A kind of preparation method of bauxite flotation desiliconization high-efficiency collector

A collector and bauxite technology, applied in flotation, solid separation and other directions, can solve the problems of poor emulsification effect of mixed collectors, difficult settlement of flotation tailings, uneven dissolution of chemicals, etc., and achieves enhanced selectivity and The effect of collecting capacity, improving mineral processing technical indicators, and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

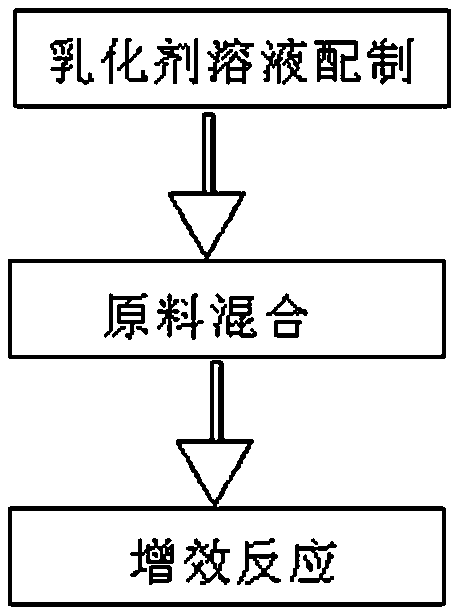

Image

Examples

Embodiment 1

[0032] Raw materials: PEG-600, TX-10, oleic acid, tall oil, T-60, triethanolamine;

[0033] Mass ratio: oleic acid: tall oil = 1:1;

[0034] Oleic acid: TX-10: PEG-600=1:0.2:0.1;

[0035] Oleic acid: T-60: triethanolamine=1:0.2:0.1;

[0036] Dosage: oleic acid 10kg (content 90% w / w, pure 9kg)

[0037] Tal oil 10kg (content 90% w / w, pure 9kg)

[0038] TX-10 2kg (content 90% w / w, pure 1.8kg)

[0039] PEG-600 1kg (content 90% w / w, pure 0.9kg)

[0040] T-60 2kg (content 90% w / w, pure 1.8kg)

[0041] Triethanolamine 1kg (content 90% w / w, pure 0.9kg)

[0042] operate:

[0043] A. Emulsifier preparation: Add regular amount of water to the reaction tank, stir, and gradually add TX-10 and PEG-600 until they dissolve evenly;

[0044] B. Mixing of raw materials: Gradually add oleic acid and tall oil, heat up to 40°C, and stir for 1 hour;

[0045] C. Synergistic reaction: After the reaction in step B is completed, place the prepared medicament mixture on an ultrasonic cleaning ma...

Embodiment 2

[0049] Raw materials: coconut oil diethanolamide, ether acid, oxidized paraffin soap, T-40, triethanolamine;

[0050] Mass ratio: ether acid: oxidized paraffin soap = 1:1;

[0051] Ether acid: coconut oil diethanolamide=1:0.2;

[0052] Ether acid: T-40: triethanolamine=1:0.1:0.1;

[0053] Dosage: ether acid 10kg (content 90% w / w, pure 9kg)

[0054] Oxidized paraffin soap 10kg (content 90% w / w, pure 9kg)

[0055] Coconut oil diethanolamide 2kg (content 90% w / w, pure 1.8kg)

[0056] T-40 1kg (content 90% w / w, pure 0.9kg)

[0057] Triethanolamine 1kg (content 90% w / w, pure 0.9kg)

[0058] operate:

[0059] A. Emulsifier preparation: Add regular amount of water in the reaction tank, stir, and gradually add coconut oil diethanolamide until it dissolves evenly;

[0060] B. Mixing of raw materials: Gradually add ether acid and oxidized paraffin soap, heat up to 30°C, and stir for 5 hours;

[0061] C. Synergistic reaction: After the reaction in step B is completed, place the p...

Embodiment 3

[0065] Raw materials: fatty alcohol polyoxyethylene ether, naphthenic acid, ether acid, T-20, methyl isobutyl carbinol;

[0066] Mass ratio: naphthenic acid: ether acid = 1:1;

[0067] Naphthenic acid: fatty alcohol polyoxyethylene ether = 1:1;

[0068] Naphthenic acid: T-20: methyl isobutyl carbinol = 1: 0.5: 0.5;

[0069] Dosage: naphthenic acid 10kg (content 90% w / w, pure 9kg)

[0070] Ether acid 10kg (content 90% w / w, pure 9kg)

[0071] Fatty alcohol polyoxyethylene ether 10kg (content 90% w / w, pure 1.8kg)

[0072] Methyl isobutyl carbinol 5kg (content 90% w / w, pure 0.9kg)

[0073] T-20 5kg (content 90% w / w, pure 1.8kg)

[0074] operate:

[0075] A. Emulsifier preparation: Add regular amount of water in the reaction tank, stir, and gradually add fatty alcohol polyoxyethylene ether until it dissolves evenly;

[0076] B. Mixing of raw materials: Gradually add naphthenic acid and ether acid, heat up to 70°C, and stir for 1 hour;

[0077] C. Synergistic reaction: After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com