High-concentration white master batch for polyvinylidene fluoride (PVDF) films and production method thereof

A polyvinylidene fluoride and polyvinylidene fluoride resin technology, applied in the field of high-concentration white masterbatch, can solve the problems of poor film forming, weak covering power, poor dispersibility, etc., and achieve good film forming, strong covering power, pigment high concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

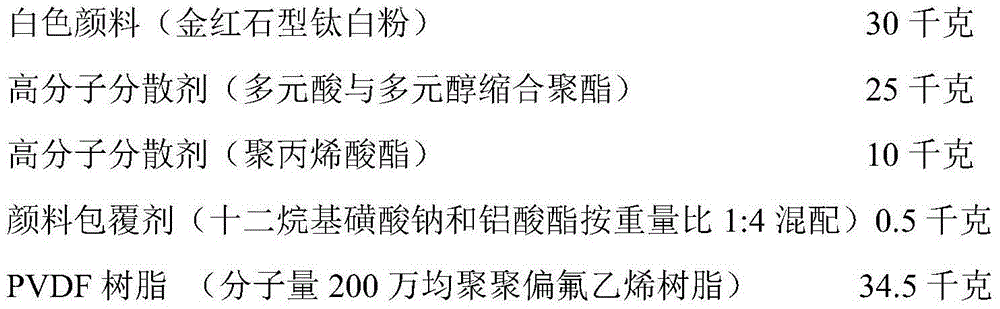

[0016] Preparation of 100 kg polyvinylidene fluoride (PVDF) film with high concentration white masterbatch

[0017] 1. The weight of each component is:

[0018]

[0019] 2. Preparation method

[0020] Add the above-mentioned components into the multi-dimensional motion mixer at one time, mix for 15 minutes, and then send the mixed materials into the twin-screw extruder with vacuum exhaust function, and the screw speed of the extruder is 90r / min, barrel and die temperature 60-220 ℃, vacuum exhaust vacuum gauge pressure -0.05MPa under the conditions of mastication, extrusion, cooling, drying and pelletizing to obtain a 30% color concentration that can be applied to direct film formation. High-concentration white masterbatch for polyvinylidene fluoride (PVDF) film with 1% thermal weight loss greater than 330°C.

[0021] 3. Film-forming property verification

[0022] The high-concentration white masterbatch for polyvinylidene fluoride (PVDF) film prepared above is directly ...

Embodiment 2

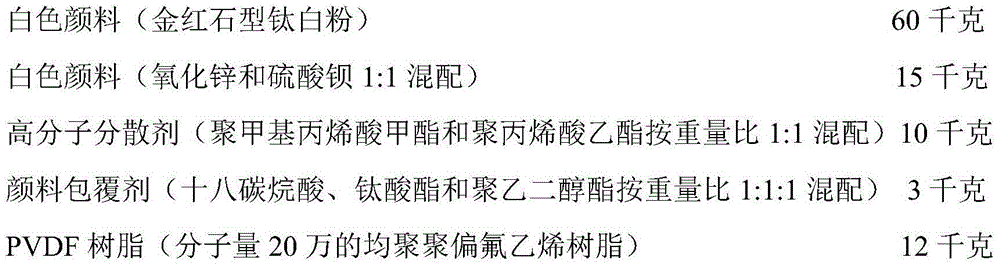

[0025] Preparation of 100 kg polyvinylidene fluoride (PVDF) film with high concentration white masterbatch

[0026] 1. The weight of each component is:

[0027]

[0028] 2. Preparation method

[0029] Add the pigment coating agent and polymer dispersant to the stirring mixer and mix evenly, then put them into the automatic feeder with weighing scale, and add the pigment titanium dioxide, pigment zinc oxide and barium sulfate mixture and PVDF resin respectively Put them into their own automatic feeders with weighing scales, set the automatic feeding linkage rate according to the weight ratio of the appeal formula, and feed them into the twin-screw extrusion granulator with vacuum exhaust function. The speed is 200r / min, the barrel and die temperature is 60-220℃, and the vacuum exhaust vacuum gauge pressure is -0.05MPa. Under the conditions of plasticizing, extrusion, cooling, drying and pelletizing, 75% color concentration and 1% thermal weight loss can be obtained. High-c...

Embodiment 3

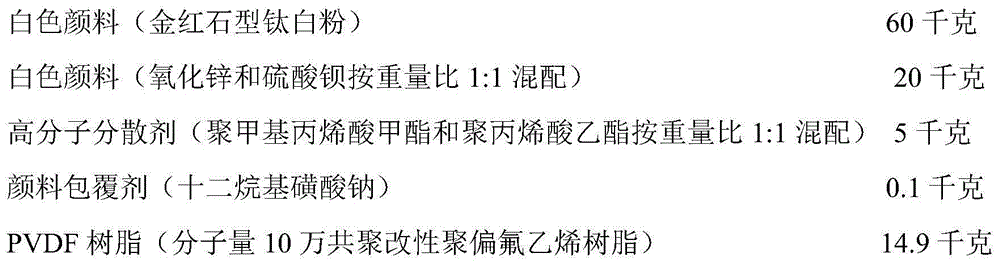

[0034] Preparation of 100 kg polyvinylidene fluoride (PVDF) film with high concentration white masterbatch

[0035] 1. The weight of each component is:

[0036]

[0037] 2. Preparation method

[0038] Add the pigment coating agent and polymer dispersant to the stirring mixer and mix evenly, then put them into the automatic feeder with weighing scale, and add the pigment titanium dioxide, pigment zinc oxide and barium sulfate mixture and PVDF resin respectively Put them into their own automatic feeders with weighing scales, set the automatic feeding linkage rate according to the weight ratio of the appeal formula, and feed them into the twin-screw extrusion granulator with vacuum exhaust function. The speed is 50r / min, the barrel and die temperature is 60-220°C, and the vacuum exhaust vacuum gauge pressure is 0MPa. Under the conditions of plasticizing, extrusion, cooling, drying and pelletizing, 80% color concentration and 1% heat loss are greater than 330. ℃ high concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com