Industrialization method for preparation of hollow glass beads based on precursor process

A hollow glass microsphere and precursor technology, which is applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of low strength of hollow glass microspheres, large fuel cost ratio, high raw material cost, and achieve particle size distribution. And controllable, reduce energy consumption, good liquidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

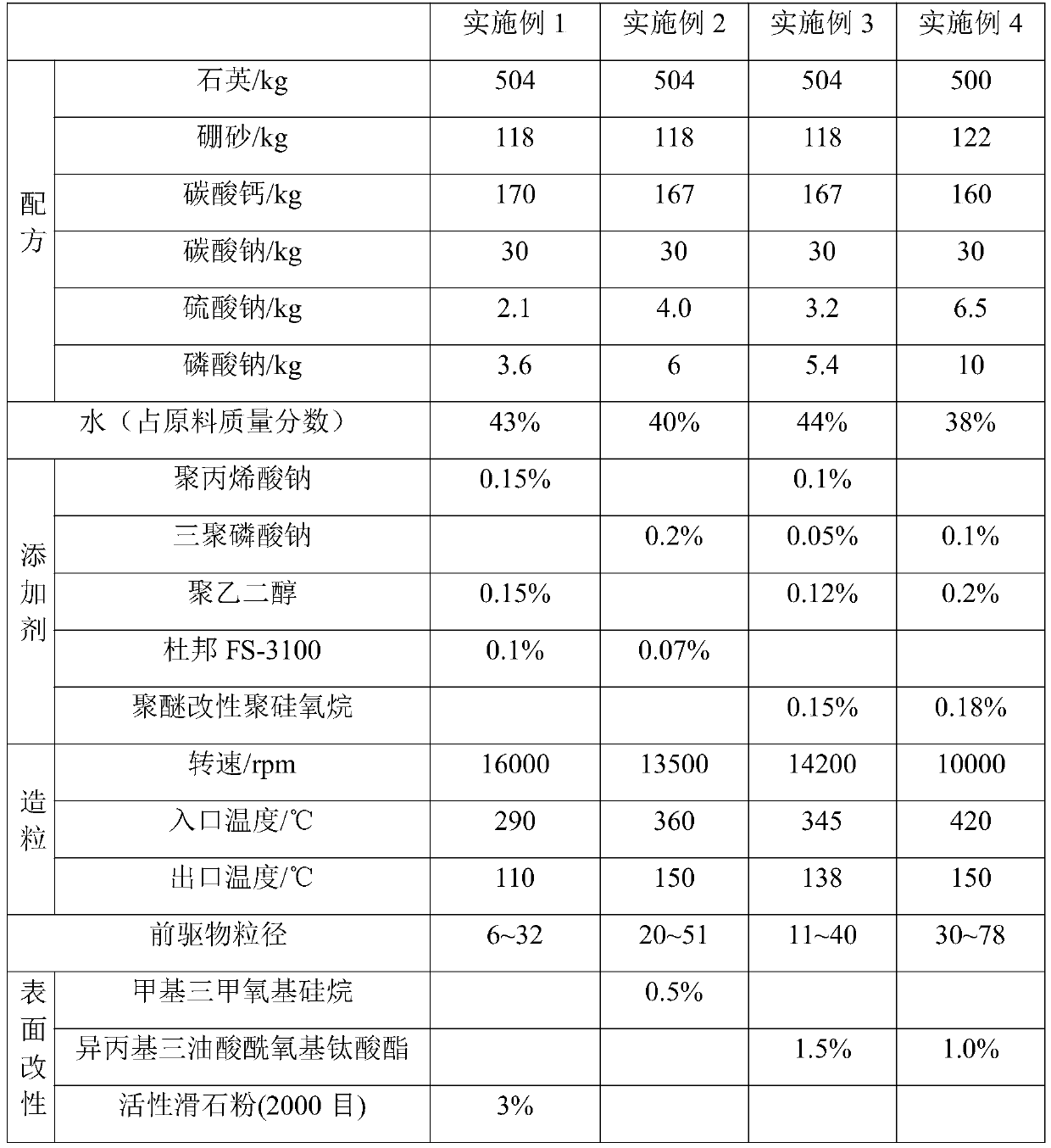

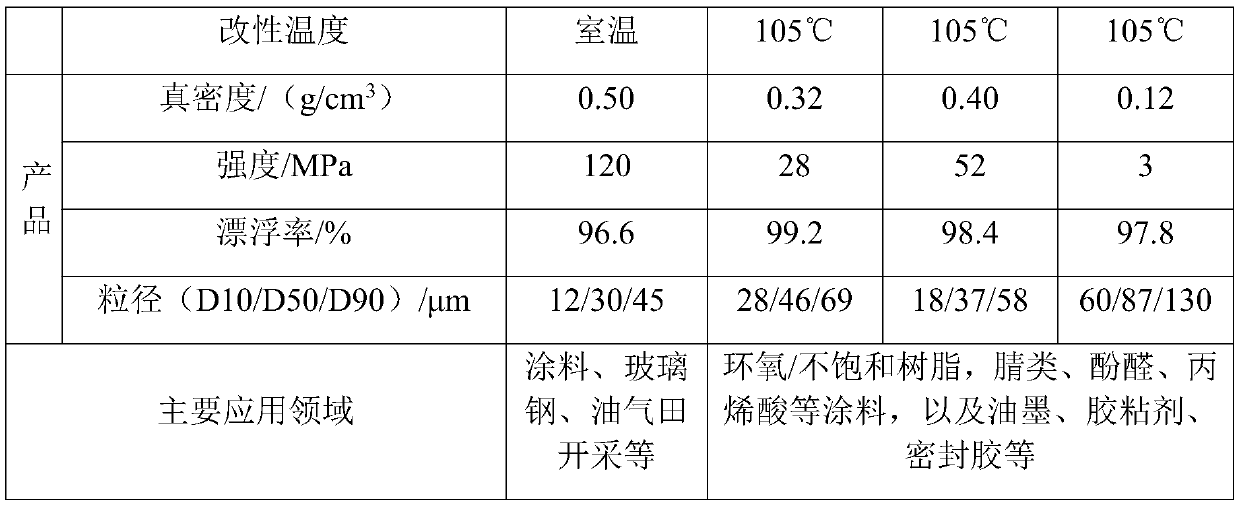

[0025] In order to further describe the present invention, the industrialization method of the present invention for preparing hollow glass microspheres based on the precursor method will be further described in conjunction with examples below. However, the present invention is not limited to the Examples.

[0026] The specific implementation process of the industrialization method for preparing hollow glass microspheres based on the precursor method of the present invention is as follows:

[0027] (1) Accurately weigh raw materials, surfactants and stable dispersants, and use a flow meter to measure a certain quality of water, mix it through a dispersion tank for 15 to 20 minutes, and then transport it to a ball mill through a feeding pump to obtain a solid phase content of 55%. ~65% slurry.

[0028] (2) The slurry is transported to the spray granulation equipment through the feeding pump, and the spray granulation is carried out under the conditions of the inlet temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com