Mobile construction waste treatment device

A construction waste and processing device technology, applied in the directions of magnetic separation, solid separation, filter and sieve, etc., can solve the problems of wasting water resources, inability to separate iron and metal, inability to decompose concrete, etc., and achieve the effect of improving processing capacity and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

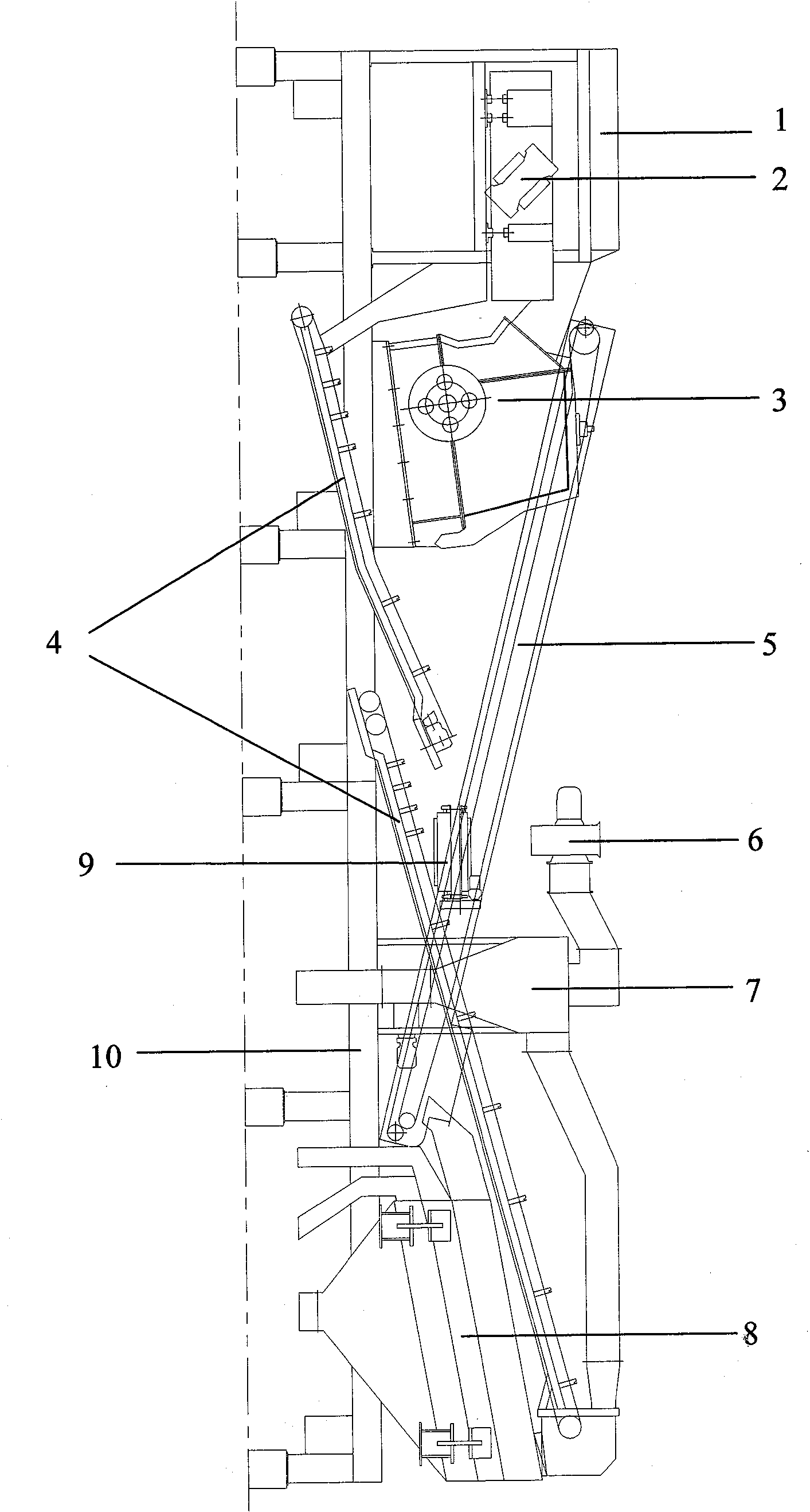

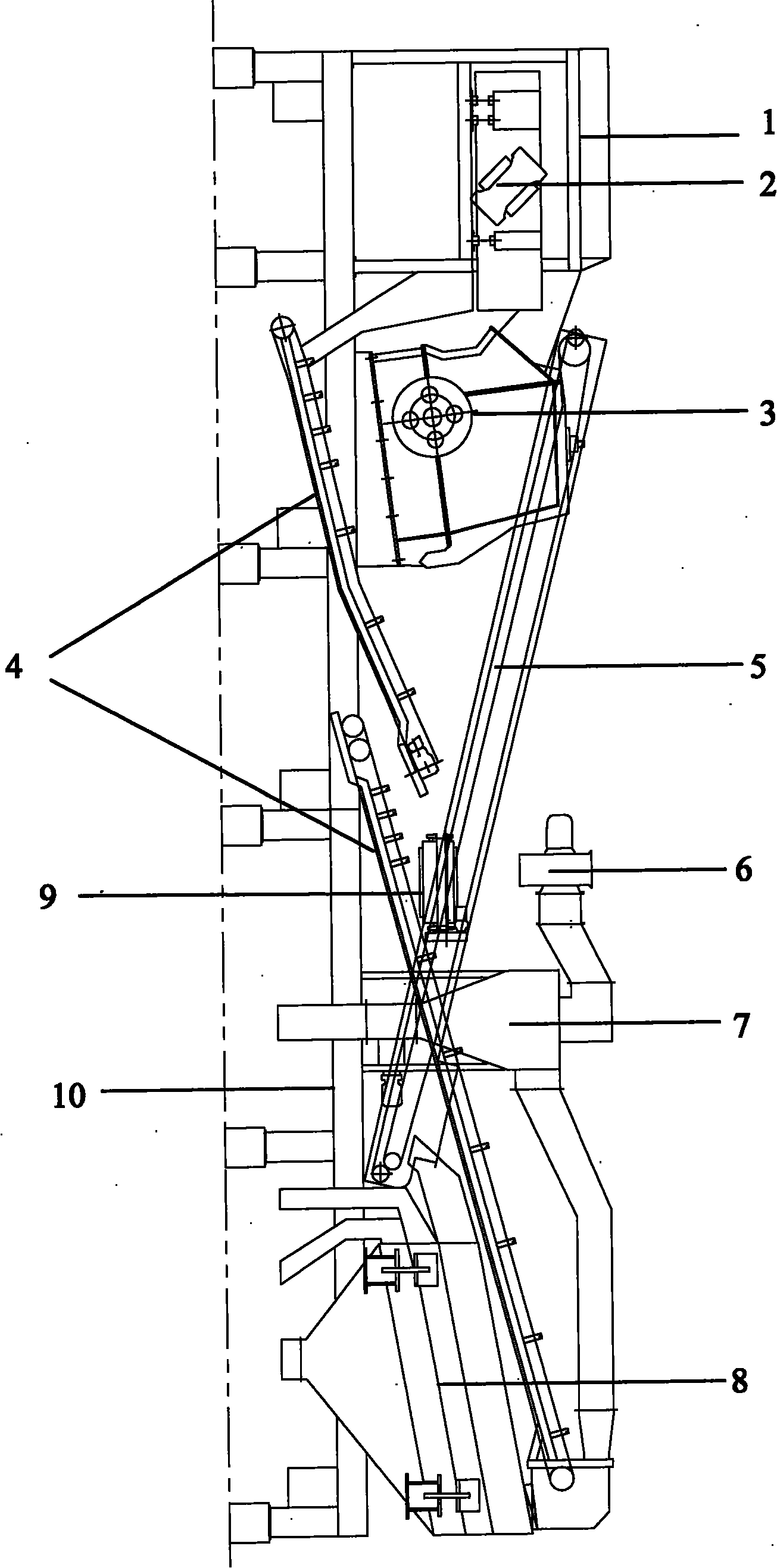

[0021] figure 1 It is a structural representation of a specific embodiment of the present invention, combined below figure 1 The embodiments of the present invention are introduced.

[0022] like figure 1 As shown, the mobile construction waste treatment device provided by the embodiment of the present invention is characterized in that it includes a movable frame (9) and a feed hopper (1), and the outlet vibrating screening feeder of the feed hopper (1) (2), the outlet under the screen of the vibrating screening feeder (2) is connected to the undersize conveyor (4), and the outlet on the screen of the vibrating screening feeding machine (2) is connected to the crusher (3) The entrance of the crusher (3) is connected to the undersize conveyor (4), and the undersize conveyor (4) is connected to the entrance of the multi-layer vibrating screening machine (8) by a magnetic separator (10). The multi-layer vibrating screening machine (8) is provided with a dust outlet, a large m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com