Glass cullet machining process

A processing technology and cullet technology, which is applied in the direction of grain processing, etc., can solve the problems of different glass shapes, different quality requirements of cullet, and different thickness of glass, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

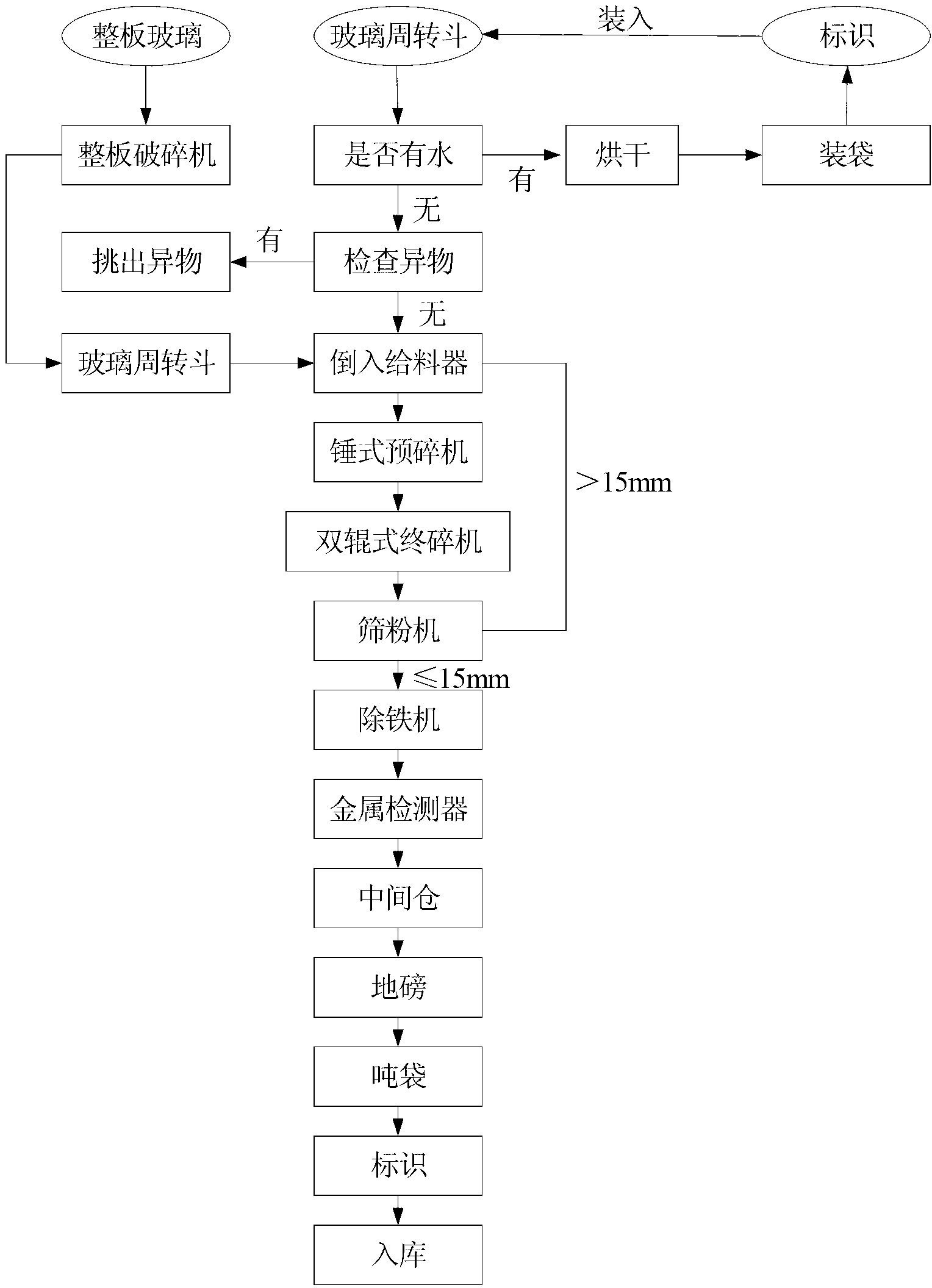

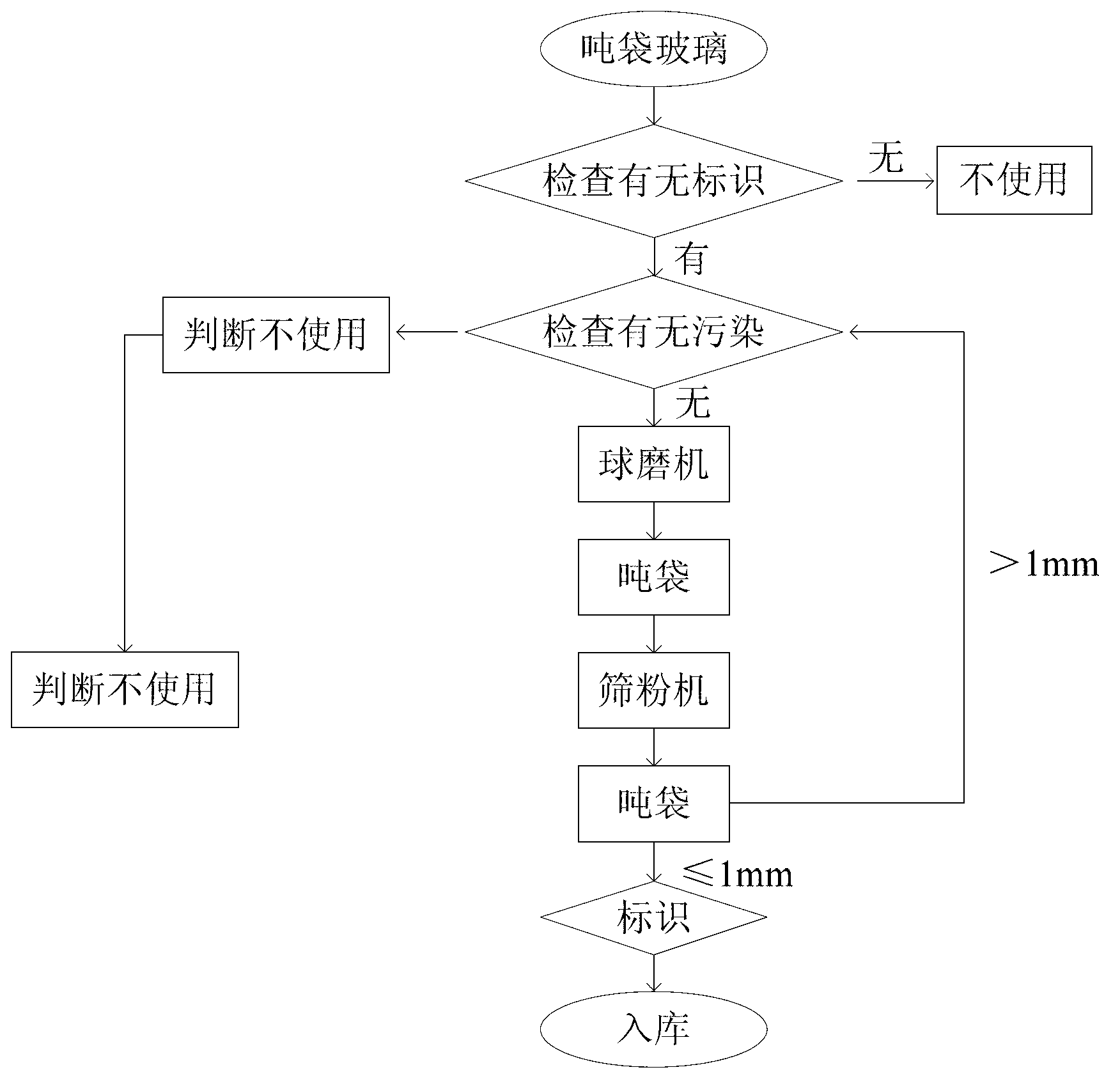

[0039] see figure 1 , figure 2 , a cullet processing technology, comprising the following steps:

[0040] a) The anhydrous glass flakes are fed into the crusher through the feeder for crushing to obtain coarsely crushed broken glass.

[0041] It should be noted that the anhydrous glass flakes can be sent into the crusher through the feeder, or the anhydrous glass flakes can be directly poured into the crusher. Preferably, the present invention feeds the anhydrous glass flakes into the feeder first. The feeder, and then the anhydrous glass flakes enter the crusher through the feeder for crushing.

[0042] Among them, the feeder used in the present invention is a vibrating feeder. When in use, anhydrous glass flakes are added to the crusher through the vibrating feeder, thereby preventing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com