Manufacturing process of high-quality wide and thick plate blank

A manufacturing process and high-quality technology, applied in the field of wide and thick slabs for wide and thick plate rolling mills, can solve problems such as low efficiency and high manufacturing costs, and achieve the effects of avoiding surface cracks, improving surface strength, and improving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

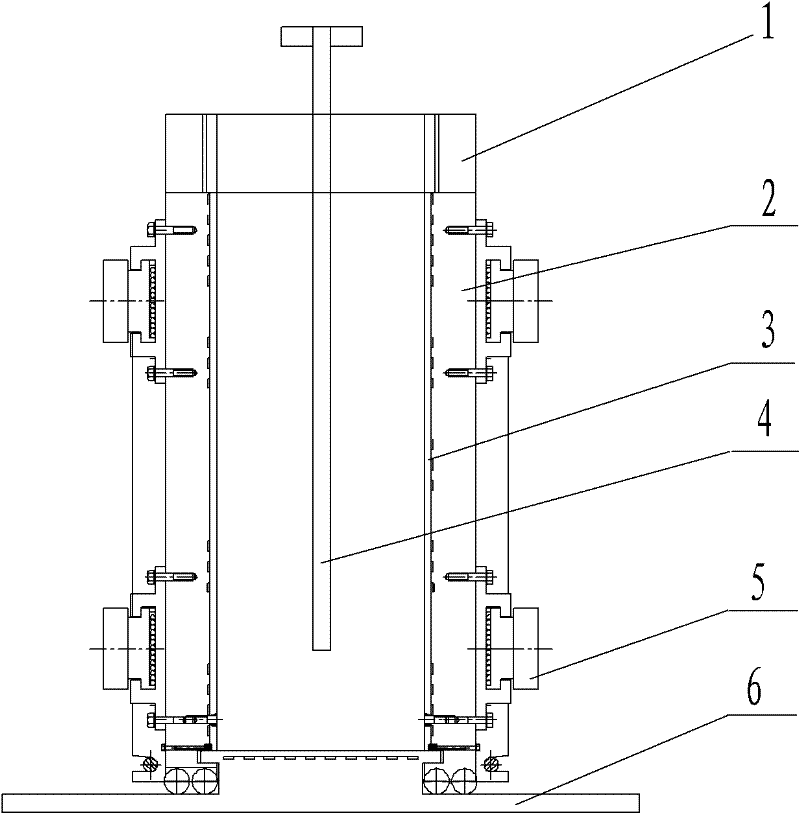

Method used

Image

Examples

Embodiment 1

[0029] Slab material: Q345E;

[0030] Slab thickness: 500mm;

[0031] Total weight of molten steel: 30 tons;

[0032] Pouring time: 15min;

[0033] Hydraulic cylinder pressurization time: 20 minutes after pouring, gradually increase the hydraulic cylinder pressure.

[0034] Maximum pressure on one side of wide and thick slabs: 4 hydraulic cylinders are arranged on each water-cooled movable mold, the maximum pressure exerted by a single hydraulic cylinder is 30 tons, and the maximum pressure on one side of wide and thick slabs is 120 tons.

[0035] Water-cooled moving mold forward distance: 5mm.

[0036] Pressure holding time of the hydraulic cylinder: 40 minutes. After the pressure holding is completed, the hydraulic cylinder applies reverse pressure to separate the water-cooled movable mold from the wide and thick slab.

[0037] The gap between the wide and thick slab and the water-cooled movable mold: 10mm.

[0038] Through the implementation of the above process, the i...

Embodiment 2

[0040] Slab material: EH36;

[0041] Slab thickness: 1000mm;

[0042] Total weight of molten steel: 60 tons;

[0043] Pouring time: 30min;

[0044] Hydraulic cylinder pressurization time: 50 minutes after pouring, gradually increase the hydraulic cylinder pressure.

[0045] Maximum pressure on one side of wide and thick slab: 4 hydraulic cylinders are arranged on each water-cooled movable mold, the maximum pressure exerted by a single hydraulic cylinder is 90 tons, and the maximum pressure on one side of wide and thick slab is 360 tons.

[0046] Water-cooled moving mold forward distance: 12mm.

[0047] Pressure holding time of the hydraulic cylinder: 90 minutes. After the end of the pressure holding, the hydraulic cylinder applies reverse pressure to separate the water-cooled movable mold from the wide and thick slab.

[0048] The gap between the wide and thick slab and the water-cooled movable mold: 15mm.

[0049]Subsequent monitoring of the surface temperature of the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com