Target material corrosive agent and application method thereof

An application method and technology of etchant, which is applied in the field of heat treatment, can solve the problems of inability to clearly display the metallographic structure of stainless steel target grains, and achieve the effect of strong corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

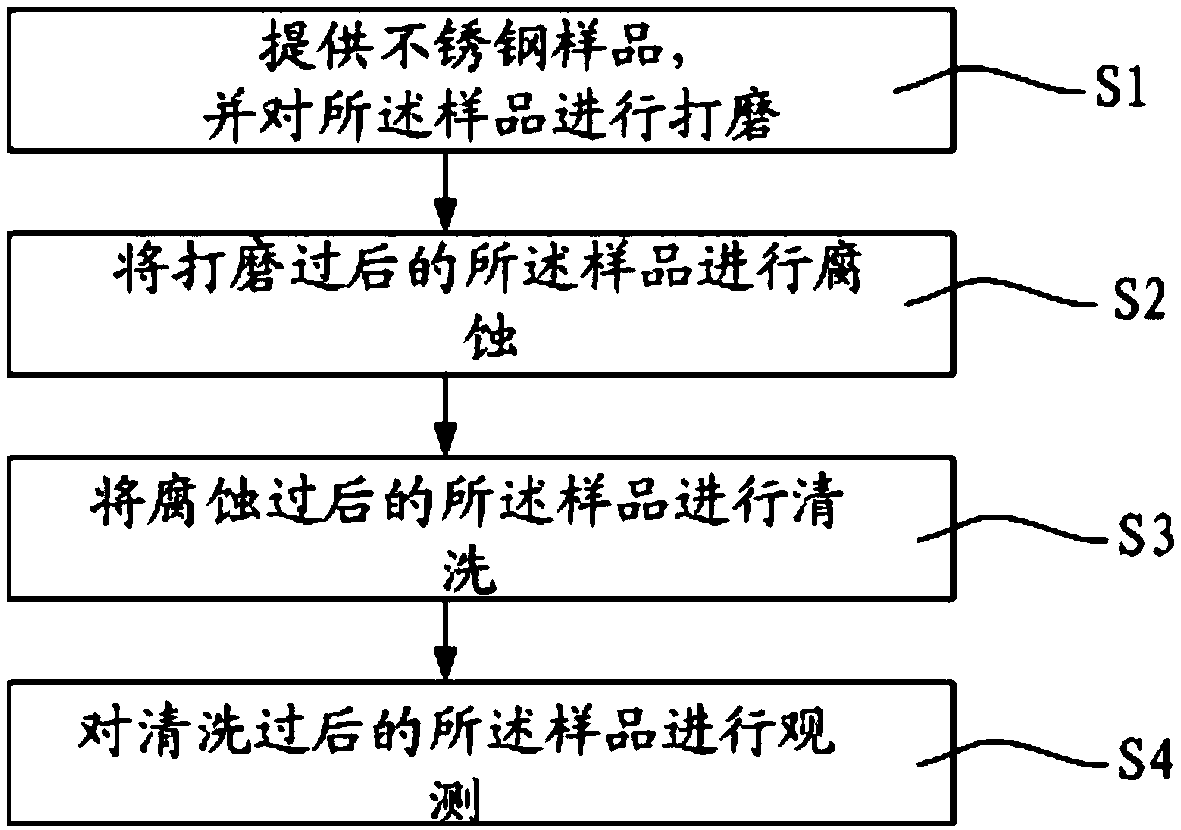

Method used

Image

Examples

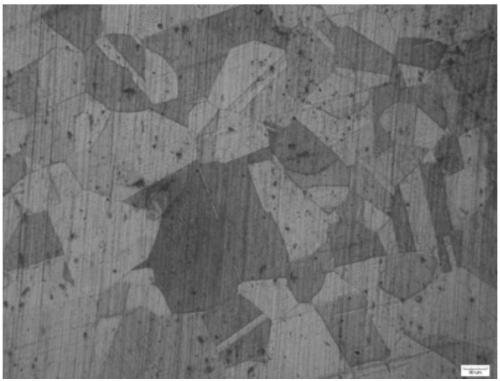

Embodiment Construction

[0025] It can be seen from the background technology that in judging the performance of the stainless steel target, it is necessary to judge the sputtering performance of the stainless steel target according to the internal structure of the stainless steel target. For example, the size of the internal grains of stainless steel has a decisive influence on the mechanical properties and corrosion resistance of stainless steel at room temperature and high temperature. Metallographic observation is the most direct and effective method to study the internal structure of stainless steel targets, so it is necessary to analyze and study the metallographic phase of the internal grains of stainless steel targets. Before conducting grain gold analysis and research, it is necessary to clearly display the grain boundaries inside the stainless steel target.

[0026] In the prior art, nitric acid and alcohol solutions are often used as target etchant to corrode stainless steel targets. Howeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com