Granular niacin production method by extrusion and granulation

An extrusion granulation and granulation technology, which is applied in the extrusion and granulation of raw materials, organic chemistry, etc., can solve the problems of difficult reprocessing for users, easy product agglomeration and agglomeration, and harsh environment, so as to avoid agglomeration, agglomeration and dust. Contamination problems, ease of processing, avoiding the effect of excessive particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

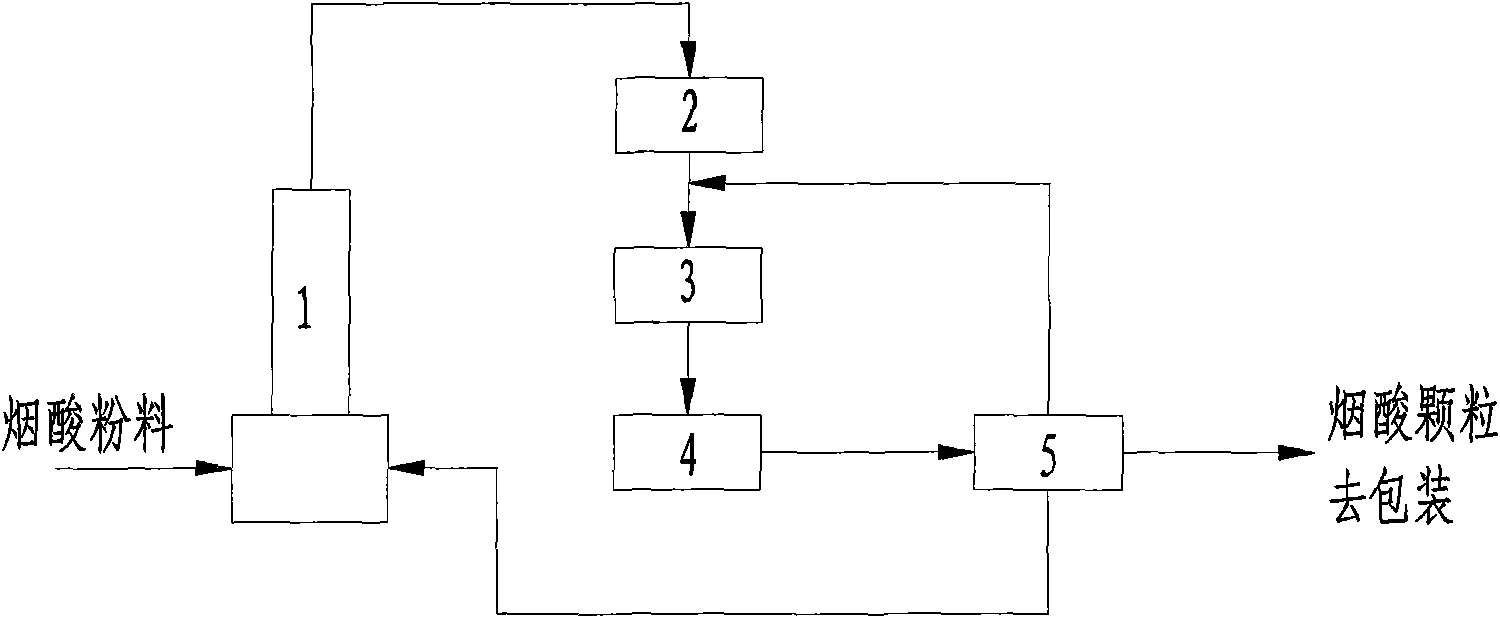

[0018] refer to figure 1 , a method for producing nicotinic acid granules by extrusion granulation, the method steps comprising:

[0019] 1. Hopper lifting and metering: the niacin powder raw material is lifted to the high-level metering tank (2) through the hopper elevator (1);

[0020] 2. Tablet compression: Send the metered niacin powder into the tablet press (3) for tablet compression. The pressure for tablet compression is 15MPa; the thickness of the powder for tablet compression is 1.0mm;

[0021] 3. Crushing: send the product obtained by tableting to the crusher (4) for crushing, and the crushing particle size is 0.1~2.0mm;

[0022] 4. Screening: The crushed product is sent to the sieve (5), which is divided into three layers, including two layers of screens, and the sieve residue on the top screen is large particles with a particle size > 0.8mm, this part of the product returns to the crusher (4); the particle size of the bottom layer of product is <0.2mm, returns to...

Embodiment 2

[0024] refer to figure 1 , a method for producing isonicotinic acid granules by extrusion granulation, the method steps comprising:

[0025] 1. Hopper lifting and metering: the raw material of isonicotinic acid powder is lifted to the high-level metering tank (2) through the hopper elevator (1);

[0026] 2. Tablet compression: send the metered isonicotinic acid powder into the tablet press (3) for tablet compression. The pressure for tablet compression is 15MPa; the thickness of the powder for compression is 1.0mm;

[0027] 3. Crushing: send the product obtained by tableting to the crusher (4) for crushing, and the crushing particle size is 0.1~2.0mm;

[0028] 4. Screening: The crushed product is sent to the sieve (5), which is divided into three layers, including two layers of screens, and the sieve residue on the top screen is large particles with a particle size > 0.8mm, this part of the product returns to the crusher (4); the bottom layer of product particle size <0.2mm,...

Embodiment 3

[0030] According to the production process steps in Example 1, the production capacity of niacin / isonicotinic acid extrusion granulation can reach 200 kg / hour, the product mesh is between 30-70 mesh, and the product does not need to be further dried, and can be directly packaged. The photo of the powder product is shown in Figure 2, and the product after granulation is shown in Figure 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com