High-pigment-content color master batch as well as preparation method and application thereof

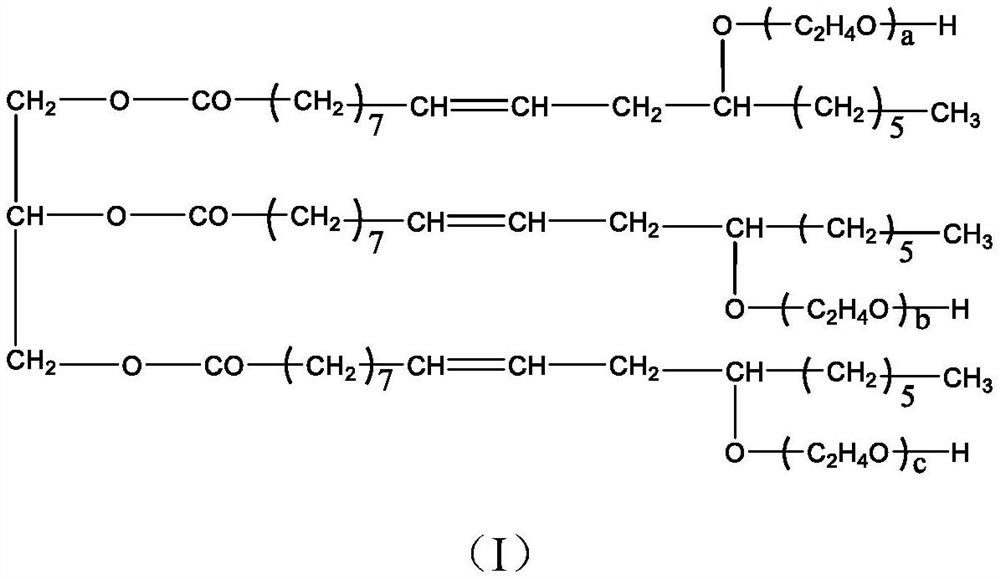

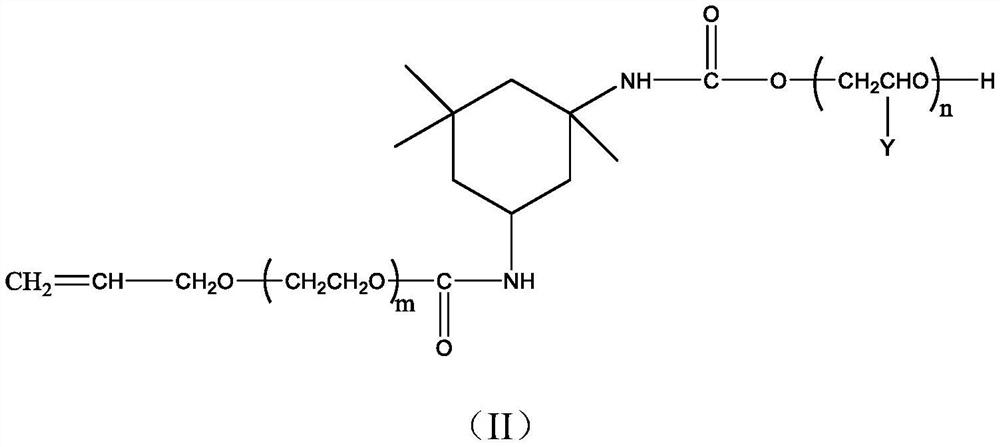

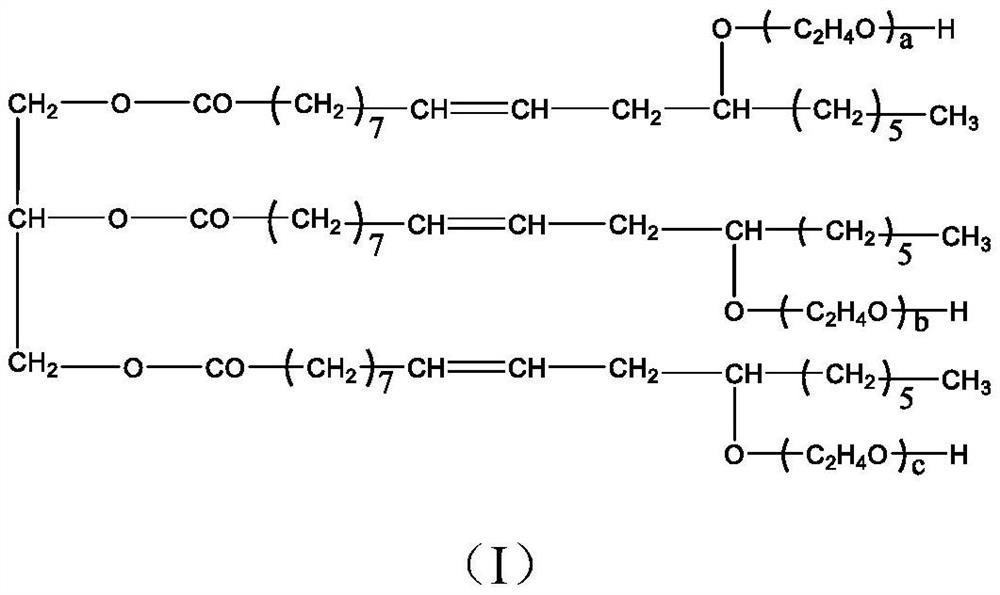

A color masterbatch and pigment technology, which is applied in the preparation of carboxylate, chemical instruments and methods, and preparation of organic compounds, etc., can solve the problems of poor compatibility between pigments and polyester carriers, uneven color of colored polyester fibers, and color masterbatches. The problem of uneven distribution of granular pigments, etc., can achieve the effect of strong color fastness to washing, reduced silk floating, and good dispersion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The present invention further provides a preparation method of the high-pigment content color masterbatch, comprising the steps of:

[0061] (a) According to the number of parts by mass, the carrier and additives are pulverized and mixed with the self-dispersing pigment evenly to obtain a mixed powder; in addition, the carrier and additives need to be dewatered before use to avoid the moisture in the mixed powder Degrade polyester during heating and melting;

[0062] (b) injecting the mixed powder into an extruder for granulation to obtain a color masterbatch with high pigment content for polyester fibers.

[0063] In the above method, the extruder is a twin-screw extruder or a single-screw extruder, the screw speed of the extruder is 200-300 rpm, and the temperature of the extruder is 240-275°C.

[0064] The color masterbatch with high pigment content of the invention can be used in polyester fiber spinning to prepare colored polyester fiber.

Embodiment 1

[0077] Add 1.5 parts of Surfactant A1 and 1.5 parts of Surfactant B1 to 62 parts of water, mix well, add 35 parts of Pigment Blue 15:3, grind and dry to obtain Self-dispersing pigments.

[0078] The polyester carrier that the mass is 62 parts, the antioxidant 1010 that the mass is 1 part, the diatomite that the mass is 1 part, the 2-(2-hydroxyl-5-tert-octylphenyl) benzo that the mass is 1 part After the triazole is ground, it is uniformly mixed with 35 parts of self-dispersing pigment by mass to obtain a mixed powder; the mixed powder is injected into an extruder for granulation to obtain a high-pigment content color masterbatch.

Embodiment 2

[0080] Add 1 part of Surfactant A2 and 2 parts of Surfactant B2 to 50 parts of water, mix well, add 20 parts of Pigment Red 122, grind and dry to obtain self-dispersing pigment.

[0081] 75 parts by mass of polyester carrier, 1 part by mass of antioxidant 1010, 1 part by mass of synthetic silica, 1 part by mass of 2-(2-hydroxyl-3,5-di-tert-butylbenzene Base)-5-chlorobenzotriazole, 2 parts of 2,4-dihydroxybenzophenone by mass are pulverized and mixed evenly with 20 parts of self-dispersing pigments by mass to obtain a mixed powder; the mixed powder Inject into the extruder for granulation to obtain high pigment content masterbatch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com