Novel aluminum alloy heat transmission material composite line

An aluminum alloy and heat transfer technology, which is applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of low production efficiency and poor quality of aluminum ingot compounding, achieve reduced labor intensity, good grinding quality, and improved production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing:

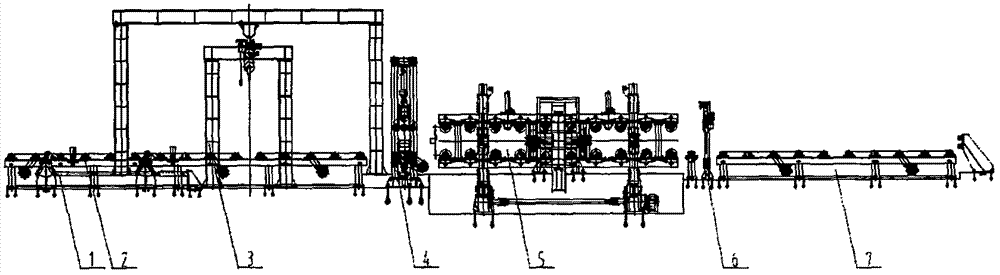

[0033] Such as figure 1 and figure 2 As shown, a new aluminum alloy heat transmission material composite line consists of the feeding buffer device 1, the feeding roller table 2, the vacuum suction crane 3, the brazing pressurization device 4, the turning The device 5, the baler 6, the discharge roller table 7, the plane rotating grinding device 8 and the turning device 9 are composed.

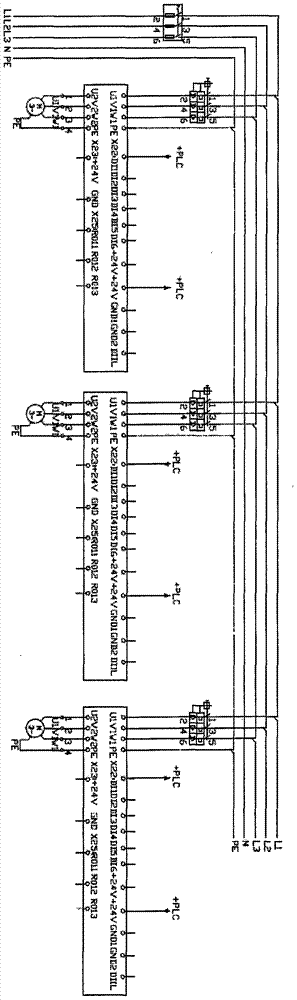

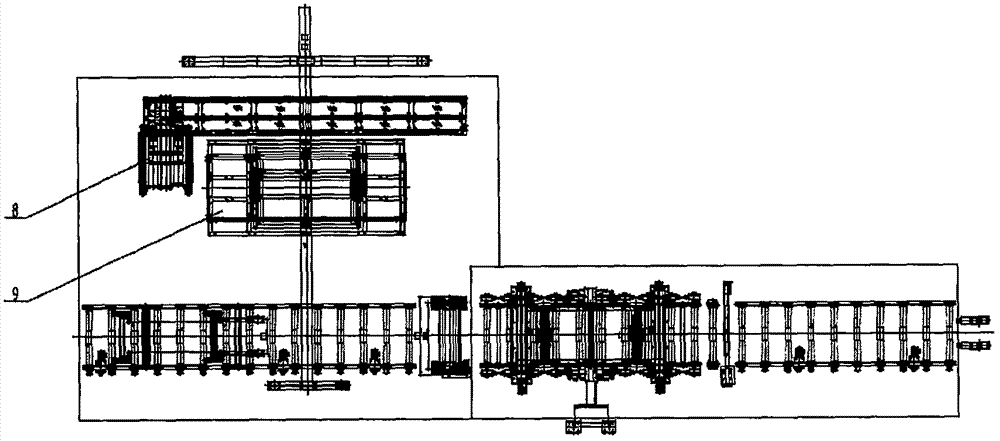

[0034] Such as image 3 and Figure 4 As shown, the plane rotary grinding device is composed of two grinding heads and a walking mechanism. The grinding head is composed of servo electric push rod 10, backward grinding head 11, servo electric push rod 14 and forward grinding head 15; the traveling mechanism is composed of base 12, support seat 13, linear guide rail 16, travel reduction motor 17, gear 18 and rack 19 compositions. After the alloy plate is placed on the grinding platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com