Method of processing un-suspension powdered aluminium

A processing method and non-floating technology, applied in the processing field of non-floating aluminum powder, can solve the problems of difficulty in ensuring product particle size and uniformity, difficult product dispersion and classification, etc., achieving less difficulty in dispersion and classification, and a metallic feel And the effect of good flash effect and strong covering power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

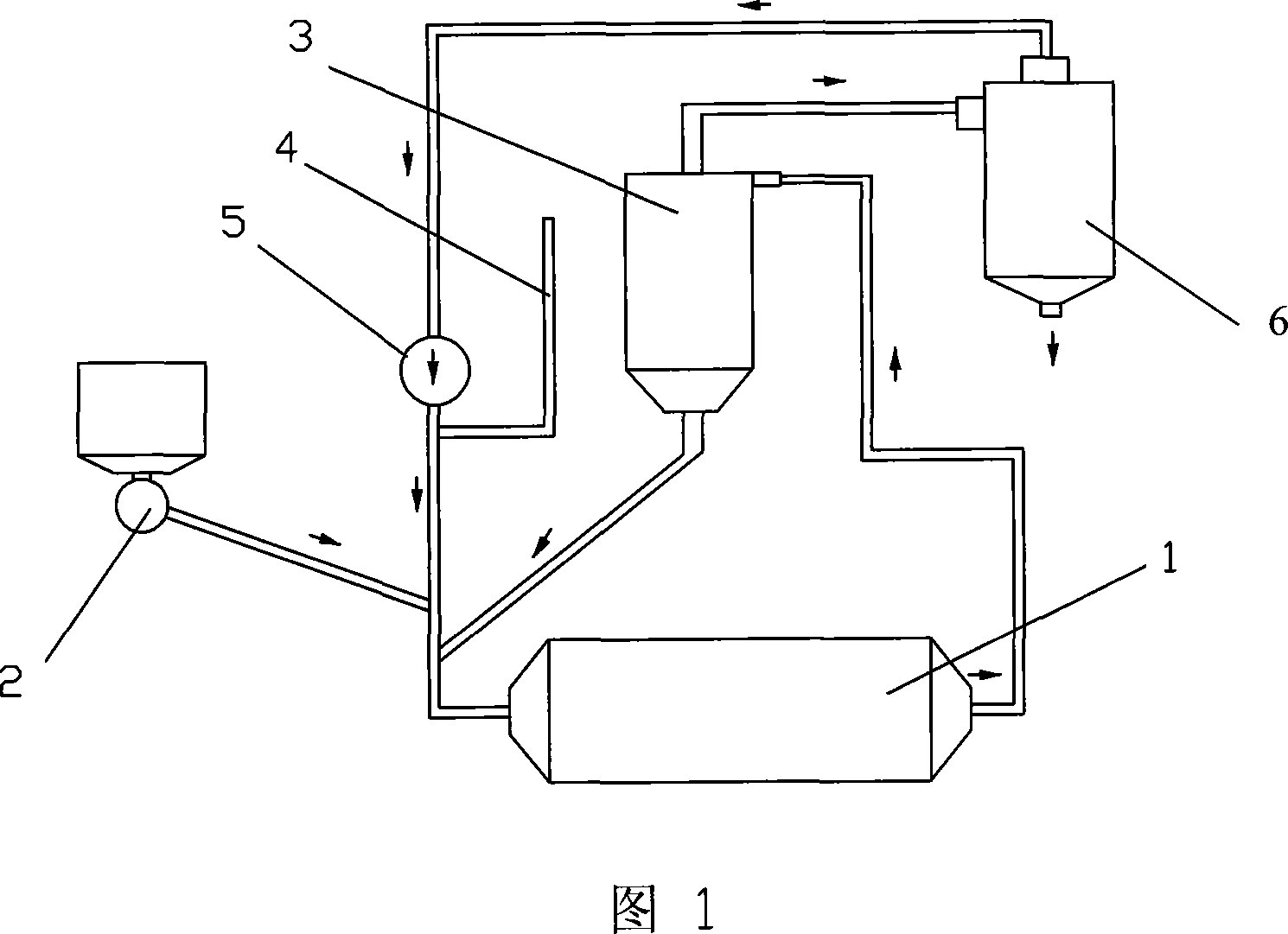

[0006] Specific Embodiment 1: The present embodiment will be specifically described below with reference to FIG. 1 . This embodiment is realized by the following steps: 1. Select the wool aluminum powder, the weight ratio of the wool aluminum powder is Fe≤0.3%, Cu≤0.1%, Si≤0.3%, the rest is active Al, and the wool aluminum powder is atomized aluminum Powder, the particle shape of the atomized aluminum powder is spherical, and its particle size is between 5 and 17 microns; 2. Grind the wool aluminum powder in the Φ1500mm×3000mm ball mill 1. The ball mill 1 has a ball capacity of 5 tons. The ball loading capacity is: 2000kg for 10mm, 1500kg for 15mm, 1500kg for 20mm. Nitrogen is used as gas protection in the ball mill 1, grease block is added in the ball mill 1 as an additive, and the weight percentage of the additive in the wool aluminum powder is 0.8% to 1.0%; 3. Blow the ground wool aluminum powder in the ball mill 1 into At the entrance of the cyclone separator 3, the wool ...

specific Embodiment approach 2

[0008] Specific Embodiment 2: The present embodiment will be specifically described below with reference to FIG. 1 . In this embodiment, the use of nitrogen as gas protection in the ball mill 1 is realized in this way: the inlet of the ball mill 1 is connected to the outlet of the feeder 2, the lower outlet of the cyclone separator 3, the outlet of the nitrogen supply pipe 4 and the air outlet of the blower 5, and the ball mill The outlet of 1 is connected to the inlet of cyclone separator 3, the upper outlet of cyclone separator 3 is connected to the inlet of cyclone collector 6, the upper outlet of cyclone collector 6 is connected to the return air outlet of blower 5, and the content of oxygen in the nitrogen in ball mill 1 is 4.5 ±0.3%. Gas protection is the basis for the continuous production of ball milled aluminum powder. Control the oxygen content in the protective gas nitrogen, so that the oxygen content in nitrogen is 4.5±0.3%, so that the aluminum powder will not be ...

specific Embodiment approach 3

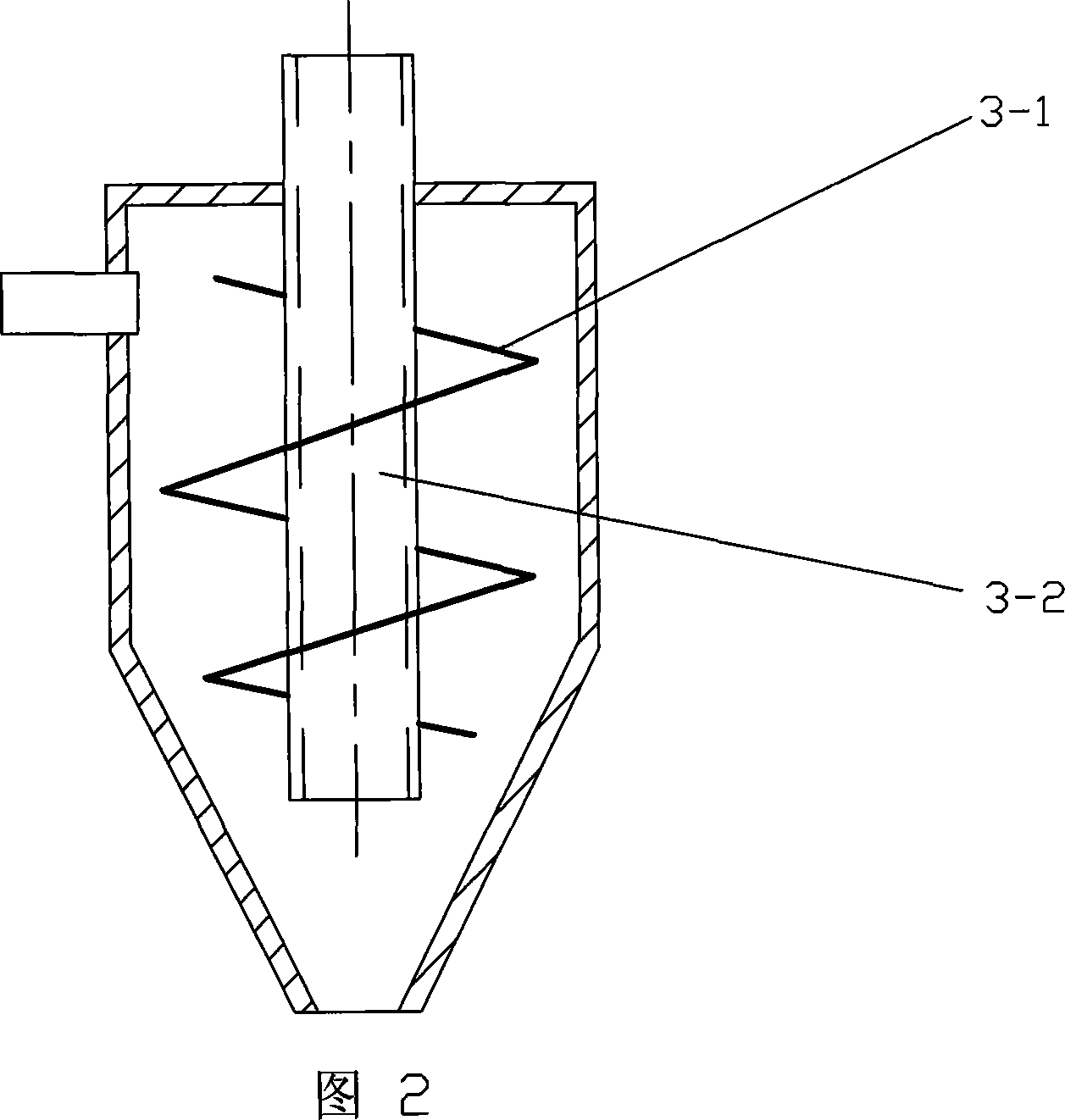

[0009] Specific Embodiment Three: The present embodiment will be specifically described below in conjunction with FIG. 2 . The difference between this embodiment and Embodiment 2 is: the air riser 3-2 in the cyclone separator 3 and the helical blade 3-1 fixed on the outer surface of the air riser 3-2 can be arranged along the height direction of the cyclone separator 3. Adjust up. With such an arrangement, the particle size of the aluminum powder separated from the upper outlet of the cyclone separator 3 can be adjusted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com