Magnetic-gravity separation technology for Anshan type lean magnetite

A lean magnetite, Anshan-style technology, applied in the field of Anshan-style lean magnetite magnetic-gravity separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

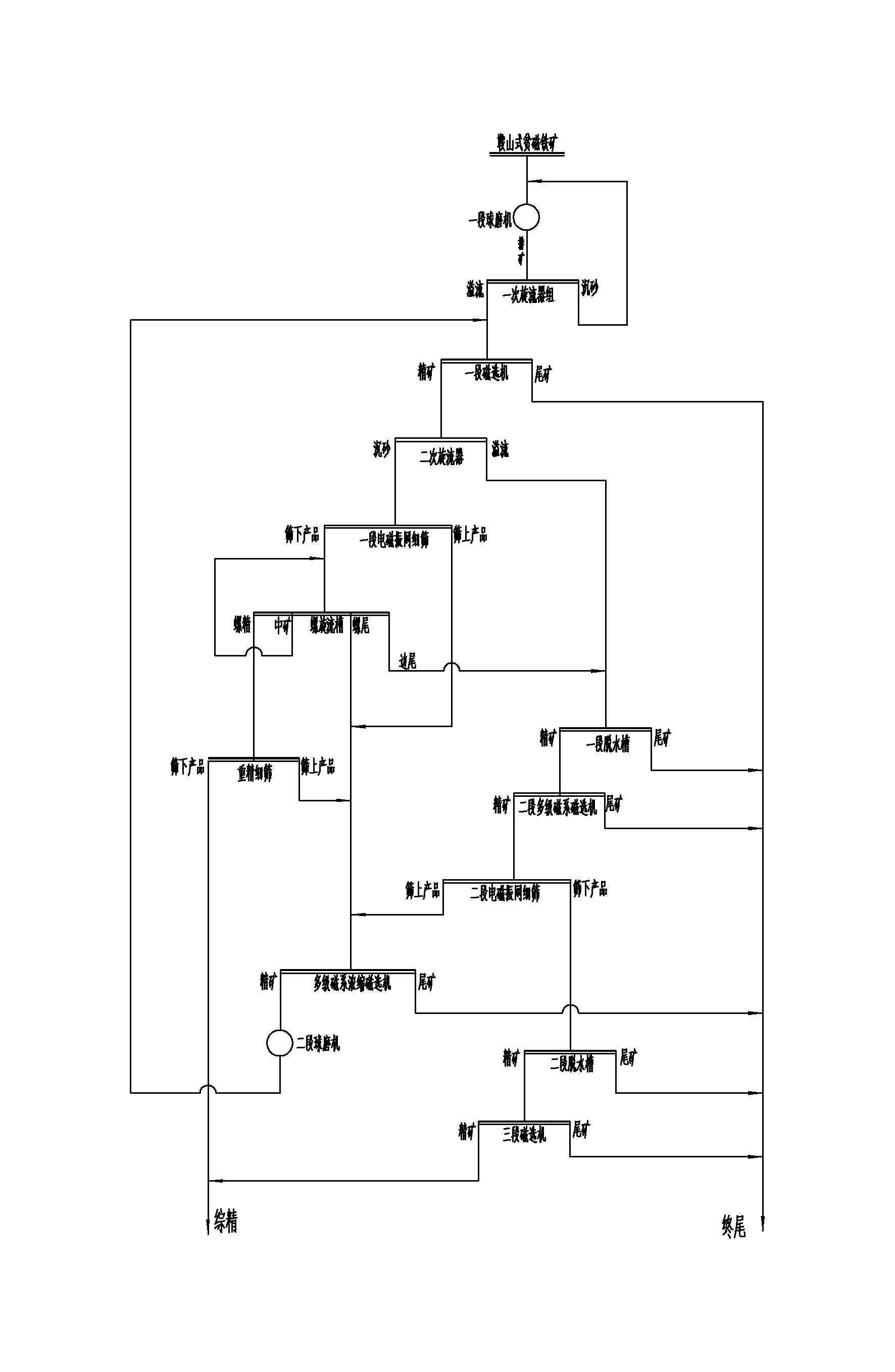

[0018] like figure 1 Shown, Anshan type lean magnetite magnetic-gravity separation process of the present invention comprises the following steps:

[0019] a) Feed the Anshan-type lean magnetite ore with a particle size of -12mm accounting for more than 93% and a grade of 25-32% into a section of Φ3600×6000mm overflow type long tube ball mill with a length-to-diameter ratio greater than or equal to 1.5 to 2 for the first-stage grinding operation , the ore discharge product of a section of Φ3600×6000mm overflow type long barrel ball mill is fed into a Φ660mm primary dynamic pressure feed cyclone group for classification operation, and the grit generated by the classification operation returns to the first section of ball mill operation by gravity, and the classification operation produces The overflow product with a particle size of -0.076mm accounting for 60-65% and a grade of 25-32% is fed into a section of CTB1232 magnetic separator, and the tailings separated by a section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com