Flocculation desliming and alkaline flotation method of high-ferrous ore fine particle products

A product, alkaline technology, used in flotation, selective sedimentation, solid separation, etc., can solve the problems of reduced concentrate grade, high tailing grade, metal loss, etc., to reduce tailings grade and improve beneficiation technology The effect of the indicator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

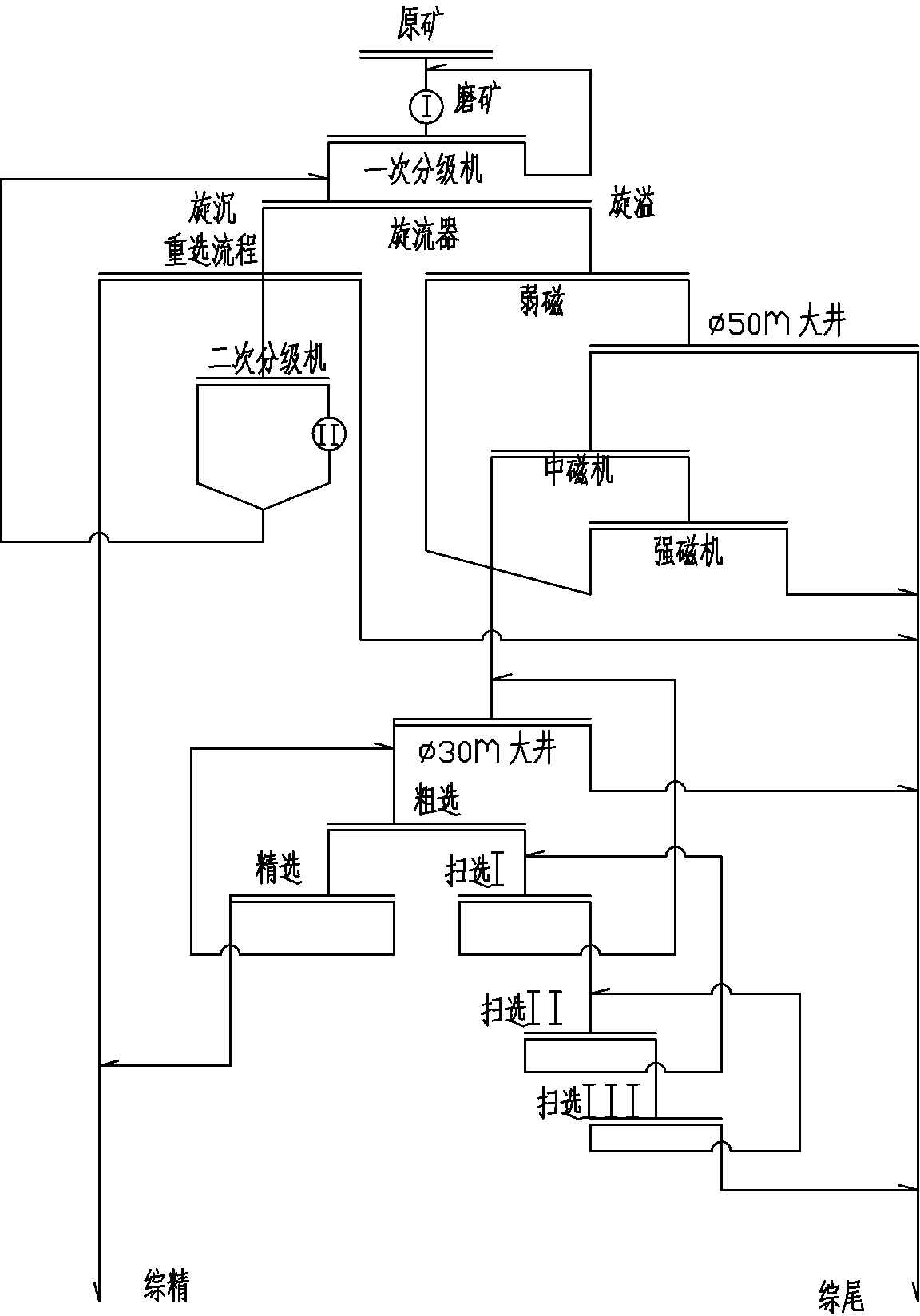

Image

Examples

Embodiment Construction

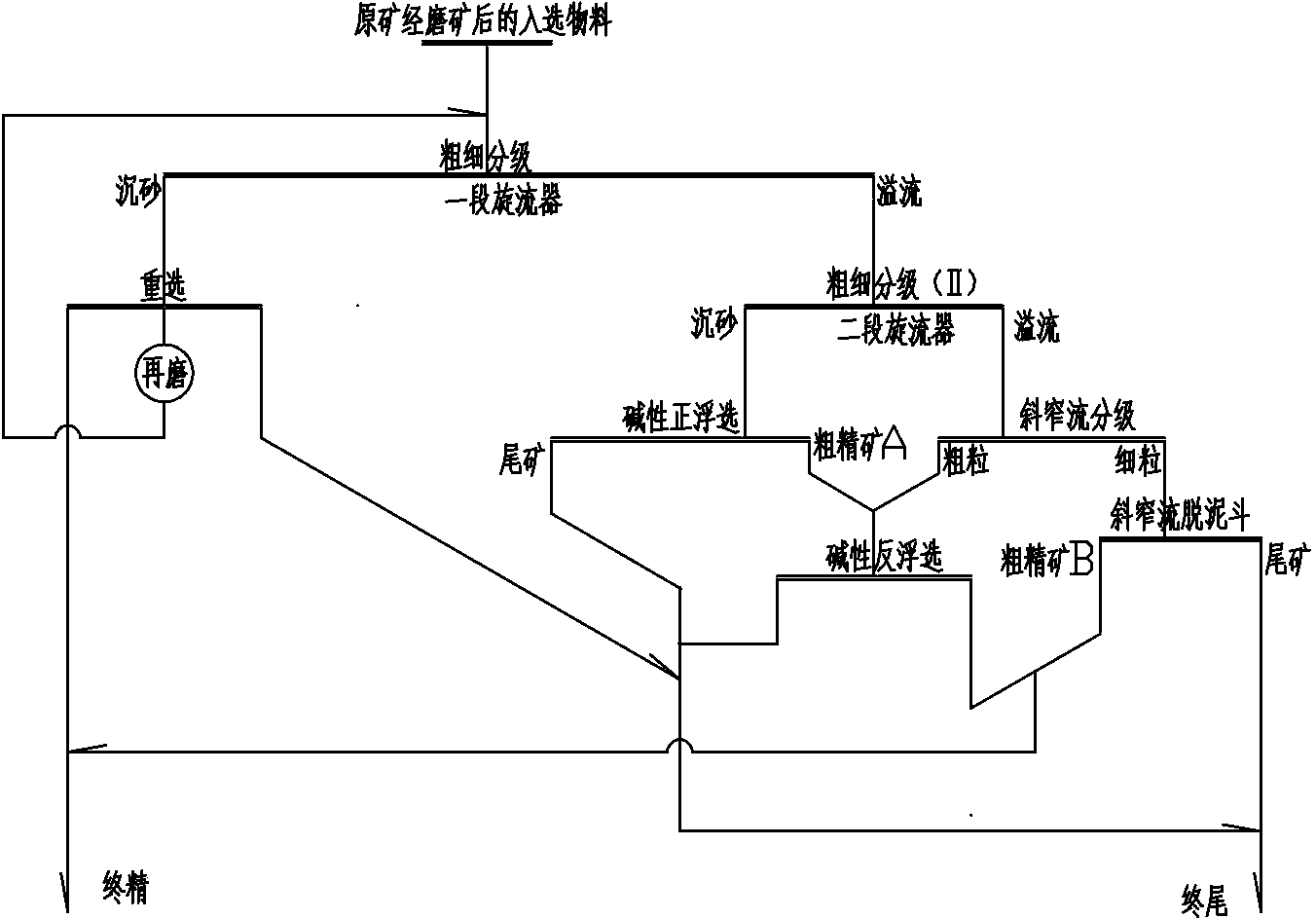

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] A method of flocculation and desliming and alkaline flotation of high-ferrous ore fine-grained products of the present invention comprises that the raw ore is ground and selected materials are fed into a section of coarse and fine-grained cyclone for classification operation, and it is characterized in that a section of coarse and fine-grained cyclone The sand settling of the device is fed into the re-selection process for selection, and the overflow of the first stage of coarse and fine classification cyclone is fed into the second stage of coarse and fine classification cyclone for selection. The specific steps are as follows:

[0021] 1) The overflow of the first stage of coarse and fine-grading cyclone is fed into the second-stage cyclone for further classification, the sand settling of the first stage of coarse and fine-grading cyclone is fed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com