Inorganic ceramic membrane device for applying to clear and filter draught beer and method thereof

An inorganic ceramic membrane and draft beer technology, which is applied in the preparation of alcoholic beverages, chemical instruments and methods, ultrafiltration, etc., can solve the problems of great influence on beer flavor and achieve the effect that meets the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

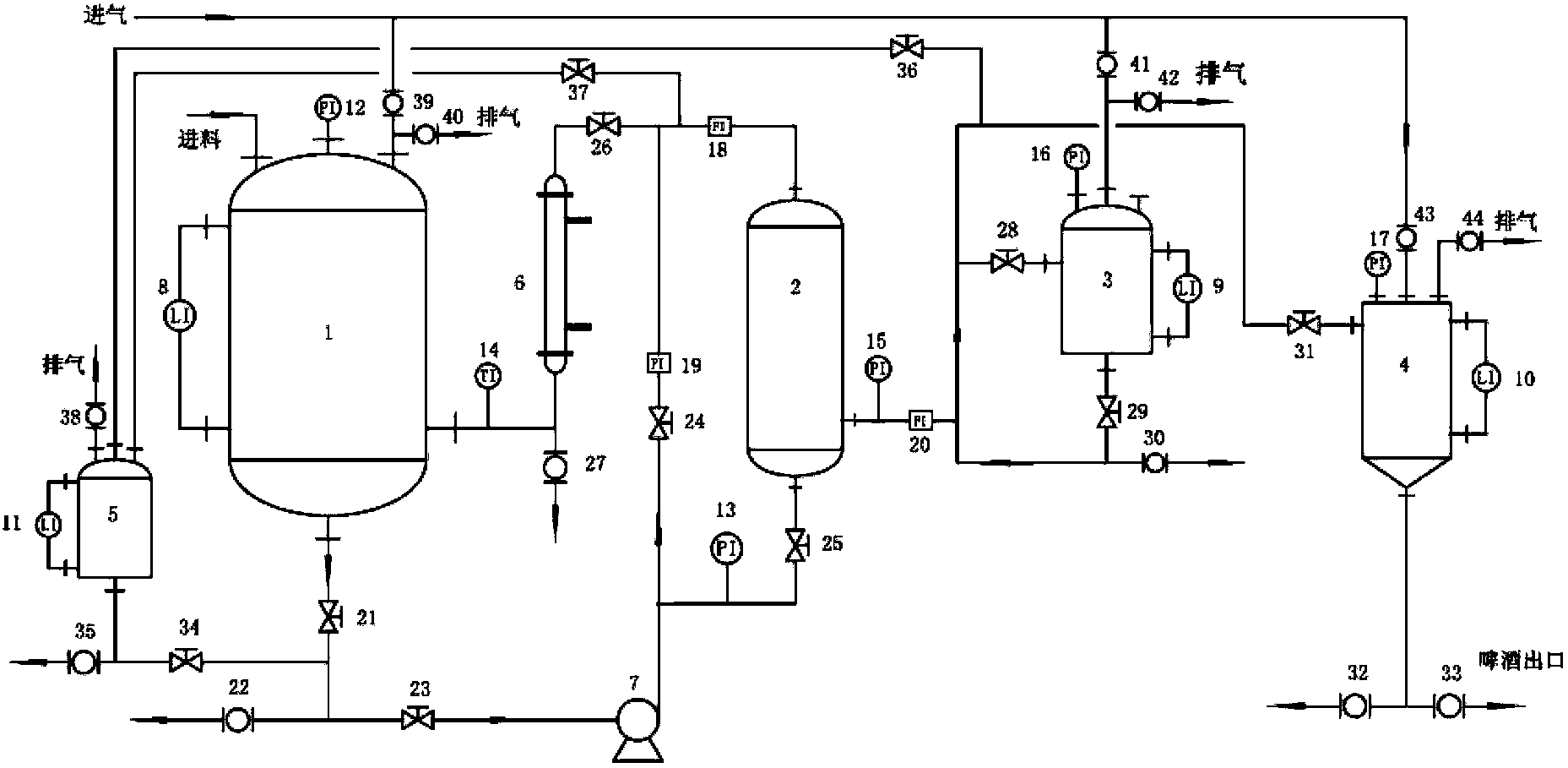

[0040] Embodiment: clarification, filtration in draft beer brewing process

[0041] Filtration process:

[0042]The beer is fermented in the yeast tank 1, and the liquid level of the fermentation tank is controlled by the yeast tank level gauge 8. After the fermentation is completed, the discharge valve 21 of the yeast tank and the valve 23 of the feed pipe are opened, and the operating pressure difference is set to 0.2 MPa through the centrifugal pump 7. The flow rate of the membrane surface is 3m / s. Part of it enters the membrane separation device 2. After separation, the dope passes through the heat exchanger 6 to keep the temperature at 0-4°C and returns to the yeast tank. The other part passes through the feed pipe circulation valve 19 and separates from the membrane. The feed circulation valve 24 of the device passes through the heat exchanger 6 to keep the temperature at 0-4°C and returns to the yeast tank again. The clear liquid enters the beer tank 4 through the beer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com