Molybdenite floatation collector

A collector, molybdenite technology, applied in flotation, solid separation and other directions, can solve the problems of environmental pollution, oil waste, etc., and achieve the effect of reducing pollution, improving utilization rate, and improving enterprise benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

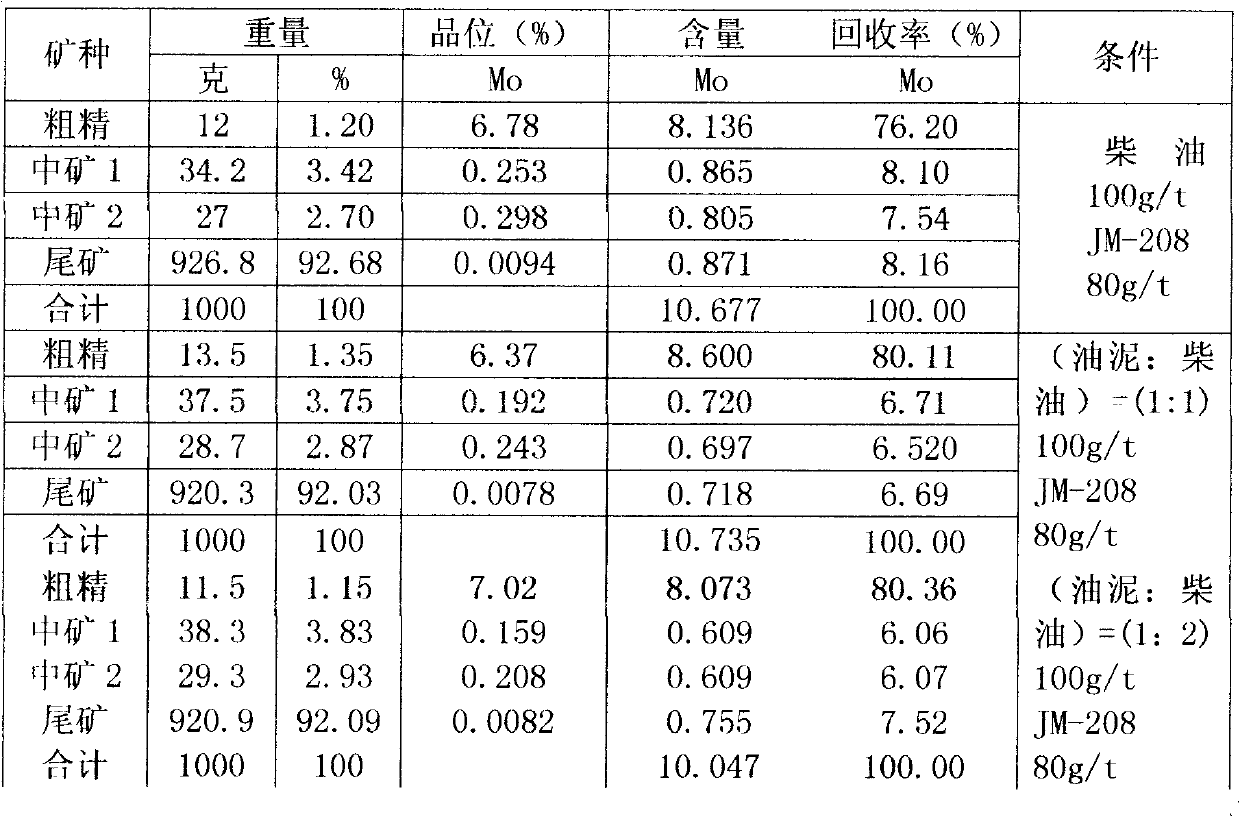

[0012] Embodiment 1: adopt diesel oil as collector and foaming agent in this example, oil sludge: diesel oil=1: 1 and 1: 2 compare as collector and foaming agent, dosing place, dosing time, dosing The conditions were all carried out under the same conditions as the original process.

[0013]

Embodiment 2

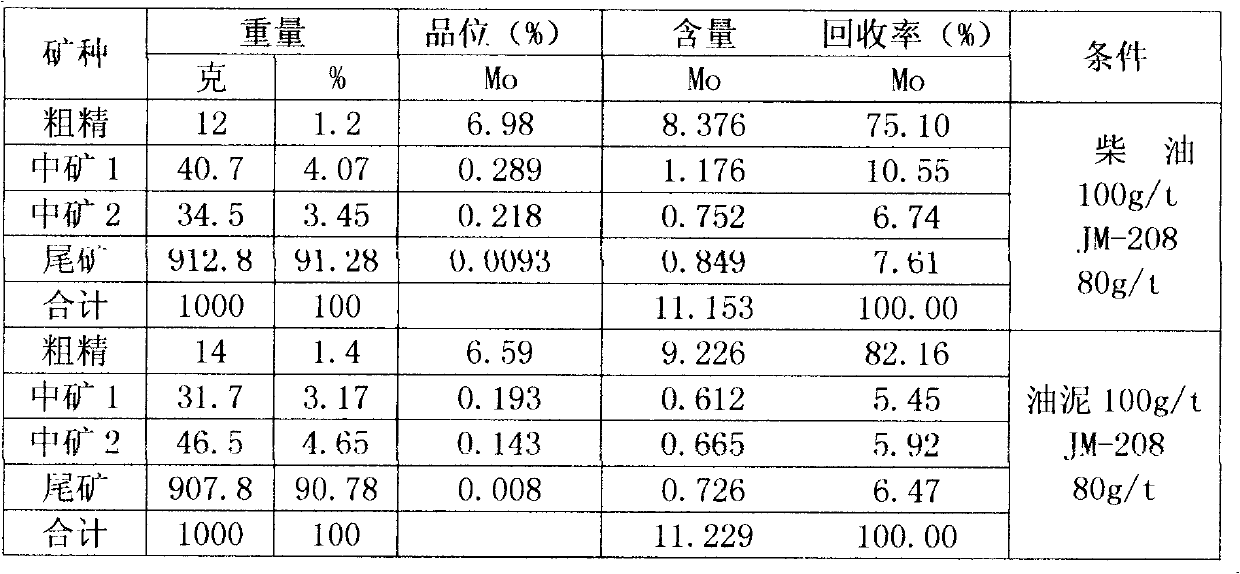

[0014] Embodiment 2: In this example, diesel oil is used as collector and foaming agent, oil sludge is compared as collector and foaming agent, and the dosing location, dosing time, and dosing conditions are all carried out under the same conditions as the original process .

[0015]

[0016] JM-208 listed in the table above is a blowing agent.

[0017] From the examples, we can see that the collector of the present invention is used under the same amount of traditional collector than the traditional collector (other conditions are also the same), and the molybdenum recovery rate is obviously improved, and the improvement range can reach 1.5 percentage points at least. The main reason is that the amount of light diesel oil and kerosene used as collectors is greatly reduced, which can save a lot of resources, reduce the production cost of enterprises, and improve economic benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com