Technology for recycling beer from beer waste yeast paste

A technology of beer waste yeast and waste yeast slime, which is applied in the field of beer production, can solve the problems of waste of resources, poor utilization of waste yeast resources, environmental pollution, etc., and achieve the reduction of environmental protection pressure, good taste and appearance, and high separation accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

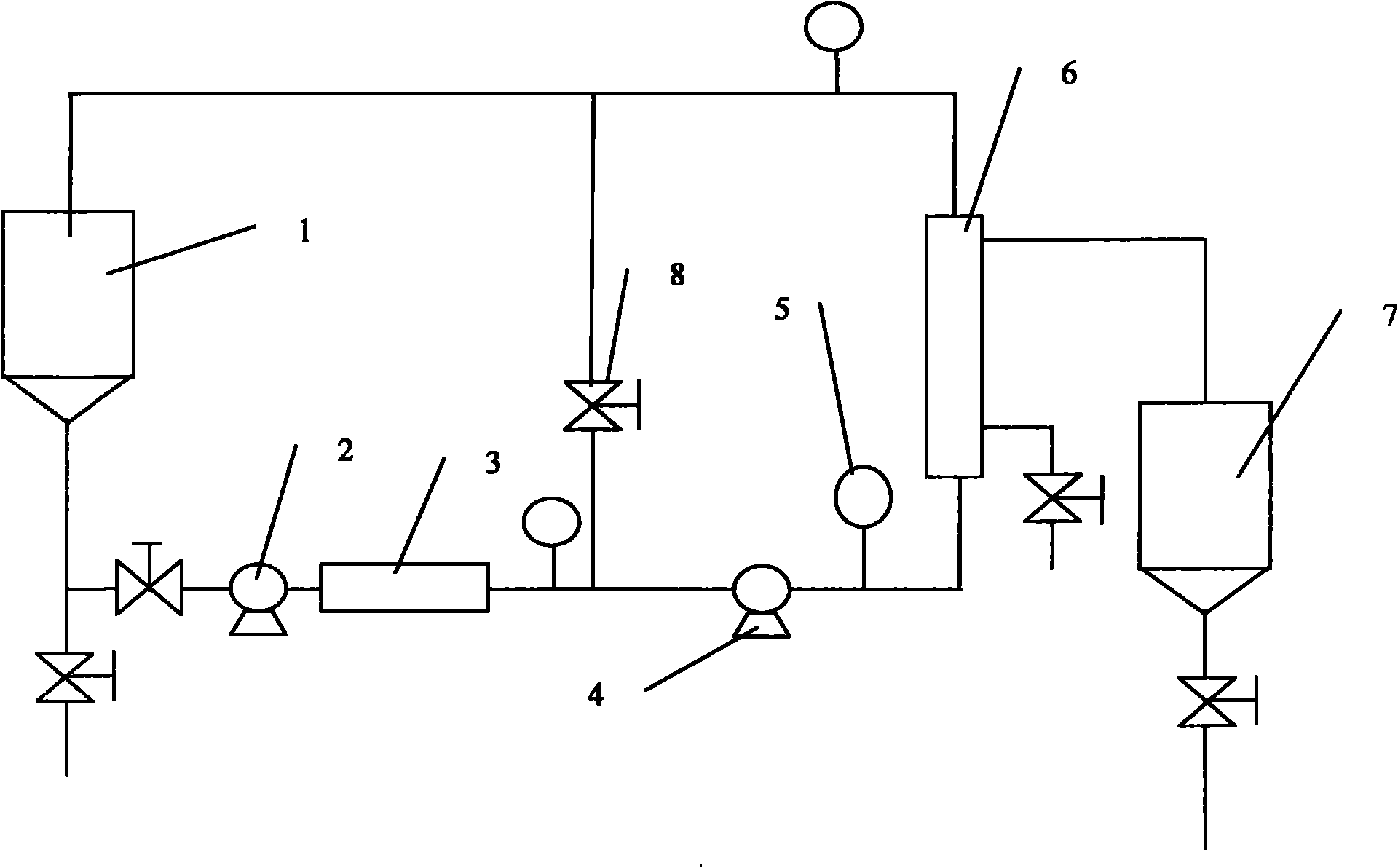

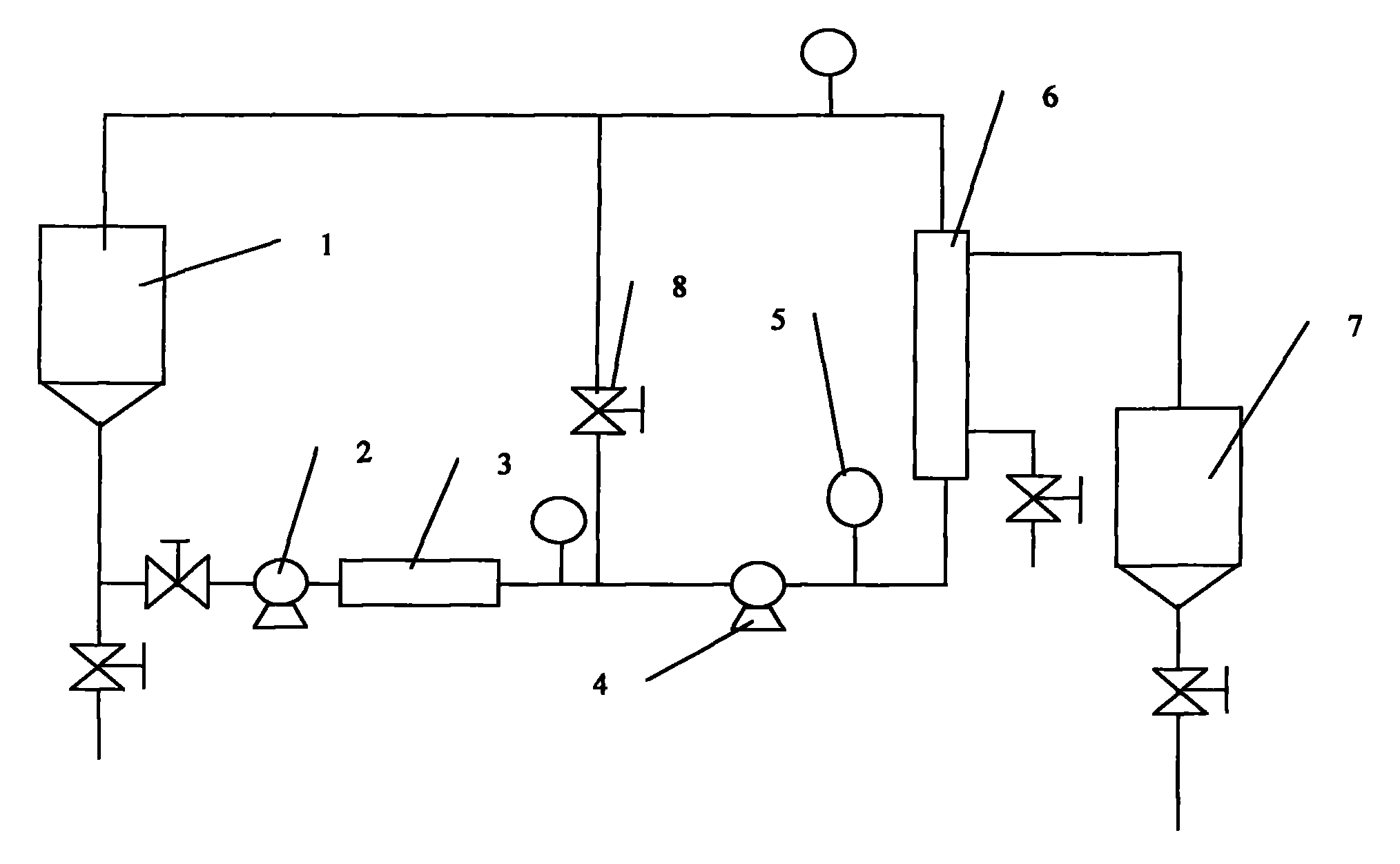

[0018] Example 1: Such as figure 1 As shown, firstly, the waste beer yeast mud is injected with a CO of 0.06~0.1Mpa 2 After the pressure of the circulating tank 1, it is sequentially cooled to 10-15°C by the condenser 3, and filtered through the metal membrane 6 with a pore size of 0.45μm-20nm through the circulating pump 4 at a pressure of 0.4-0.6Mpa; the separated beer After the permeate is sent to tank 7, it enters the pure draft beer semi-finished product processing system for subsequent processing. Part of the separated waste yeast mud mother liquor is returned to the waste yeast mud circulation tank 1, and the other part is in the valve 8, circulating pump 4, and pressure gauge. 5. Metal membrane 6. Circulate filtration in the formed internal circulation system. At the same time of circulation, under the action of pressure, part of the beer seeps out, and the waste beer yeast mud in the circulation tank 1 is continuously fed in through the feed pump 2 In the internal circ...

Embodiment 2

[0020] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the metal film is changed to a ceramic film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com