Patents

Literature

73 results about "Draught beer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Draught beer, also spelt draft, is beer served from a cask or keg rather than from a bottle or can. Draught beer served from a pressurised keg is also known as keg beer.

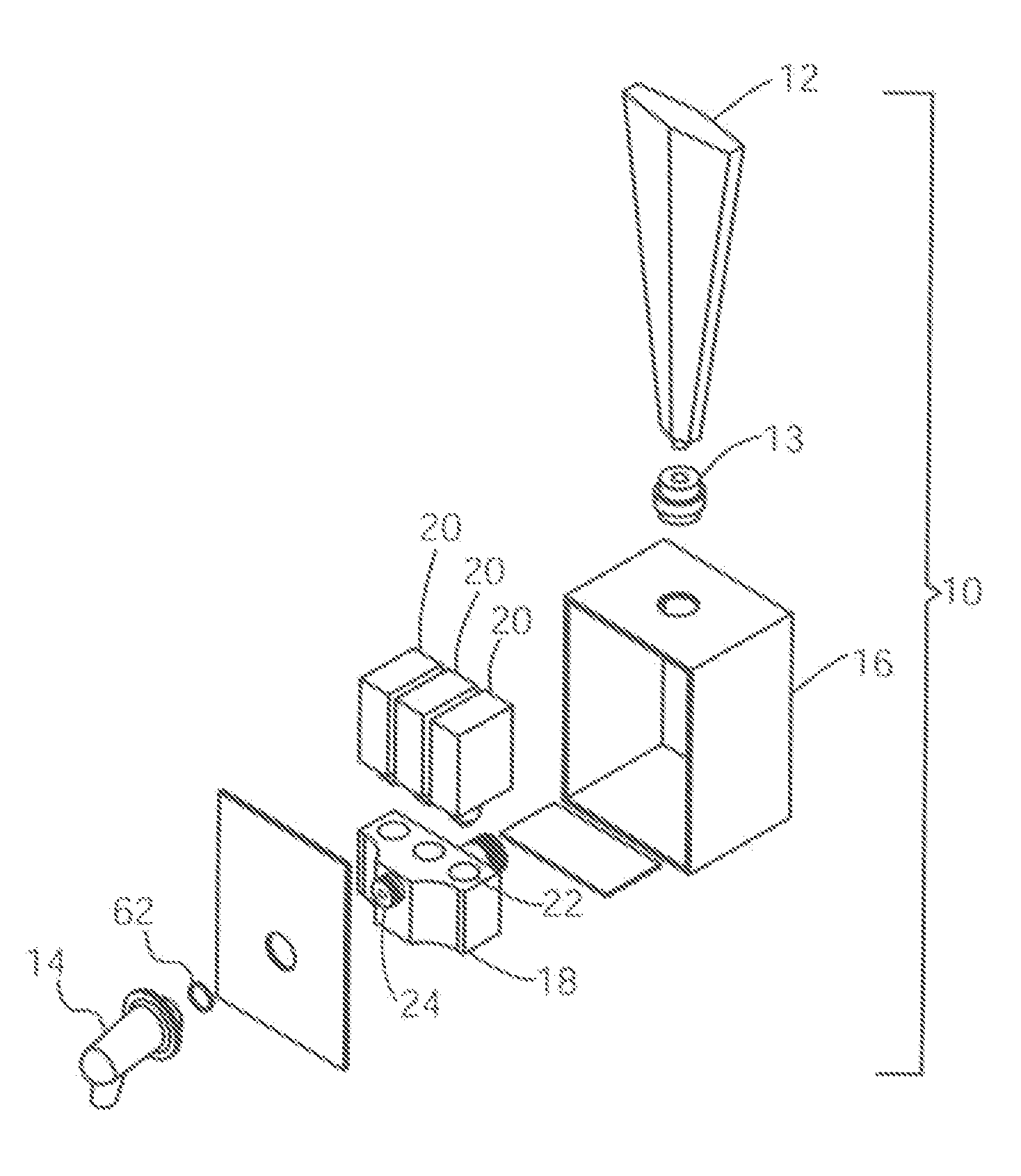

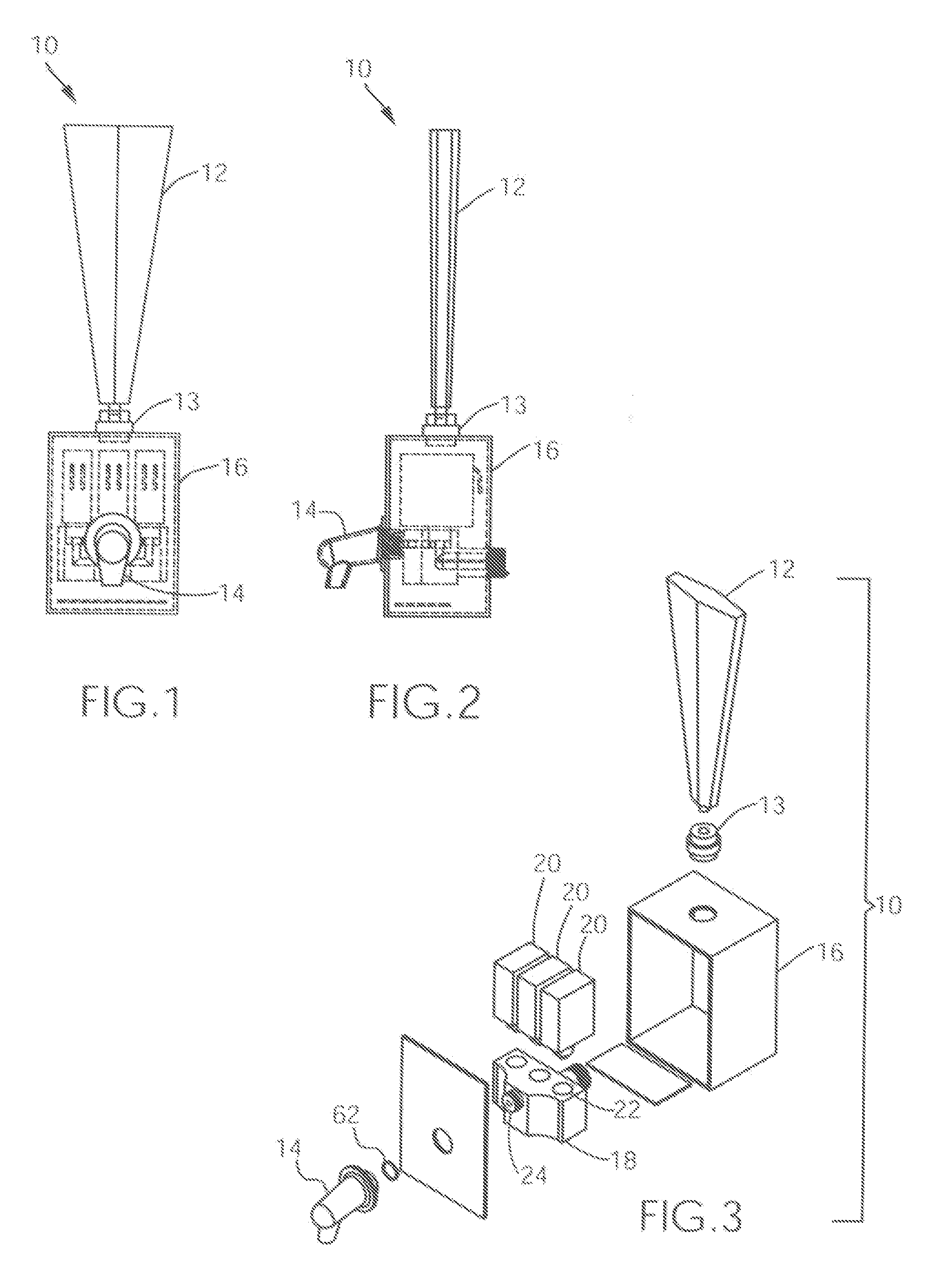

Multi-stream draught beer dispensing system

InactiveUS8167173B1Maximize selectionPrecise alignmentOperating means/releasing devices for valvesServomotor componentsDraught beerEngineering

A tap is provided that allows multiple streams of draught beers to be dispersed from one keg handle. The tap has one tap handle, one spigot, at least three fluid streams for connecting to at least three pressurized tanks corresponding with the fluid streams. A floating transfer block functions as a selection valve that aligns with a selected fluid stream no that multiple streams of draught beers to be independently dispersed from said one tap handle.

Owner:3HABTO

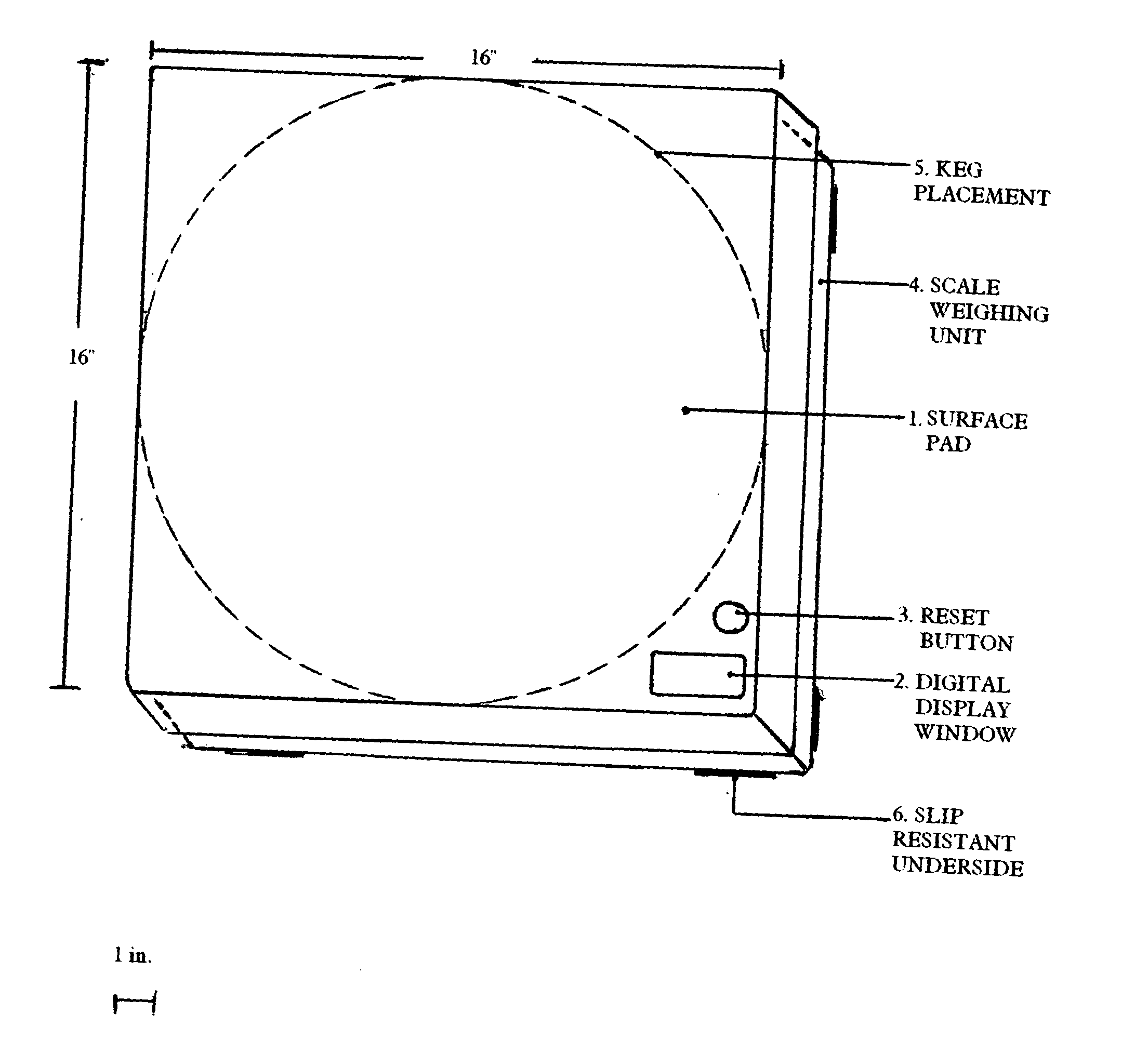

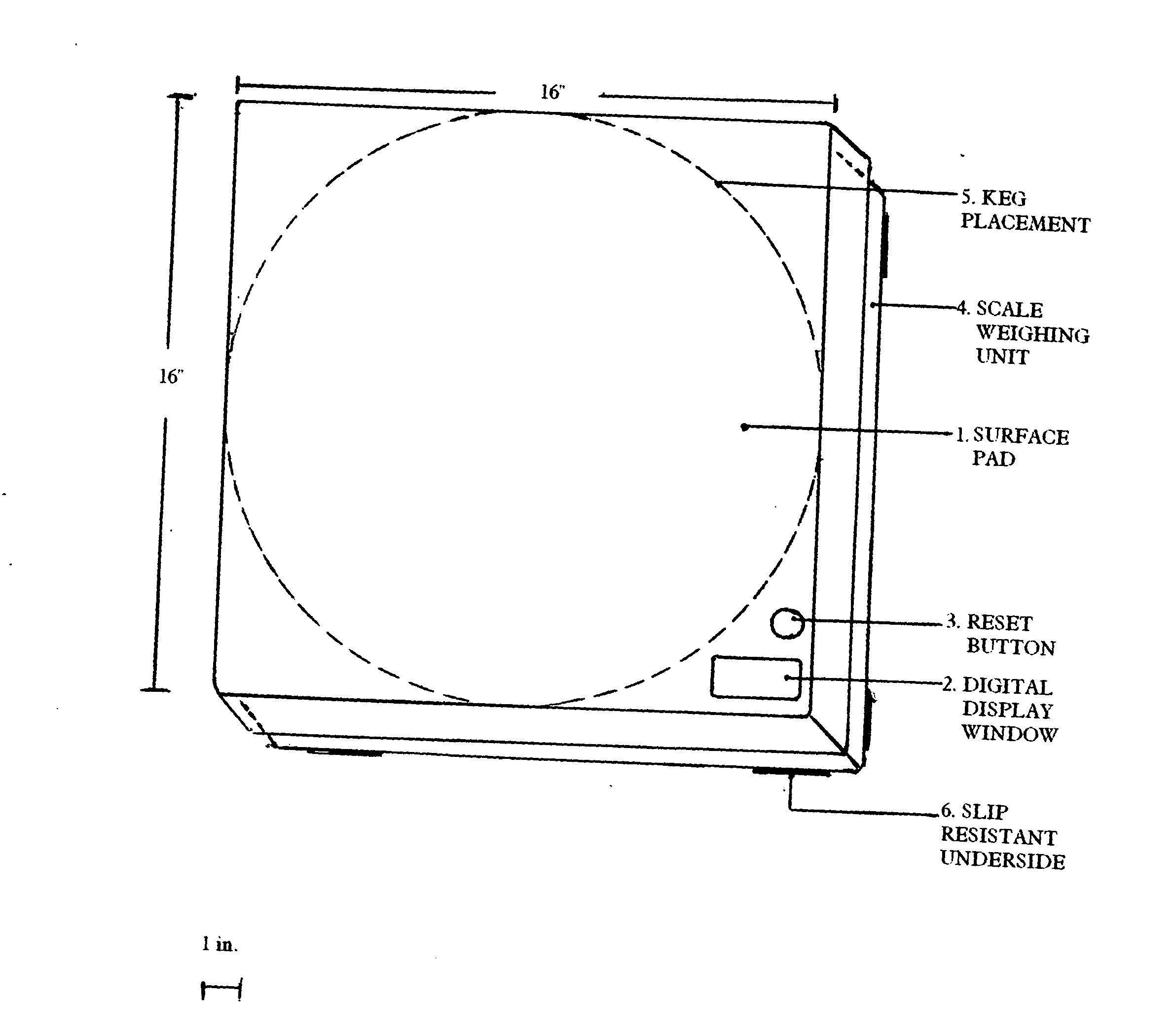

Draughtscale for weighing draught beer

InactiveUS20050000737A1Thorough and productive decision making processReducing common dilemmaWeighing apparatus for materials with special property/formWeighing auxillary devicesCelsius DegreeEngineering

This is a weighing scale specifically designed for the weighing of kegs in the bar and restaurant industry. It is comprised of a stainless steel surface, a digital display unit that measures in ounces, a reset button and a slip resistant underbottom. The scale will also be able to withstand temperatures 4 degrees Celsius and lower so that it can remain a permanent fixture inside the refrigeration unit.

Owner:FOX WENDY MAE +2

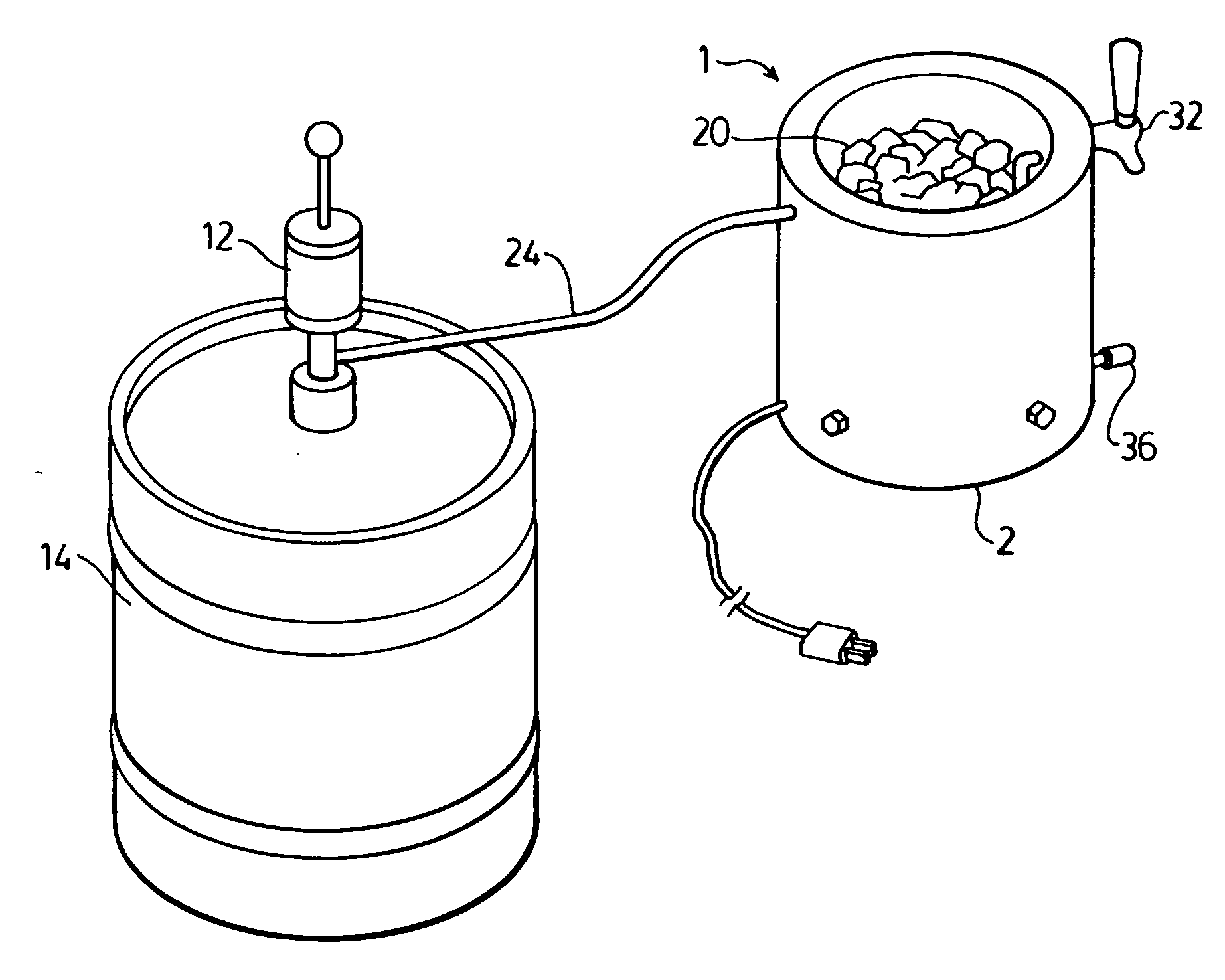

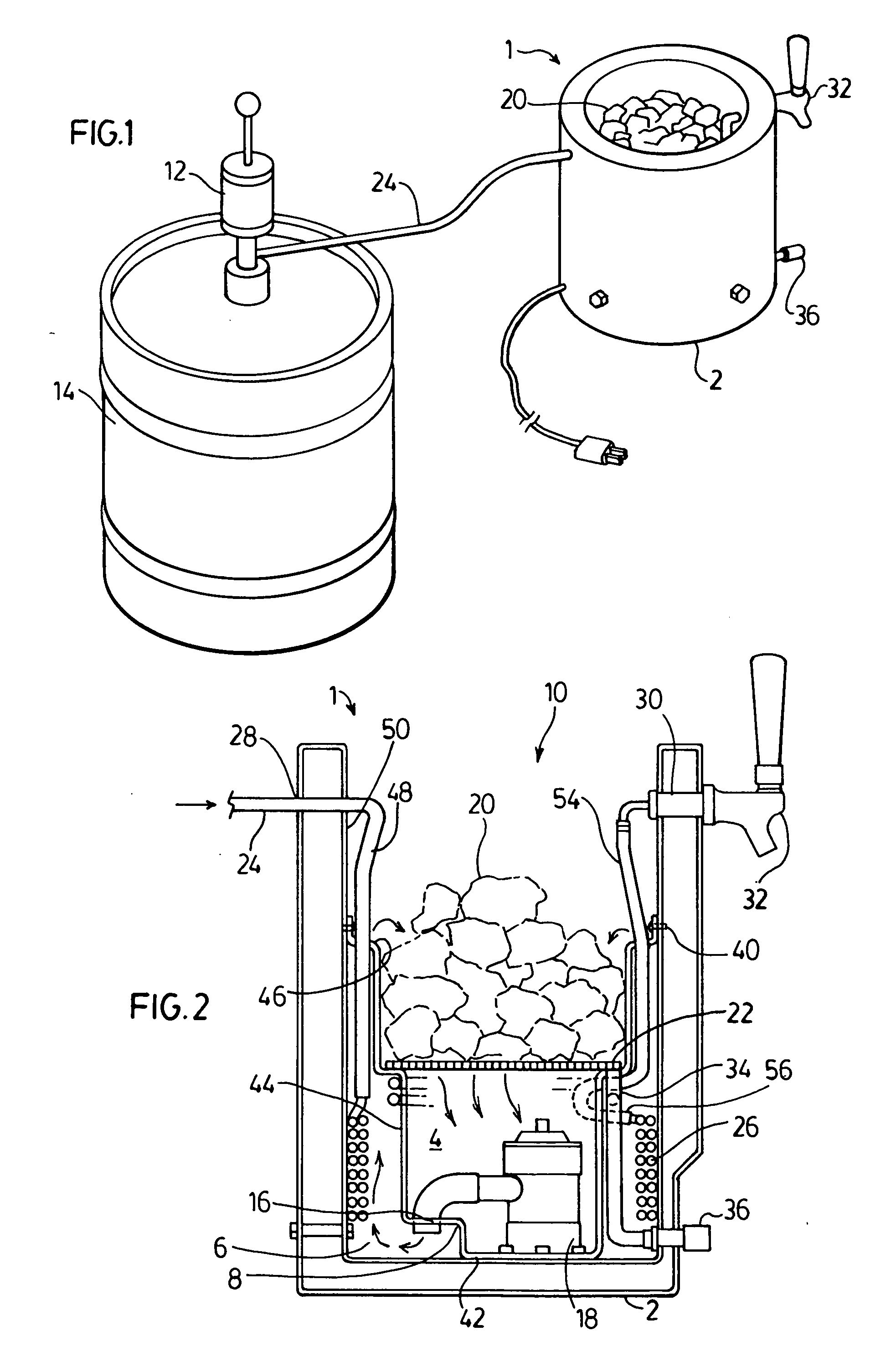

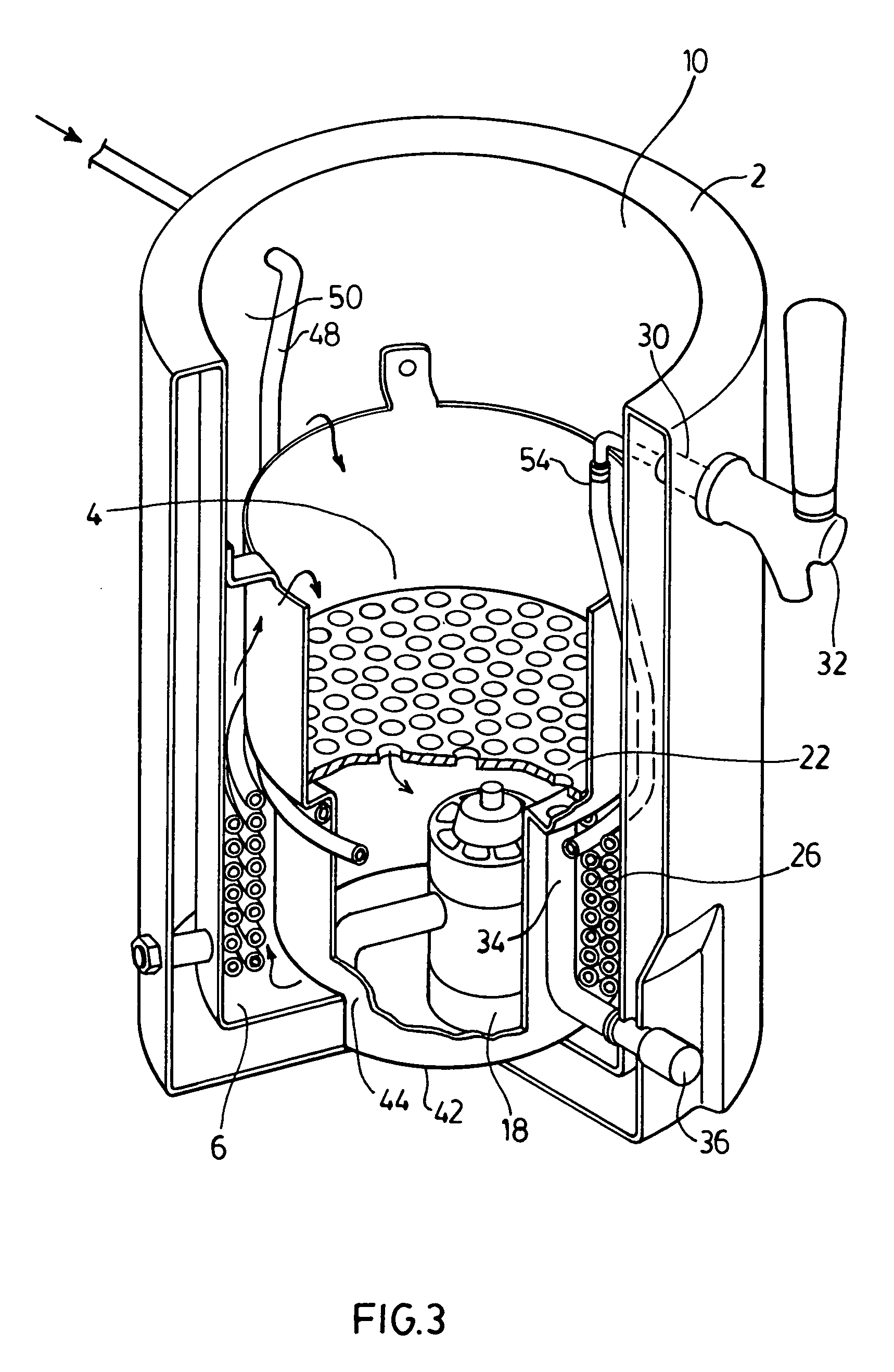

Portable apparatus for chilling draught beverages

InactiveUS20070051125A1Domestic cooling apparatusLighting and heating apparatusCoolant flowEngineering

An apparatus and method for dispensing a liquid stored in a container is provided. The apparatus has a housing defining an inner chamber for holding a quantity of a coolant fluid. The housing also has an outer chamber that surrounds the inner chamber. The two chambers are separated by a barrier. A pump located in the inner chamber pumps coolant fluid from the inner chamber into the outer chamber. The pumping action causes the coolant fluid to flow along a flow path up the outer chamber and over the barrier and back into the inner chamber as outer chamber fills. A refrigeration means is located in the flow path for cooling the coolant fluid. The coolant fluid flows over a fluid conduit received in the housing. The fluid conduit is received in the inlet and exits the housing through the outlet for delivering the liquid from the container through the housing to the exterior of the housing. The invention provides a portable apparatus that provides a cool and non-foamed beverage from a beverage container to a dispensing tap.

Owner:ICEFLOE TECH INC

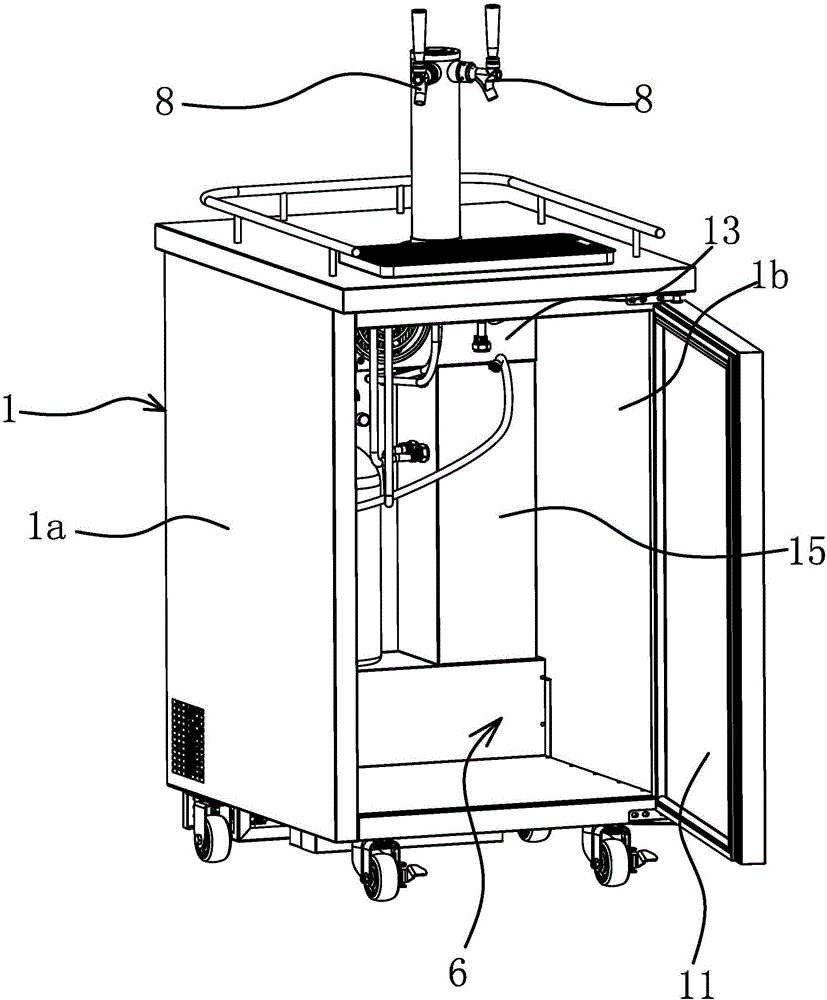

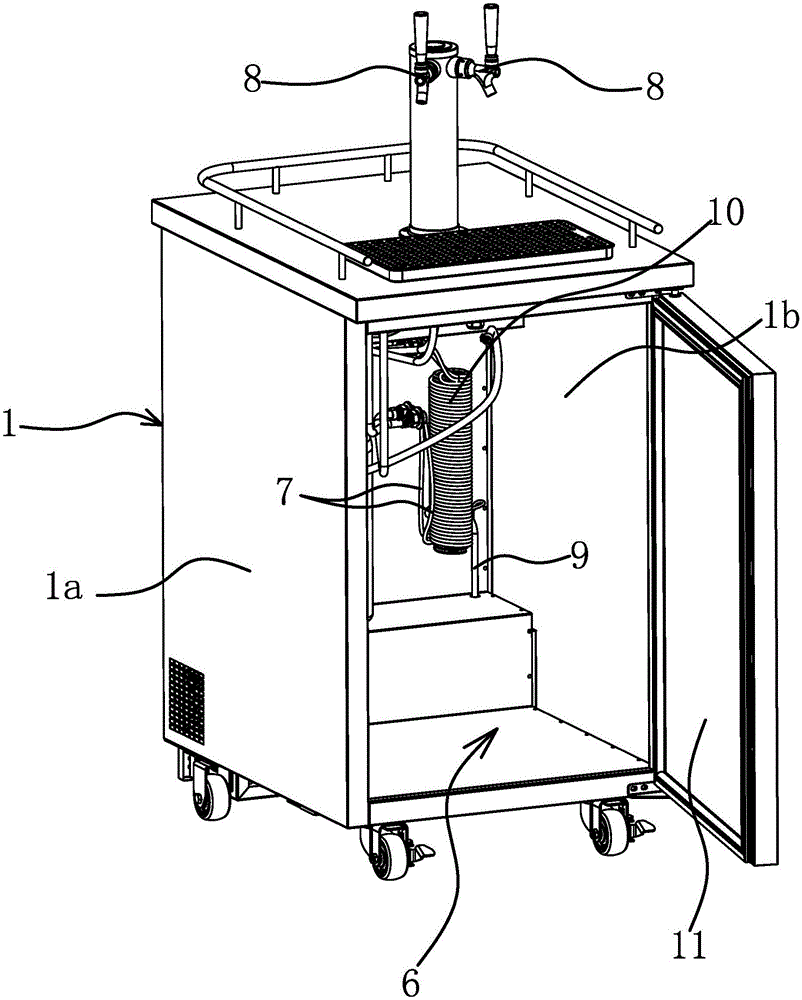

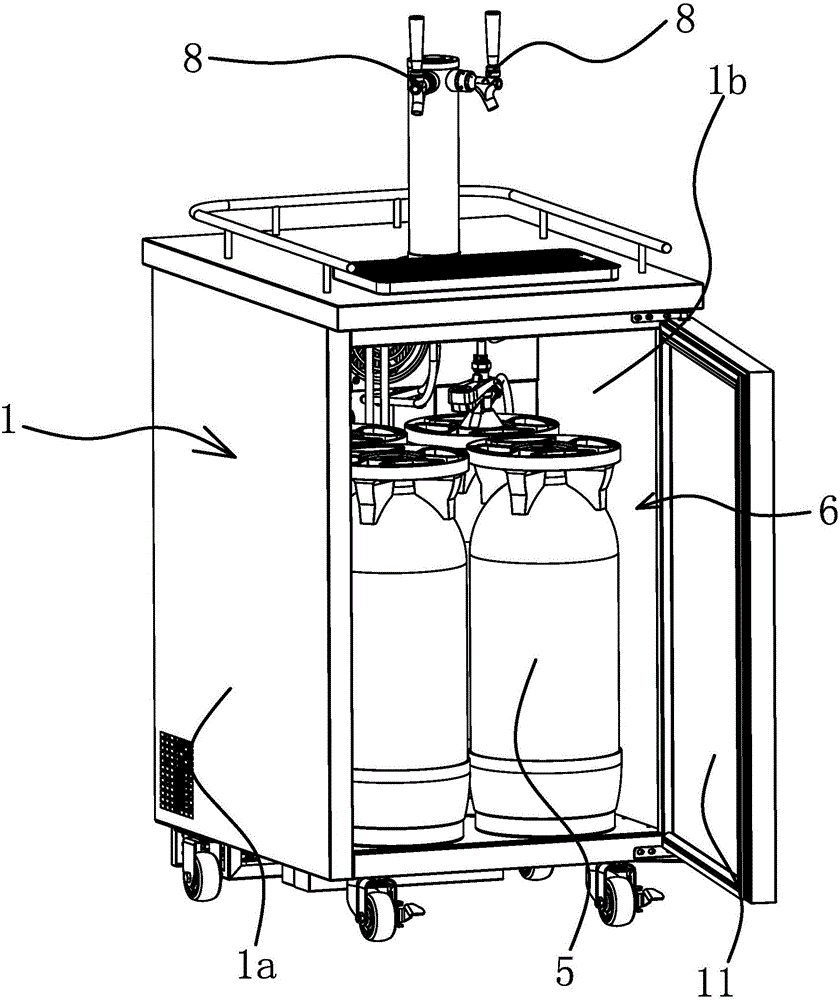

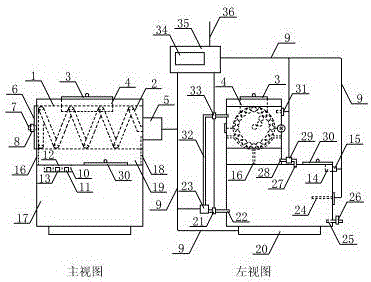

Dual cooling type draught beer machine

ActiveCN106322916AReduce the temperatureIncrease profitLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigeration

The invention provides a dual cooling type draught beer machine, and belongs to the technical field of drinks drinking equipment. The dual cooling type draught beer machine solves the problem that the refrigeration effect of a dual cooling draught beer machine in the prior art is low. The dual cooling type draught beer machine comprises a box. A refrigeration loop which comprises a compressor, a condenser and an evaporator is arranged in the box. A refrigerating cavity capable of containing beer barrels is formed in the box. The evaporator can carry out refrigeration on the refrigerating cavity. Beer outlet pipes are further arranged in the box. Beer outlet faucets are fixed outside the box. The outer ends of the beer outlet pipes communicate with the beer outlet faucets, and the inner ends of the beer outlet pipes are used for communicating with the beer barrels. The dual cooling type draught beer machine is characterized in that the refrigerating cavity is of a single cavity structure; a refrigeration pipe is arranged in the refrigerating cavity and connected into the refrigeration loop and is in parallel connection with the evaporator; and the refrigeration pipe and the beer outlet pipes are wound into a cylindrically or cylindroid quick cooler in a side-by-side screw manner. The draught beer machine can efficiently utilize the cold quantity, and the beer outlet refrigeration efficiency can be improved.

Owner:TALOS TECH CORP

Solid compound enzyme for cleaning filtering membrane of draught beer

InactiveCN102078770AEasy to cleanReduce surface tensionSemi-permeable membranesPectinaseNeutral protease

The invention belongs to the field of membrane filtering and relates to a solid compound enzyme for cleaning a filtering membrane of draught beer. The solid compound enzyme comprises the following components in part by weight: 0.5 to 2.0 parts of xylanase, 0.5 to 2.0 parts of beta-glucanase, 0.5 to 2.5 parts of neutral protease, 0.5 to 1.0 part of pectinase, 0.05 to 0.1 part of calcium chloride, and 0.5 to 1.0 part of ethylene diamine tetraacetic acid (EDTA). The solid compound enzyme cleaning agent which degrades membrane obstruction is prepared aiming at the characteristics of the structure and property of the membrane obstruction of the draught beer; and the filtering membrane of the draught beer can be effectively cleaned with the cleaning agent, so that the service life of the membrane is greatly prolonged, filtering cost is reduced, the environmental pollution brought by acid and base used by the cleaning the membrane can be reduced, and the cleaning agent has realistic significance.

Owner:SOUTH CHINA AGRI UNIV

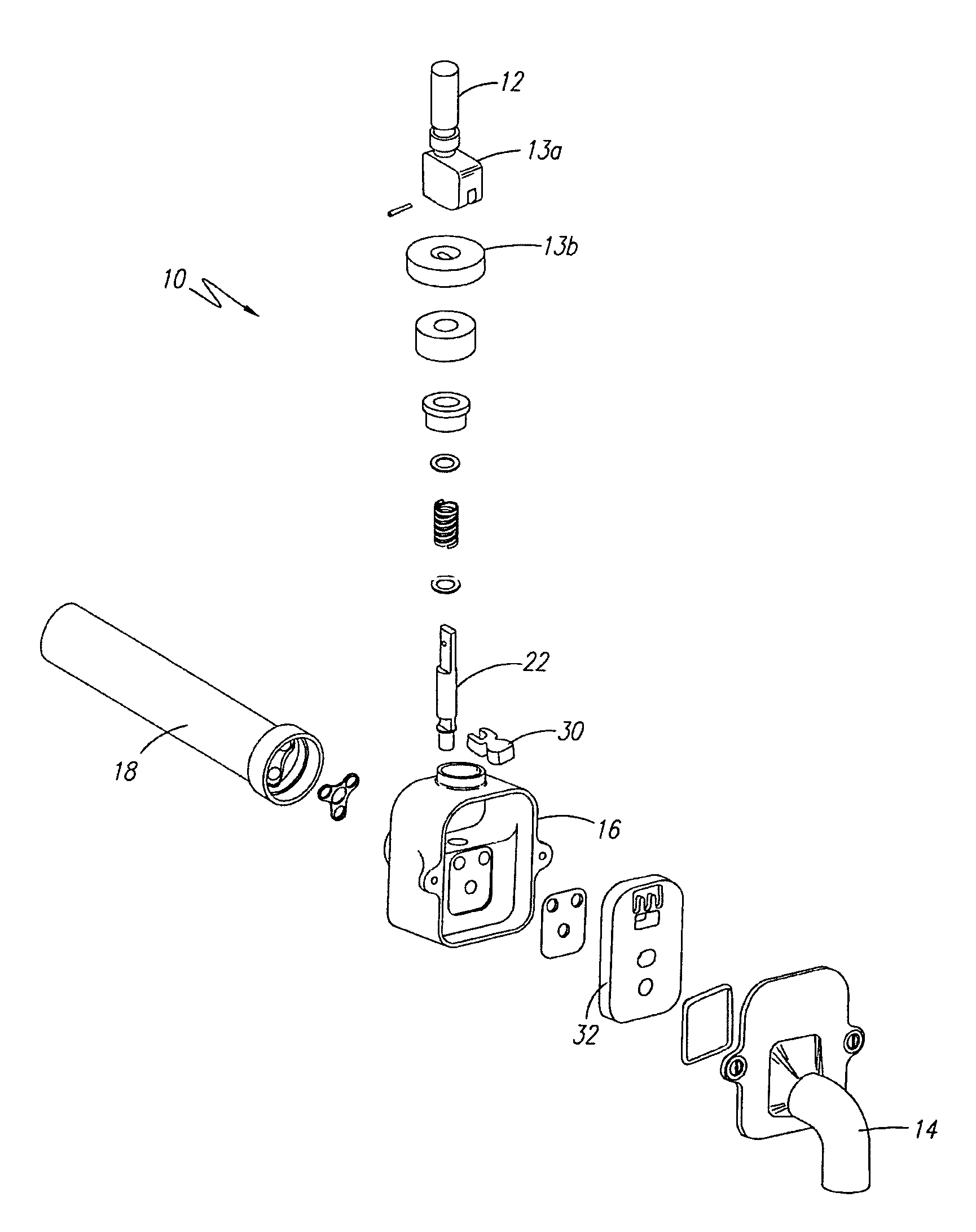

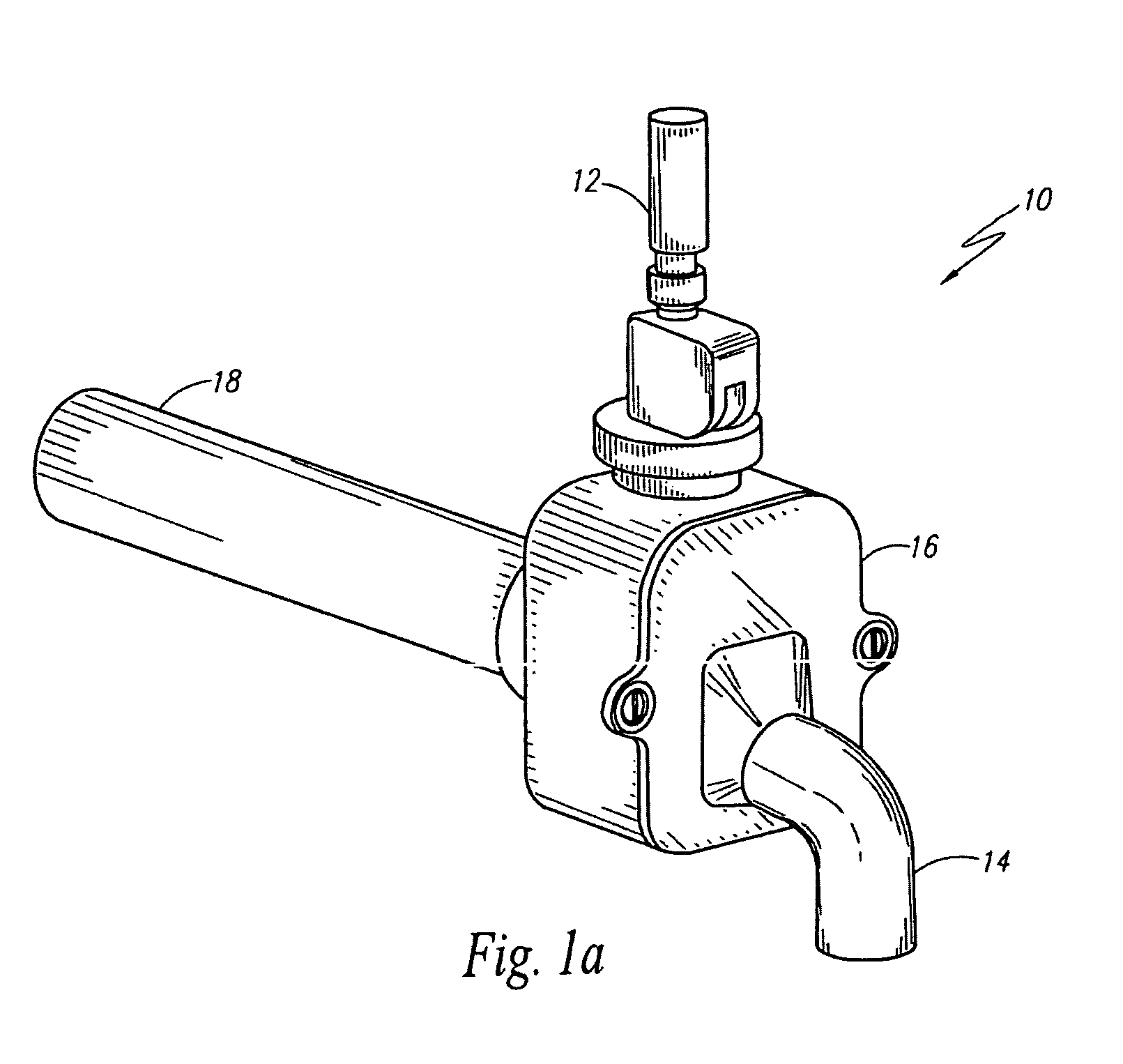

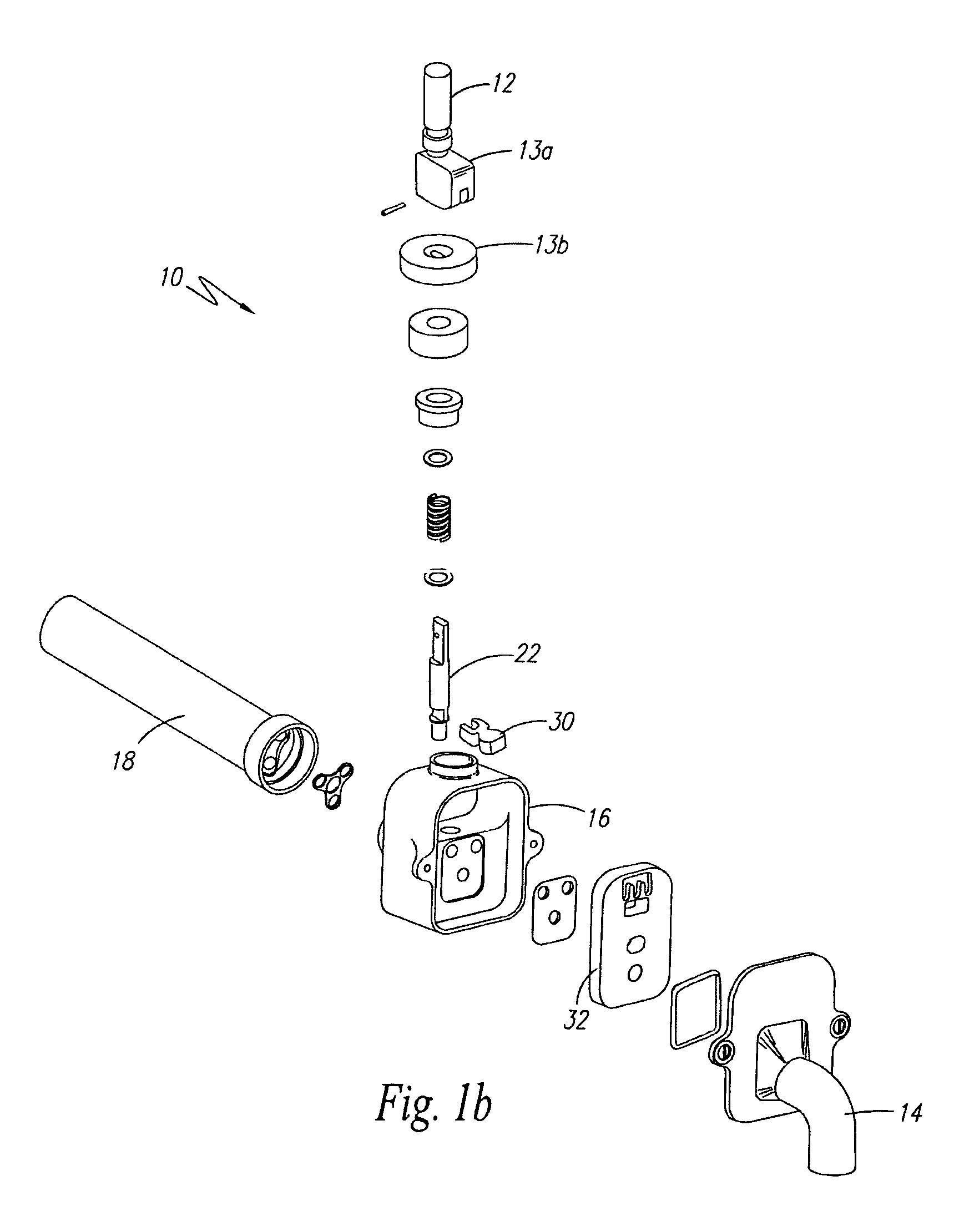

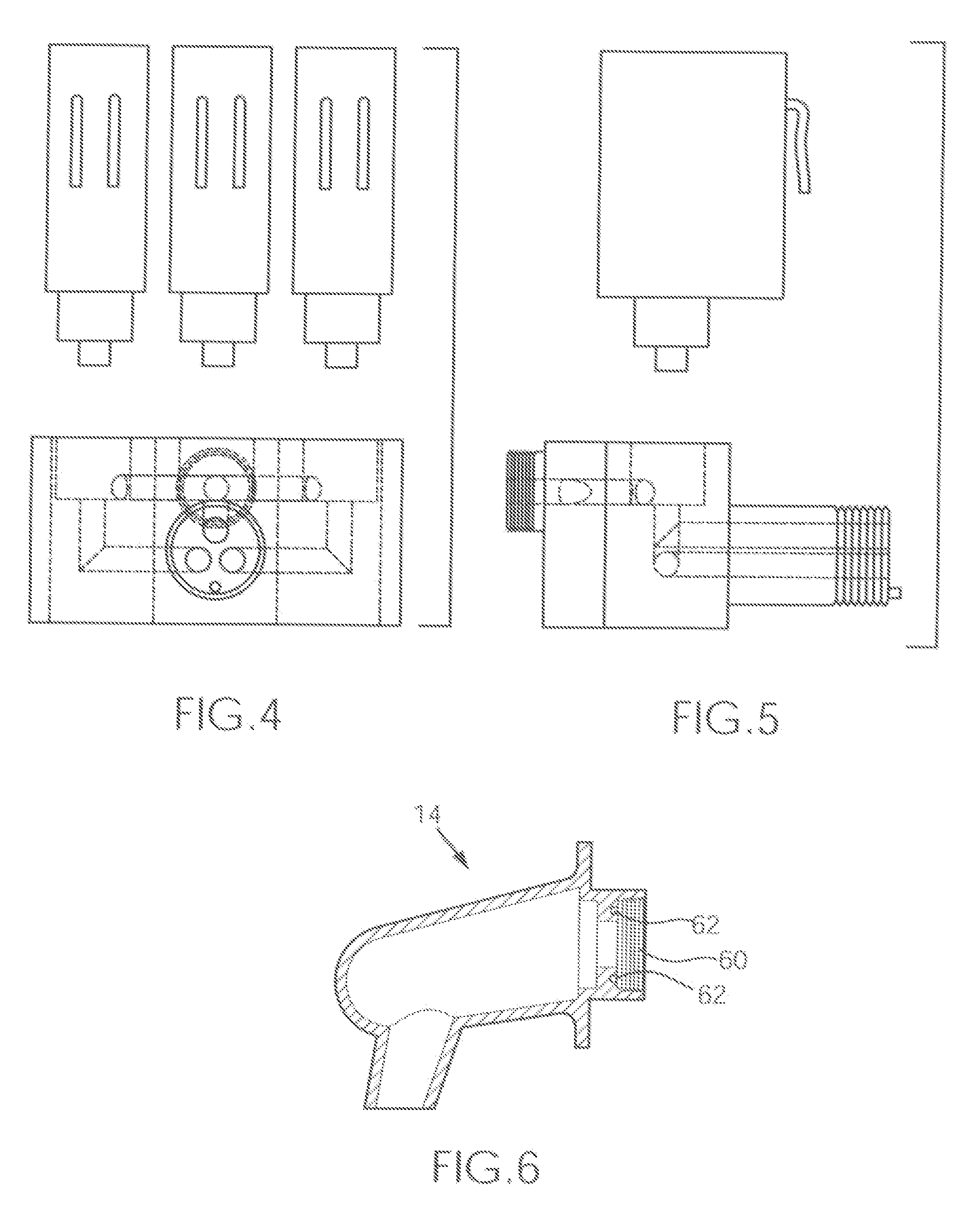

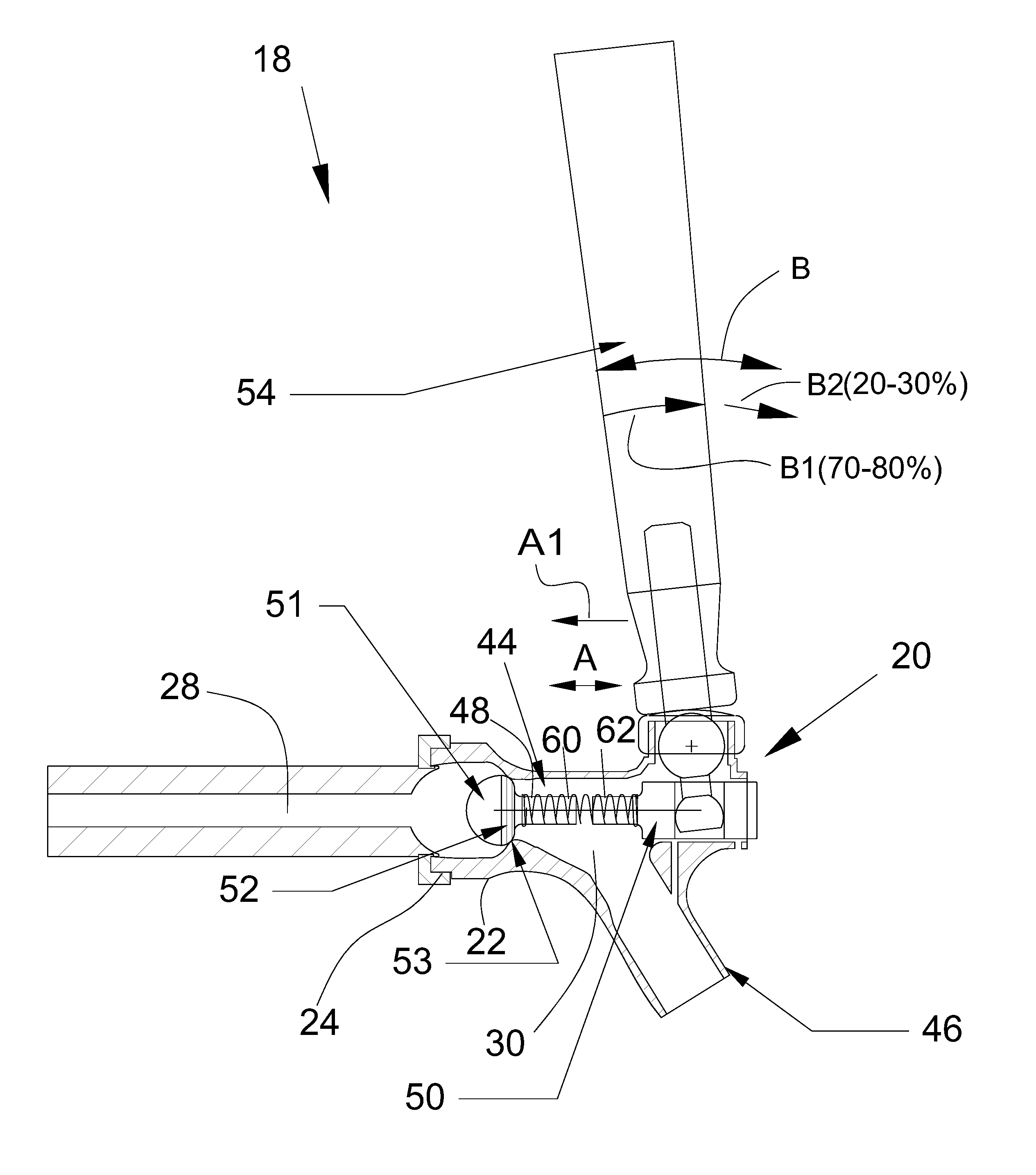

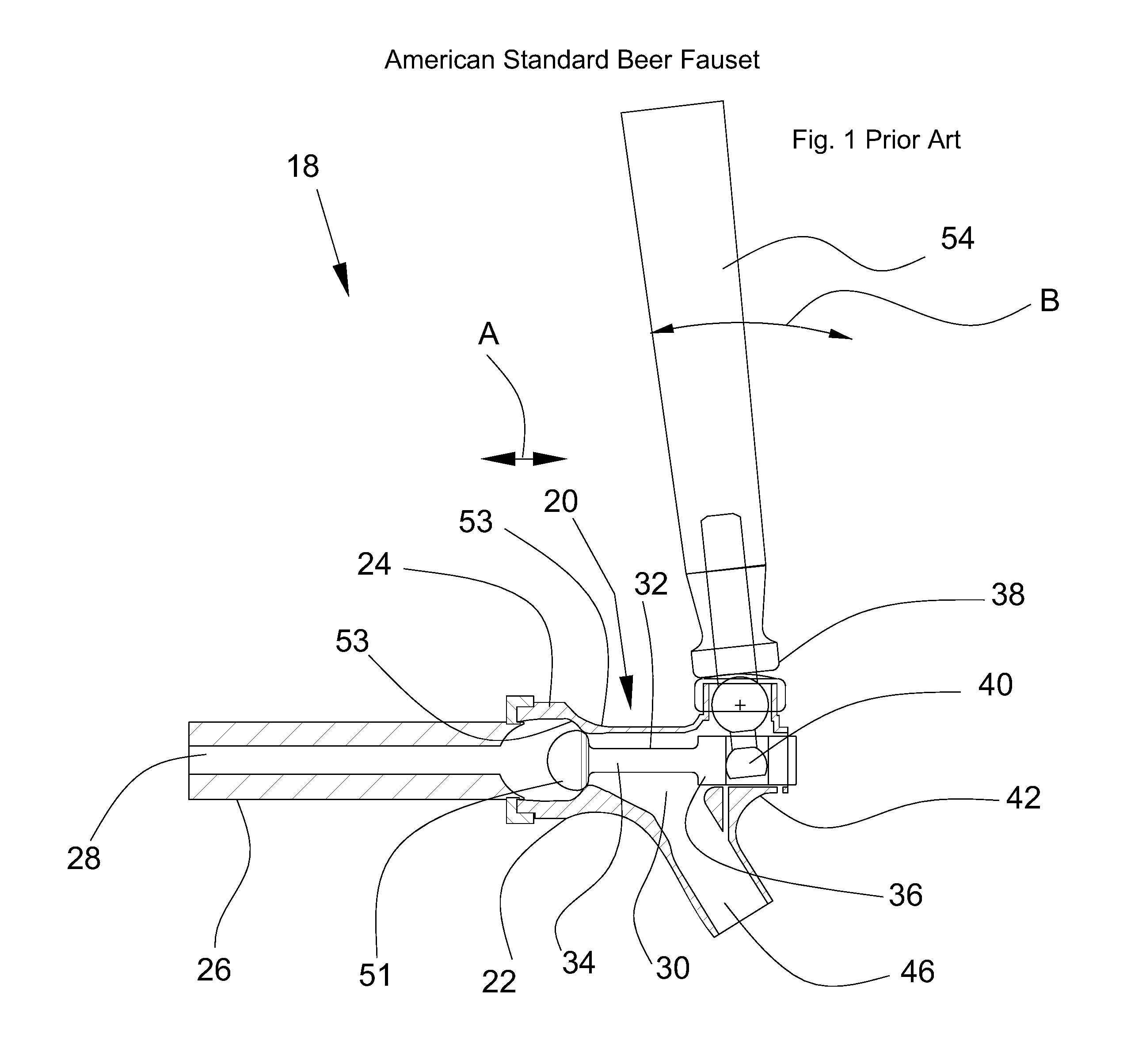

Multi-Stream Draught Beer Dispensing System

InactiveUS20100264160A1Increase draught dispensingMaximize selectionOpening closed containersBottle/container closureEngineeringMulti stream

A multiple draught beer dispensing system comprises one tap handle, one spigot, at least three fluid streams, and at least three pressurized tanks corresponding with the fluid streams. A plurality of individual electronic poppet control valves are used to control multiple fluid streams. When the tap handle selects a draft, the poppet valve is actuated by the tap dispenser handle to the beer stream selected so that beer can travel out of the spigot.

Owner:3HABRO

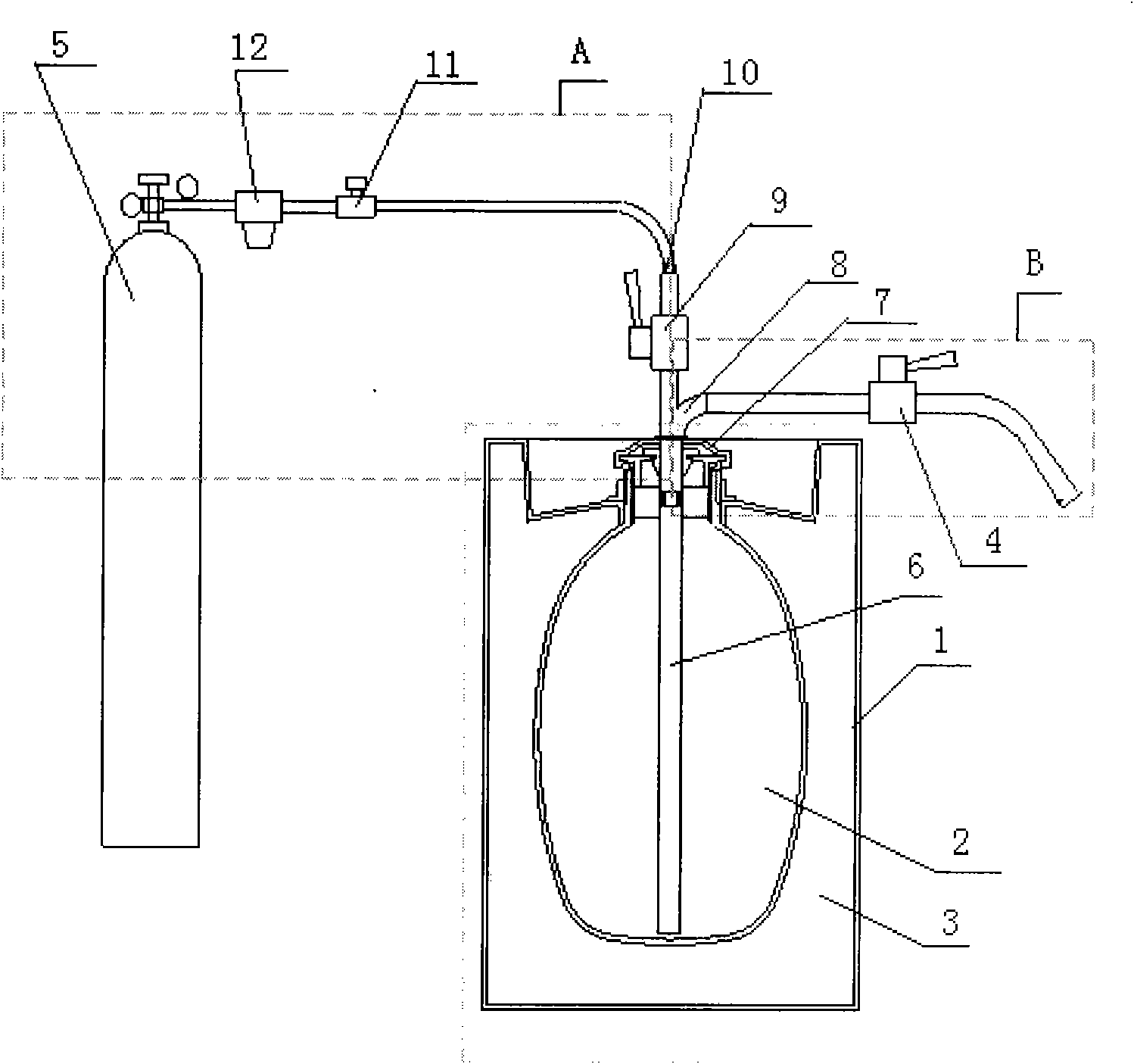

Beer fresh preservation bucket and wine vapor branch distributer thereof

InactiveCN102101556ASimple structureEasy to operateClosuresDomestic cooling apparatusEngineeringOxygen

The invention discloses a beer fresh preservation bucket, which consists of a bucket body and a wine spear cover, wherein the wine spear cover is arranged on the bucket body; a wine vapor branch distributer can be inserted into the wine spear cover, and has the characteristics of: reasonable structure, convenience in operating, sanitary appliances, smooth wine discharging, flexible assembly and disassembly, easiness and convenience in cleaning, stable air supply and the like. Due to the adoption of the wine discharging way, the problems of air-discharging wine discharging, aerobic storage, deterioration of drinks, pollution to appliances are fundamentally solved, the defects of the conventional beer fresh preservation bucket and draught beer machine are overcome, oxygen insulation operation in an entire wine injection, discharging and storing is ensured, and the quality and mouthfeel of bucket beer or beverages are ensured. The beer fresh preservation bucket is an ideal packing container of drinks such as beer, beverages, a branch distributor of air-feeding wine discharging as well as an upgraded product of the conventional beer fresh preservation bucket.

Owner:贺钢 +1

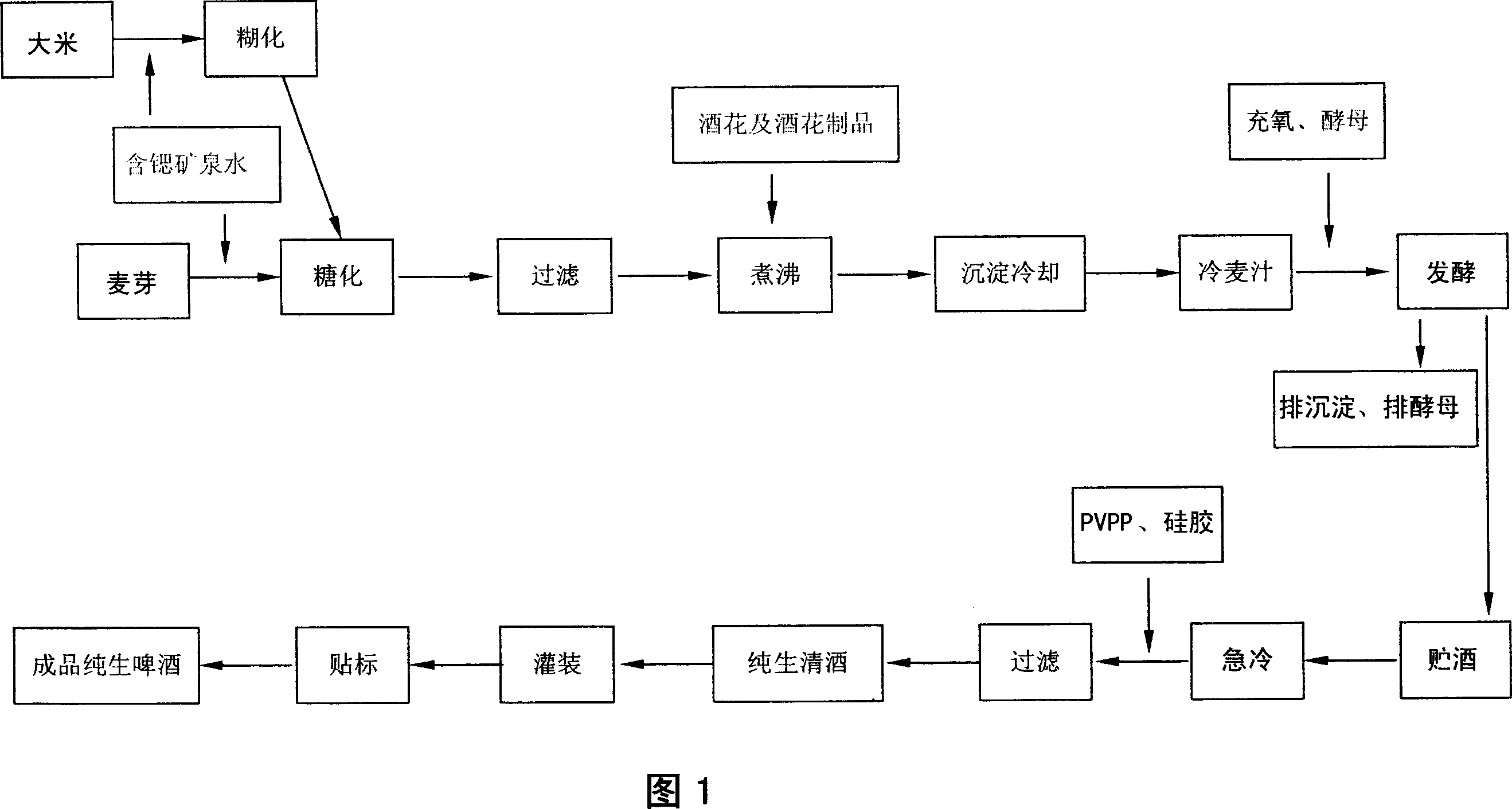

Strontium-containing pure draught beer and brewing method

The present invention relates to beer brewing technology, and is especially strontium containing draft beer and its brewing process. The strontium containing draft beer is brewed with barley malt, rice and strontium containing mineral water as main material and has strontium content not lower than 0.20 mg / L. During its brewing, strontium containing mineral water, and bitter type hops, fragrant type hops and hops product are used; and relevant measures are taken in the fermentation stage and the filtering stage, so that the strontium containing draft beer product in the shelf life has foam retaining period of 200-350 sec. The strontium containing draft beer has good pure taste, hops scent and unique flavor.

Owner:BEIJING YANJING BREWERY

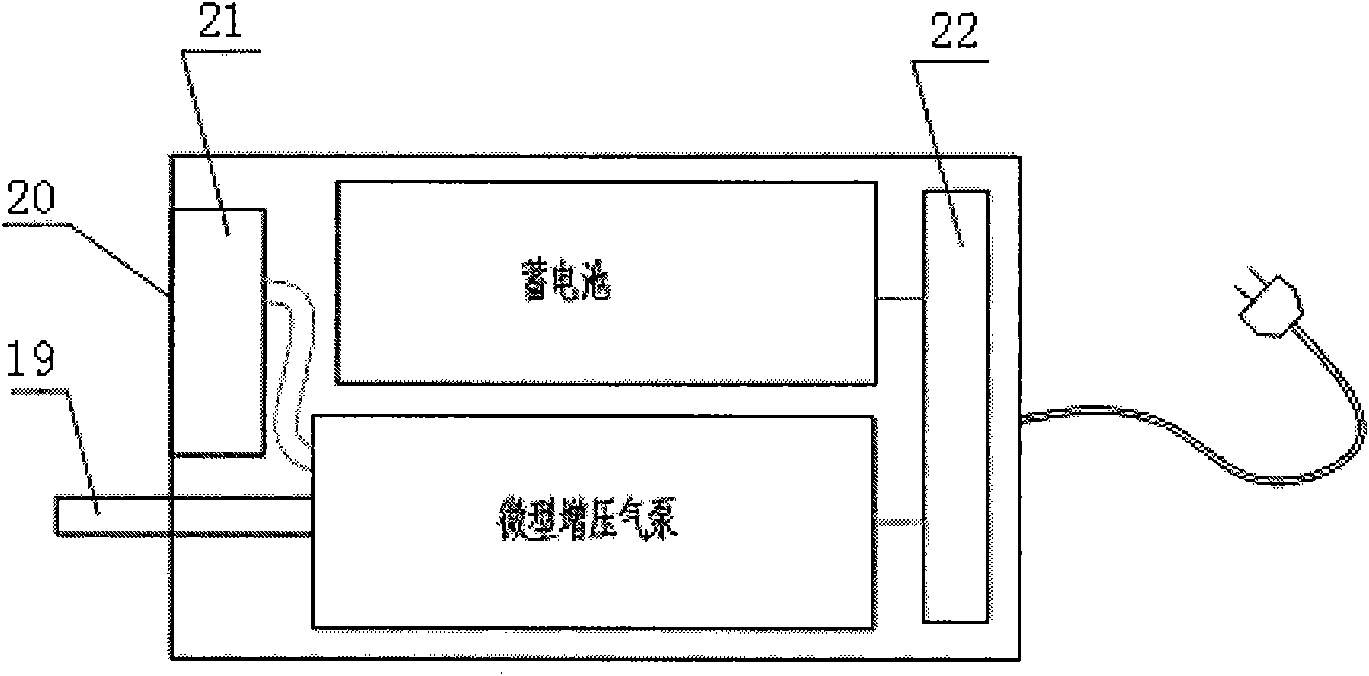

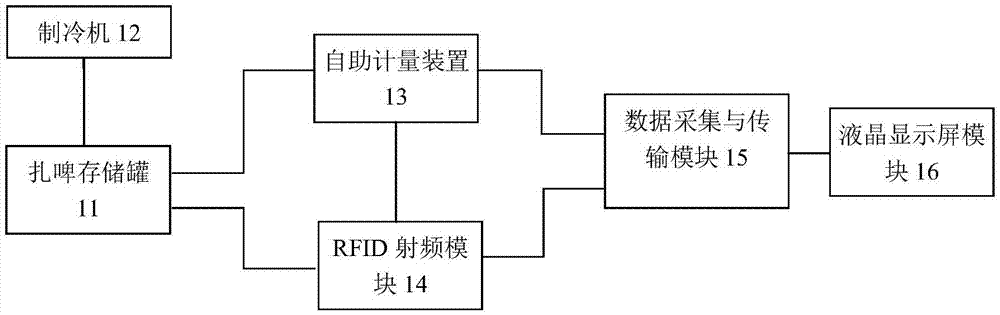

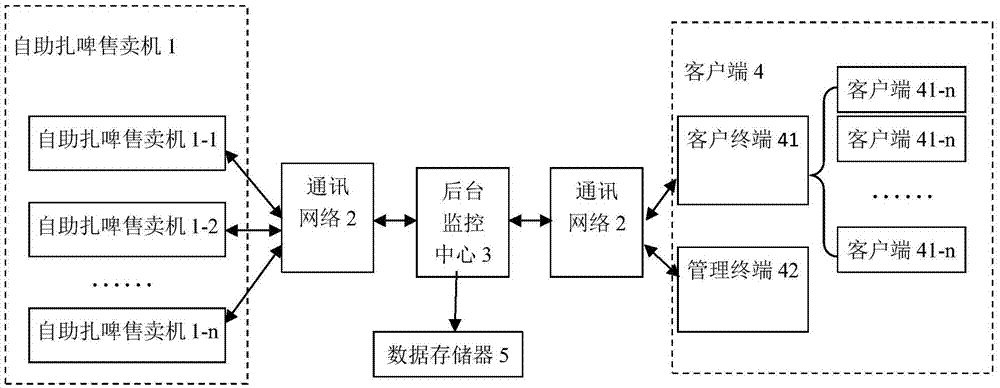

Self-help draught beer vending machine and query and monitor system thereof

ActiveCN105447977AGet location in real timeKnow the draft beer release dateApparatus for dispensing fluids/granular materialsLiquid-crystal displayData acquisition

The invention discloses a self-help draught beer vending machine which comprises a draught beer storage tank, a refrigerating machine, an automatic metering device, an RFID radio frequency module, a liquid crystal display screen module and a data collecting and transmitting module. The refrigerating machine is connected with the draught beer storage tank; the automatic metering device is installed at a beer outlet of the draught beer storage tank; the RFID radio frequency module is connected with a beer outlet valve of the draught beer storage tank; the data collecting and transmitting module is connected with the automatic metering device, the RFID radio frequency module and the liquid crystal display screen module. Meanwhile, the invention further discloses a query and monitor system of the self-help draught beer vending machine. According to the self-help draught beer vending machine and the query and monitor system thereof, not only can a client terminal acquire position and draught beer information of the self-help draught beer vending machine in real time to achieve self-help purchase through an RFID radio frequency technique, but also a management terminal can be helped to acquire information such as regional sale statistics, draught beer retaining amount statistics, alarm and maintenance, promotion and optimal arranging locations.

Owner:QINGDAO ACAD FOR OPTO ELECTRONICS ENG

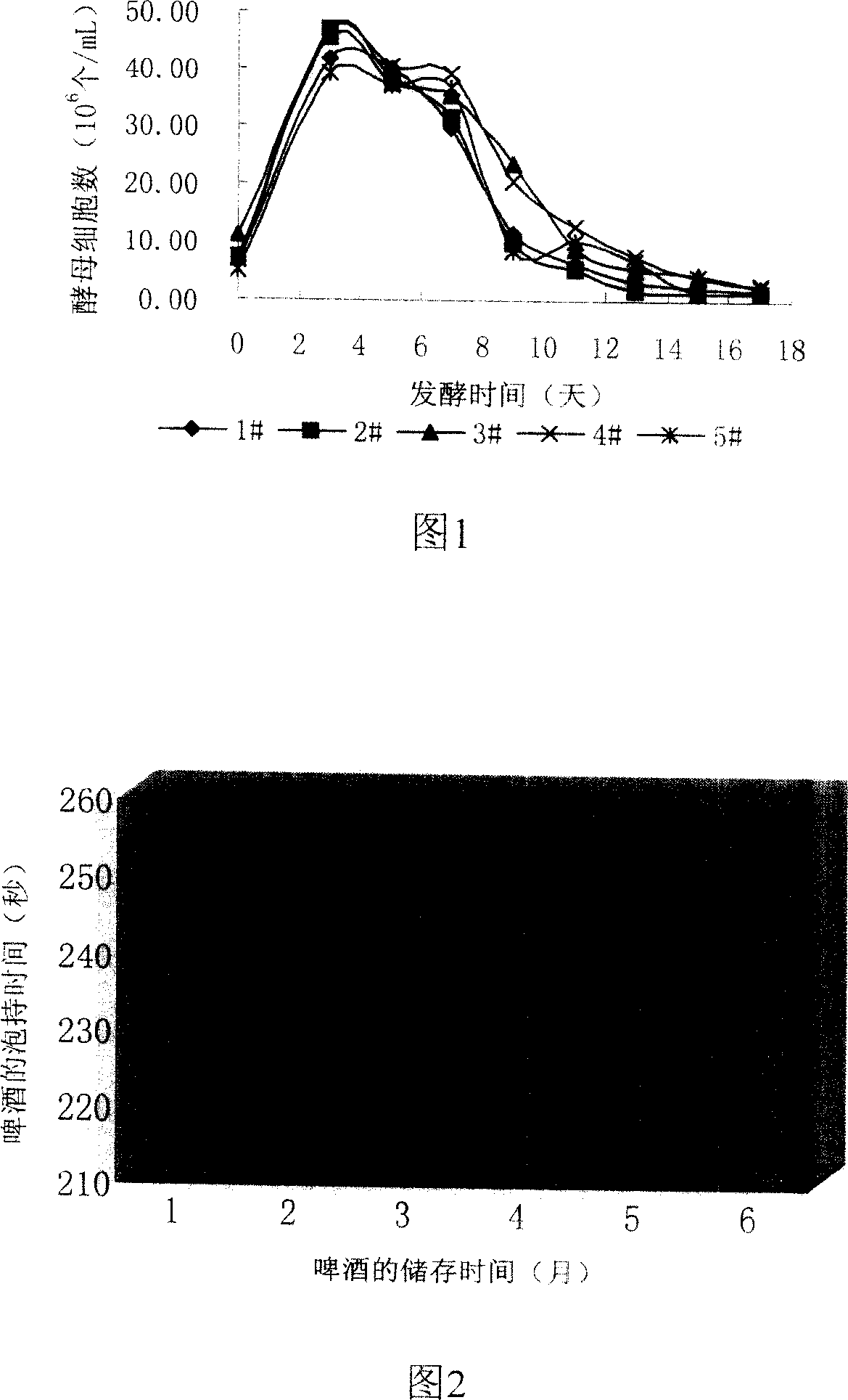

Prolease A defective yeast suitable for pure draft beer brewage and its usage method

The invention discloses a proteinase A defect yeast and using method to brew pure draught beer in the biological engineering technical domain, wherein the reserving number of brewing yeast (Saccharomyces Carlsbergensis) QD06-2 is CGMCC No1858; the modified strain of proteinase A doesn't contain any exogeneous gene; the technical parameter is 11 deg. C with alpha-amino nitrogen is not less than 200mg / 100mL and oxygen aerating quantity is 12mg / L; the density of yeast cell is 1. 8*106-2. 1*106 / mL, which can brew draught beer.

Owner:JIANGNAN UNIV

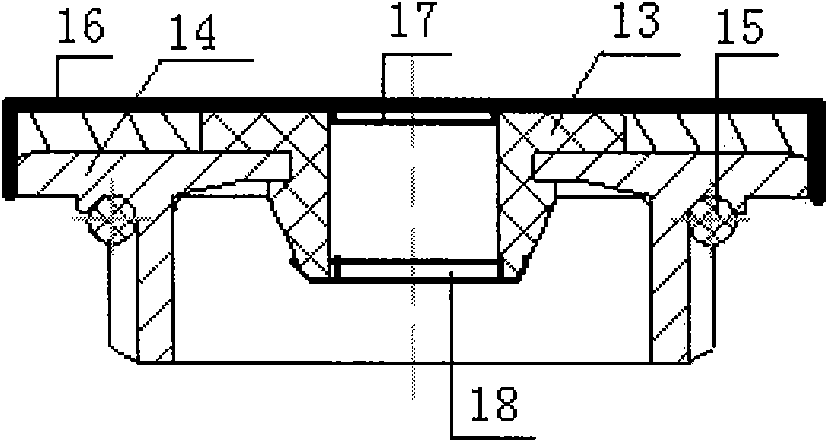

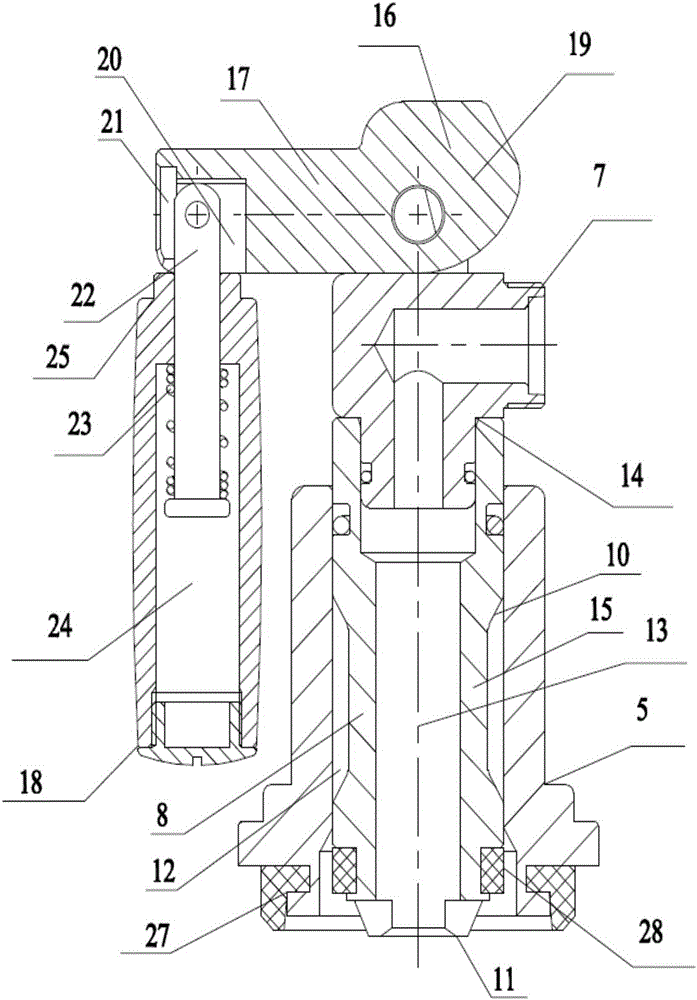

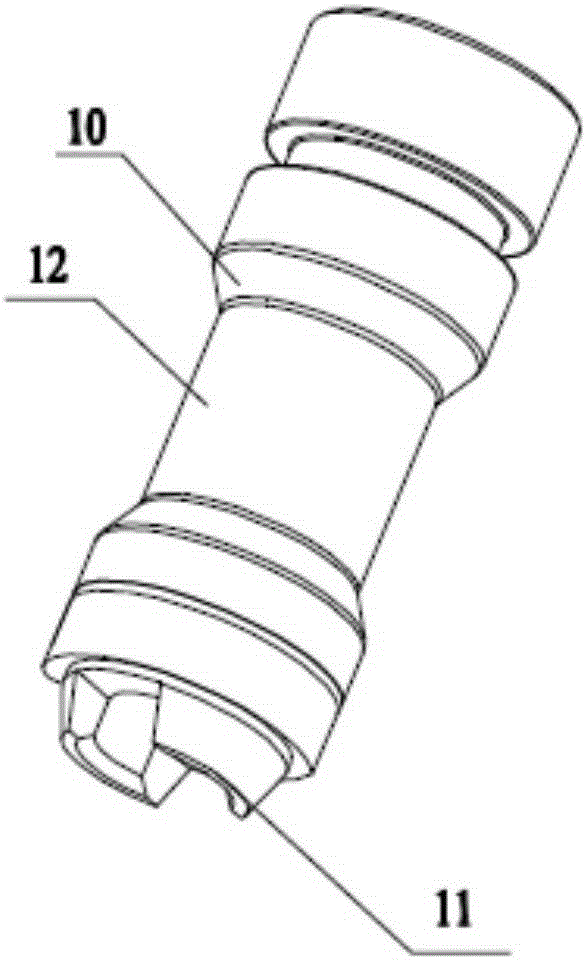

Distributor for beer fresh-keeping keg

ActiveCN105197866ATo achieve the purpose of drinkingImprove securityLiquid flow controllersLiquid dispensingPiston ringSelf locking

The invention discloses a distributor for a draught beer keg. The draught beer keg comprises an air feeding device (1) and a beer barrel (3), wherein a beer spear (2) is mounted on the beer barrel (3); the beer barrel (3) is used for storing liquid beverage; a non-return valve (9) which can be opened by touch triggering is arranged at the outlet of the air feeding device; the distributor (4) at least comprises a distributor seat (5), an air inlet end (6), a liquid outlet end (7) and a piston (8); the piston is provided with a piston non-return valve touch part (10) suitable for touch opening of the non-return valve (9) of the air feeding device, a piston bulge (11) suitable for press opening of the beer spear (2), a piston ring groove (12) suitable for being in gas communication with the air inlet end (6) and the beer barrel (3), and a piston longitudinal hole (13) suitable for being in fluid communication with the beer barrel (3) and the liquid outlet end (7). The distributor can be used for the integrated beer fresh-keeping keg; the piston of the distributor can control a gas passage and a fluid passage in a linking manner; an operating handle of the distributor is in the foldable form and adopts a self-locking structure, and the distributor has relatively high safety performance compared with that in the prior art.

Owner:NINGBO MASTER DRAFT BEER KEG EQUIP CO

Method for extracting protease A inhibitor and its application

InactiveCN1546525ALow costEnhanced inhibitory effectPeptide preparation methodsProtease inhibitorsFiltrationBaking powder

The invetion relates to a process for extracting proteinase A (PrA) from lucid ganoderma submerged cultuse liquid or lucid ganoderma baking powder and its use, the process comprises obtaining crude PrA suppression agent from the raffinate of lucid ganoderma fermentation liquid or baking powder through ethanol grading or film filtration grading, then obtaining refined PrA depressant by molecular screen chromatography to collect 30KD-40KD and partial cryodesiccation. The depressant can be applied to the production of pure draught beer.

Owner:JIANGNAN UNIV

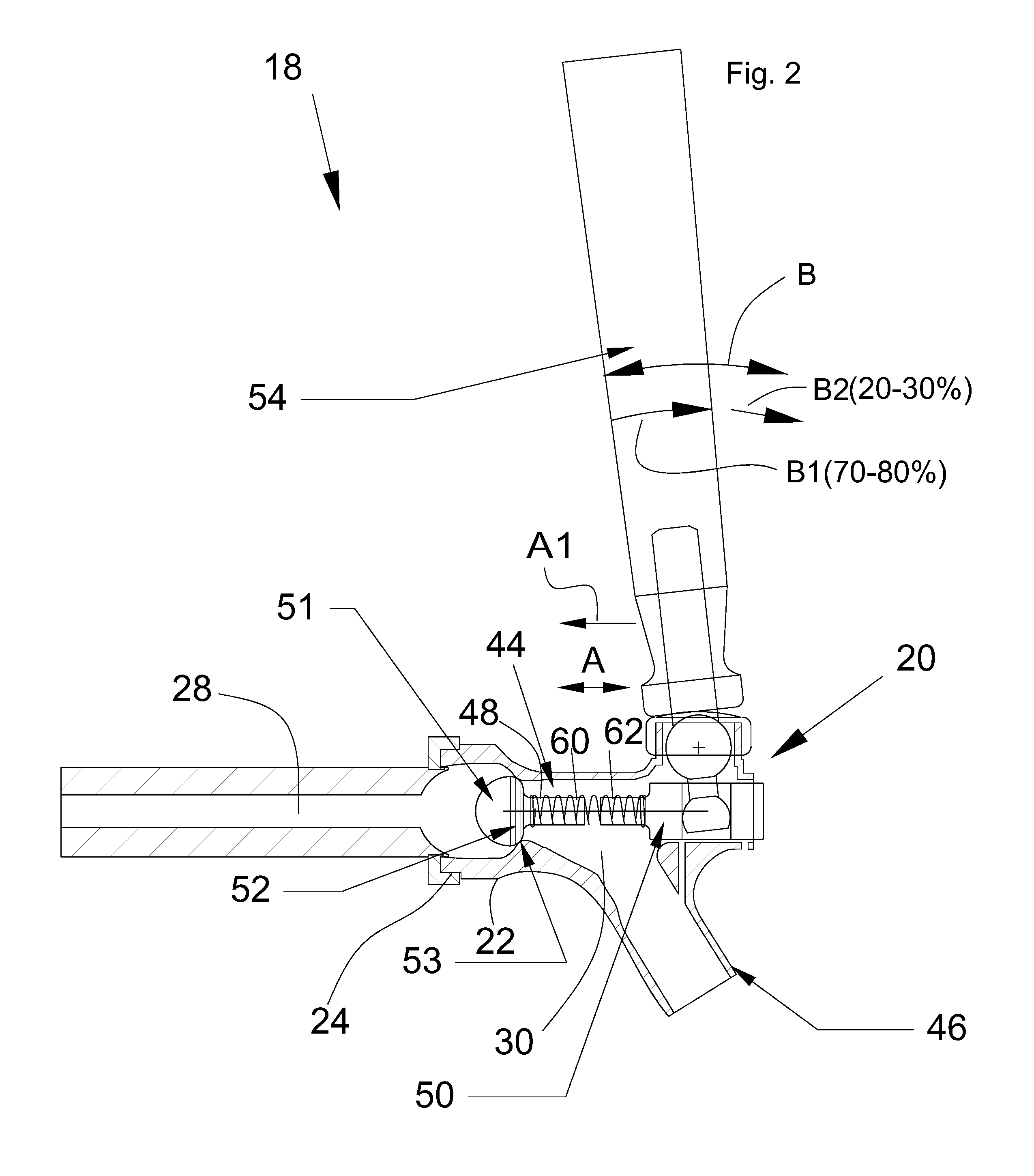

Beverage dispensing system with apparatus for controlling foaming and flow rate

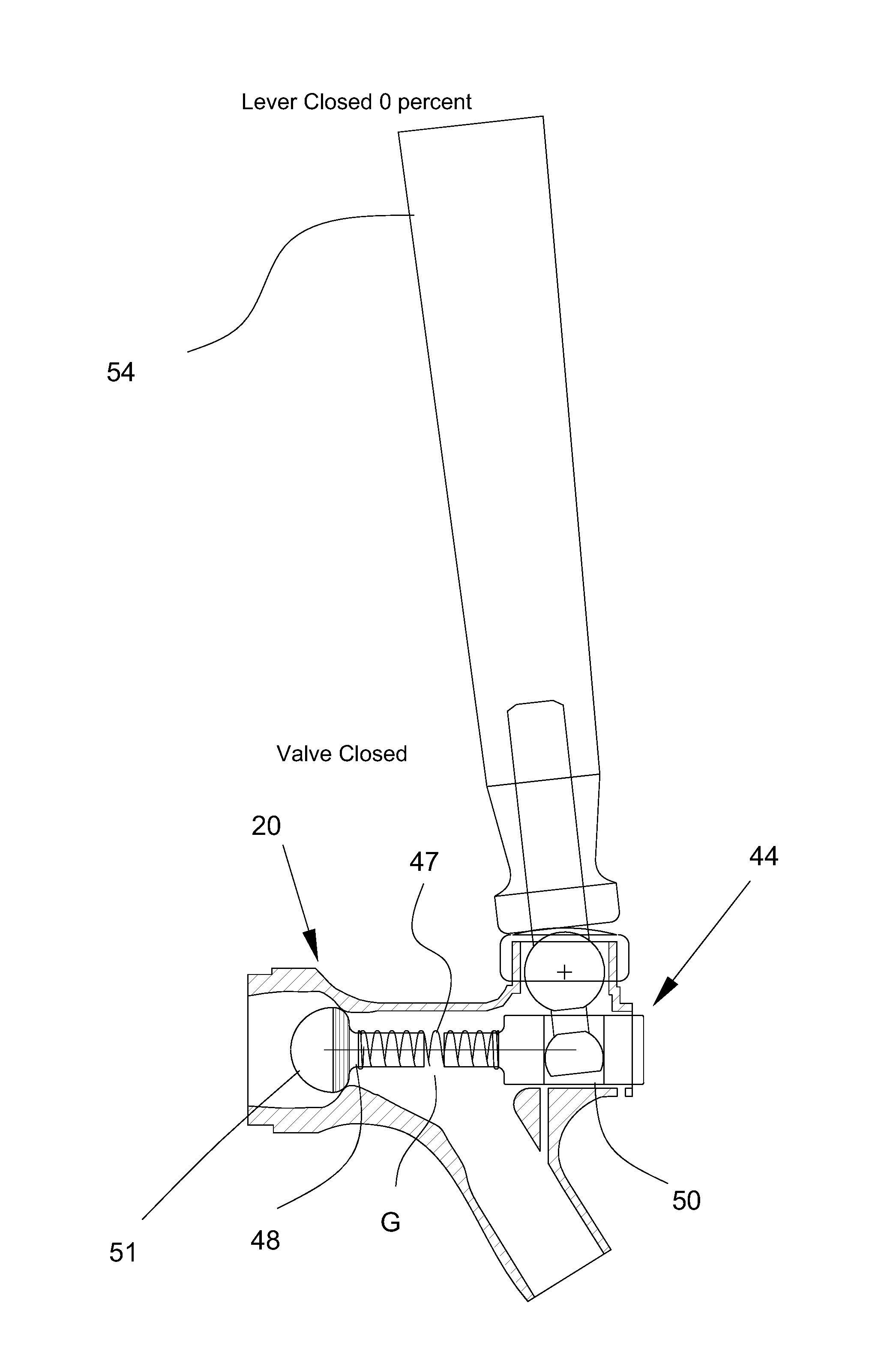

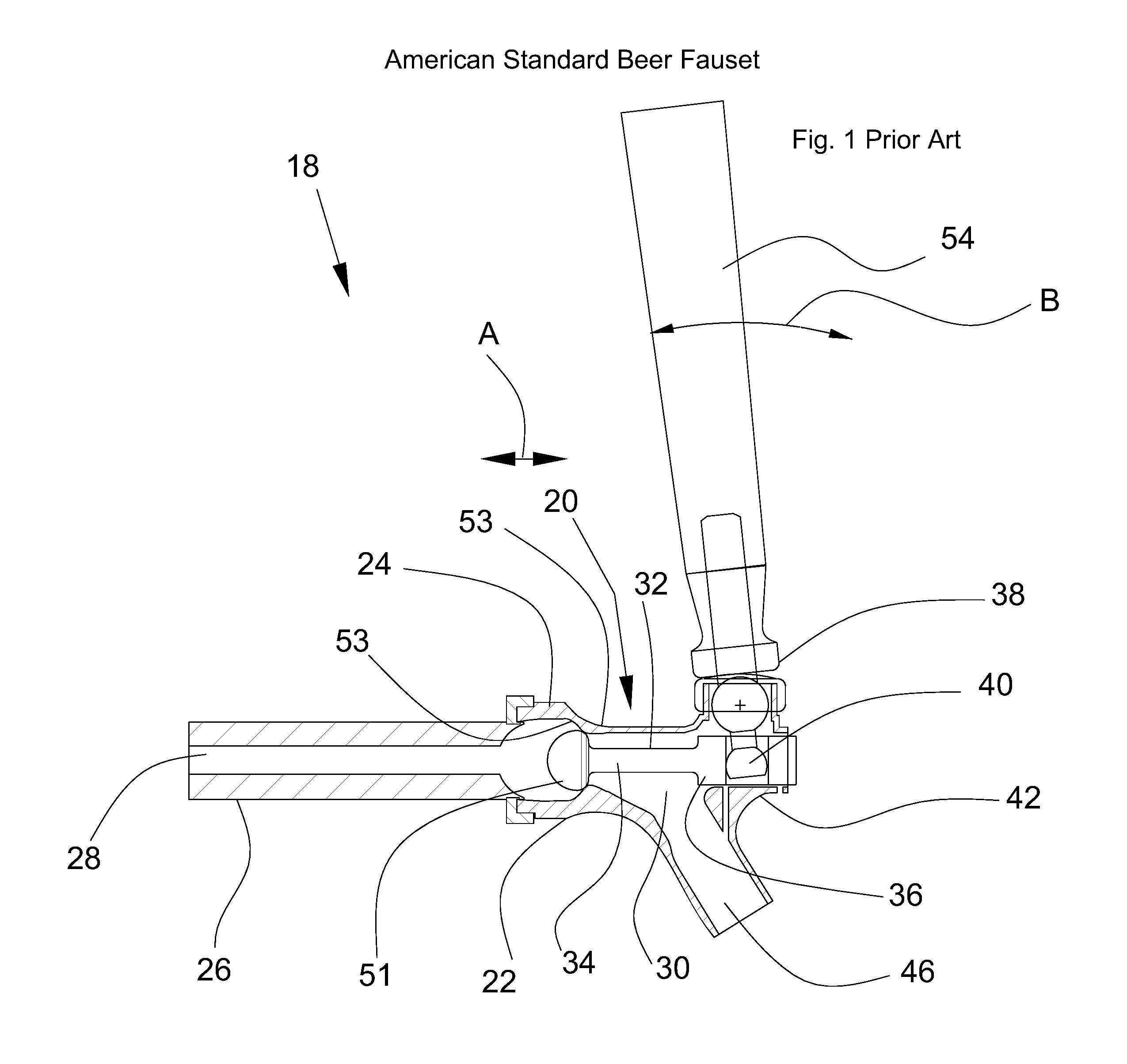

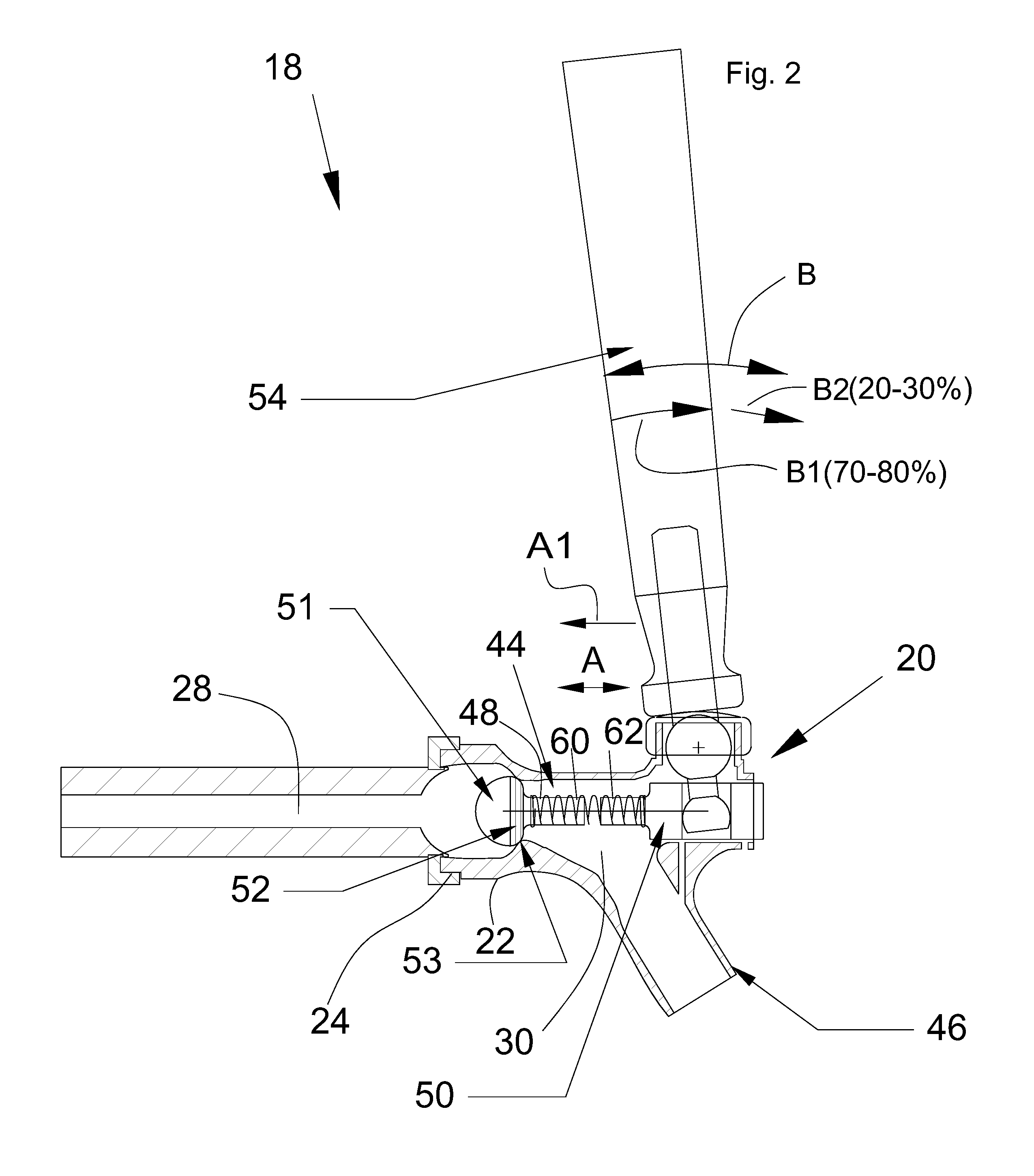

ActiveUS20130082075A1Easy to operateReduced beverage foamingLiquid flow controllersLiquid transferring devicesStored energyEngineering

The beverage dispensing system includes a dispensing faucet defining a flow path, a valve head in the flow path movable between a closed position in sealed contact with a valve seat, and an open position. An actuator is manually movable to operate the faucet, and a biasing element is cooperable with the actuator and valve head such that an initial movement of the actuator will automatically cause sufficient energy to be stored or loaded in the biasing element for moving the valve head to the open position but without doing so. Occurrence of a subsequent predetermined event such as a further movement of the actuator will cause the stored energy to be automatically released to rapidly or nearly instantaneously move the valve head to the open position. As a result, no instruction or skill is required to operate the faucet to uniformly dispense pressurized beverages such as draught beer.

Owner:ANHEUSER-BUSCH

Method for improving foaming characteristic of draught beer

InactiveCN101974378AIncrease the number of bubblesLong durationFermentationBeer brewingProteinase activityProtease

The invention discloses a method for improving the foaming characteristic of draught beer. The method comprises the following step of adding casein hydrolyzate into fermented and unfiltered draught beer and uniformly stirring the mixture; and the casein hydrolyzate is prepared by the following steps of: dissolving casein into water; adding protease; performing full enzymolysis and ending reaction; filtering; removing bacteria from filtrate; and concentrating and performing spray drying to prepare the casein hydrolyzate. By adding the casein hydrolyzate into the unfiltered draught beer, the number of foams of the draught beer is increased and the duration of the foaming of the beer after two months is increased, and the method is convenient to operate and has wide application prospect.

Owner:ZHEJIANG UNIV +1

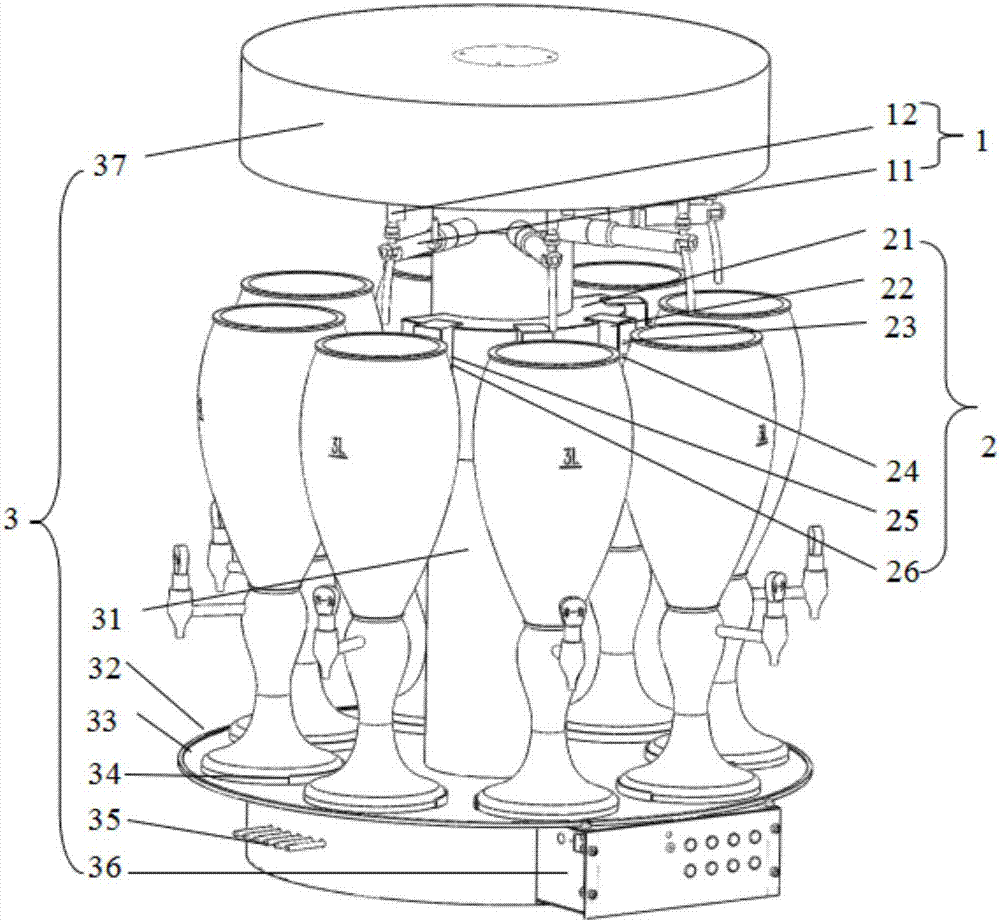

Automatic draught beer pouring machine and draught beer cup beer level control method thereof

ActiveCN106927414AConvenient careReduce labor intensityLiquid flow controllersLiquid dispensingEngineeringSanitation

The invention discloses an automatic draught beer pouring machine which comprises a draught beer cup placement tray, a stand column and at least one draught beer head. The draught beer cup placement tray is arranged on the stand column and can rotate around the stand column in the horizontal direction. The draught beer heads are arranged on the upper portion of the stand column. In addition, the invention discloses a draught beer cup beer level control method of the automatic draught beer pouring machine. According to the automatic draught beer pouring machine, the structure is simple, metering is accurate, and cleaning and sanitation are easy; and meanwhile, the labor intensity of staff is greatly relieved, and automatic draught beer pouring is achieved.

Owner:深圳海伦司企业管理有限公司

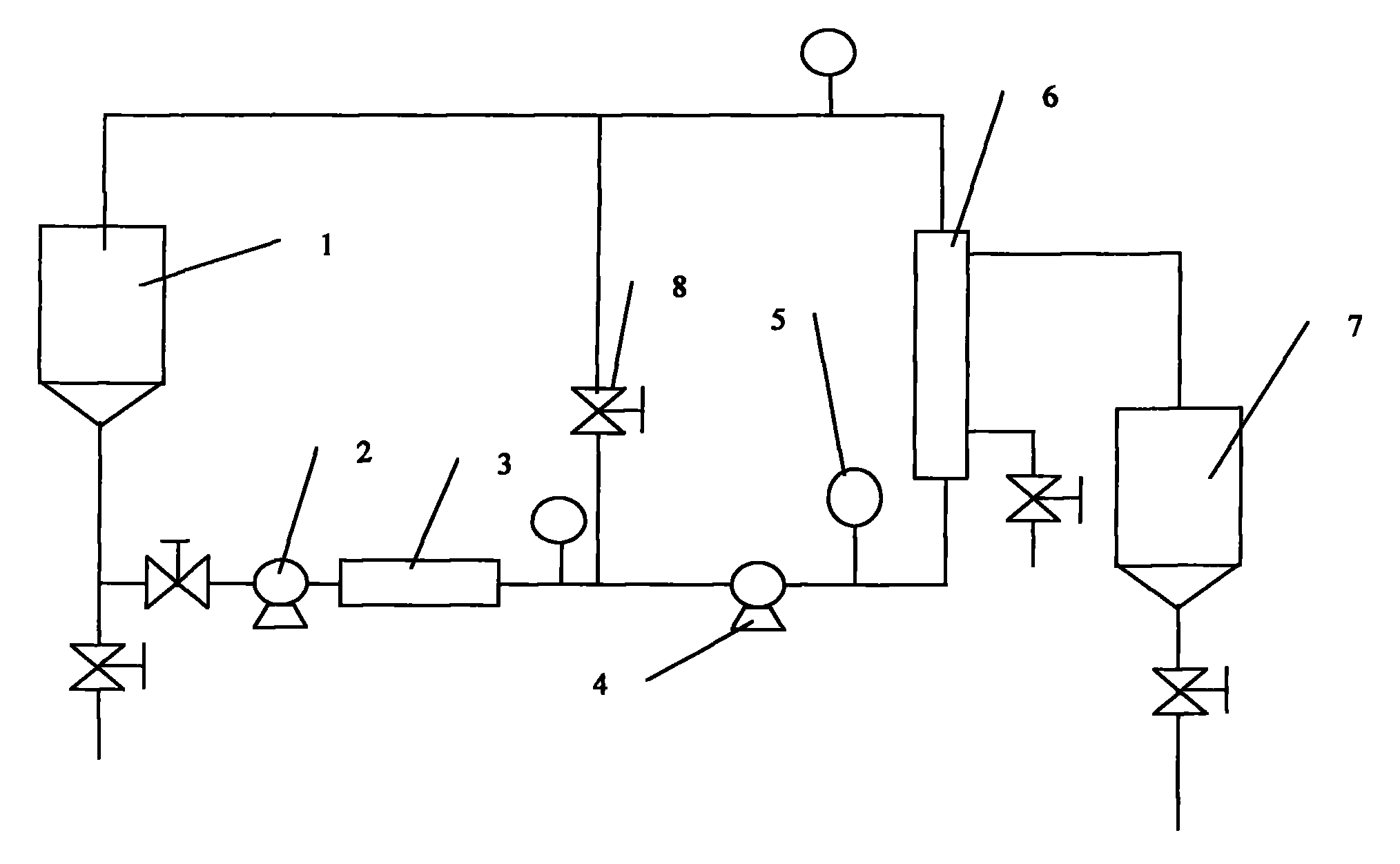

Technology for recycling beer from beer waste yeast paste

InactiveCN101974381AIncrease productionImprove qualityBy-product recoveryEngineeringCeramic membrane

The invention discloses a technology for recycling beer from beer waste yeast paste, which comprises the steps that the beer waste yeast paste is injected into a circulation tank, and filtered and separated by a metal membrane or a ceramic membrane through a feeding pump, a condenser and a circulation pump; the separated beer penetrating fluid is added to a semi-finished product processing system; a part of waste yeast paste mother liquor returns to the circulation tank, and the other part is filtered by the metal membrane or the ceramic membrane through the circulation pump; and the waste yeast paste is exhausted to enter a deep processing system when the seepage of filter membrane beer is less than 20L / m<2>h. The technology has the advantages of effective separation and clarification of the beer waste yeast paste, high separation speed, high precision, direct elimination of yeast and bacteria, and sterilization technology ignorance, and the separated beer can directly enter a draught beer processing system. After the beer yeast paste is separated by the membranes, the beer is recycled, no waste is exhausted, the yield and the quality of the beer are enhanced, 100 to 150 thousand tons of the beer can be recycled every year equivalent to about RMB 200 million, the BOD (Biochemical Oxygen Demand) value can be reduced by about 50%, and the environment protection load can be greatly reduced.

Owner:河北美邦工程科技股份有限公司

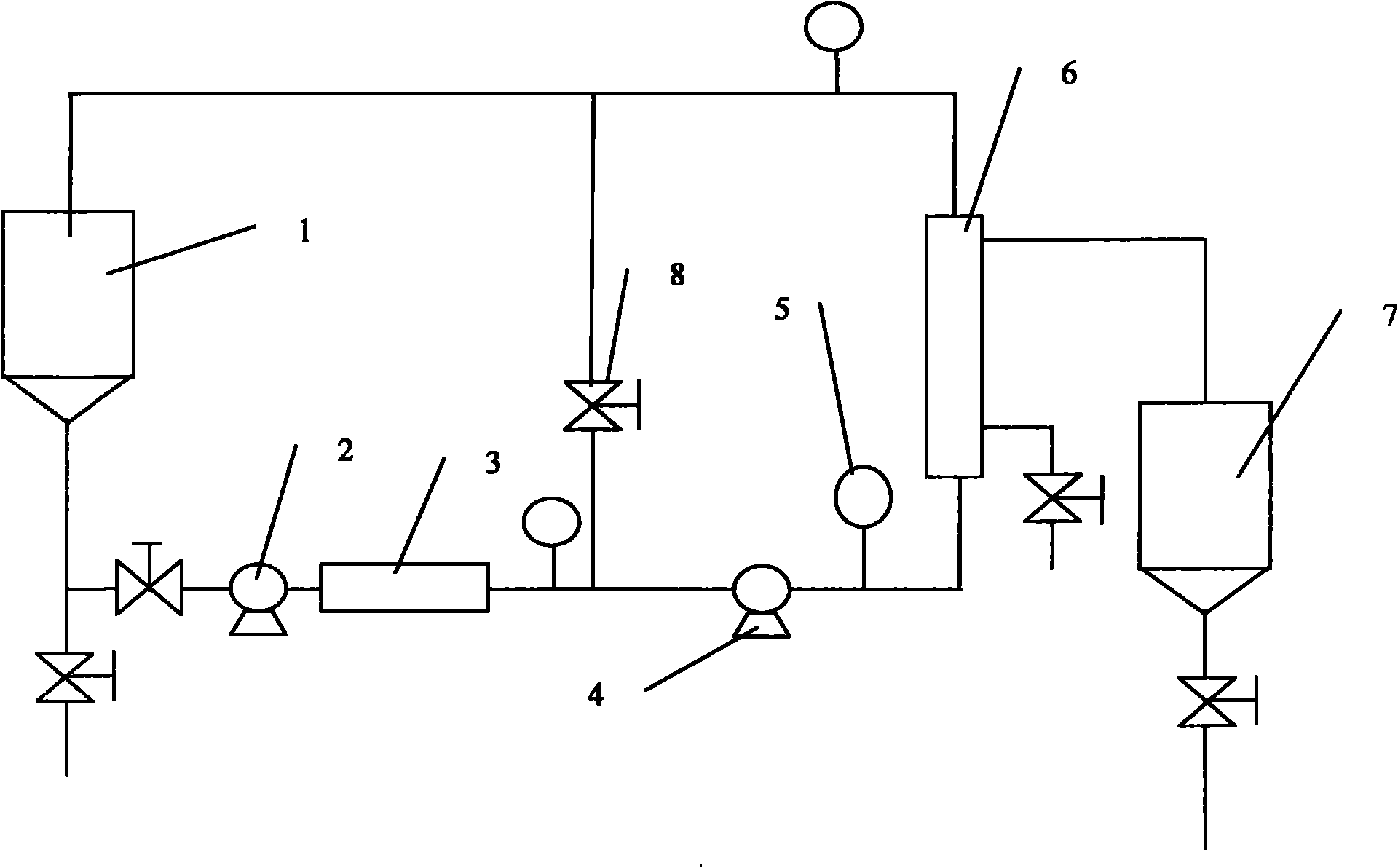

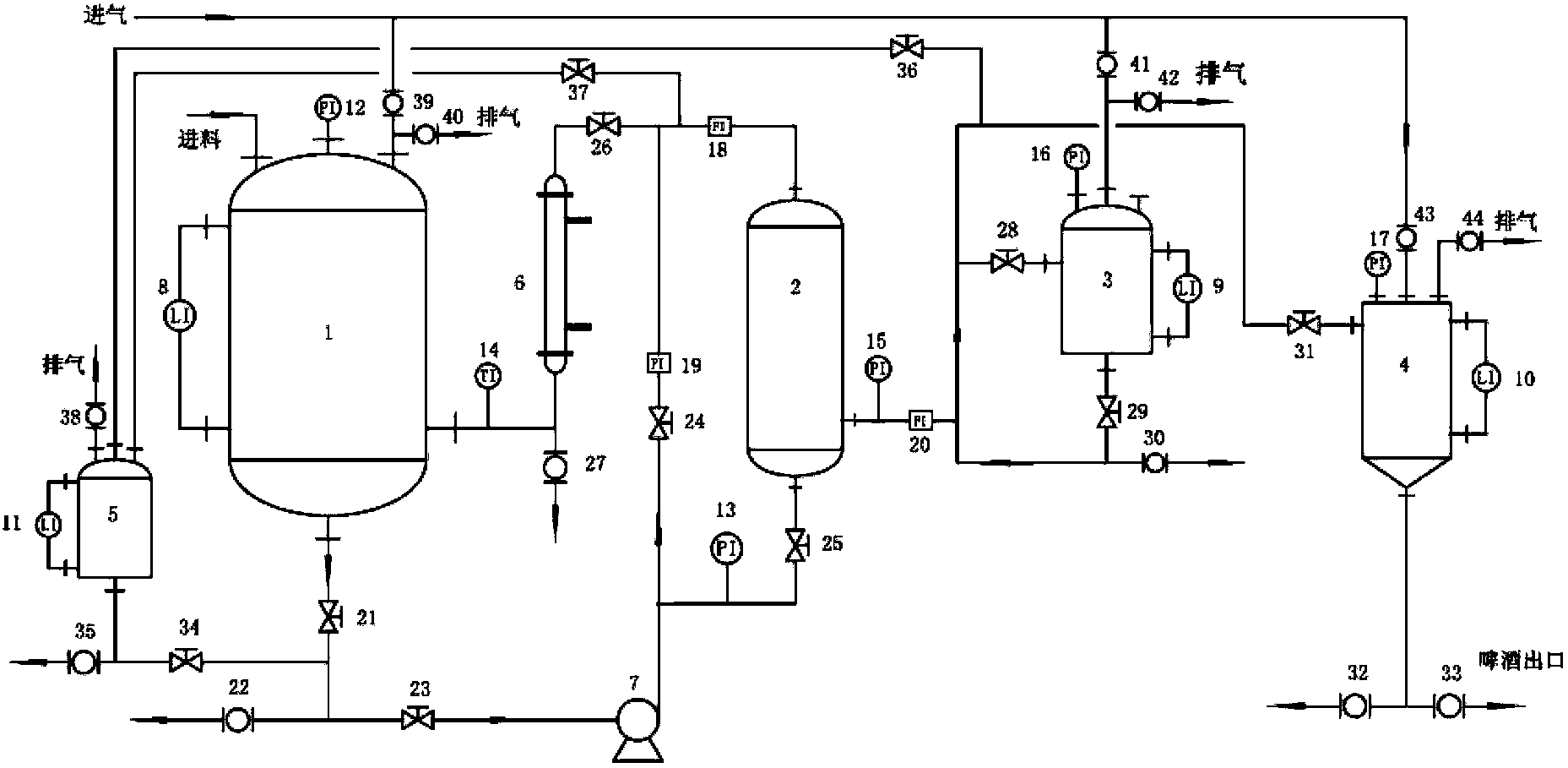

Inorganic ceramic membrane device for applying to clear and filter draught beer and method thereof

ActiveCN103894064AMeet quality requirementsPhysicochemically stableUltrafiltrationAlcoholic beverage preparationFlocculationColloid

The invention relates to an inorganic ceramic membrane device for applying to clear and filter draught beer and a method thereof. The device structurally comprises a yeast tank, a series of separator main bodies, a ceramic membrane separation element, a backlash tank, a cleaning tank and a pump. The pump is utilized to pump the draught beer in the yeast tank in the inorganic ceramic membrane separation device; the draught beer is filtered through the ceramic membrane separation element to remove saccharomycetes and microorganism such as bacteria in the beer and a colloid deposit sediment generated by cooling flocculation; the clear beer is separated and sent into a subsequent manufacturing procedure; and one part of a mother solution containing yeast returns to the yeast tank, and the other part of the mother solution is circularly filtered through a circulating pump. The inorganic ceramic membrane device provided by the invention adopts the inorganic ceramic membrane as a filtering element, so that the inorganic ceramic membrane device can carry out steam sterilization and disinfection.

Owner:安徽安赐环保科技有限公司 +1

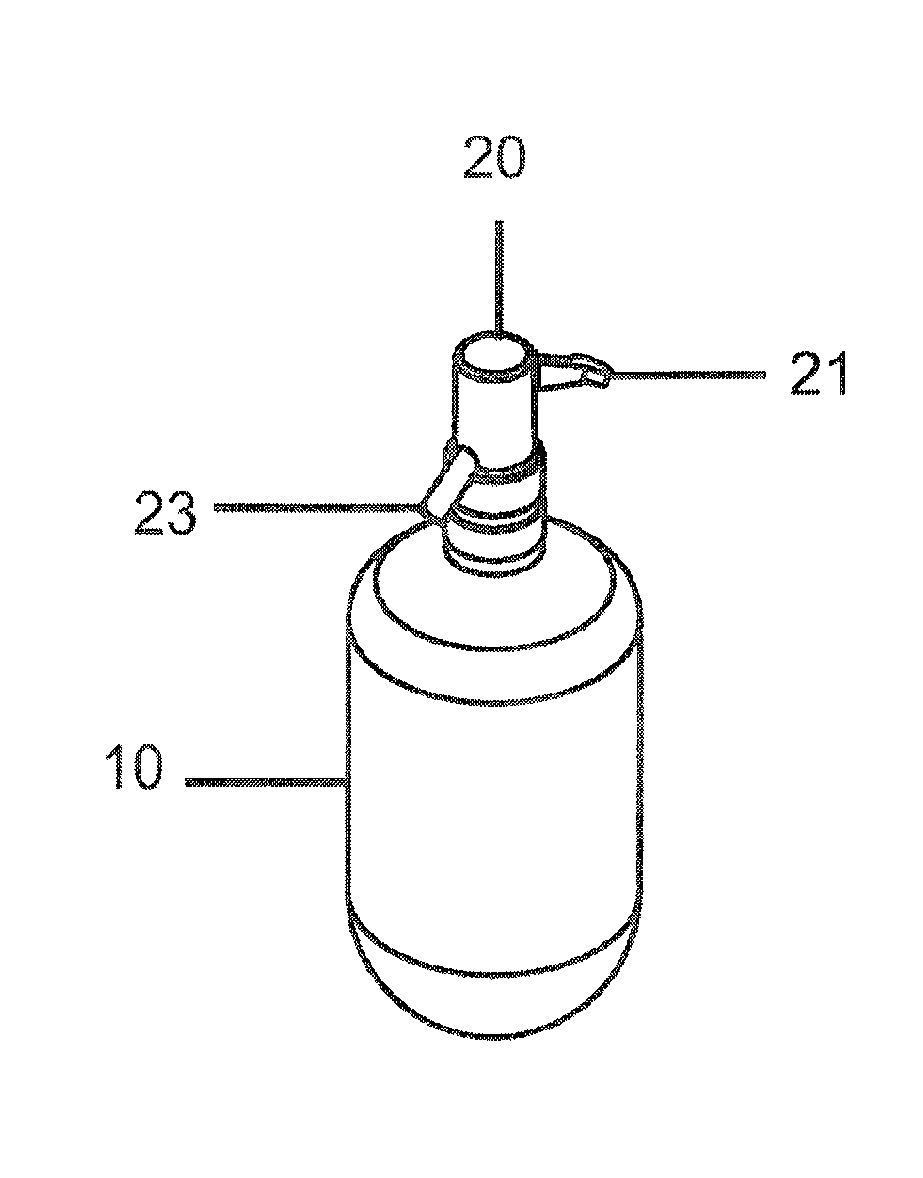

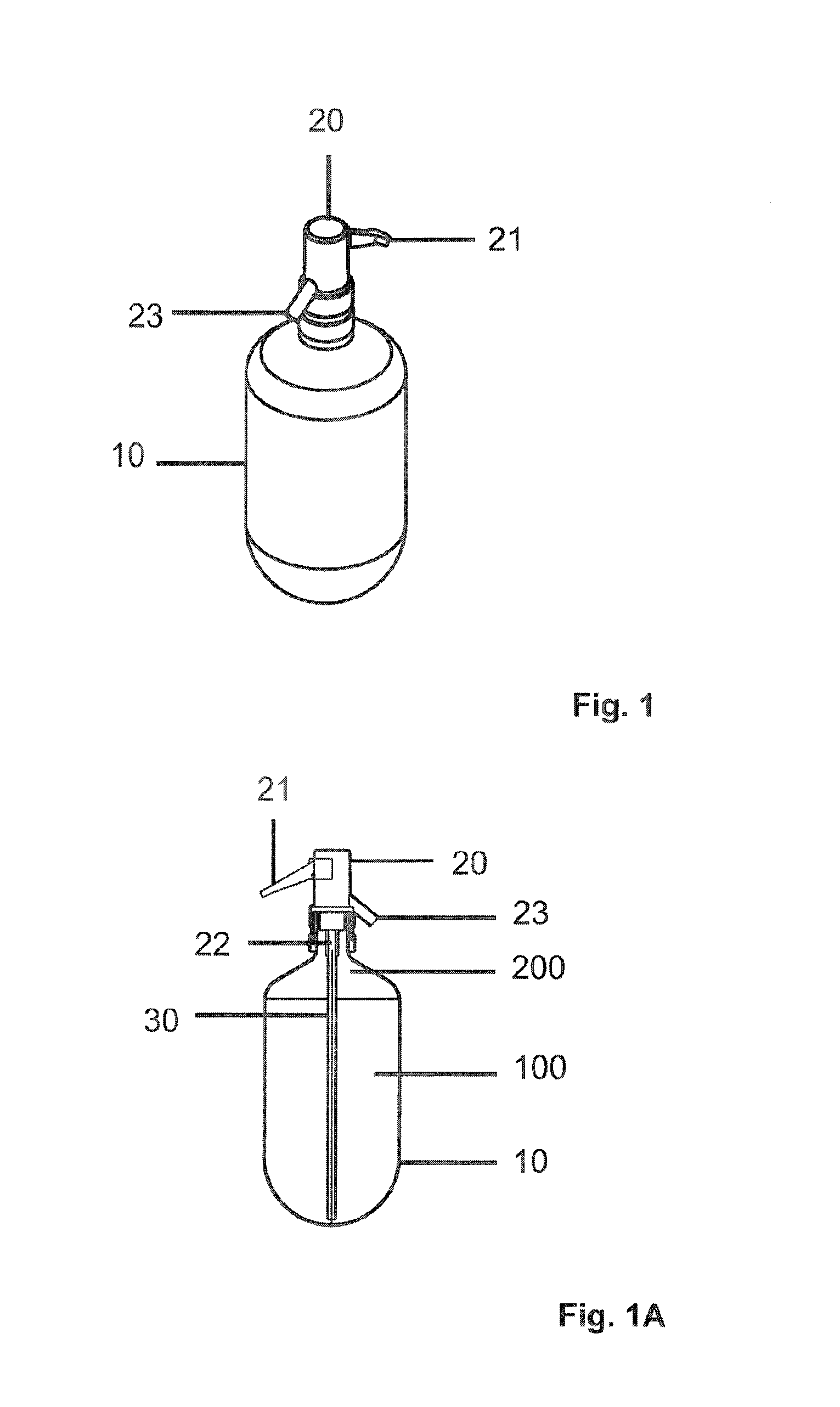

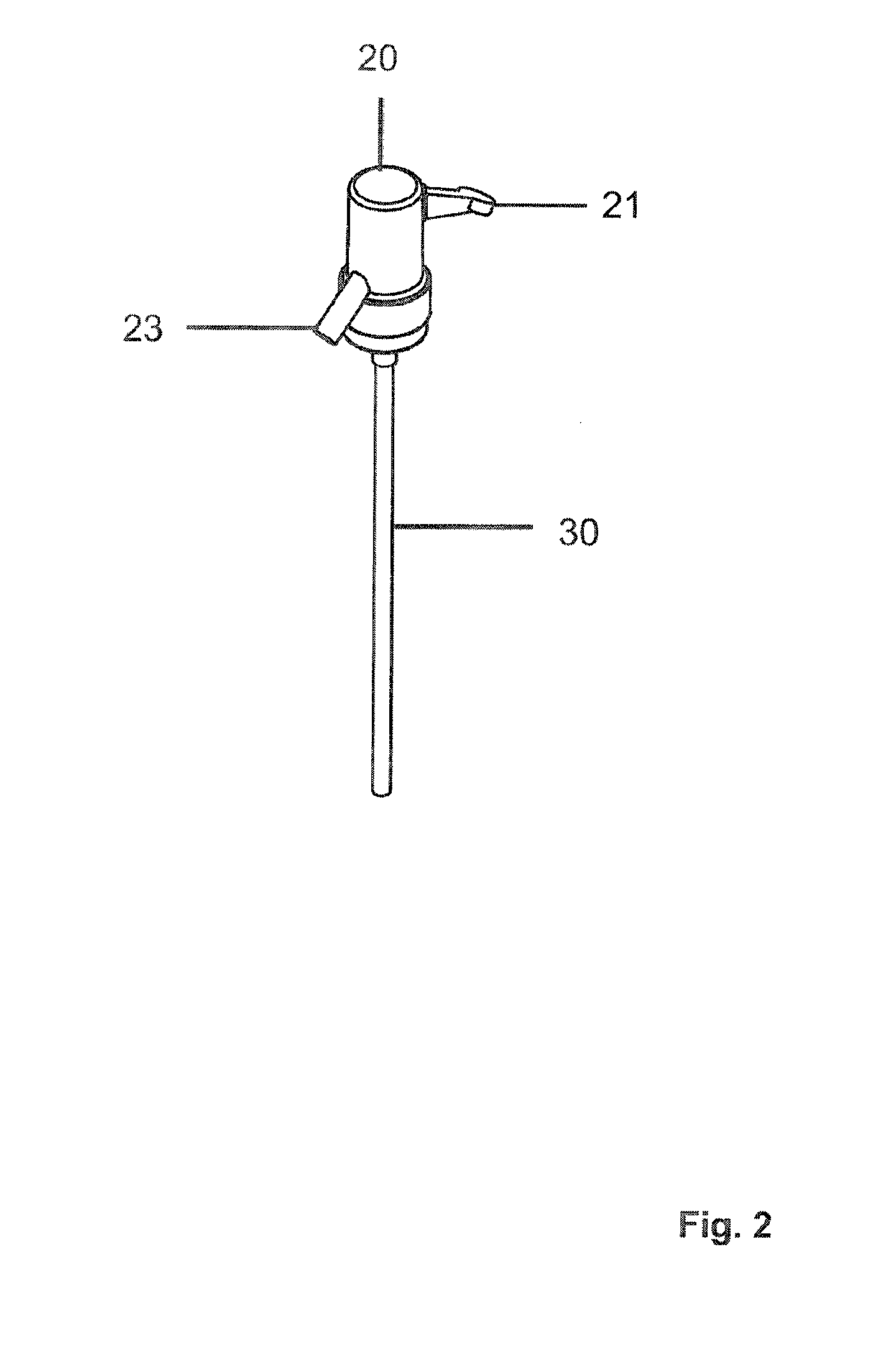

Packaging for filling and extraction of carbonated beverage

InactiveUS20140339269A1Without injury to organoleptic characteristicWithout risk of oxidationBeer fermentationLiquid dispensingSolubilitySiphon

A packaging for filling and extraction of carbonated beverage, preferably draught beer and beer, with addition of an appropriate gas for beverages with low solubility in the carbonated liquid, preferably nitrogen, and the said gas be deposited directly into the filling packaging and filling in contact with carbonated liquid, without being stored in external recipient or in internal device pressure regulator of the packaging, and said packaging include a body (10) provided with a hole where is positioned an extractor valve (20) coupled in a siphon tube (30) sized for the release of carbonated beverages without excessive foaming, whose siphon tube (30) presenting reason between measure diameter of siphon (30) and the respective measure of length up to 2.0%.

Owner:FEZER GUSTAVO FORESTI

Whole strawberry juice pure draft beer

The invention relates to whole strawberry juice pure draft beer and nonalcoholic or low-alcohol beer, which are novel beer produced by taking strawberries as raw materials, adding hops after preparation of fruit juice, adopting the purified brewing procedure, without malt manufacturing procedure and the wort manufacturing procedure, and filtering and sterilizing wine liquid, together with the typical wort pure draft beer technique without undergoing thermal sterilization, or are whole strawberry juice pure draft beer and nonalcoholic or low-alcohol beer produced by using the fermentation-limited method and the alcohol removal method to control or remove alcohols, together with the hole strawberry juice pure draft beer technique. The whole strawberry juice pure draft beer and the nonalcoholic or low-alcohol beer not only have the style of typical wort pure draft beer but also have unique strawberry flavor, have rich and balanced nutritional ingredients and good medical care value, save foodstuffs, lands, coal, electricity and water, improve the labor productivity, and have the social benefit and the economic benefit by reducing emission of 'the three wastes'. The beer can be produced in general breweries only by addition of a little factory building equipment.

Owner:徐乐三

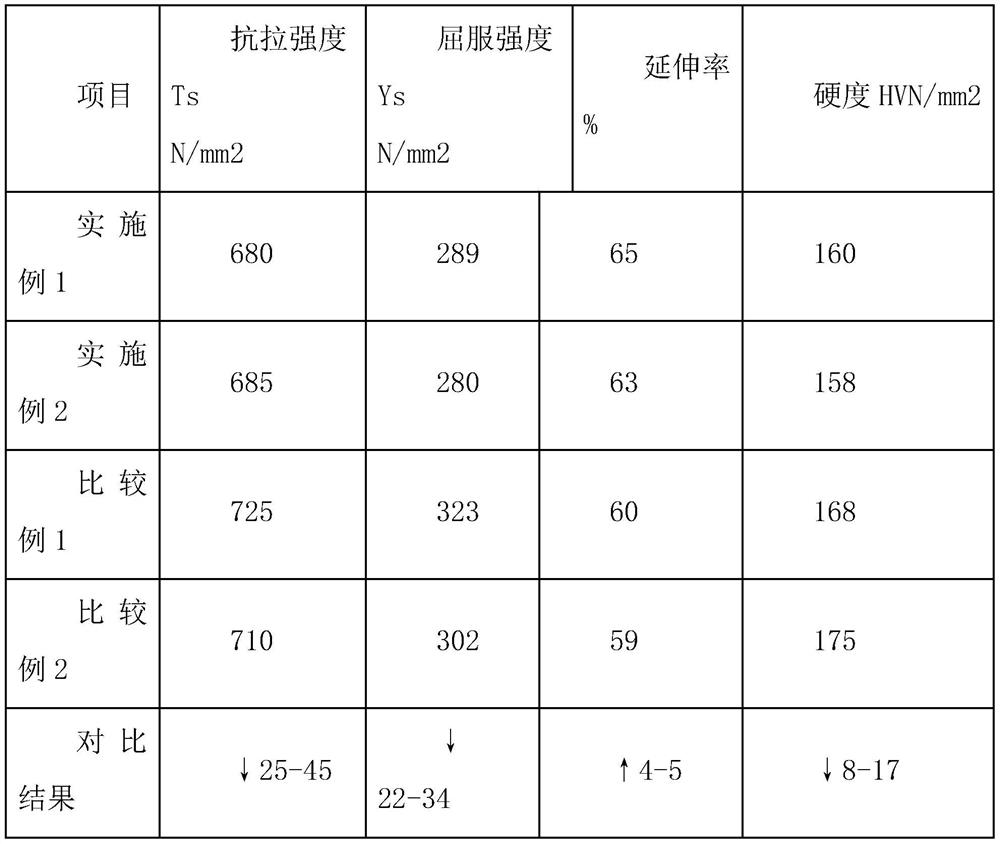

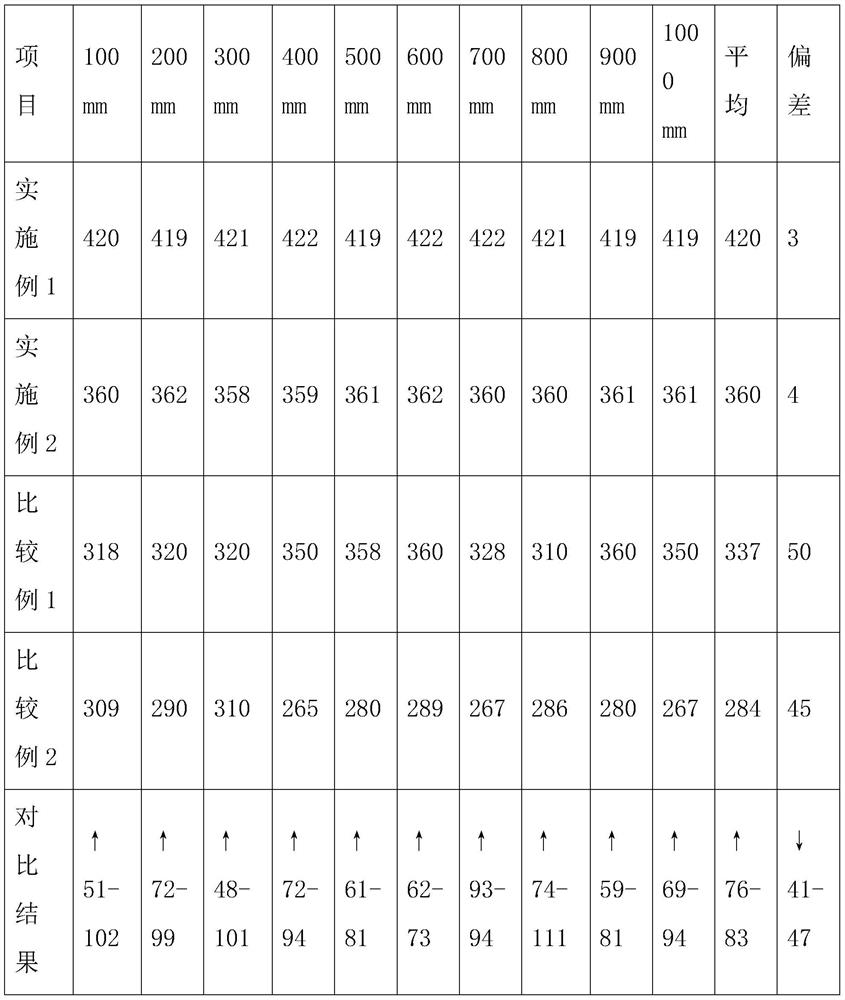

Manufacturing method of austenitic stainless steel for non-magnetic color-difference-free beer barrel

ActiveCN113106222AIncrease awarenessReduce solid solution precipitationProcess efficiency improvementSmelting processAustenite

The invention provides a manufacturing method of austenitic stainless steel for a non-magnetic color-difference-free beer barrel. The manufacturing method comprises the following steps: continuously casting raw materials of the austenitic stainless steel into a steel billet through a smelting process; sequentially carrying out hot rolling, hot rolled steel coil annealing and pickling, defect grinding, cold rolling, cold rolling, annealing and pickling and finishing on the obtained steel billet; and sequentially performing surface color difference and material magnetism detection on the steel billet machined through the finishing process in the S2 to obtain the austenitic stainless steel suitable for producing the non-magnetic color-difference-free beer barrel. According to the manufacturing method of the austenitic stainless steel for the non-magnetic and color-difference-free beer barrel, stainless steel materials produced by the manufacturing method are used for nearly 3 million stainless steel beer barrels, draught beer barrels, wine barrels, beer fresh-keeping barrels, beer kettles and chemical barrels in numerous international famous brewery enterprises, the advanced technology of steel manufacturing in China is shown, the popularity of enterprises and products is improved, and about 30 million economic benefits are created for the enterprises.

Owner:天津太钢天管不锈钢有限公司

Ice blocks with beer yeast live bacteria and preparation method thereof

InactiveCN102391951ASolve the problem of not being able to save for a long timeReduce wasteMicroorganism based processesMicroorganism preservationSaccharomycesDraft beer

The invention relates to ice blocks with beer yeast live bacteria and a preparation method, belongs to the technical field of brewing of beer and particularly relates a live yeast bacteria conservation method for preparing draft beer, namely fresh beer. The ice blocks contain beer yeast solution, and the beer yeast bacteria in the beer yeast solution are still live; according to the volume ratio of liquid, the ice blocks comprise 900-970 parts of clean water and 30-100 parts of the beer yeast solution; the ice blocks are formed by uniformly mixing the clean water with the beer yeast solution according to the volume ratio and then freezing; and the beer yeast solution is yeast solution for preparing the beer, and the live yeast are contained in the beer yeast solution. The ice blocks have the advantages that as long as the ice blocks are melted in pasteurimd beer under the normal temperature state of 10-40 DEG C, the ice blocks with the beer yeast live bacteria can turn the pasteurimd beer to the fresh beer, the problem that the fresh beer can not be conserved for a long time can be solved, the transportation cost is saved and the current waste of the fresh beer is reduced.

Owner:熊正康

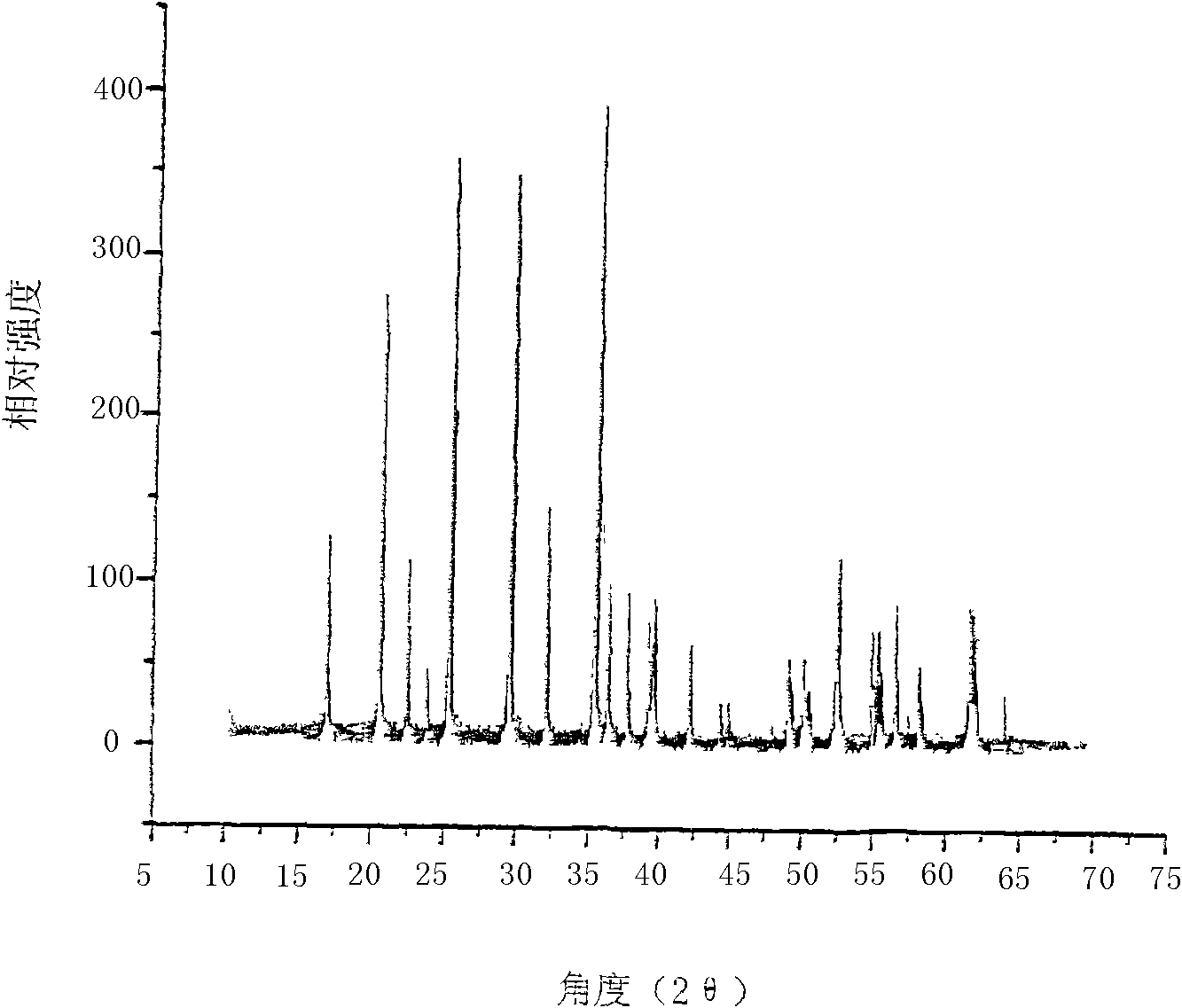

Method for synthesizing LiFePO4 by using biosurfactant

InactiveCN101555003AEvenly distributedShape is easy to controlCell electrodesPhosphorus compoundsMicrowaveCoprecipitation

The invention relates to a method for synthesizing LiFePO4 by using a biosurfactant, which belongs to the technical field of the biochemical industry. The Li2CO3, the (NH4)2HPO4 and the FeSO4.7H2O react in equal molar ratio and then are added with a biosurfactant (draught beer), an LiFePO4 precursor is prepared by a coprecipitation method, and then the LiFePO4 precursor is sintered under microwave to obtain the product. Since the biosurfactant is added in during the preparation process of the precursor, the synthesized LiFePO4 has more ideal particle morphology: spherical particles, uniform size, 1-2mum of grain size in average and even dispersion. The process has the advantages of easy control, low production cost, short preparation cycle and feasibility of the industrialization.

Owner:QILU UNIV OF TECH

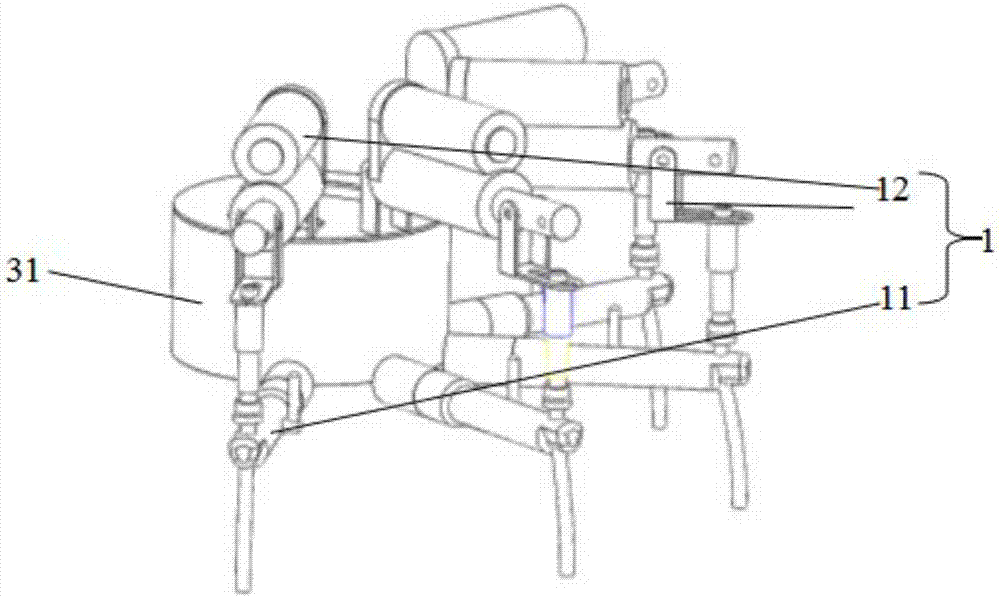

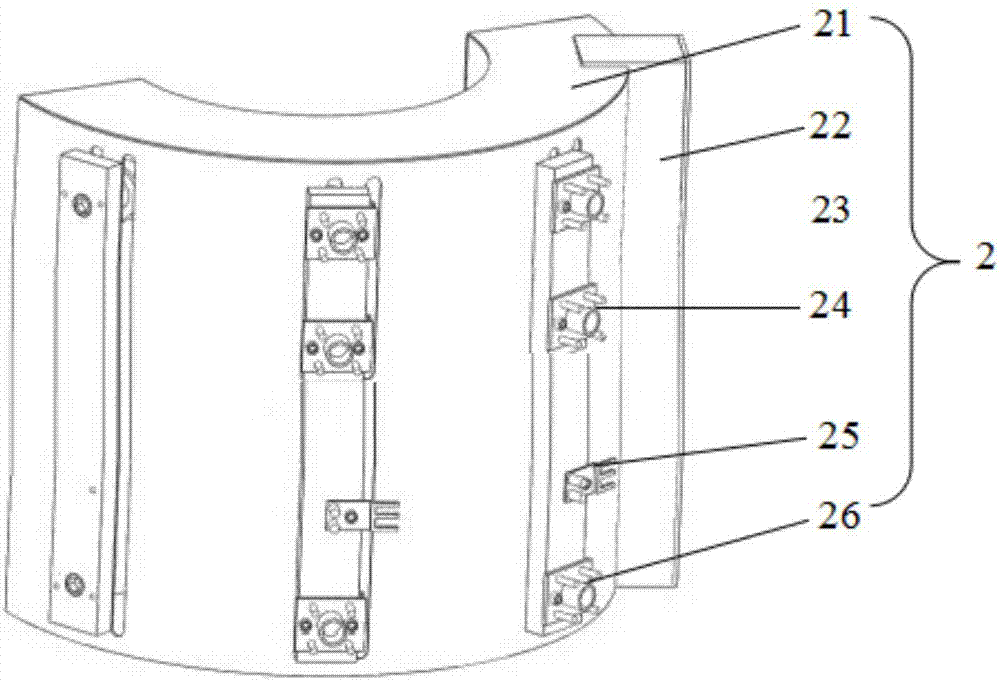

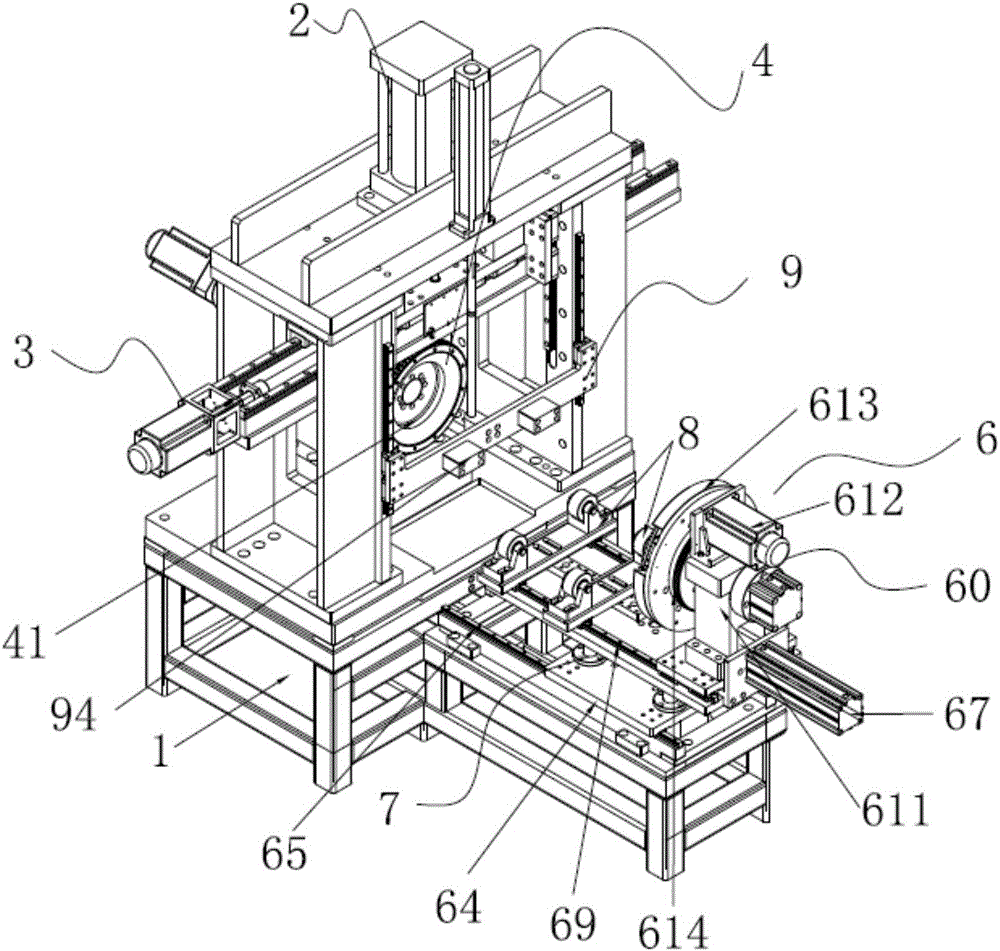

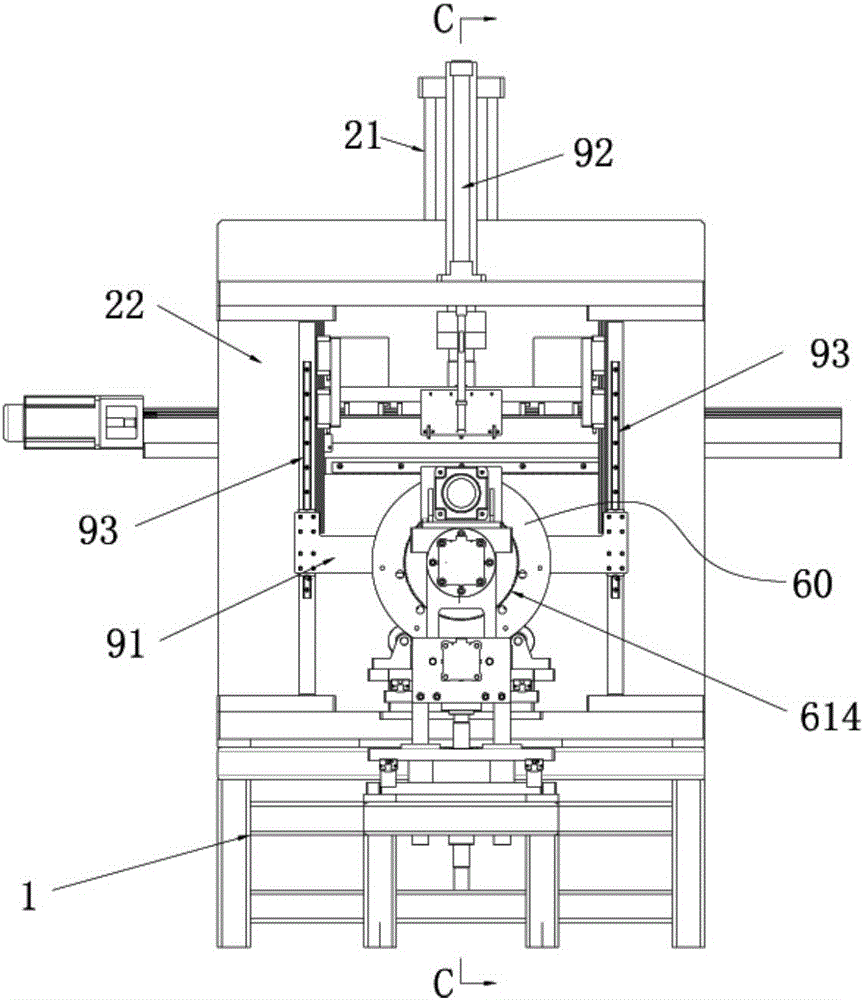

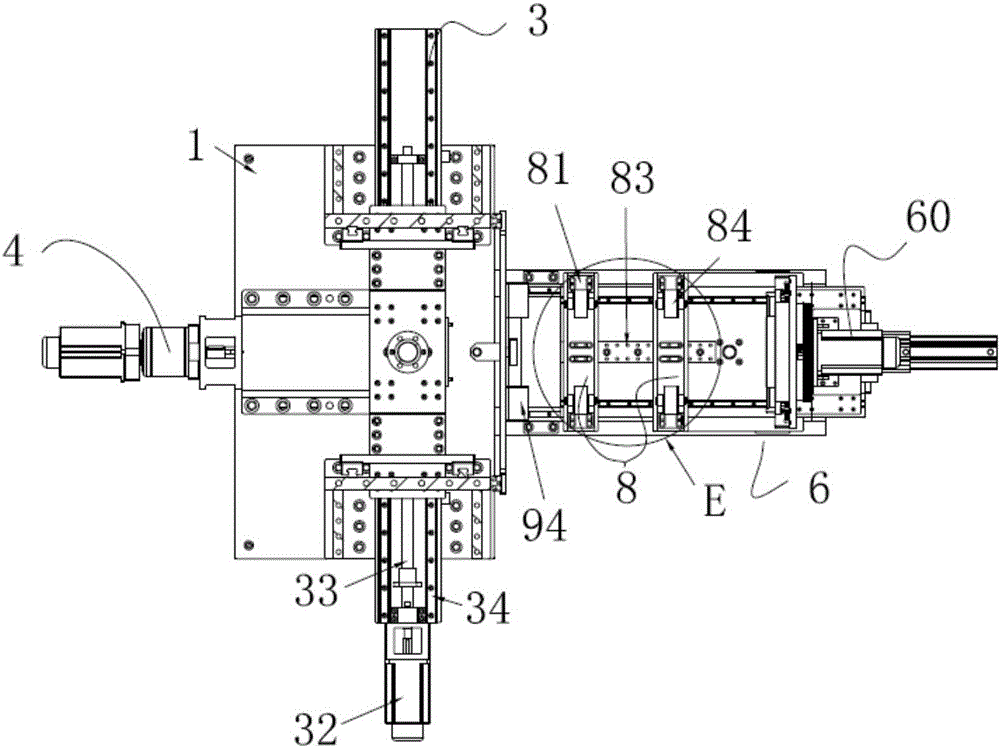

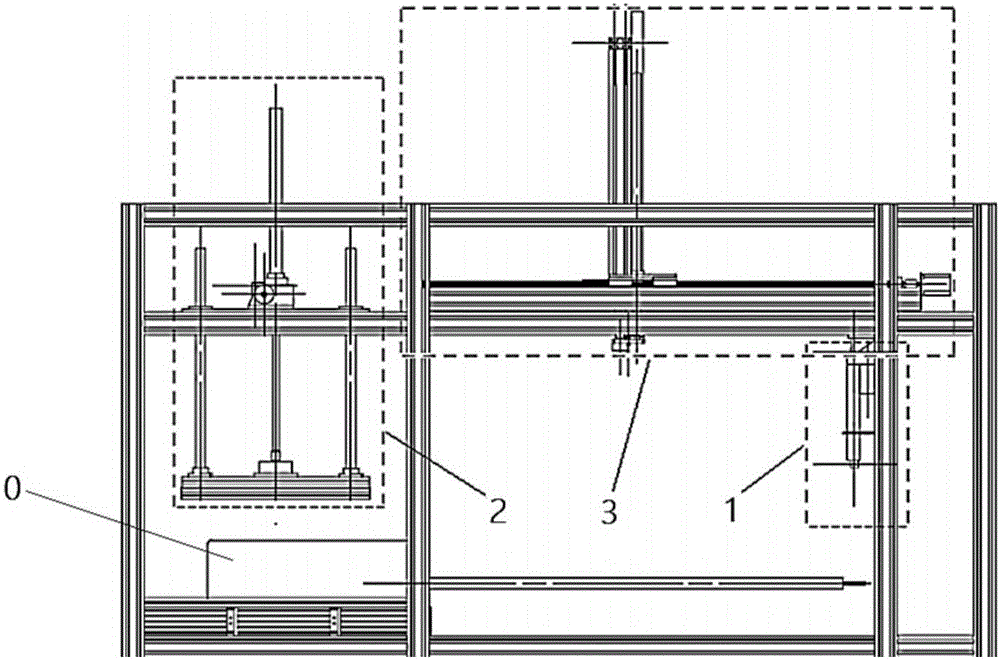

Device and process for printing characters on draught beer barrel

ActiveCN105799347AAvoid the defect that the printing process is also uselessReduce processStampingElectrical and Electronics engineeringDraught beer

The invention discloses a device for printing characters on a draught beer barrel. The device comprises a machine frame, a hydraulic push device, a beer barrel outer side character printing device, a beer barrel inner side character printing device, a beer barrel drive mechanism and a plurality of character die assemblies, wherein the hydraulic push device, the beer barrel outer side character printing device, the beer barrel inner side character printing device, the beer barrel drive mechanism and the character die assemblies are installed on the machine frame. Each character die assembly comprises a male die and a female die, wherein the male die and the female die are used in cooperation for forming a single character through impressing. The beer barrel outer side character printing device, the beer barrel inner side character printing device and the beer barrel drive mechanism can all be independently operated. The beer barrel outer side character printing device and the beer barrel inner side character printing device can automatically find the corresponding female dies and the corresponding male dies according to impressed content and send the corresponding female dies and the corresponding male dies to impressing positions. The beer barrel drive mechanism can automatically rotate a beer barrel to the appropriate angle according to the impressed content. Therefore, operation is quite convenient, impressing is attractive, efficiency is high, and a great convenient effect is achieved for engraving and printing of concave-convex series numbers.

Owner:NINGBO MASTER DRAFT BEER KEG EQUIP CO

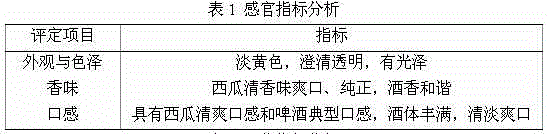

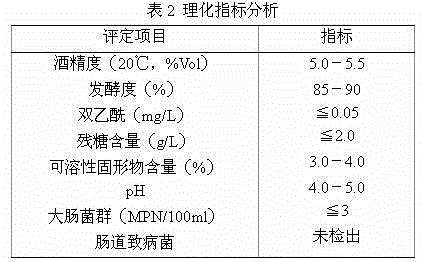

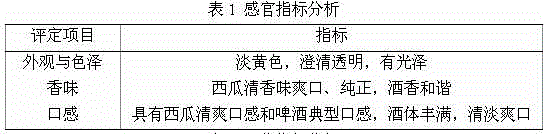

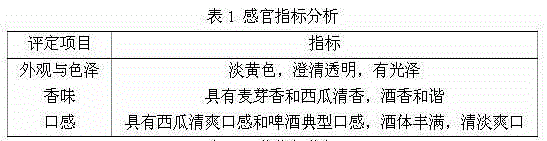

Brewing process of beer with watermelon juice

InactiveCN104388222AFully concentrated listing periodMake full use of the centralized listing periodBeer fermentationMicroorganism based processesDraught beerBiotechnology

The invention relates to a brewing process of beer with watermelon juice. The brewing process comprises the following steps: 1) weighing soybean cake powder and peanut cake powder which are free of mildew and crushed, uniformly mixing the soybean cake powder and peanut cake powder with crushed barley malts to form a mixture I, then, preparing malt juice by saccharifying, filtering, boiling, circulating and precipitating, and cooling, and pumping the malt juice into a sterile fermentation tank; 2) quickly pumping watermelon juice into the fermentation tank, mixing with the malt juice, then, adding honey which accounts for 1.0-1.5wt% of the watermelon juice; 3) inoculating activated beer dry yeast to ferment, and introducing oxygen gas to enable the oxygen content to reach 11-13mg / L, and measuring sugar degree once every 24 hours; 4) after the fermentation is ended, filtering by use of a diatomite filter to obtain the beer with watermelon juice. According to the brewing process of the beer with the watermelon juice disclosed by the invention, the watermelon juice is taken as the main material, the barely malts, the soybean cake powder, the peanut cake powder, the honey, and the like are taken as auxiliary materials, so that the flavor substances in the watermelon are kept as much as possible in a low-temperature fermentation process, and therefore, the variety of the summer draught beer is enriched.

Owner:HENAN UNIVERSITY

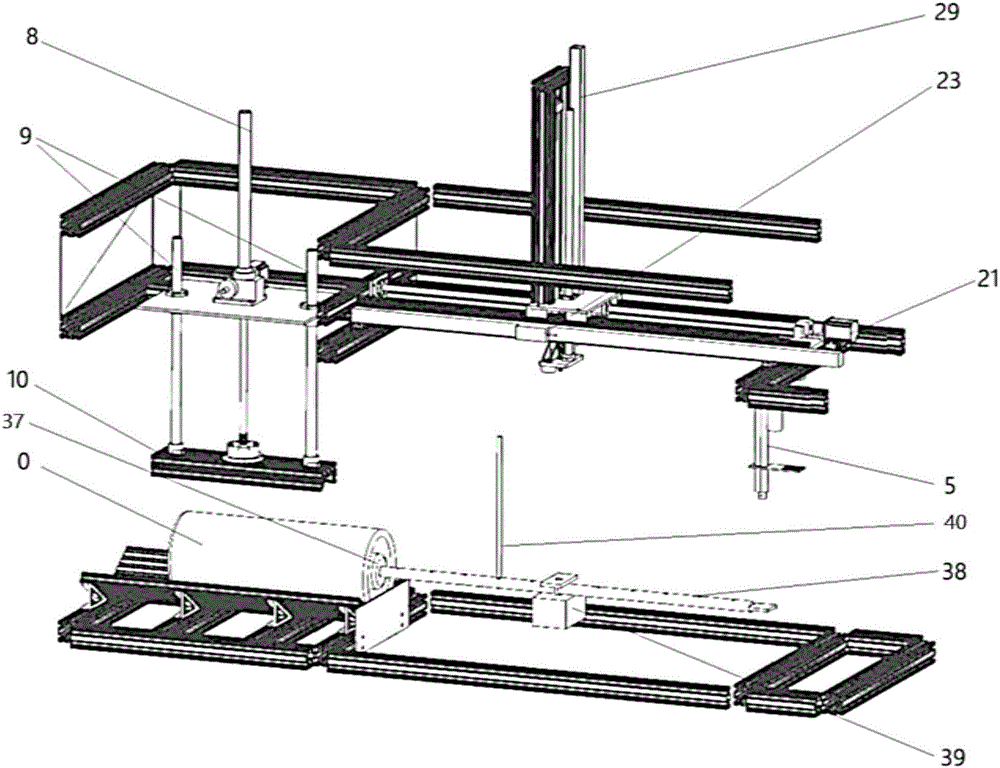

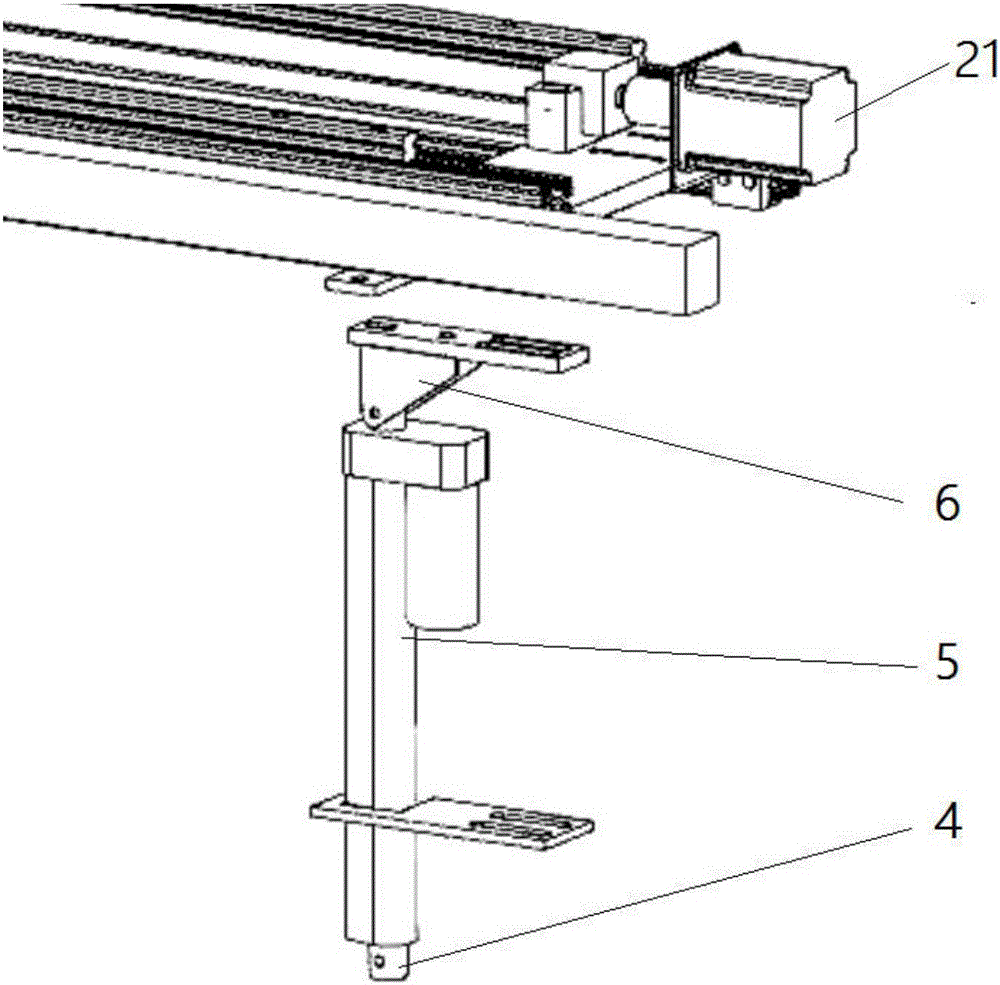

Automatic testing method and system for radial mechanical properties of cork base of draught-beer barrel

InactiveCN105865895AAvoid cumbersome operating proceduresAvoid high-intensity laborUsing optical meansStrength propertiesTest efficiencyEngineering

The invention provides an automatic testing method and system for radial mechanical properties of a cork base of a draught-beer barrel. According to the invention, a crossbeam is arranged at the port of the cork base and used as a conducting material for applied load; in testing, standard dynamic or static load force vertically acts on an assigned position of the crossbeam, and prescribed bending moment test load is accurately applied on the cork base so as to allow the cork base to undergo radial deviation; and the value of deflection of the far end of the crossbeam is acquired and used for measurement of radial deviation of the cork base. The automatic testing method and system provided by the invention can realize accurate positioning and clamping of a to-be-tested draught-beer barrel, automatic continuous loading of load and accurate measurement and storage of testing data, so disadvantages of conventional manual operation in testing of the radial mechanical properties of cork bases in factories are overcome, and testing efficiency and precision are improved.

Owner:SHANGHAI JIAO TONG UNIV

Intelligent beer machine with canister filtration and stirring

The invention relates to an intelligent beer machine with canister filtration and stirring, belonging to the technical fields of IOT (Internet of Things) and wireless communication. The intelligent beer machine is composed of a canister filter, a spiral stirring rod, a mash tub, a boiling tub, a controller, a controller display screen, a heater, a thermometer, a humulus lupulus tank and the like. All the process programs of the intelligent beer machine with canister filtration and stirring are controlled by a computer; the computer programs are corresponding to the corresponding malt, humulus lupulus and yeast; the customer scans or inputs the two-dimensional codes or bar codes or numeric characters printed on the malt, humulus lupulus and yeast packaging bag on the controller display screen; the controller calls out the process programs of beer to be processed; the malt, humulus lupulus and yeast are respectively added into the canister filter, humulus lupulus tank and storage tank; and the button is pressed to start, so that the high-quality draught beer can be brewed. When the manufacturer wants to update the original variety process or a new brewage process emerges, the programs can be received in real time by a sending antenna on the controller of the intelligent beer machine through the IOT.

Owner:云酿智能科技无锡有限公司

Beverage dispensing system with apparatus for controlling foaming and flow rate

ActiveUS8777067B2Less foamImprove satisfactionLiquid flow controllersLiquid transferring devicesStored energyStream flow

The beverage dispensing system includes a dispensing faucet defining a flow path, a valve head in the flow path movable between a closed position in sealed contact with a valve seat, and an open position. An actuator is manually movable to operate the faucet, and a biasing element is cooperable with the actuator and valve head such that an initial movement of the actuator will automatically cause sufficient energy to be stored or loaded in the biasing element for moving the valve head to the open position but without doing so. Occurrence of a subsequent predetermined event such as a further movement of the actuator will cause the stored energy to be automatically released to rapidly or nearly instantaneously move the valve head to the open position. As a result, no instruction or skill is required to operate the faucet to uniformly dispense pressurized beverages such as draught beer.

Owner:ANHEUSER BUSCH INC

Brewing Technology of Full Juice Watermelon Beer

InactiveCN104388222BFully concentrated listing periodMake full use of the centralized listing periodBeer fermentationMicroorganism based processesYeastFlavor

Owner:HENAN UNIVERSITY

Process for brewing half-juice watermelon beer

InactiveCN104388221AReduce storage costsSolve the problem of slow salesBeer fermentationMicroorganism based processesBiotechnologyDiacetyl

The invention relates to a process for brewing half-juice watermelon beer. The process comprises the following steps: a) inoculating and fermenting, namely, inoculating and culturing bottom fermentation beer yeast at the logarithmic phase into wort, and meanwhile introducing oxygen till the oxygen concentration is 8-10mg / L; b) adding watermelon juice, namely, when the high kransen of fermentation begins after 2-3 days, adding fresh watermelon juice which accounts for 40% of the total volume of a fermented material, and continuously fermenting; and c) performing later fermentation, namely, performing later fermentation when the content of diacetyl is reduced to be less than 0.1mg / L, and filtering the obtained material by using a kieselguhr filtering method after the later fermentation is completed, thereby obtaining the half-juice watermelon beer, wherein the later fermentation comprises two stages, namely, warm storage and cold storage. According to the process, barley malt and fresh watermelon juice are taken as main raw materials, the flavor substances in watermelon are maintained as much as possible in the low-temperature fermentation process, and the variety of draught beer in summer is enriched.

Owner:HENAN UNIVERSITY

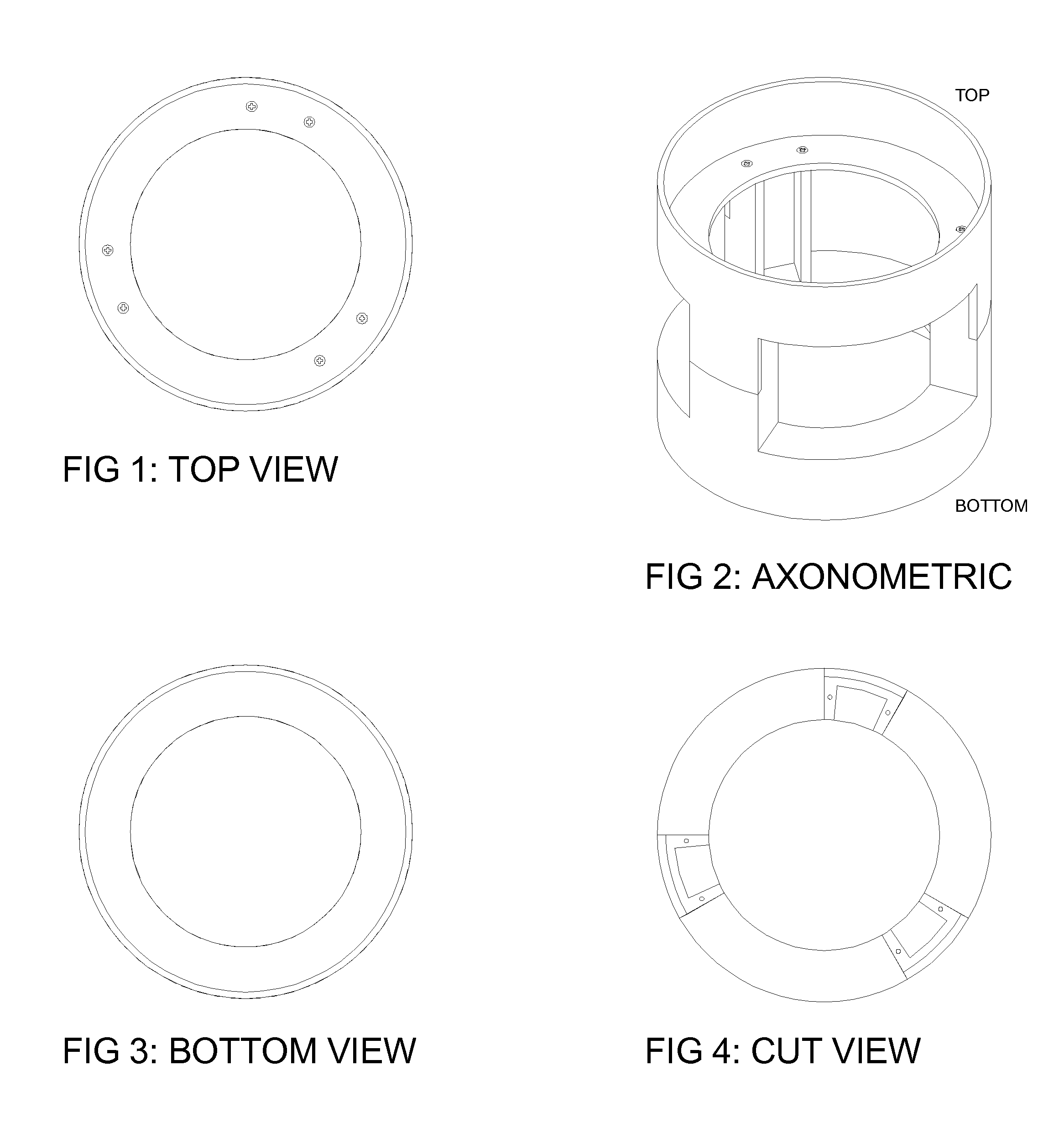

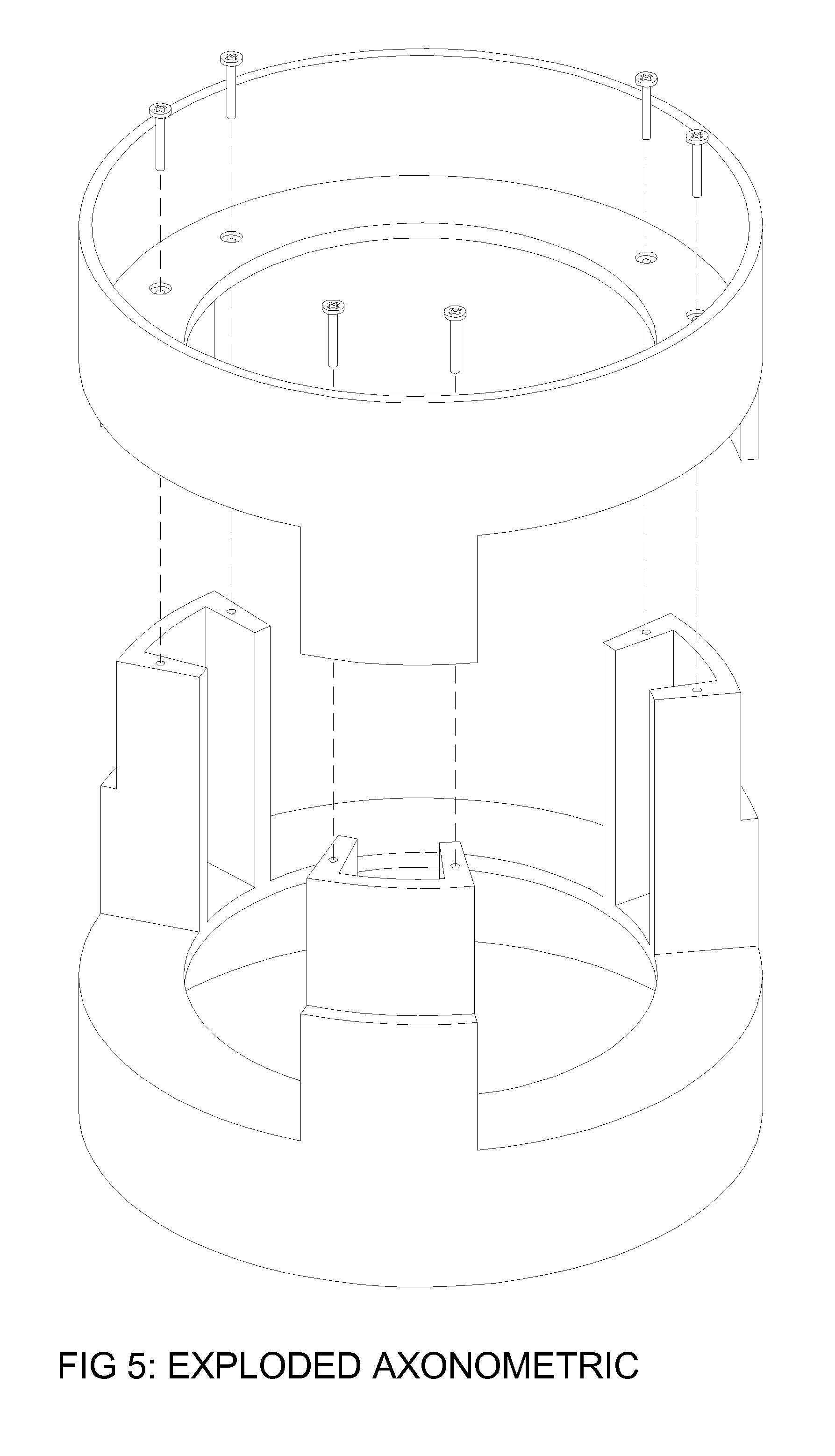

Sixtel Keg Tapping and Stacking Apparatus

InactiveUS20160075546A1Create horizontal space efficiencyPrevent tippingLiquid dispensingRigid containersEngineeringRefrigeration

The sixtel keg stacking apparatus is a device designed to create horizontal space efficiency by allowing sixtel kegs to be stacked while simultaneously being tapped and dispensed into a draught beer system. The apparatus offers similar function when utilized with cornelius kegs which have nominally the same dimensions as a sixtel keg. The device is intended to allow pub owners, beer retailers and homebrewers to decrease the square footage of refrigeration space necessary to store and dispense draught beer packaged in the newer, preferred sixtel and cornelius kegs. The apparatus enables these kegs to be vertically stacked upon each other and simultaneously dispensed

Owner:COLE SEAN E

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com