Refrigerator performance detecting method and temperature compensating method

A detection method and refrigerator technology, applied in the direction of measuring devices, machine/structural parts testing, instruments, etc., can solve the problems of huge expenditure, investment, detection equipment can not be moved, etc., to reduce pre-cooling time, misjudgment rate and The effect of low missed judgment rate and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below through specific embodiments and in conjunction with the accompanying drawings.

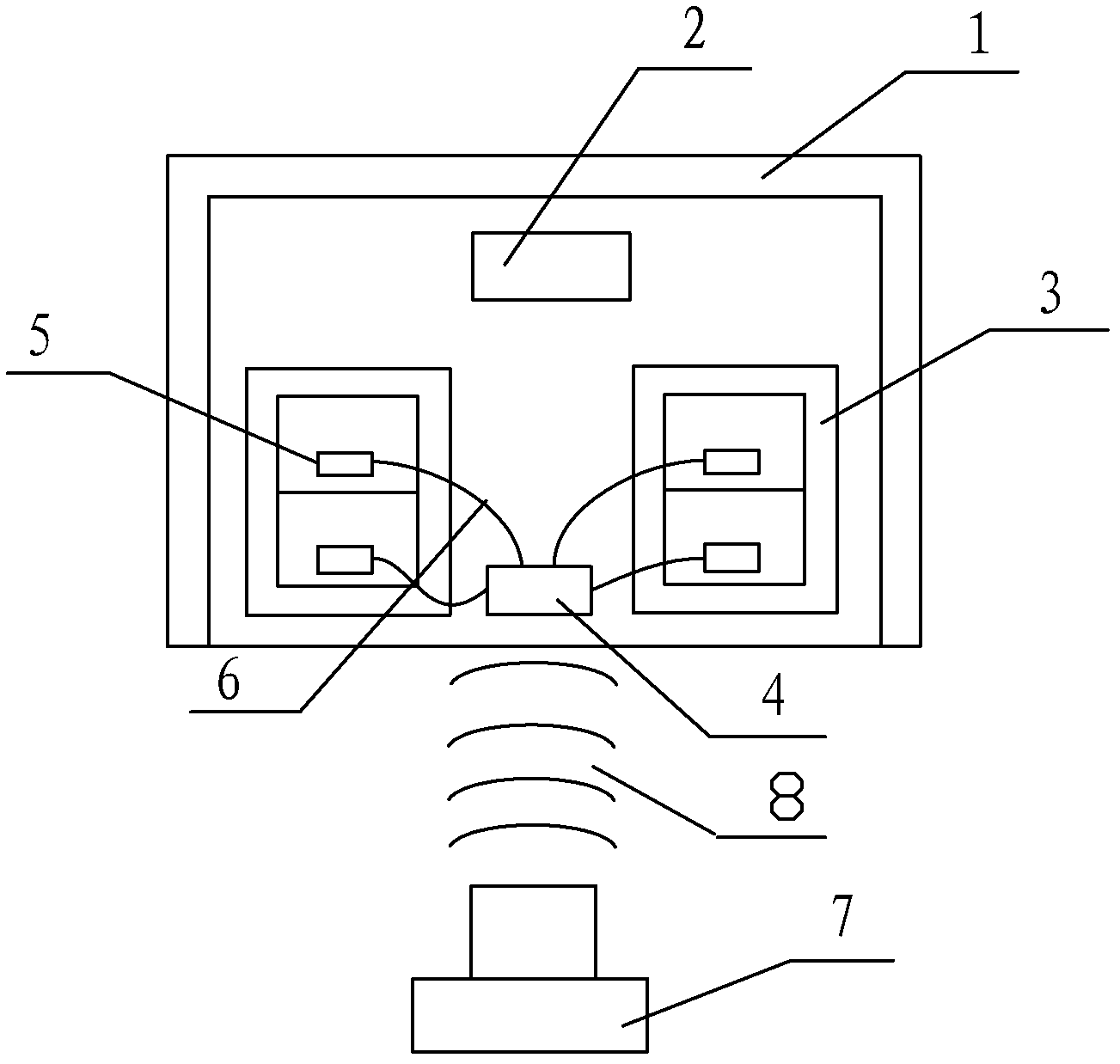

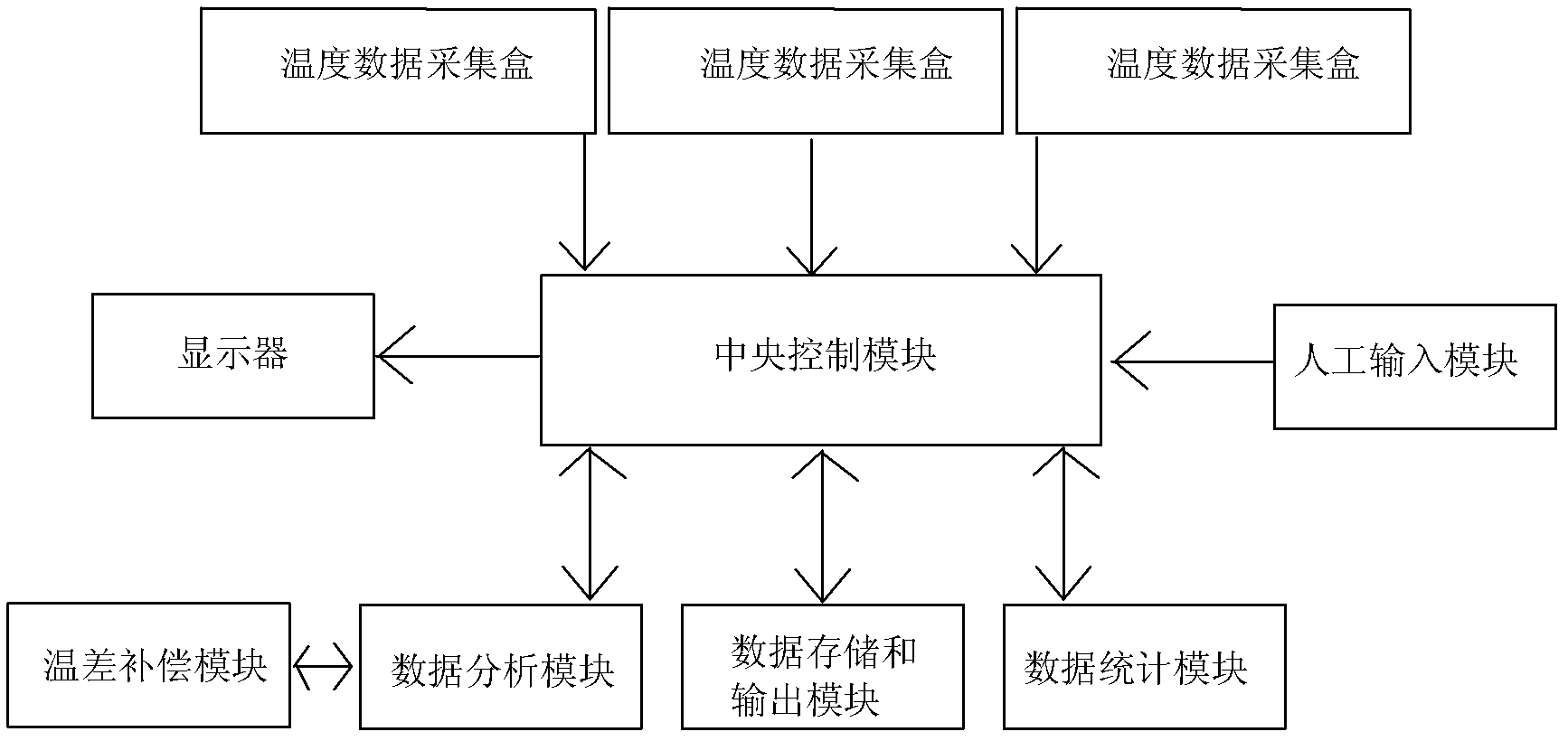

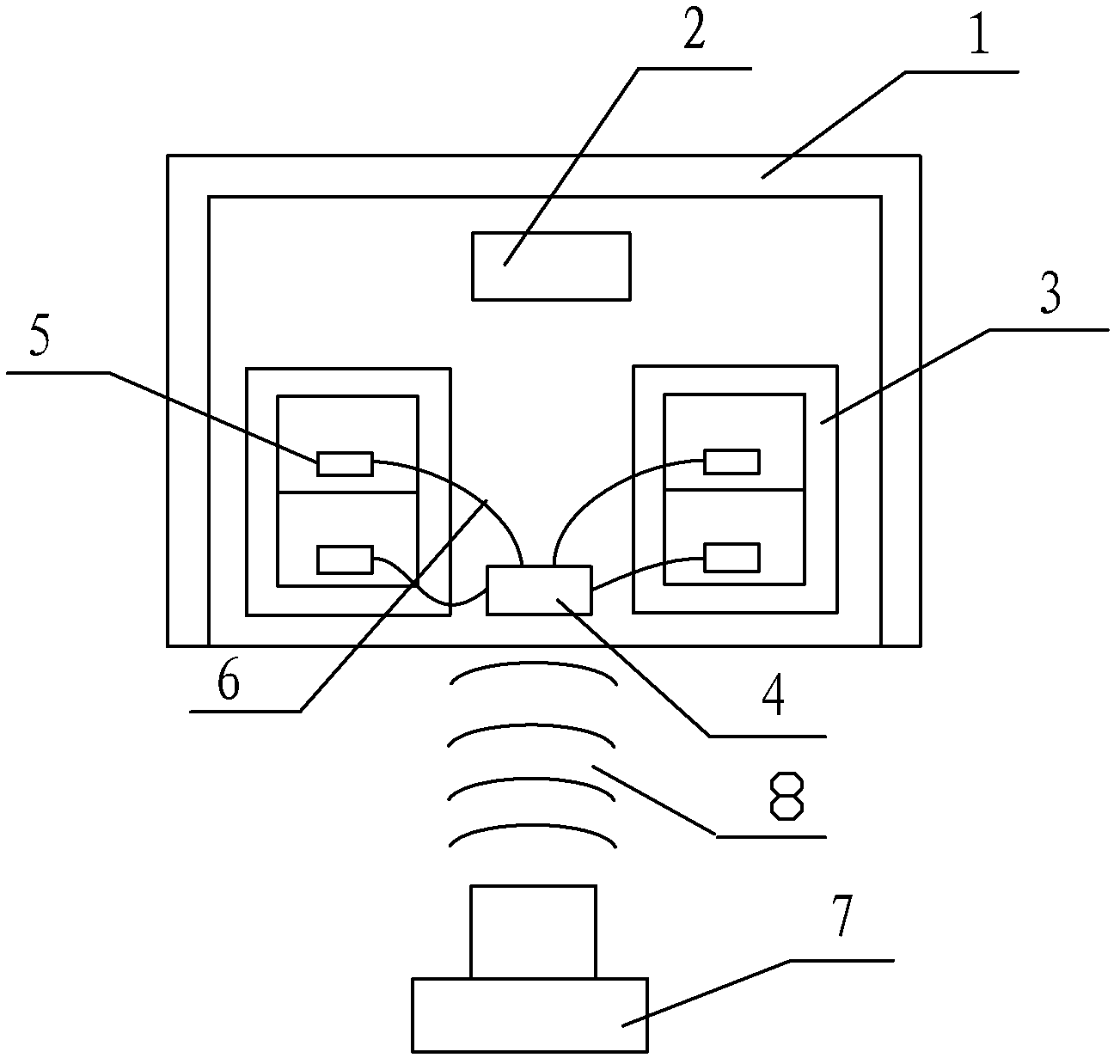

[0022] see Figure 1-2 , The refrigerator performance test equipment of the present invention includes a test chamber 1, a temperature sensor 5, a temperature data collector 4, a transmitting and receiving device 8, and an industrial computer 7. An air conditioner unit 2 is installed in the test room to keep the temperature of the test room constant, and a refrigerator 3 is placed on the test bench of the test room. When the test starts, the temperature sensor 5 is placed at a suitable position in the refrigerator 3 to be tested, that is, the temperature point to be measured. Each temperature sensor 5 is equipped with and connected 6 to the temperature data collector 4 through the test line. The data transfer between the industrial computer 7 and the temperature data collector 4 is transmitted through the transmitting and receiving de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com