Centerless grinder used for magnetic elements

A centerless grinding machine and magnetic element technology, which can be used in grinding machine, grinding bed, grinding frame, etc., can solve the problems of large water consumption, affecting the quality of magnetic element grinding, waste of water resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

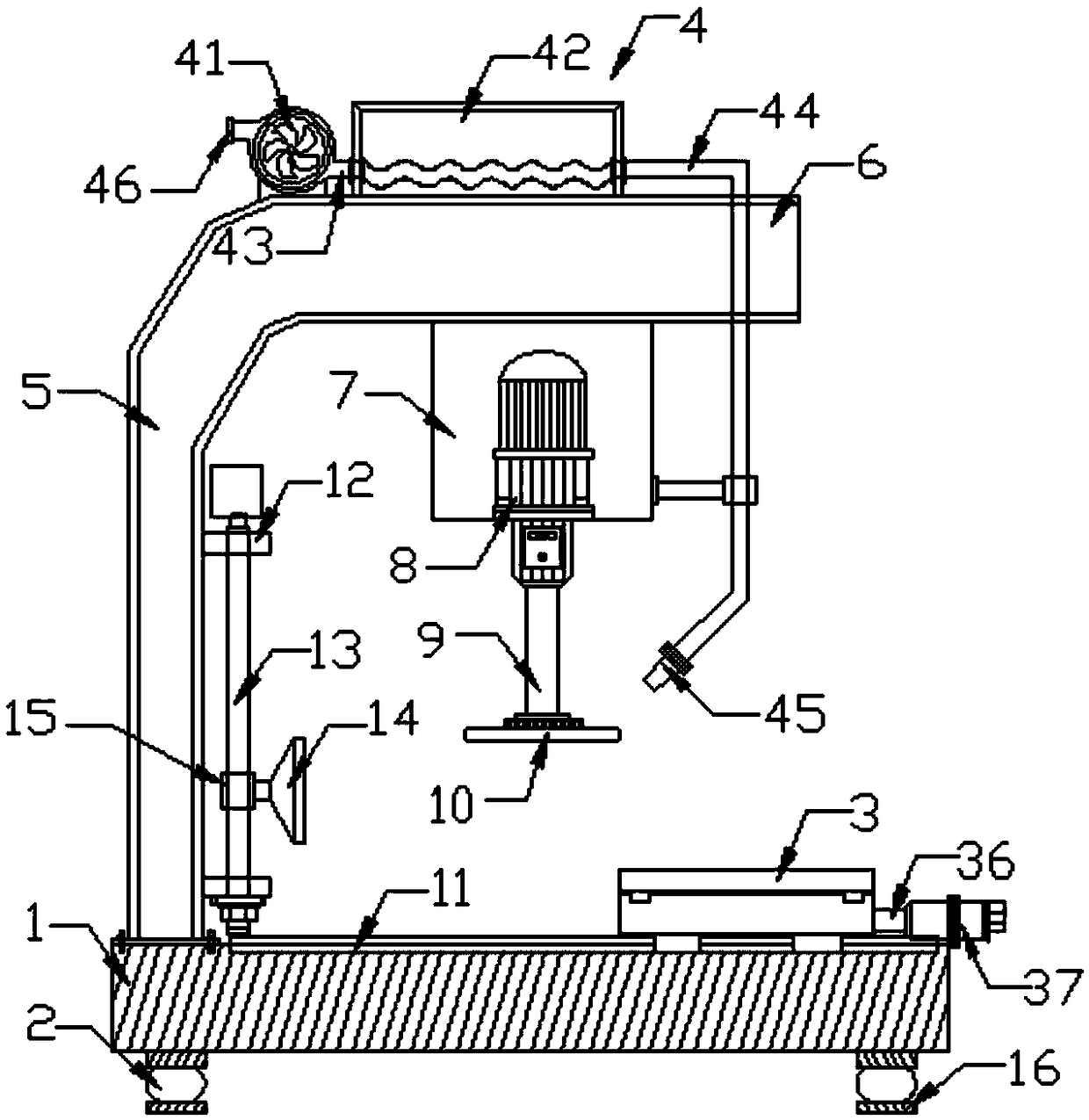

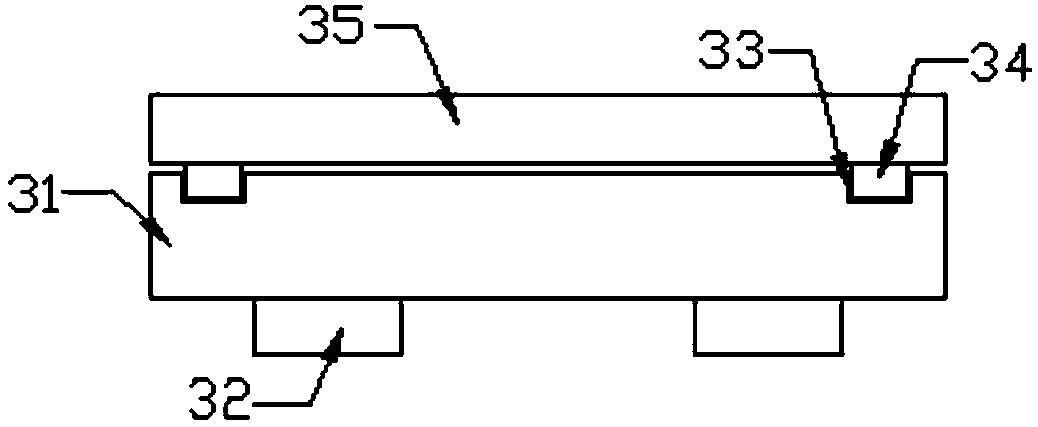

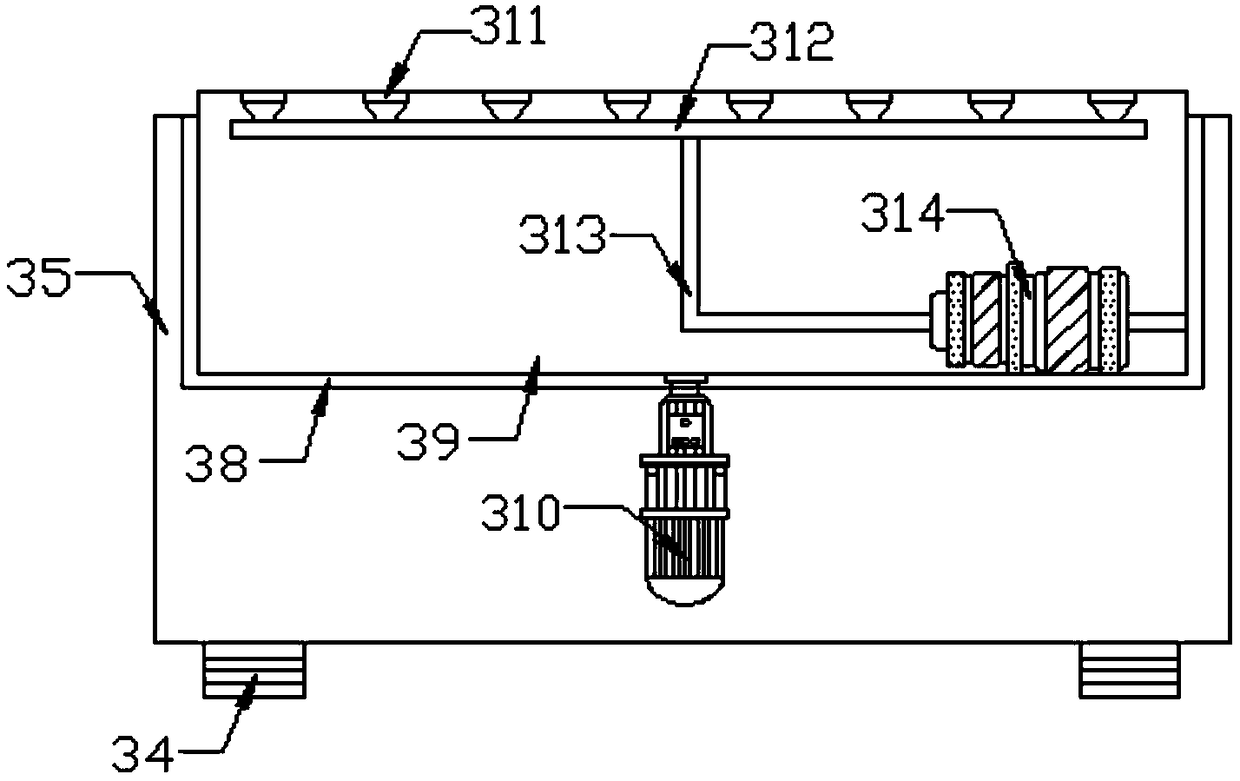

[0022] Such as Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a centerless grinding machine for magnetic components, including a load-bearing base 1, a support base 2, a movable table 3, a cooling device 4, a bracket 5, a beam 6, a mounting base 7, and a grinding motor 8 , rotating rod 9, grinding wheel 10, guide rail 11, mounting plate 12, adjusting screw mandrel 13, dust remover 14 and movable part 15, the bottom of described load-bearing base 1 is fixedly installed with supporting base 2, and described supporting base 2 is provided with Four, the top of the load-bearing base 1 is provided with a guide rail 11, the guide rail 11 is provided with two, the top of the load-bearing base 1 is equipped with a movable table 3, and one end of the top of the load-bearing base 1 is fixedly installed with a bracket 5 A beam 6 is fixedly installed on the top of the bracket 5, a cooling device 4 is installed on the beam 6, an L-shaped arrangement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com