Multifunctional rubbing machine

A multi-function, wire machine technology, applied in agricultural machinery and implements, cutting equipment, applications, etc., can solve problems such as work efficiency and insufficient appearance, and achieve the effect of saving raw materials, improving work efficiency, and improving working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

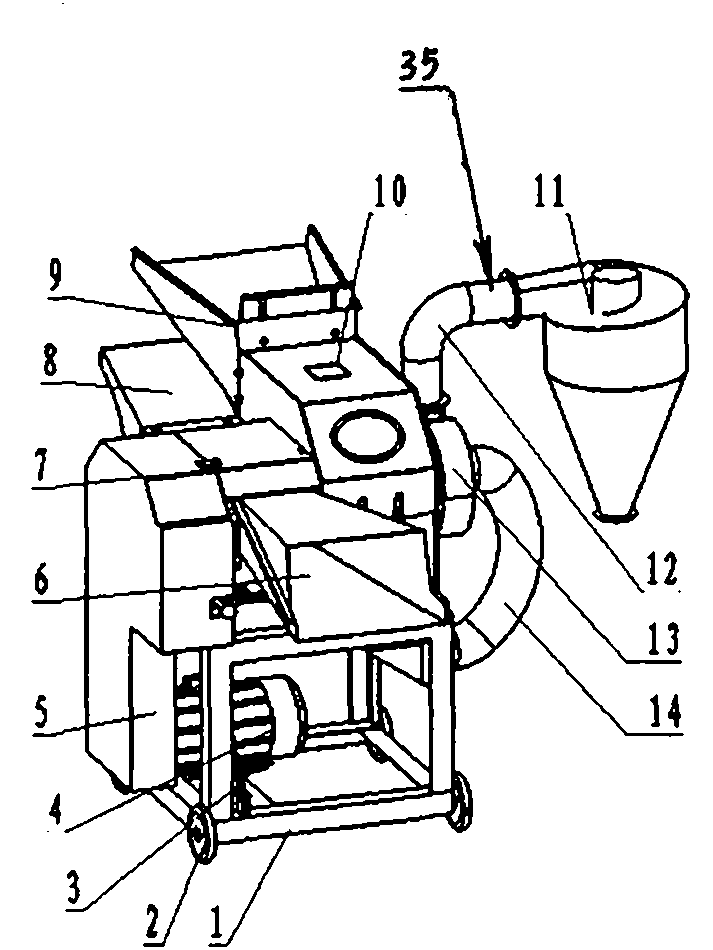

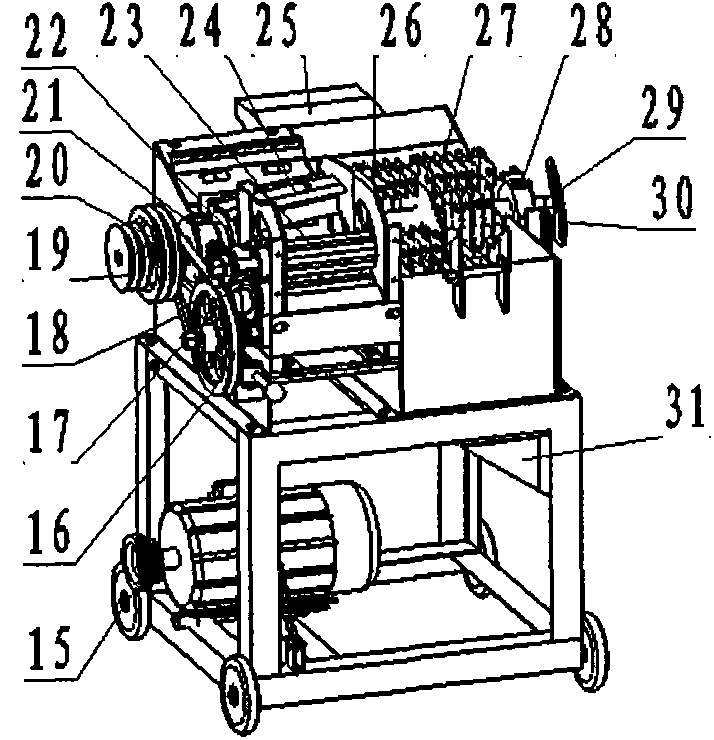

[0027] A multifunctional kneading machine, comprising a motor 4, a blower fan 13, a base 1, a main shaft 29, a chaff box 7, a crushing box 10, a cutter head assembly 24, a grass roller assembly 23 and a powder collector assembly 35, wherein , the base 1 is fixed with a motor frame 3, the motor 4 is fixed on the motor frame 3, the power output shaft of the motor 4 is equipped with a motor wheel 15, and the four corners of the base 1 bottom are respectively equipped with ground wheels 2.

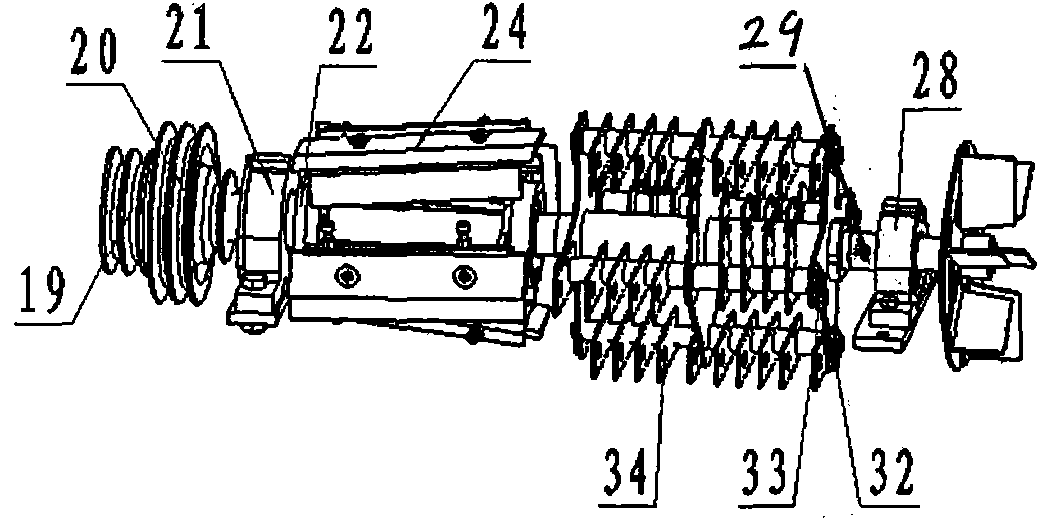

[0028] The main shaft 29 is installed on the hay cutting box 7 and the crushing box 10, and is supported by the crushing bearing seat 28 fixed on the crushing box 10 and the chaff bearing seat 21 fixed on the chaffing box 7. The front and rear sides are respectively equipped with an inlet hopper 6 and an outlet hopper 8. The cutter head assembly 24 is installed on the main shaft 29. The cutter head assembly 24 is connected with a connecting shaft 22 by bolts, and the connecting shaft 22 is equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com