Online roller grinding method capable of realizing reverse width rolling

A technology of rolling and grinding rolls, which is applied in the field of online grinding rolls, can solve the problems of difficult control of plate shape quality, lack of grinding roll control methods, etc., and achieve the effect of expanding rolling kilometers, large application and promotion value, and increasing grinding amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

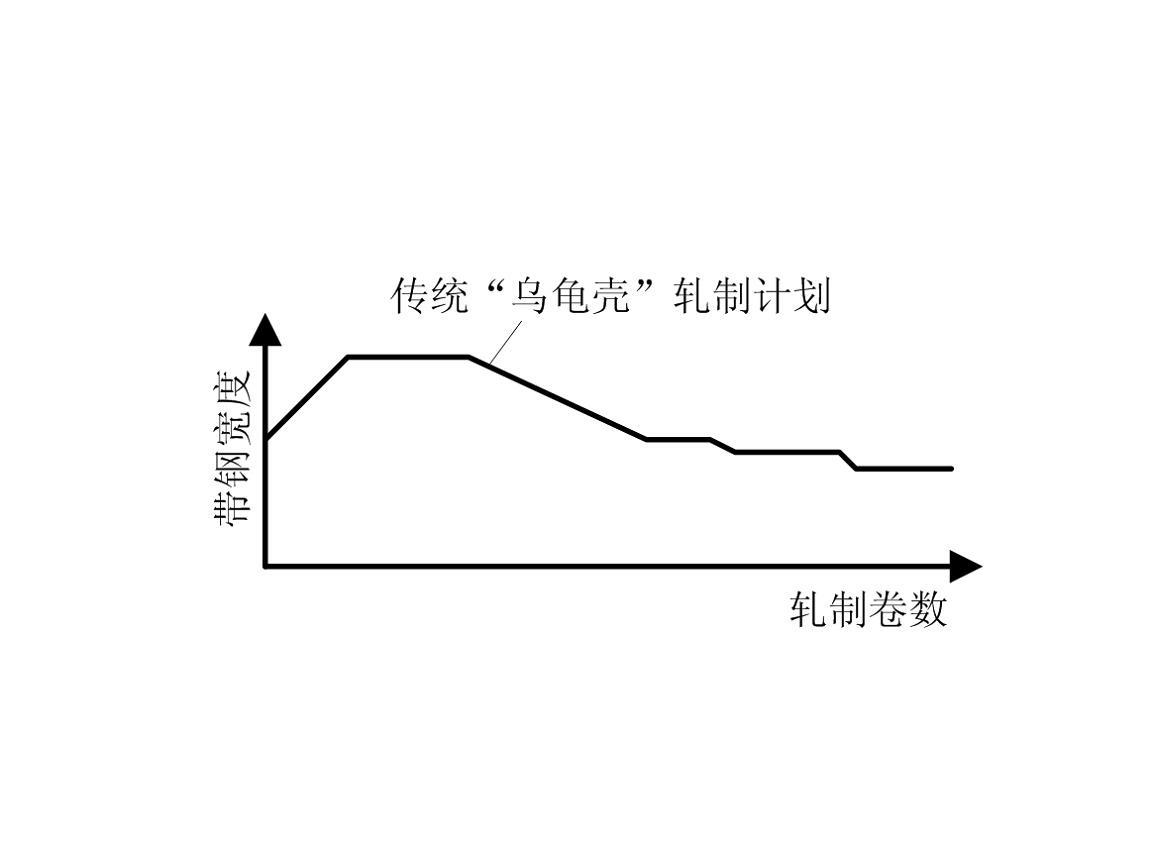

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

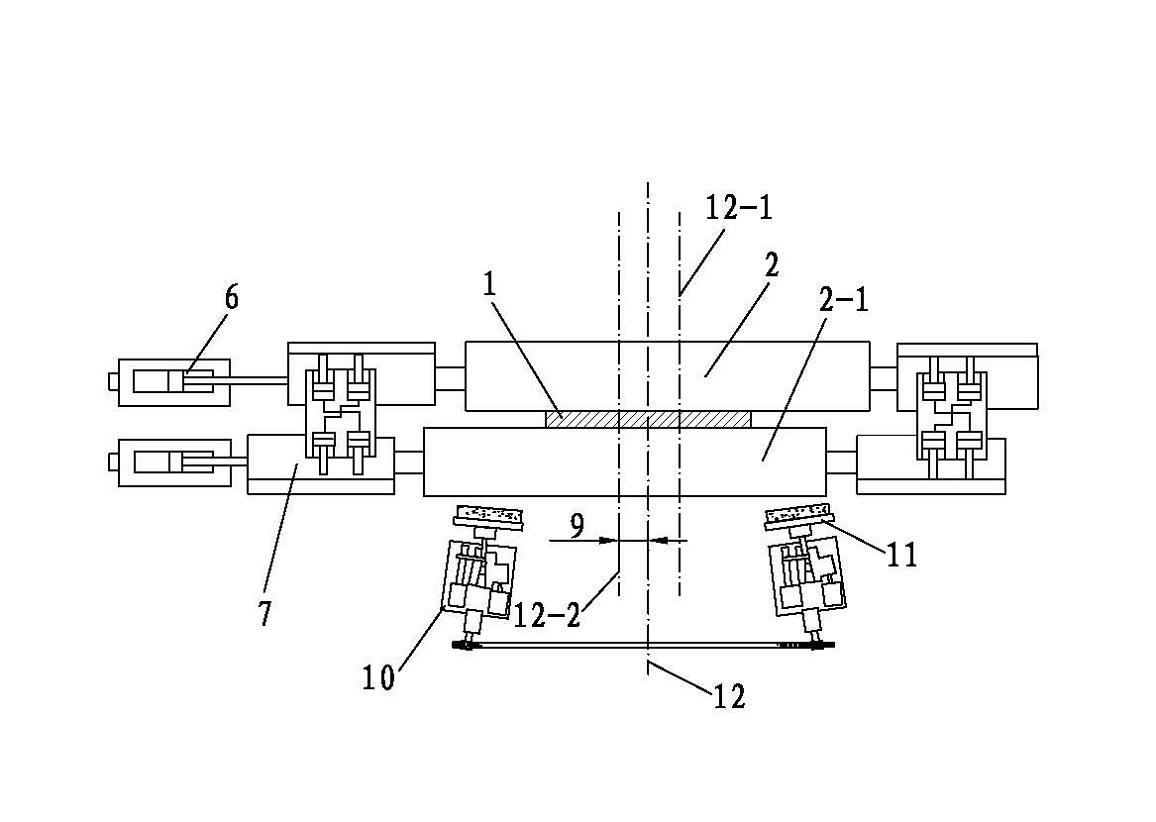

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

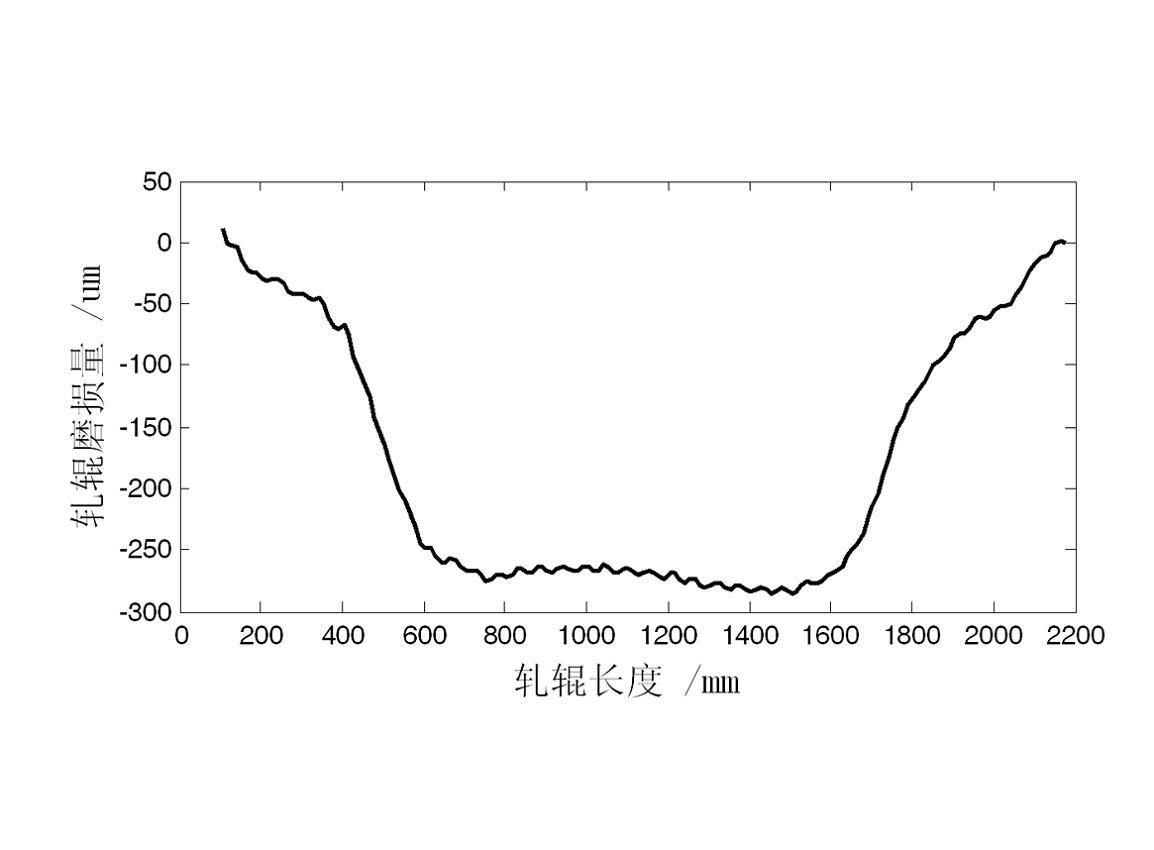

[0044] What the present invention discloses is an on-line roller grinding method that can realize inverse wide rolling. Before the description, what is the key to realize inverse wide rolling? Such as Figure 4 As shown, in order to realize inverse wide rolling, the key is to ensure that the roll shape in the roll pass area 13 is good, that is, the roll shape in the central groove area is flat and there are no obvious slopes on both sides. The plate-through area 13 refers to the area where the steel strip contacts the rolls during the entire rolling process. For a rolling mill with roll shifting function, the plate-through area includes the maximum plate width and the amount of roll shifting on both sides. The number 14 in the figure is the roll shape of the lower machine after adopting the conventional online grinding method. Due to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com