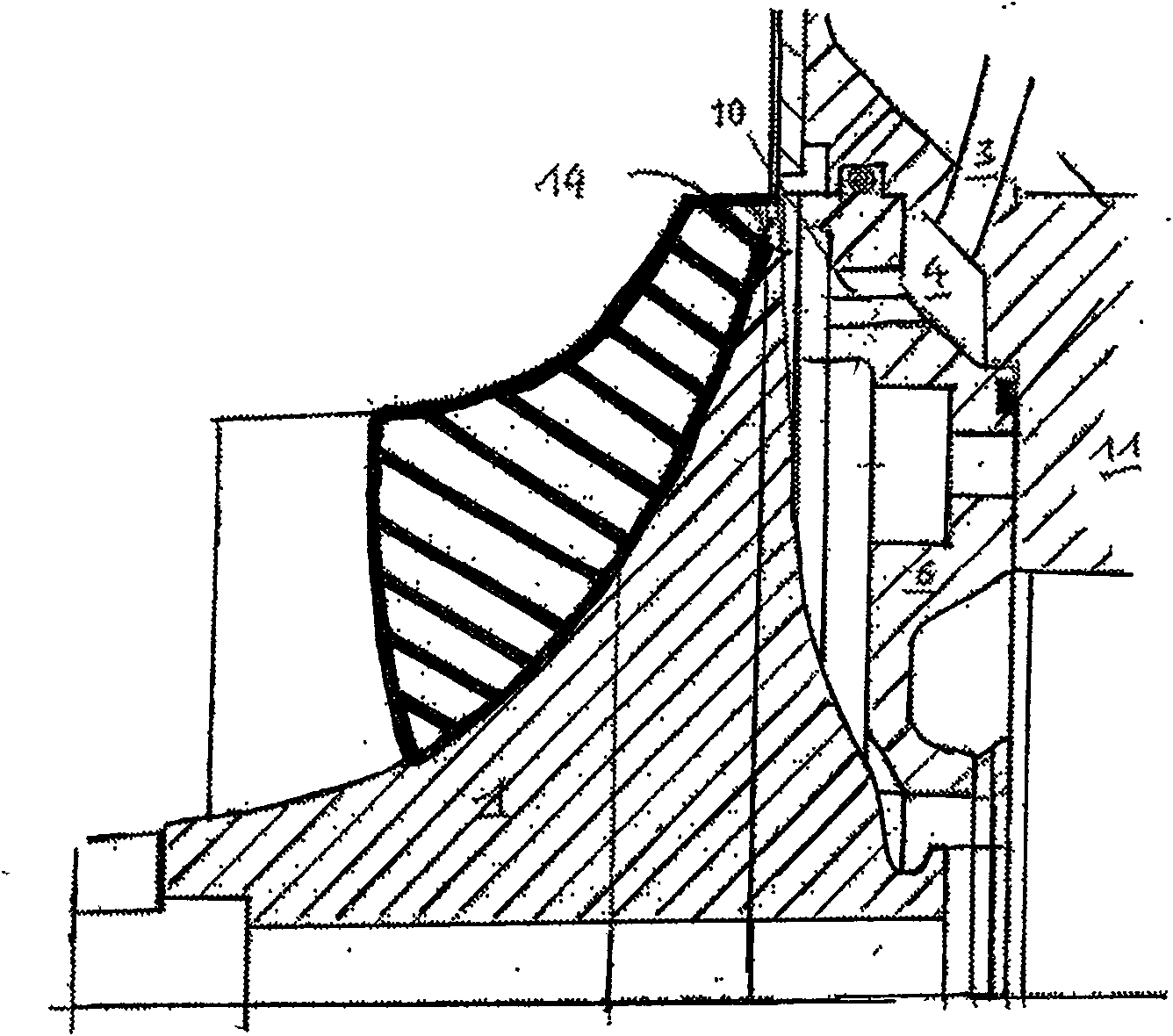

[0033] figure 1 A side view of components of a compressor according to a first embodiment of the present invention is schematically illustrated. The compressor comprises a compressor wheel 1 , which is mounted rotatably in a compressor housing 11 and is separated from the compressor housing by a radial gap 14 . A plurality of compressor blades 12 curved in the circumferential direction are distributed on the hub circumference of the compressor impeller, figure 1 Only one is shown.

[0034] The compressor blade 12 is made of aluminum oxide AI 2 o 3 A heat input-reducing coating 2 is produced, which in the exemplary embodiment extends from the inlet edge 13 of the sub-blade set to the impeller outlet and is applied by thermal spraying. Although in figure 1 It cannot be recognized that the surface area of the compressor hub is also provided with a coating in this area.

[0035] The air is accelerated by the compressor blades 12 in radial and circumferential directions, de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com