Loaded metallocene catalyst and preparation method thereof

A technology of metallocene catalysts and metallocene compounds, applied in the field of supported metallocene catalysts and their preparation, can solve the problems of small particle size and low catalytic activity of mesoporous materials, and achieve the effect of ensuring particle size and catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

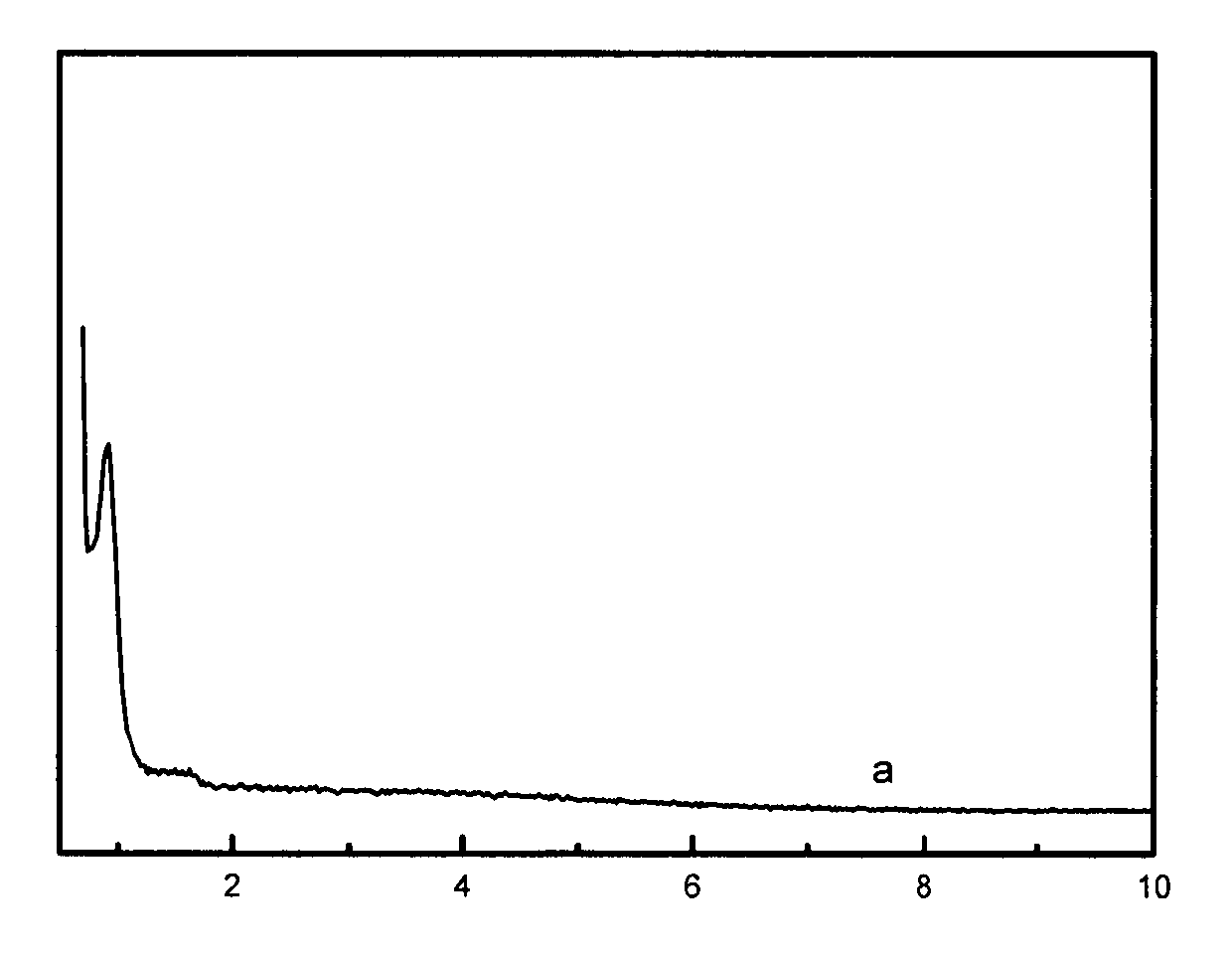

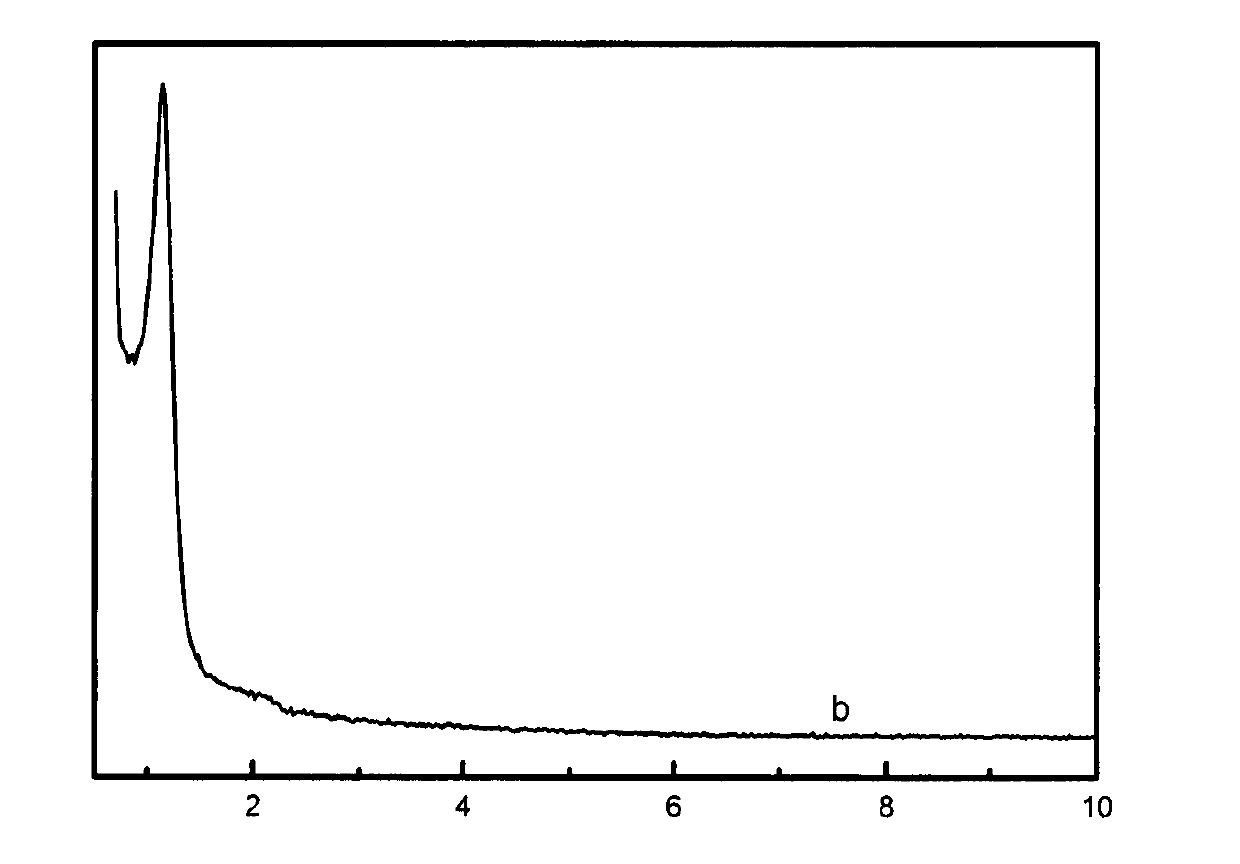

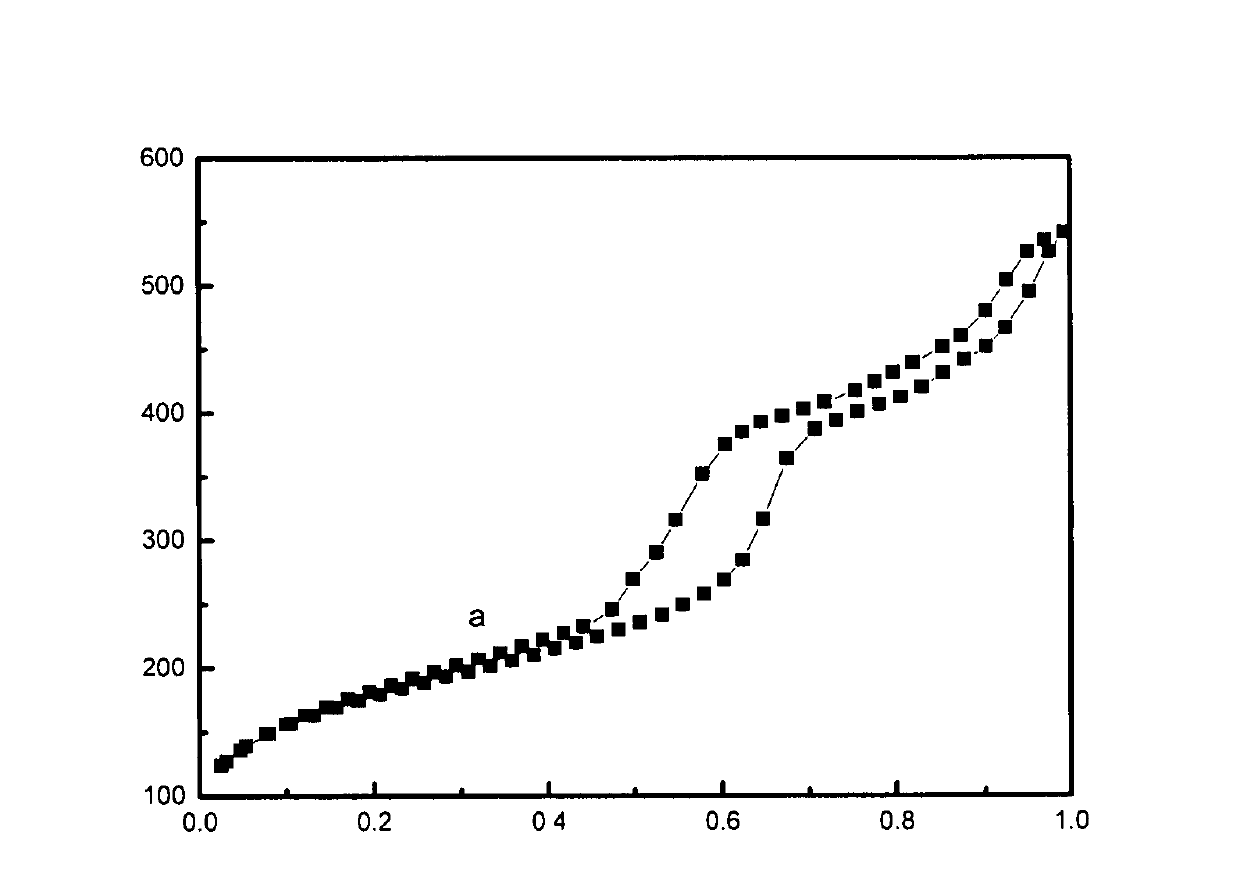

Image

Examples

Embodiment approach

[0059] According to an embodiment of the present invention, the preparation method of the supported metallocene catalyst includes the following steps:

[0060] In the first step, add the triblock copolymer polyoxyethylene-polyoxypropylene-polyoxyethylene and N,N-dimethylformamide (DMF) to the hydrochloric acid aqueous solution at a molar ratio of

[0061] The triblock copolymer polyethylene oxide-polypropylene oxide-polyethylene oxide: N, N-dimethylformamide (DMF): water: hydrogen chloride=1: 300-700: 10000-20000: 100-500, preferably 1:550-650:10000-13000:150-480, particularly preferably 1:596:1411:326,

[0062] Stir to dissolve at 25-60℃;

[0063] In the second step, add ethyl orthosilicate to the solution obtained in the previous step, stir at 25-60°C for 1-2 hours, then add silica gel, and stir for 10-40 hours; The weight ratio may be 3-6:1, preferably 4-5:1, more preferably 4.45:1.

[0064] In the third step, the crystallization product is filtered, washed, and dried to obtain the...

preparation example 1

[0076] This preparation example is used to illustrate the supported metallocene catalyst and its preparation method according to the present invention.

[0077] Add 2.0 g of P123, 15 g of N, N-dimethylformamide (DMF) and 64 ml of water to 11.2 g of 37% hydrochloric acid solution, and stir at 40°C until P123 is completely dissolved; then 4.45 g of ethyl orthosilicate The ester was added to the above solution and stirred at 40°C for 1 hour, and then 1 gram of industrial ES955 silica gel was added. After filtering, washing and drying, the raw powder composite material was obtained; the composite material was calcined in a muffle furnace at 600°C for 24 hours to remove Template agent to obtain the final product of spherical mesoporous silica (named GJ-MBQ).

[0078] The above-mentioned composite material GJ-MBQ is calcined at 400°C for 10 hours under the protection of nitrogen to remove hydroxyl groups and residual moisture, thereby obtaining a thermally activated composite material.

...

Embodiment 1

[0091] This example is used to illustrate the catalytic activity of the supported metallocene catalyst according to the present invention.

[0092] In a 2-liter stainless steel autoclave, replace with nitrogen and ethylene three times each, then add 200 ml of hexane, raise the temperature of the kettle to 80°C, and then add 800 ml of hexane, and with the addition of hexane, add 2 ml A triethylaluminum (TEA) hexane solution with a concentration of 1 mol / L, then 60.6 mg MAO / GJ-MBQ-BU was added, and ethylene was introduced to increase the pressure to 1.0 MPa and maintain it at 1.0 MPa, and react at 70°C 1 hour. Obtained 146 grams of polyethylene particle powder, the bulk density (BD) of the polyethylene particle powder is 0.317g / ml, and the melt index MI 2.16 =0.051g / 10min. After calculation, the efficiency of the catalyst is 2409g PE / gcat·h (that is, 6.2×10 7 g PE / (mol Zr h)).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com