Manufacturing method of austenitic stainless steel for non-magnetic color-difference-free beer barrel

A technology of austenitic stainless steel and manufacturing method, which is applied in the field of austenitic stainless steel, can solve the problems of affecting the taste of beer drinking, not being able to fully meet the demand, and affecting the service life, so as to improve the popularity of enterprises and products, avoid the occurrence of color difference defects, Effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

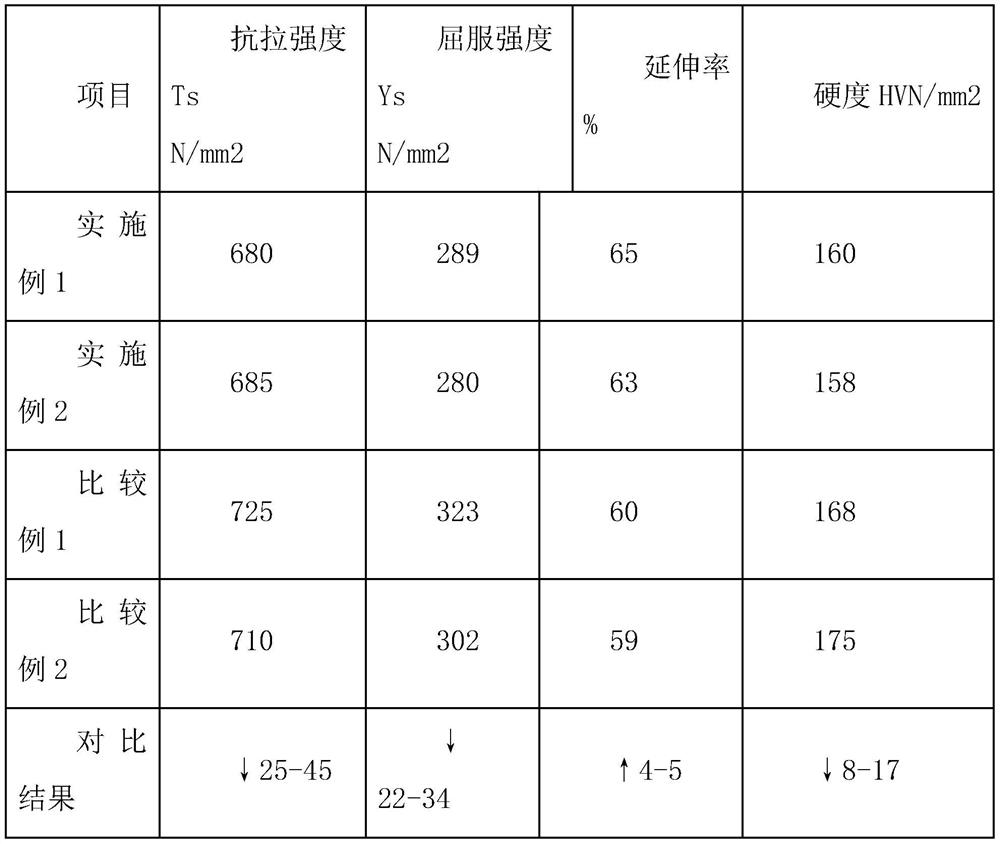

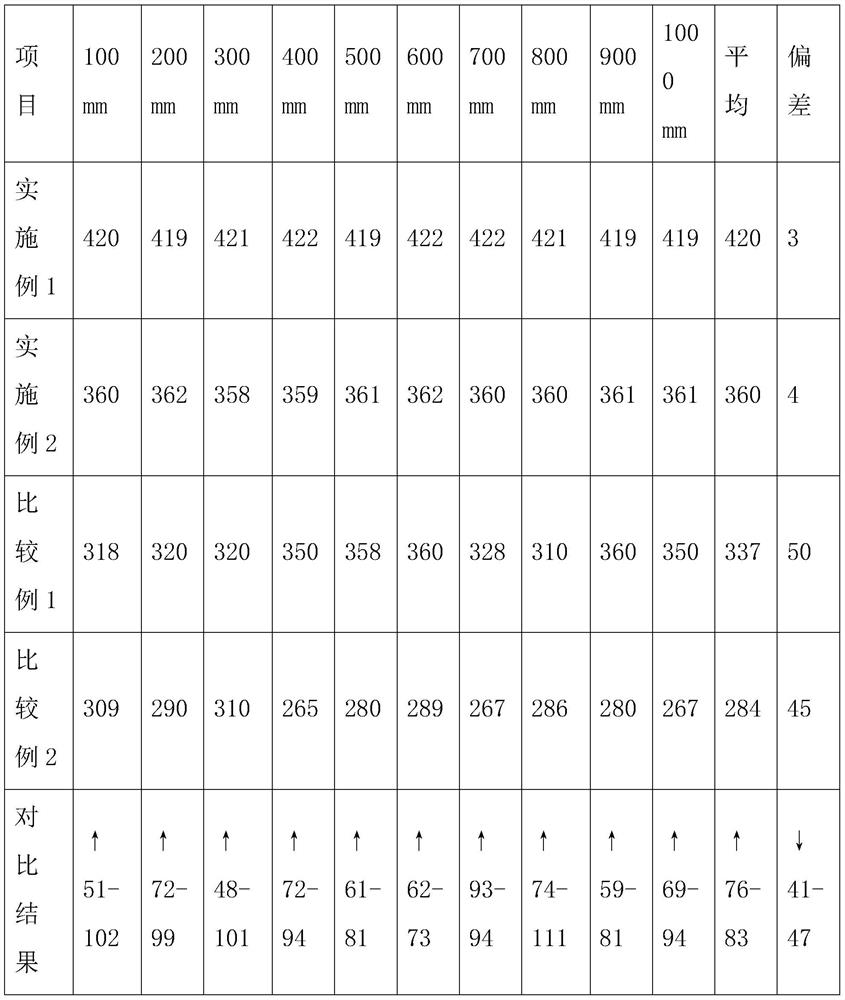

Examples

Embodiment 1

[0047] This embodiment provides a kind of austenitic stainless steel suitable for the production of non-magnetic and non-chromatic beer kegs. Nickel 8.02%, copper 0.45%, and iron balance. The manufacturing method of the austenitic stainless steel material of the non-magnetic and non-chromatic beer keg is as follows:

[0048] S1. Smelting and continuous casting of the various raw materials of the austenitic stainless steel into billets, and then performing hot rolling, annealing and pickling of hot-rolled steel coils, defect grinding, cold rolling, cold rolling, annealing and pickling of the obtained billets in sequence, and Finishing, surface color difference, material magnetic testing.

[0049] S2. The hot-rolled black steel coil is continuously annealed at 950-1200°C, the temperature in the first preheating zone is 980°C, the temperature in the first to fifth heating zones is 1170°C, and the temperature in the first holding zone is 1170°C. After annealing, fast water coolin...

Embodiment 2

[0057] This embodiment provides a kind of austenitic stainless steel suitable for the production of non-magnetic and non-chromatic beer kegs. Nickel 8.03%, copper 0.48%, and iron balance. The manufacturing method of the austenitic stainless steel material of the non-magnetic and non-chromatic beer keg is as follows:

[0058] S1. Smelting and continuous casting of the various raw materials of the austenitic stainless steel into billets, and then performing hot rolling, annealing and pickling of hot-rolled steel coils, defect grinding, cold rolling, cold rolling, annealing and pickling of the obtained billets in sequence, and Finishing, surface color difference, material magnetic testing.

[0059] S2. The hot-rolled black steel coil is continuously annealed at 950-1200°C, the temperature in the first preheating zone is 980°C, the temperature in the first to fifth heating zones is 1165°C, and the temperature in the first holding zone is 1165°C. After annealing, fast water cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com