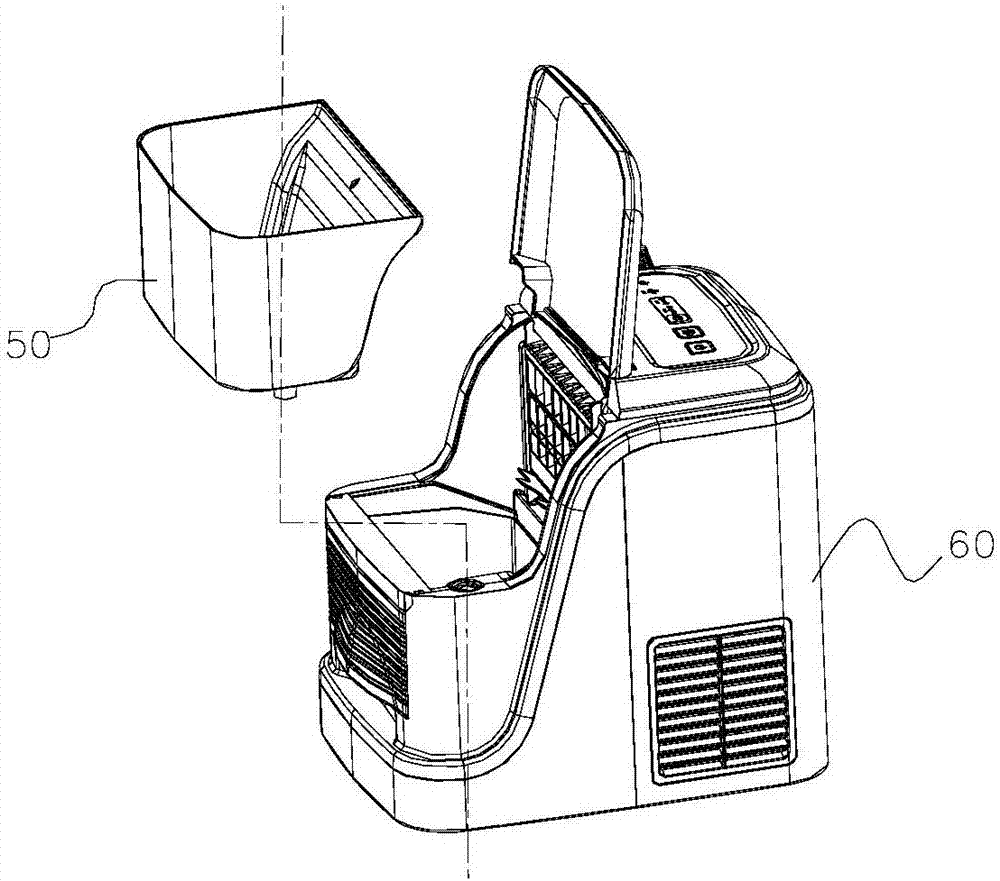

External water tank and ice maker

A technology for ice machines and water tanks, which is applied to ice making, ice making, lighting and heating equipment, etc. It can solve the problems of frequent water addition, inconvenient water addition, and long cooling time, so as to shorten the pre-cooling time and improve ice production. Efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

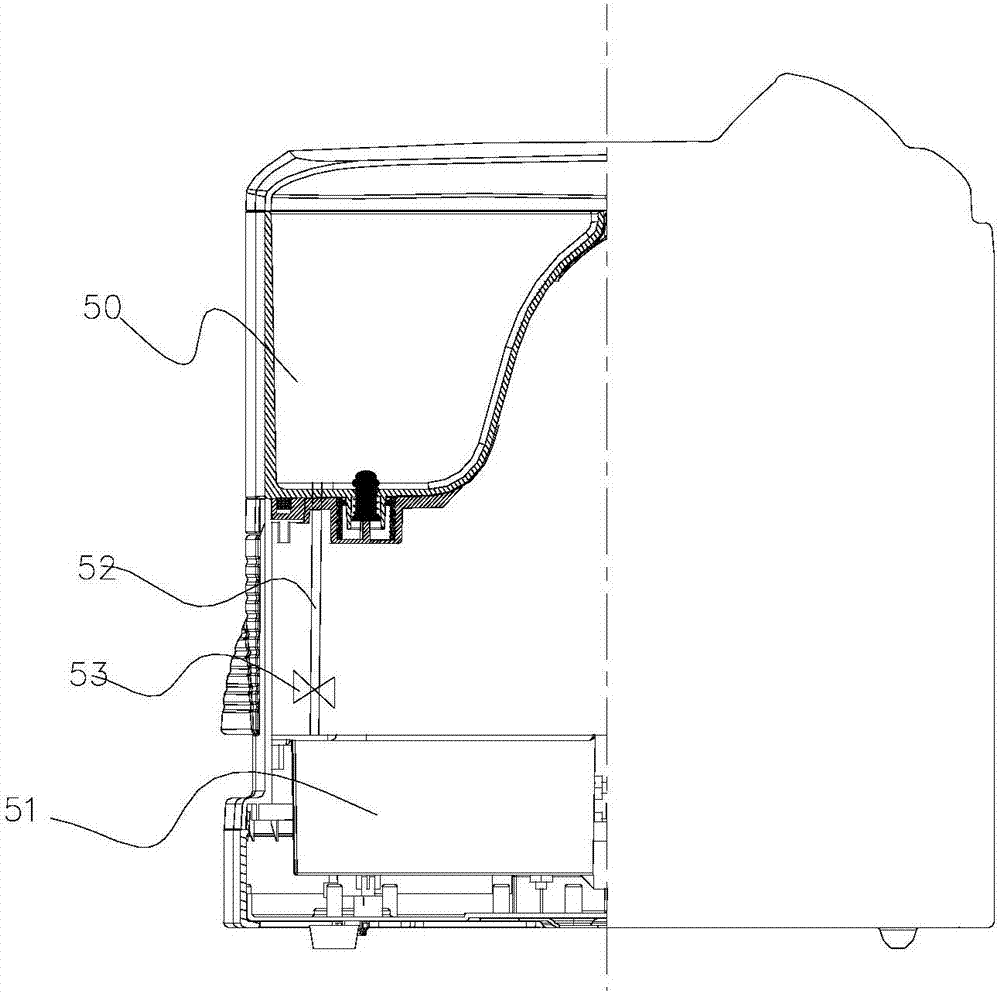

[0039] The ice machine body 60 mentioned in the present invention refers to the body in the art that has components such as water pumps and evaporators that can make water into ice. The invention of the present invention lies in the water tank and its corresponding configuration (connection) method, sealing method), the change of the water supply system or the method brought about by the change, so it will not be repeated.

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

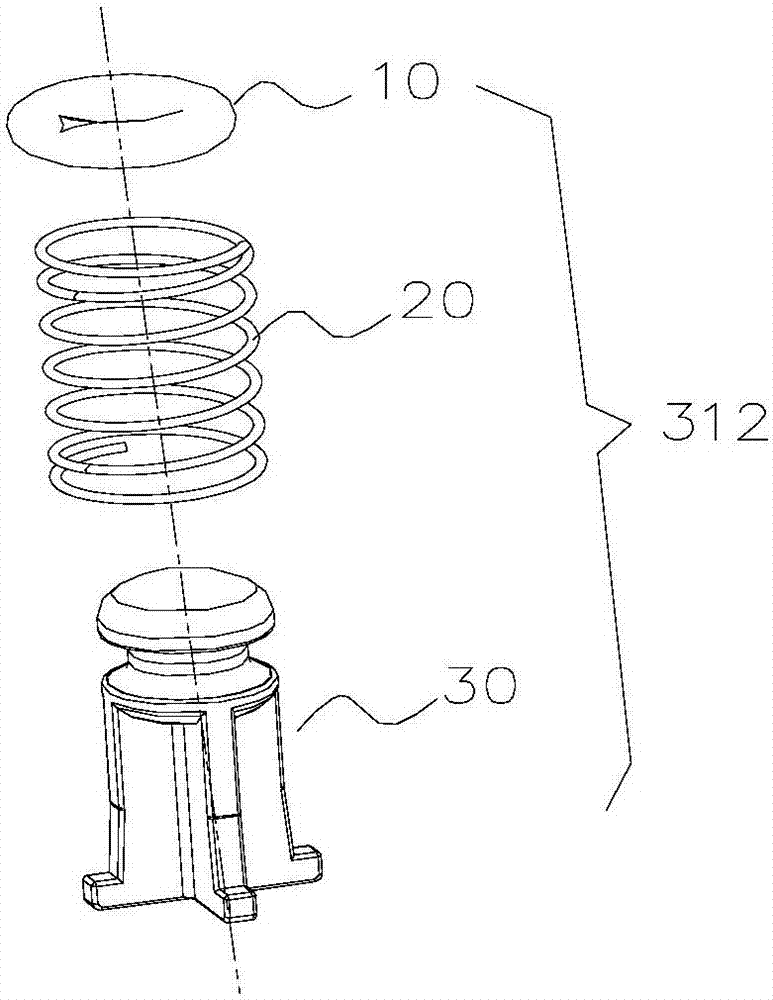

[0041] Figure 4 , 6 , 7, 8, and 9 schematically show an external water tank according to an embodiment of the present invention. As shown in the figure, the bottom section of the external water tank is narrow, the opening section is wide, and the transition connection between the bottom and the opening is in the form of Inverted conical structure, the drain port 501 at the bottom of the external water tank is sealed by the elastic seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com